Pumps & Systems Sep2010

Transcript of Pumps & Systems Sep2010

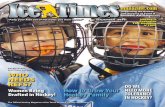

The Magazine for Pump Users Worldwide September 2010

pump-zone.com

The Magazine for Pump Users Worldwide

pump-zone.com

September 2010

circle 101 on card or go to psfreeinfo.com

2 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Letter from the Editor

PUMPS & SYSTEMS (ISSN# 1065-108X) is published monthly by Pumps & Systems, a member of the Cahaba Media Group, 1900 28th Avenue So., Suite 110, Birmingham, AL 35209. Periodicals postage paid at Birmingham, AL, and additional mailing offi ces. Subscriptions: Free of charge to qualifi ed industrial pump users. Publisher reserves the right to determine qualifi cations. Annual sub-scriptions: US and possessions $48, all other countries $125 US funds (via air mail). Single copies: US and possessions $5, all other countries $15 US funds (via air mail). Call (630) 482-3050 inside or outside the U.S. POSTMASTER: send change of address to Pumps & Systems, PO BOX 9, Batavia, IL 60510-0009. ©2010 Cahaba Media Group, Inc. No part of this publication may be reproduced without the written consent of the publisher. The publisher does not warrant, either expressly or by implication, the factual accuracy of any advertisements, articles or descriptions herein, nor does the publisher warrant the validity of any views or opinions offered by the authors of said articles or descriptions. The opinions expressed are those of the individual authors, and do not necessarily represent the opinions of Cahaba Media Group. Cahaba Media Group makes no representation or warranties regarding the accuracy or appropriateness of the advice or any advertisements contained in this magazine. SUBMISSIONS: We welcome submissions. Unless otherwise negotiated in writing by the editors, by sending us your submission, you grant Cahaba Media Group, Inc. permission by an irrevocable license to edit, reproduce, distribute, publish and adapt your submission in any medium on multiple occasions. You are free to publish your submission yourself or to allow others to republish your submission. Submissions will not be returned.

is a member of the following organizations:

It’s September, and as the mother of two extremely active children (ages 12 and 15), I am continually asked if I’m ready for “back

to school.” Is it just me…or am I the only mom in America who embraces September as an opportunity to focus on wastewater treatment?

Yes, it’s probably just me.h is is the time of year that we prepare for

WEFTEC, our biggest tradeshow of the year. h is generally means it is also our biggest issue. So while I am helping my daughter with her Civil War essay and my son is cramming all his summer reading into about two days, I’m learn-ing about wastewater treatment. Surprisingly, they do not teach this stuff in the Alabama public school system.

I have learned that it was not until the 19th century that large cities began to realize the necessity of reducing the amount of pollutants used in the water that was discharged into the environment. Many outbreaks of life-threat-ening diseases were traced to bacteria found in polluted water. Since then, many impactful technological advancements have been made to perfect wastewater collection and treatment.

Several million gallons of wastewater fl ow through a typical wastewater treatment plant daily. Some statistics show this can amount to 50 to 100 gallons for every person using the system.

In this issue of Pumps & Systems, which is “All About Water,” we explore technologies

that contribute to the importance of wastewa-ter treatment, and Dr. Lev Nelik takes a look at the future of wastewater treatment (page 24). In this issue, we also cover everything from sealing technologies, the importance of fl ow meters and eff ective remote communication used in water applications to reverse osmosis and metering and submersible pump technologies. Even the island of Alcatraz cannot escape from the need for wastewater treatment (page 80).

Please visit the Pumps & Systems team at our WEFTEC Booth (#2959 in F Hall) in New Orleans, La., Oct. 2 – 6. We will also be attending and co-sponsoring the Submersible Wastewater Pump Association’s 5th Annual Advanced Controls Training Seminar in con-junction with its 9th Annual Pumping Systems Training Seminar. For more information on this event, please contact SWPA Executive Director Adam Stolberg at [email protected].

In the meantime, please let us know about any advancements in wastewater treatment technologies that you are using.

Best Regards,

Michelle [email protected]

PUBLISHER

Walter B. Evans, Jr.

ASSOCIATE PUBLISHER

VP-SALES

George [email protected]

205-345-0477

EDITOR

VP-EDITORIAL

Michelle [email protected]

205-314-8279

MANAGING EDITOR

Lori K. [email protected]

205-314-8269

MANAGING EDITOR—

ELECTRONIC MEDIA

Julie [email protected]

205-314-8265

CONTRIBUTING EDITORS

Laurel DonohoJoe Evans, PhD

Dr. Lev Nelik, PE, APICS

SENIOR ART DIRECTOR

Greg Ragsdale

PRODUCTION MANAGER

Lisa [email protected]

205-212-9402

CIRCULATION

630-482-3050

ACCOUNT EXECUTIVES

Charli K. [email protected]

205-345-2992

Derrell [email protected]

205-345-0784

Mary-Kathryn [email protected]

205-345-6036

Mark [email protected]

205-345-6414

ADMINISTRATIVE ASSISTANT

Ashley [email protected]

205-561-2600

A Publication of

P.O. Box 530067Birmingham, AL 35253

Editorial & Production1900 28th Avenue South, Suite 110

Birmingham, AL 35209Phone: 205-212-9402

Advertising Sales2126 McFarland Blvd. East,. Suite A

Tuscaloosa, AL 35404Phone: 205-345-0477 or 205-561-2600

Editorial Advisory Board

William V. Adams, Director, New Business Development/Corp. Mktg., Flowserve Corporation

Thomas L. Angle, PE, Vice President, Product Engineering, Weir Specialty Pumps

Robert K. Asdal, Executive Director, Hydraulic Institute

Bryan S. Barrington, Machinery Engineer, Lyondell Chemical Co.

Kerry Baskins, Vice President, Grundfos Pumps Corporation

R. Thomas Brown III, President, Advanced Sealing International (ASI)

John Carter, President, Warren Rupp, Inc.

David A. Doty, North American Sales Manager, Moyno Industrial Pumps

Ralph P. Gabriel, Director of Product Development,

John Crane

William E. Neis, PE, President, NorthEast Industrial Sales

Dr. Lev Nelik, PE, Apics, President, Pumping Machinery, LLC

Henry Peck, President, Geiger Pumps & Equipment/Smith-Koch, Inc.

Mike Pemberton, Manager, ITT Performance Services

Earl Rogalski, Sr. Product Manager, KLOZURE®, Garlock Sealing Technologies

Focus on what you

can control. Everything.

Think about ITT.

www.flygtus.com

The new Flygt Station Control Panel System delivers:

Introducing the Flygt Standard Control Panel.

Experience the launch of the Flygt Standard Control Panel at Booth 5025

at WEFTEC 2010, October 4–6 in New Orleans, LA.

circle 109 on card or go to psfreeinfo.com

4 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

ALL ABOUT WATER

p Predictable Pump Motor Maintenance at a Cranberry Bog

Chris Rayburn, Fluke CorporationDue to the delicate nature of the cranberry, pump failure is not an option.

p Cellular Communications for SCADA ApplicationsIra Sharp, Phoenix Contact

Effective and secure cellular communications for remote data acquisition.

p Technology Saves Valuable EquipmentBrad Clarke & Kari Oksanen, Singer Valve

Airdrie, Canada, prevents cavitation damage by using an anti-cavitation trim.

p Considerations for Choosing a Flow MeterMarcus P. Davis, McCrometer

Find the right fl ow meter for your process and plant.

p Clean Water for Florida CommunityHenia Yacubowicz, Koch Membrane Systems

An RO system solved the problem of purifying brackish water.

p The Balancing Act of DP Flow Meter SelectionKitty Elshot & Emily Vinella, Emerson Rosemount Measurement

Choosing the right differential pressure fl ow meter for an application can be challenging. This article outlines the considerations and trade-offs in selecting the optimal technology.

p WEFTEC PreviewLearn what to expect at North America’s largest water quality event.

SEALING TECHNOLOGIES

p Reliable Flange SealingPamela Dauphinais, A.W. Chesterton Company

Improve sealing reliability in bolted fl ange connections.

p Unique Sealing Solution Solves Sulfur Leakage Problem

Alton R. Smith, EagleBurgmannSulfur leakage, causing housekeeping and environmental issues in a refi nery, was stopped with an innovative seal confi guration.

METERING & SUBMERSIBLE PUMPS

SPECIAL SECTION

p Non-Metallic Mag Drive Pumps—Great Equipment for Abrasive Fluids

Travis Lee, Pulsafeeder, Inc.Non-metallic magnetic driven gear pump technology improves equipment life and maintenance costs for metering and transfer applications.

p Peristaltic Pump FactsTodd Loudin, Larox Flowsys

The peristaltic pump explained—from advancements to maintenance.

p Escape to AlcatrazBill Nestor

A low-pressure wastewater disposal alternative offers a cost-saving installation solution for wastewater and raw sewage disposal.

Table of Contents

29

32

38

40

46

50

58

60

66

70

78

82

PRACTICE & OPERATIONS

p Reclaiming the GoldMike Dwyer, Quadna

Investment in mine expands production capabilities.

p When Maintenance Becomes EmergencyDonald Spencer, P.E., HydroAire, Inc.

In this case study, routine maintenance of a condensate pump at a nuclear power plant becomes an emergency situation.

DEPARTMENTS

Readers Respond. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

P&S News . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pump Ed 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Joe Evans, Ph.D.AC Power (Part Four): Transformers

Pumping Prescriptions . . . . . . . . . . . . . . . . . . . . . . . 24Dr. Lev Nelik, P.E., APICS, President, Pumping Machinery, LLCChris Staud, Engineering, Wastewater Group, Atlanta, Ga.Wastewater Treatment Industry: Present Challenges and Future Horizons

Business of the Business . . . . . . . . . . . . . . . . . . . . . 26Jen Yao, Frost & SullivanElectric Motors: Driving to Higher Effi ciency

Maintenance Minders. . . . . . . . . . . . . . . . . . . . . . . . . 86Preston Walker, Jr., Caliber Pump RepairUnderstanding the Basics of Pump Repair

Efficiency Matters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90Greg KriebelPrimer on Polymer Handling

HI Pump FAQs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Centrifugal pumps: how do they handle slurries, and what is their maximum allowable working pressure?

FSA Sealing Sense. . . . . . . . . . . . . . . . . . . . . . . . . . . 96What is the Sealing System Energy Footprint for Controlling Process or Barrier Fluid Temperature?

Product Pipeline . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Index of Advertisers . . . . . . . . . . . . . . . . . . . . . . . . . 107

P&S Stats and Interesting Facts . . . . . . . . . . . . . . . .112

September 2010

Volume 18 • Number 9

The Magazine for Pump Users Worldwide September 2010

pump-zone.com

The Magazine for Pump Users Worldwide

pump-zone.com

September 2010

100

102

Are you laying awake at night thinking about the recent changes in bearing isolator product

availability? Are you thinking about the price increases that seem to be strapping your facility to the

breaking point or supply chains that just aren’t working right?

If yes, Garlock is here to meet your needs. Since 1887, Garlock has been a stable and reliable source

for your sealing needs. Garlock offers a global infrastructure, a world class and stable supply chain

and offers the industry’s most effective sealing technology at affordable prices.

Let us put your mind at ease. Give us a call today!

MICRO-TEC® II ISO-GARD® GUARDIAN®

www.splitisolator.com | www.klozure.com | www.microtec2.com

1.866.556.9873

GARLOCK BEARING ISOLATOR FAMILY

Check on garlock.com later in the year for exciting new technologies!

circle 112 on card or go to psfreeinfo.com

6 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Readers Respond

Energy Savings with the Correct Duty

Point, June 2010Your recent article “Energy Savings with the Correct

Duty Point” presented some interesting details about VSX-Vogel analysis software tools.

Since I am not familiar with EN 12056/DIN 1986, Formula 3 (the domestic-wastewater-drainage) and Formula 4 (storm-water-outfl ow) were new to me.

In Formulas 2 and 6, the “p” symbol appears to be used as mass density: i.e., rho. In Formula 5, if “p” is used without a “g,” the resulting units would be weight per unit volume for friction loss. Is “g” a missing factor in the numerator of Formula 5?

I am accustomed to seeing “Hv” as a symbol for velocity head. In Formula 6, if the (Va2 x Ve2)/2g term should have been (Va2 - Ve2)/2g, then this term would be the velocity head, and Hv(Q) would, therefore, be the friction head loss. Under Formula 6, Va and Ve are defi ned as pipe length. I assume this was a typo.

h anks for the commentaries and fi gures.Lee RuizOceanside, CA

Jens-Uwe Vogel responds: h ank you for your feedback. I need to agree with you.

Unfortunately, some mistakes arose during the whole docu-ment process.

You stated that in Formulas 2 and 6, the “p” symbol appears to be used as mass density: i.e., rho. You are right; it should be the Greek letter ρ (rho).

P1 = Q • H • ρ • g

ηtotP1 = Power inputρ = Density of the mediumg = Gravitational accelerationηtot = Total effi ciency of the unit

Formula 2. Power requirement of a centrifugal pump

Also, in Formula 5, if “p” is used without a “g,” the result-ing units would be weight per unit volume for friction loss, and you wondered if “g” were a missing factor in the numerator of Formula 5. h e friction loss here is given as pressure p. Anyway, even here a mistake came in. Below, you will fi nd the correct formula, where I have added the metric units in brackets (see Formula 5 below).

You are absolutely right regarding Formula 6. h e correct formula is of course:

Htot = pa - pe

ρ • g + (za - ze) + Hv(Q) +

va2 - ve

2

2gpa - pe = Pressure diff erence between suction and discharge tankza - ze = Hgeo = geodetic heightHv(Q) = Pressure loss in dependancy of fl ow rateva, ve = Pipe length

Formula 6. Head of the plant

I am somewhat surprised that so many mistakes came into our article. It says to me that we have to improve our quality management for such documents throughout the whole pro-cess. Finally, I want to apologize for any trouble that may have been caused by this incorrectness.

Once again, thank you for your feedback.

pv [Pa = N

m2 =

kg m

s2 m2 =

kg

s2 m ] =

U [m] • L [m]

4A [m2] •

ρ[ kg

m3] • = v2[(m

s )2 =

m2

s2 ]2

• λ [–]

pv = Friction lossA = Passed cross section areaU = Circumference related to AL = Pipe lengthρ = Density of fl uidv = Average fl ow velocityλ = Friction factor

Formula 5. Friction loss in straight pipes

YA S K AWA A M E R I C A , I N C . - D R I V E S & M O T I O N D I V I S I O N

1 - 8 0 0 -YA S K AWA YA S K AWA . C O M

V E S & M O T I O N D I V I S I O N

K AWA . C O M

ª

Follow us:

http://Ez.com/yai41

FQPÔV"NQUG"[QWT"LQD

The wrong variable frequency drive (VFD) selection can cause poor results –and that can cost you your job. Consider Yaskawa VFDs for your next project. High mean time between failure, round the clock tech support and performance that just won’t quit.

Call Yaskawa for your next VFD selection and you won’t have pink in your future.

circle 126 on card or go to psfreeinfo.com

8 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Readers Respond

Suction-Side System Design, March 2010h e “Relative Resistance of Materials to Cavitation

Damage” chart shows two aluminum alloys. Can these be defi ned?

Excellent magazine.Alexander Kargilis, PEALKAR Engineering Company

Terry Henshaw responds: Stepanoff (Note 1 from the article) places “aluminum”

between bronze and steel. Yedidiah (Note 5) places “aluminum and certain alloys” below plastics. I don’t know which is correct or why the apparent discrepancy. I would put more faith in the Stepanoff report.

Vertical Turbine Pump

Reliability, March 2010I read your interesting VT Pump

Reliability article in the March P&S.I am curious if Item 13 in Figure 2

could possibly be a lan-tern ring. If so, maybe there was a fl ush con-nection at the box that wasn’t being used.

Lee RuizOceanside, CA

Lev Nelik resonds: Very observant and true. h e fl ush

indeed was disconnected. Otherwise, it would (at least) provide an expan-sion outlet for the vapors being formed (water boiling) to expand and not create a pressure cooker eff ect.

Responding to other

readers, April 2010My eye was caught by the graphic

accompanying Jim Elsey’s letter in the “Readers Respond” section, April 2010. His point was in reference to the posi-tioning of an eccentric reducer at the suction inlet of a pump. His conten-tion is that the fl at side of the eccentric

Lee Ruiz

714-893-8529

www.bluwhite.com

fax: 714.894.9492

5300 Business DriveHuntington Beach, CA 92649 USA

Benefi ts Include:

Single and Dual Pump Systems.

Tough, lightweight, powder-coated, welded aluminum Structure Construction.

Stainless Steel mounting pads.

Drip Containment Tray for easy removal and cleaning.

Flow Indicator. Compact design for

small footprint. Can be shipped via UPS.

INNOVATION | FUNCTIONALITY | DEPENDABILITY

BHAT*LNK ÉÛPeristaltic Metering Pumps

?DAI*BAA@ ÉÛOGE@ÛOUOPAI

FLEX-PRO® Benefi ts Include:

Feed Rates to 171 GPH pressures to 125 PSI.

2500:1 turndown ratio. Tube Failure Detection (Patented). Brushless DC motor.

BHAT*LNKÉÛÙ1 BHAT*LNKÉÛÙ0

TKSTKSTKSTKSTKSTKSTKSTKSTKSTKSKSKSKSKSSG :G :G :G :G :G :G :G :G :G :G :G :G :G":G":G":G":G":^̂̂̂̂̂̂̂̂̂̂̂̂̂]GY]GY]GY]GY]GY]GY]GY]GY]GY]GYGYGYN JN JN JNN JN JN JN JN JN JN JN"JN"JN"JN"JJU]U]U]U]U]TU]TU]TU]TU]TU]TU]TU]TU]TU]TU]T

?DAI*BAA@ÉÛ@KQ>HAÛOGE@ÛOUOPAI

NEW!

NEW!

circle 135 on card or go to psfreeinfo.com

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 9

reducer should be on top only if the suction source is below the pump and that the fl at side should be on the bottom if the suc-tion source is above the pump.

Mr. Elsey is absolutely correct if the pump in question is a horizontal, end suction design, and if we ignore the fact that the elbow should be 5 to 10 diameters away from the pump suction in any well-designed piping system.

However, when you relate his state-ment to the diagram accompanying the letter and the fact that it identifi es a double suction pump, the positioning of the eccentric reducer has very little eff ect on the fl ow pattern to the impeller eye in the pump. h e fl ow patterns within the casing design in such a pump can accommodate any disruption that may be caused by either arrangement.

A more frequent and expen-sive problem of pump suction piping arrangements with a double suction design occurs when the elbow approach-ing the pump suction is on a parallel plane with the pump shaft. When the pump is horizontal and the suction piping leading to the pump is also in a horizontal plane and turns through a horizontal elbow into the pump suction, then the trouble starts. Under such con-ditions, seal or bearing failure will occur with alarming regularity owing to the

hydraulic imbalance created within the pump.Ross MackayConsultant in Pump ReliabilityAuthor of “h e Practical Pumping

Handbook”Creator of h e Mackay Pump School

P&S Ross Mackay

Don’t Forget to Enter Your

Product

Deadline for Submissions

October 1

www.pump-zone.com

Answers.

3126

Call, click, or chat live!

800-323-4340 ColeParmer.com/8036

Think Cole-Parmer Unique products combined with

exceptional service and tech support.

Visit us at

WEFTEC

Booth #1644

circle 137 on card or go to psfreeinfo.com

10 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

P&S News

PEOPLE

CRANE PUMPS & SYSTEMS (PIQUA,

OHIO) adds key sales personnel to support growth in the plumbing, pressure sewer, HVAC and municipal markets. Graham Hackett is the new regional sales manager for the Western Region, Plumbing. He will develope and manage wholesale repre-sentatives and distribution channels in the plumbing market. Nathan Kimball is the new regional sales manager for the West-ern Region, HVAC and Industrial. Nathan will be growing Crane Pumps & Systems’ presence in the region. John Lazinski is the new regional sales manager for the South-east Region, Municipal and Pressure Sewer. He will be growing municipal sales and supporting pressure sewer projects in the region.

Crane Pumps & Systems is a manu-facturer of pumps, accessories and services, providing solutions for pressure sewer, municipal, plumbing, HVAC, industrial, military and dewatering markets. www.cranepumps.com

ITT WATER & WASTEWATER U.S.A.

(CHARLOTTE, N.C.) announces that Chris Ambrose has joined the company as the new director of marketing and business develop-ment. Ambrose was most recently the vice president of sales and marketing for John Zinc Company managing the sales and mar-keting of engineered combustion products throughout the Americas. Ambrose received his Bachelor of Science Chemistry degree from Florida Atlantic University.

ITT is an engineering and manufacturing company in water and fl uids management, global defenses, and motion and fl ow control. www.itt.com

HINES INDUSTRIES (ANN ARBOR, MICH.)

names Matthew Pohl as general manager of sales and marketing. Pohl will be respon-sible for all sales and marketing initiatives, expanding the industrial, high-perfor-mance, and aftermarket business units in North America and abroad.

Hines Industries provides balancing solutions to pump manufacturers, pump rebuilders and rotat-ing equipment professionals through a wide variety of standard machines and custom equipment. www.hinesindustries.com

COLFAX CORPORATION (RICHMOND, VA.) announces that William E. Roller has been promoted to executive vice president of Colfax Americas. He was most recently senior

vice president and general manager of Colfax Americas. In his expanded role, he is responsible for the company’s operations in the Americas, as well as its global oil & gas and Colfax Defense Solutions organi-zations. His duties also include expanding the two-screw pump business and driving global sourcing.

Colfax Corporation produces fl uid-handling products and technologies. h rough its subsidiaries, Colfax manufac-tures positive displacement industrial pumps and valves used in oil & gas, power generation, commercial marine, defense and general industrial markets. www.colfaxcorp.com

DANFOSS (NORDBORG, DENMARK) announces that its VLT division has appointed Frank Taaning-Grundholm as Global Pump OEM business manager.

In this position, Taaning-Grundholm will be responsible for sales to all interna-tional and major regional pump original equipment manufacturers (OEMs), includ-ing business development, marketing, prod-uct portfolio and application support.

Danfoss is a manufacturer of electronic and mechani-cal components and controls for air-conditioning, heating, refrigeration and motion systems. www.danfoss.us

AROUND THE INDUSTRY

KSB GROUP (FRANKENTHAL, GERMANY) acquired Stan-dard Alloys Inc., based in Port Arthur, Texas, on July 29, 2010. Standard Alloys Inc. specializes in spare parts man-agement for pumps and compressors. Standard Alloys brings experience in Rapid Cast Technology (RCT) and engineer-ing expertise in pump hydraulics to KSB Group. KSB will use this experience and applied technology to bring a greater level of service and satisfaction to its customers.

Standard Alloys has two locations with a total employ-ment of 90 people. h e main facility located in Port Arthur, Texas, houses engineering, administration and foundry activities. Component machining, pump repair, and assembly take place in the Vidor, Texas, location.

KSB is a manufacturer of pumps, valves and related systems for industrial applications and building services, for water and wastewater management and for the energy and mining sectors. www.ksb.com

Graham Hackett

William E. Roller

Frank Taaning-

Grundholm

Chris Ambrose

Matthew Pohl

John Lazinski

Nathan Kimball

THE ORIGINAL BEARING ISOLATORSTRONGER THAN EVER

www.inpro-seal.com

As part of Waukesha Bearings and Dover Corporation, Inpro/Seal is

stronger than ever…with the horsepower to deliver our high-performing solutions

and superior customer service around the globe. Industry-leading bearing protection,

unmatched experience and same-day shipments – only with Inpro/Seal.

So don’t lay awake at night…trust Inpro/Seal to design and deliver your custom-engineered

bearing isolator, right when you need it; our installed base of over 4,000,000 speaks for itself.

Trust Inpro/Seal, the clear leader in bearing isolators.

cir

cle

114

on c

ard

or

go t

o p

sfr

ee

info

.co

m

12 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

P&S News

PUMPTECH, INC., (BELLEVUE, WASH.) has been appointed the Grundfos Master Distributor for its Grundfos/Aldos line of chemical dosing pumps in the Pacifi c Northwest. h e prod-uct line includes the DDI and DME digital dosing pumps as well as the DM and DMH series of diaphragm dosing pumps. PumpTech has invested $100,000 in inventory to service the states of Washington and Oregon.

PumpTech is a distributor and manufacturer of packaged pumping systems for the municipal and industrial sectors. www.pumptechnw.com

TENCARVA MACHINERY COMPANY (GREENSBORO, N.C.) announces the acquisition of the assets and operations of Greensboro-based Electric Service and Sales Company Inc. (ESSCO), a division of Enerphase Industrial Solutions Inc., as of May 28, 2010.

ESSCO is a distributor for Toshiba motors and drives, Marathon motors, and ABB drives and controls. h e assets of ESSCO were acquired from Enerphase Industrial Solutions, Inc., of which ESSCO was a division.

Tencarva Machinery Company is a distributor specializ-ing in liquid process, compressed air, vacuum equipment and custom-designed systems for the industrial and municipal mar-ketplace. www.tencarva.com.

GRAPHITE METALLIZING CORP. (YONKERS, N.Y.) announced that NSF® International—an independent, not-for-profi t/non-governmental organization that provides mate-rials evaluation, standards testing and product certifi cation services involving public health and safety issues—has just certifi ed two grades of GRAPHALLOY® material for use in municipal well pumps and water treatment plant applica-tions. h e two newly certifi ed GRAPHALLOY® Grades are certifi ed to NSF/ANSI Standard 6—“Drinking Water System Components—Health Eff ects” and approved in the category for Multiple Water Contact Materials (MLTPL) up to 180 deg F. h ese newly certifi ed grades are used in the manufacture of pump bushings and bearings for both vertical and horizontal pumps.

Graphite Metallizing Corporation produces GRAPHALLOY®, a graphite/metal alloy bearing material used in the manufacture of self-lubricat-ing bearings and components for pumps, machin-ery and process systems. www.graphalloy.com

VARNA PRODUCTS (CAMERON PARK, CALIF.) announced the release of Calculating the Value of Prelube spreadsheet & ANDROID phone application. h is application can be used to

[qwt"rtqeguu"pggfuÈ

000rgtkuvcnvke"vgejpqnqi{

Xkukv"wu"cv"YGHVGE

Dqqvj"764;

yyy0xgtfgt0eqo

XgtfgtÞgz̶"rgtkuvcnvke"rworu"/"Qwt" gzvgpukxg" tcpig" qh" ceewtcvg" fqukpi" vwdg"rworu"cpf"vqwij"jqug"rworu"yqtm"cv"vjg"jgctv"qh"{qwt"rtqeguu0"

Vgn<"3":22":54"6784"y"Gockn<"kphqBxgtfgt0eqo

circle 156 on card or go to psfreeinfo.com

Bigger doesn’t necessarily mean better. You may think we’re small, but EagleBurgmann

has been producing products of uncompromising quality, durability and reliability for more than

120 years. We’ve got the engineering expertise and the know-how to meet your toughest sealing

challenge, no matter what the size. Our 5,200 employees worldwide remain strong in their

customer commitment to ensure you can always rely on EagleBurgmann for your seal and service

needs. To find out more, visit www.EagleBurgmannSeals.com or 1-800-303-7735.

circle 106 on card or go to psfreeinfo.com

14 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

P&S News

calculate the savings and value of prelube for your industrial/marine application.

VARNA produces solutions for prelube, soakback, transfer and many other applications in industrial/marine oil & fuel pumps & turnkey control.

VARNA Products is the production arm of Transportation Research Corporation specializing in custom fl uid control solu-tions for diesel engine systems. www.varnaproducts.com

EAGLEBURGMANN (HOUSTON, TEXAS) has become one of four Fraunhofer institutes and seven other partners to receive the Stifterverband Award. h e award, one of German industry’s joint initiatives for supporting research and higher education, was presented to EagleBurgmann as one of the partners in the alliance that developed DiaCer®, a new diamond-ceramic com-posite material for applications under extreme conditions in industrial environments.

EagleBurgmann manufactures mechanical seals, systems, packing and expansion joints. www.eagleburgmann.com

JWC ENVIRONMENTAL (COSTA MESA, CALIF.) announced that Big Fish Environmental is using its products in a unique and effi cient septage receiving and treatment plant design. h e products being used are the Honey Monster® septage receiving system, the Muffi n Monster® grinder and the Auger Monster®

screen. Part of Big Fish’s development process is achieving EPA Environmental Technology Verifi cation (ETV) which is now in the fi nal approval stages. Biosolids produced at some plants are approved by the State of Michigan as EQ Class A reusable biosolids and are being distributed over agricultural fi elds.

JWC Environmental produces a family of wastewater, stormwater and sewage treatment products. JWC Environmental distributes its products through a global network of indepen-dent representatives and distributors. www.jwce.com

IDEX CORPORATION (NORTHBROOK, ILL.) announced the acquisition of OBL, S.r.l. A provider of mechanical and hydraulic diaphragm pumps, OBL provides polymer blending systems and related accessories for a diverse range of industries, including water, wastewater, oil and gas, petrochemical and power generation markets. Headquartered in Milan, Italy, with annual revenues of approximately €8.5 million, OBL will oper-ate within IDEX’s Fluid and Metering Technologies segment as part of the water and waste water group of companies.

IDEX Corporation is an applied solutions company spe-cializing in fl uid and metering technologies; health and science technologies; dispensing equipment; and fi re, safety and other diversifi ed products built to its customers’ specifi cations. www.idexcorp.com.

circle 130 on card or go to psfreeinfo.com

circle 120 on card or go to psfreeinfo.com

16 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

P&S News

UPCOMING EVENTS

PUMPTEC

September 20 – 21Holiday Inn Select / Norcross, Ga.Presented by Pumping Machinery, LLC770-310-0866 / www.pumpingmachinery.com

SPE ANNUAL TECH CONFERENCE

September 20 – 22 Fortezza da Basso / Florence, ItalyPresented by Society of Petroleum Engineers+39-055-33611 / www.spe.org/atce/2010

CADWORX UNIVERSITY

September 27 – 29Woodlands Waterway Marriott Hotel / Houston, TexasPresented by COADEwww.cadworxuniversity.com

WEFTEC

October 2 – 6Ernest N. Morial Convention Center / New Orleans, La.Presented by the Water Environment Federation 877-933-4734 / www.weftec.org

TURBOMACHINERY SYMPOSIUM

October 5 – 7George R. Brown Convention Center / Houston, TexasPresented by the Texas A&M Turbomachinery Lab979-845-7417 / turbolab.tamu.edu

SMRP CONFERENCE

October 18 – 21Midwest Airlines Center / Milwaukee, Wisc.Presented by the Society for Maintenance and Reliability Professionals703-245-8011 / www.smrp.org

FSA FALL MEETING

October 19 – 21Austin, TexasPresented by the Fluid Sealing Association 610-971-4850 / www.fl uidsealing.com

CERTIFIED OPC PROFESSIONAL

TRAINING

Level 1: OPC & DCOM Diagnostics – October 19 – 20 Level 2: OPC Security – October 21 – 22Level 3: OPC Unifi ed Architecture – October 25 – 26Level 4: OPC Integration Projects – October 27 – 28ExecuTrain Houston / Houston, Texas780-784-4444 / www.opcti.com

PACK EXPO

October 31 – November 3McCormick Place / Chicago, Ill.Presented by the Packaging Manufacturers Machinery Institute703-243-8555 / www.packexpo.com

INFRAMATION

November 8 – 12Bally’s Hotel / Las Vegas, Nev.Presented by FLIR Systems, Inc. 866-872-4647 / www.inframation.org

P&S

GRIFFCO VALVE

Innovation, technology and reliability.

Vjtgg"tgcuqpu"yj{"gpikpggtu."rtqlgev"ocpcigtu"cpf"rncpv"qrgtcvqtu"tgswguv"Itkhheq"Xcnxgu"hqt"vjgkt"ejgokecn"hggf"

u{uvgou0"Qwt"pgy"I"cpf"O"ugtkgu"xcnxgu"ykvj"vjgkt"kplgevkqp"oqnfgf"

Pqt{n"vqru"kortqxg"vgorgtcvwtg"cpf"rtguuwtg"tcvkpiu"yjkng"eqpvkpwkpi"vq"fgnkxgt"cp"gzvtgogn{"tgnkcdng."equv"

ghhgevkxg"yc{"vq"cejkgxg"eqpukuvgpv."wugt"cflwuvcdng"tcvgu"qh"àqy"cpf"uchgv{"

tgnkgh"kp"ejgokecn"hggf"crrnkecvkqpu0"

www.griffcovalve.com 6010 North Bailey Ave, Suite 1B

Amherst, NY 14226

Email [email protected]

Your source for high quality

chemical feed accessories

G-SERIES BACK

PRESSURE VALVES

M-SERIES

PRESSURE

RELIEF VALVES

Made in the USA

circle 141 on card or go to psfreeinfo.com

DWYER INSTRUMENTS, INC.

Phone: 1-800-872-9141E-mail: [email protected]

TALK TO US

• Non-contact

• Mapping software creates a narrow 3˝ beam diameter enabling use in applicationwith limited space from obstructions

• FM approved explosion-proof

SERIES PBLT2 & PBLTXSubmersible Level Transmitters

• Lightning protected

• Clog-proof with large diameter flush diaphragm

• Stand-off plate to protect diaphragm

• UL intrinsically safe option

SERIES EDAElectronic Pressure Control ler

• Indicating gage, 2 switches and a transmitter all in one package

• 316SS wetted materials and NEMA 4X for wide application use

SERIES PUX2Portable Ultrasonic Flowmeter Converter

• Flow rate, flow velocity and flow totalization functions

• Clamp on technology saves time and reduces labor costs

SERIES ULTUltrasonic Level Transmitter

Find out more and order online at:

www.dwyer-inst.com/WW-6

From $825.00 list From $530.00 list

From $230.00 list From $6249.00 list

Visit us at WEFTEC Booth 6531!

circle 105 on card or go to psfreeinfo.com

18 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Pump Ed 101

Last month, we studied the properties and eff ects of resistive, inductive and capacitive loads in an AC cir-cuit. h is month, we will take self induction a step

further and apply it to that simple machine that is at the heart of AC power—the transformer.

As I mentioned in Part One, (Pumps & Systems, June 2010) a unique quality of AC power is that its voltage can be changed easily and in either direction—up or down. h is allows us to generate power at some voltage and step it up to a higher voltage for long distance transmission. h is decreases losses due to heat and signifi cantly reduces the wire size. Once it reaches its point of use, voltage can be reduced to a useable intensity. h e key element in this process is the transformer, and the key to its operation is a phenomenon known as mutual induction.

Mutual InductionIf two coils of wire are placed near each other (see Figure 1), an alternating current fl owing in one will create a magnetic fi eld that induces a voltage and current in the one nearby, even though they are not in direct contact. h is occurs because the lines of fl ux associated with the magnetic fi eld extend well beyond the coil that created them. h is property is called mutual inductance or mutual induction, and it is the

basis of the transformer. h e transformer gets its name from the process of transforming electrical energy into magnetic energy and then back to electrical energy. h e coil that pro-duces the magnetic fi eld is called the primary (input) and the coil that intercepts that fi eld is called the secondary (output).

Although some transformers consist of coils separated by an air gap, most use insulated wire wound about a laminated iron core (see Figure 2). h e iron core increases transformer effi ciency by directing nearly all the fl ux produced by the primary through the secondary coil. h e laminations reduce eddy current losses that would be much higher in a solid core design. Depending on the design and capacity, trans-former effi ciency can range from 20 to 99 percent. Larger ones—for example those designed for power distribution

Joe Evans, Ph.D.

AC Power (Part Four): Transformers

Figure 2 Figure 3

Figure 1

Last of four parts

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 19

applications—operate at 98 percent or better. Another impor-tant property of the transformer is electrical isolation. Since the primary and secondary coils are not in contact, the power source is isolated from the point of use.

Voltage, Current and the Turns RatioAccording to Faraday’s law, voltage produced in the secondary of a transformer depends on the voltage in the primary and the number of turns (loops) in the primary and secondary coils. h is may sound a little compli-cated, but this relationship can be simply stated with something called the turns to voltage ratio. h e equation below—where V is voltage, N is the number of turns, p is the primary and s is the sec-ondary—explains this relationship:

Vs = (Ns / Np) x Vp

Secondary voltage is directly pro-portional to the product of the turns ratio and primary voltage. If Ns is greater than Np, then the voltage in the second-ary coil is greater than that of the pri-mary coil, and the transformer is called a step-up transformer. If the opposite is true, we have a step-down transformer. For example, suppose a transformer has a primary with 1,000 turns and a sec-ondary with 100 turns. Based on the equation above, the turns ratio is 1/10 or 0.1. If the voltage feeding the primary is 1,200 V then the secondary voltage will be 120 V.

However, what about current? How do we calculate its change? h e trans-former is an intelligent machine because it automatically adjusts the current to keep power (in watts) constant. A slight modifi cation of the original equation explains this relationship:

Is = (Np / Ns) x Ip

In the equation above, current (I) replaces voltage and the turns ratio is reversed. When fewer turns are in the secondary, a transformer steps down voltage, but it increases current and, therefore, keeps power constant. In the case of our step-down transformer example above, if the primary is fed by 1,200 V at 1 A, then the secondary

would provide 120 V at 10 A. Both volt/amp combinations provide 1,200 W of power.

Winding Confi gurationsTransformers allow an extremely fl exible secondary output and are not limited to a single secondary winding. Figure 3 shows

NEW!NEW!non-clogs that don’t clog

New 4SH series with three different styles

of impellers offers superior clog resistance

and efficiency.

Plug-and-play cable system for the Frame 21

sizes will result in significant reduction in

maintenance costs and inventory.

X-Pruf® ratings with FM and CSA certifications

design with industry-leading lead time.

fi

›

‹

www.cranepumps.com

circle 138 on card or go to psfreeinfo.com

20 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

an example of a typical power supply transformer. h e primary is fed by 110 V and induces three individual secondary coils providing 5 V, 6.3 V and 700 V. h e 700-V coil shows another feature of the trans-former. A “tap” placed at the center of the coil provides two 350-V outputs in addition to its full voltage output. Multiple taps may also be placed within a single coil.

Three Phase Transformers

Transformers used in three-phase appli-cations can consist of three, single-phase transformers or a single transformer wound in a manner that accommo-dates all three phases. h e primary and secondary windings of the three-phase transformer are confi gured in two basic patterns—Delta and Wye. h e primary and secondary can be any combination of the two (such as Wye/Delta, Delta/Wye, Delta/Delta and Wye/Wye). h is article will examine the Delta and Wye secondary characteristics only. Additional resources are provided at the end of the article if you are interested in pursuing the eff ect of a particular pri-mary on a secondary.

Figure 4 is the schematic of a Delta secondary that produces three individ-ual-phase voltages of 120 V. h e Delta gets its name from the Greek letter that has a similar appearance. You might think that such a confi guration would short circuit since they are connected in series. However, note the angle associ-ated with each phase starting at the top and proceeding counter clockwise. If you refer to the three-phase power curve in Figure 3 of Part Two (Pumps & Systems, July 2010), you will see that the volt-ages cancel one another and no current fl ows through the circuit. If, however, a load is connected across any two of the three “lines,” a current will fl ow and the line-to-line voltage will be the sum of the phase voltages, which equals 240 V.

Figure 5 is the schematic of a WYE secondary that also produces three indi-vidual-phase voltages of 120 V. It gets its name from its resemblance to the letter Y and is sometimes called a “star.” At the junction of the three phases, a separate connection, known as a “neutral” is usu-ally supplied. A load connected between the “neutral” and any of the three “lines”

Pump Ed 101

Figure 4

SENTRY Pulsation Dampeners & Surge

Suppressors remove hydraulic shock and

vibration, enhancing all-around performance

and reliability of fluid flow applications.

SENTINEL Diaphragm Seals protect and

isolate all forms of system instrumentation

from hazardous and corrosive process fluids.

More than just leak detection! The patented

SPILLSTOP Leak Containment System

prevents costly and hazardous spills caused

by pump diaphragm failure.

Don’t Pump Without Us

800.603.7867 ■ 951.342.3100 ■ www.BLACOH.com ■ [email protected]

circle 134 on card or go to psfreeinfo.com

See Us At

WEFTEC

Booth # 3733

circle 118 on card or go to psfreeinfo.com

22 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Pump Ed 101

will see a voltage of 120 V. When a load is connected across any two of the three “lines,” the voltage will not be the sum of the two phases. Instead, it will be approximately 208 V. h e reason this occurs is due to the phase angle and the way the coils are connected. Although we will not show one here, a phasor diagram would illustrate that the voltage vector created by any two WYE phases produces a voltage that is only 1.732 of the phase voltage. If you are interested in viewing WYE and

Delta phasors, check out “h e Changing Voltage Puzzler” on my website.

Based on the line-to-line voltage, it would appear that the WYE transformer is less effi cient than the Delta. However, an interesting event occurs within the Delta confi guration. A phasor diagram would show that the line-to-line cur-rent is only 1.732 of the phase current. h erefore, the relationship below will hold true for any circuit regardless of whether it is Delta and WYE connected:

Power (watts) =

volts x amps x 1.732 x power factor

I hope that this brief introduction to AC power has been useful. A lot more is involved, so below are several websites that you can visit for more information. In the future, I plan to write a similar series on AC motors.

P&S

Resources

All About Circuits: www.allaboutcircuits.com/

vol_2/index.html

Integrated Publishing – EE Training Series:

www.tpub.com/content/neets/

Electronics – Tutorials:

www.electronics-tutorials.ws/index.html

Siemens:

www3.sea.siemens.com/step/templates/lesson.

mason?bep:2:1:1

Electrician’s Toolbox: www.elec-toolbox.com

RLC Circuits – Java Applet:

www.walter-fendt.de/ph14e/accircuit.htm

Joe Evans is responsible for cus-tomer and employee education at PumpTech, Inc., a pumps and packaged systems manufacturer and distributor with branches through-out the Pacifi c Northwest. He can be reached via his website www.PumpEd101.com. If there are topics that you would like to see discussed in future columns, drop him an email.

Figure 5

Ugg"jqy"vq"tgfweg"{qwt"ycvgt"cpf"gpgti{eqpuworvkqp."kpetgcug"gswkrogpv

tgnkcdknkv{"cpf"kortqxg"{qwtdqvvqo"nkpg"ykvj"UGREQ̶Óujkij"rgthqtocpeg"ugcnkpi

uqnwvkqpu0"Hqt"{qwthceknkv{"cpf"{qwtqyp"rgceg"qh"okpf."ejgem"qwv

UGREQ̶0

800.633.4770 – www.sepcoUSA.com

Ugcnkpi"Gswkrogpv"Rtqfwevu"Eq0."Kpe0

UGREQ̶"ECP"UCXG"[QW"OQTG"VJCP"QWT"RTQFWEVU"EQUV0

IHQ̶"ku"c"tgikuvgtgf"vtcfgoctm"qh""Y0"N0"Iqtg"cpf"Cuuqekcvgu0

ÐKh"kv"fqgupÓv"uc{"322'"IHQ."kv"kupÓvÑ

HIGH PERFORMANCE PRODUCTS,

world class solutions.

circle 152 on card or go to psfreeinfo.com

circle 123 on card or go to psfreeinfo.com

24 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

These days, the importance of a fresh water supply and safely-treated wastewater returned to the river cannot be overemphasized. No matter how hard we try, we

are still a long way from the most effi cient, economic and reliable ways to ensure that our cities are properly equipped and ready for the clean water challenge.

As a civilization, we have achieved isolated instances of superb effi ciency in water treatment and reuse, such as space shuttles and stations that rely on the almost perfect use and transformation of the precious water cycle, as there is no alternative other than that in space. But on the ground, the quantity of issues are grander and not as technically advanced. Yet this is where are our world is and what we have to work with—a world in which we must be in tune with nature and our environment as we look toward more innovative ways to maintain a fresh water supply and safely treat wastewater.

Chemical vs

Biological Treatment MethodsIs wastewater about to be treated in other more innovative ways? Currently, most plants use a combination of biologi-cal and chemical waste stabilization. Increasingly, the EPA is presenting the idea of making wastewater effl uents cleaner in terms of nutrients. h is forces more plants to add large quantities of chemicals to polish their effl uents.

h e other unintended eff ect is that multiple systems now need more maintenance. Wastewater plant operators have trouble maintaining complicated systems while keep-ing costs low. Eventually, chemical stabilization methods will displace some of the biological stabilization techniques.

For instance, one big problem area is biological phos-phorus removal followed by anaerobic digestion. h e unfor-tunate consequence of this procedure is the release of phos-phorus back into the plant, whereas chemical phosphorus removal permanently ties up the phosphorus until it leaves the system. Complex systems are not only hard to run, they are expensive to maintain.

Pump ProtectionProtecting treatment pumps (primary, secondary and ter-tiary) from grit that accompanies the incoming water is an

important component of extending equipment life. h e ways that water is pumped have undergone changes, as well. h e traditional end suction pumps have steadily been replaced by wet submersible units and now even by dry submersibles, which are mounted into a dry pit and connected to a wet pit allowing easy access to the pumps for repair or maintenance.

Combined SewersCombined sewers present challenges, and separating the water streams is expensive. In practice, the more readily acces-sible piping is handled fi rst, and the more diffi cult accesses are put on hold until later. With the complexities involved in sewer separations and the disruptions to business, many communities are turning to tunnel collection systems when upgrading (due to capacity issues or government regula-tion) is required. Increasingly, deep drop shafts have become common in many urban areas. h e drainage of storm water will be benefi ted by the implementation of drop shafts.

Simplifi ed Repairs and New MaterialsRepairs must become simpler and faster. Presently, main-tenance departments conduct simple repairs in house, and large and more sophisticated equipment is repaired by out-side contractors. Systems are more complex, and more com-puters are used to control them.

Computer specialists, who have good technical under-standing of the systems, are more common at wastewater treatment plants, but they may lack the knowledge of work-ing on the equipment. Likewise, maintenance personnel may be experienced with the equipment, but may lack the technical knowledge of the systems. A disconnect between the equipment handling and the systems that operate and control the handling can occur. More training is required to bridge this gap. In addition, more interaction between the departments and groups is essential.

New materials are available today that were novel or nonexistent years ago. For example, duplex stainless steel per-forms better in high-G centrifuge applications. Composites are becoming more common, bringing with them the advan-tages of light weight, cavitation resistance and corrosion resistance.

Dr. Lev Nelik, P.E., APICS, President, Pumping Machinery, LLCChris Staud, Engineering, Wastewater Group, Atlanta, Ga.

Wastewater Treatment Industry: Present Challenges and Future Horizons

Pumping Prescriptions

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 25

The Future

How will our plants look 20 years from now? Hopefully, higher effi ciencies and eff ectiveness of systems will mean less waste and a better recycling of resources. We may see technologies applied and new trends. Perhaps water and waste treatment plants will combine, and less wastewater will be discharged into rivers, with more of it contained in a closed cycle, making our rivers safer and more environmen-tally friendly.

Plant space (or green areas), par-ticularly in cities, will have to be used better, and some communities will likely apply new methods—such as closed-cycle water systems—to be more self-sustaining and less pollut-ing. Remember the experiment with biosphere conducted in Arizona years ago? h is type process can work in a small-scale situation. h e challenge is to implement it on a wider scale.

h e benefi ts of closed-water sys-tems would be impressive. Less water discharged to rivers would mean less piping, less repairs and less ground-work disruptions, and an easier-to-pre-serve infrastructure. Problems that are common today—such as cracked pipes, infi ltration and plugging—would be eliminated.

Solar energy could be better used, with solar panels and special bacteria growing methods that may advance us even further, making us less energy dependent and more effi cient.

Perhaps one day, present issues with our water supply will be reversed with more innovative water treatment and delivery systems. h e public is increas-ingly concerned about whether we actu-ally remove all the harmful pathogens in drinking water in urban areas.

It is diffi cult to tell, how the world will look in 20 years. However, if we do not try to imagine it today, we may fi nd ourselves unprepared in the future. Perhaps the time to plan or at least talk about it, is now. We would like to hear input from our readers, and we wel-come any additional ideas, challenges or thoughts that you may have.

P&S

Dr. Nelik (aka “Dr. Pump”) is president of Pumping Machinery, LLC, an Atlanta-based fi rm specializing in pump consulting, training, equipment troubleshooting and pump repairs. Dr. Nelik has 30 years of experience in pumps and pumping equipment. He can be contacted at www.PumpingMachinery.com.

VFD-Induced Bearing Currents

Kill Motors!

SGRBEARING PROTECTION RING

Save energy with a VFD, Save your motor with

Proven in hundreds of thousands of installations, the AEGIS™ SGR protects motor bearings from damaging VFD-induced currents and extends motor life. It also dramatically reduces downtime and improves the reliability of motor-driven equipment and systems.

Safely channels harmful currents away from bearings to ground

Patented time-tested design

Maintenance-free, easy to install, lasts for life of motor

Standard sizes for any motor

To download a free technical paper on bearing protection technologies, visit our website:

1-866-738-1857 | sales @ est-aegis.comwww.est-aegis.com/ps1

Conductive epoxy mounting simplifi es fi eld installation

®

circle 139 on card or go to psfreeinfo.com

26 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

Business of the Business

The freefall in electric motor sales is a direct eff ect of the worldwide eco-nomic downturn, which has severely

depressed industrial and commercial produc-tions. Despite the 20 to 30 percent drop in motor sales in 2009, manufacturers remain optimistic about the future market landscape, as the economic recovery, the need to improve energy effi ciency and the demand in high-growth sectors will create need for high-per-formance motors.

When selecting a new motor today, a buyer has two choices for electric motor effi -ciency: EPAct (Energy Policy Act of 1992) effi ciency or NEMA (National Electrical Manufacturers Association) Premium effi ciency, which has a higher effi ciency requirement and costs 10 to 15 percent more than motors that just meet the EPAct standard. With the passage of the Energy Independence and Security Act of 2007 (EISA), all general purpose motors of at least 1 hp and less than 200 hp will have to meet or exceed NEMA Premium motor effi ciency levels beginning on December 19, 2010.

As a result of this legislation, motor selection is likely to be consolidated, and NEMA Premium is expected to become the new industry motor effi ciency standard. h e inclusion of the NEMA motor effi ciency standards into U.S. law and the recognition of NEMA standards by environmental

groups, such as the American Council for an Energy Effi cient Economy (ACEEE), has resulted of a resurgence in a mature electric motors market.

Despite the high, premium costs associated with high effi ciency motors and concerns with making new capital investments amidst an uncertain economic environment, the trend toward higher energy effi ciency has been gaining momentum in North America. To adhere to EISA, end users are replacing less effi cient motors with NEMA Premium effi -ciency motors.

h e U.S. Congress and President Obama passed the American Recovery and Reinvestment Act, or “h e Stimulus Plan,” which provides funding for the federal government,

states and cities to improve energy effi ciency in buildings and schools. ARRA also provides enhanced incentives for consumers to upgrade existing heating and cooling equipment and allows consumers to purchase energy effi cient HVAC systems, energy effi cient motors and energy effi cient water heaters. h ese incentives include receiving a tax credit of up to 30 per-cent of the cost for energy effi cient products. h e stimulus encouraged consumers to make their homes more energy effi cient, and also drives the sales of high effi ciency motors.

To off set the price factor associated with

Electric Motors: Driving to Higher Effi ciencyJen Yao, Frost & Sullivan

Figure 1

Figure 2

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 27

NEMA Premium motors and encourage faster adoption, the U.S. Senate’s Energy and Natural Resources Committee voted in favor of adopting the NEMA advocated premium energy-effi cient motor rebate program, known as “crush for credit.” Once the $700 million motor rebate bill is passed, it will pro-vide a $25 per horsepower rebate for the purchase of NEMA Premium energy effi cient motors, and a $5 per horsepower rebate for the disposal of the old, non-NEMA Premium motor.

With all the emphasis on energy independence, other opportunities for electric motors exist. Wind power is gaining acceptance and becoming an increasingly cost-eff ective and clean alternative to conventional energy sources. Electric AC motors and servo motors are used in yaw drives, pitch controls and other control systems. h e North American wind power market has experienced tremendous growth during the last three years, growing at an average annual rate of 37 percent from 2006 to 2009 and reached a capacity of 34,000 MW and $13.5 billion in rev-enue in 2009. Increasing government concerns about energy security and independence, government incentives on renewable energy and other factors such as rising energy prices and volatil-ity of fuel costs have contributed to the accelerated market growth.

Looking forward, wind power con-tinues to be a strong growth sector; it is expected to reach a capacity of 127,000 MW and $37.1 billion in revenue by 2015, with an average annual growth rate of 24 percent. Since electrical and control systems (including yaw systems, pitch systems, brake systems, power converters and transformers) account for 13.8 percent of the capital cost of a wind turbine generator system, electric motors used in wind energy are pro-jected to experience strong growth to meet the strong demand.

Manufacturers moved quickly to make changes to their product off erings to ensure NEMA Premium compliance and began moving more inventory to the new levels to ensure availability and a smooth transition to high-performance

motors. Furthermore, manufacturers are seeking opportunities within the high-growth sectors, such as wind energy, to stay competitive. With the economic recovery, the requirement to meet energy effi ciency standards and demand from high-growth sectors, the electric motors market is expected to see a fast recovery.

P&S

Jen Yao is a research analyst with Frost & Sullivan.

Suction pressure

down to 1 psi a

Double Diaphragm with

monitoring system

Extreme

operational safety

Highest

metering precision

API 675 Compliance

Simple installation

and start-up

Compact design

Protect your process

with LEWA’s Double-

Diaphragm design

Never ask for less –

New LEWA®

www.lewa-inc.comLEWA, Inc. · 132 Hopping Brook Road

Holliston, MA 01746 · Phone +1 508 429-7403

circle 144 on card or go to psfreeinfo.com

All About Water

SPECIAL SECTION CONTENTS

Predictable Pump Motor Maintenance at a Cranberry Bog . . . . . . 29

Cellular Communications for SCADA Applications. . . . . . . . . . . . . 32

Technology Saves Valuable Equipment. . . . . . . . . . . . . . . . . . . . . . 38

Considerations for Choosing a Flow Meter . . . . . . . . . . . . . . . . . . 40

Clean Water for Florida Community . . . . . . . . . . . . . . . . . . . . . . . . 46

The Balancing Act of DP Flow Meter Selection . . . . . . . . . . . . . . . 50

WEFTEC Preview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 29

When a pump or motor fails at Sea Wind Cranberry Farm in Langlois, Ore., farm manager Knute Andersson’s business is at stake. An equipment

malfunction could allow the farm’s cranberry fi elds to cool just a couple degrees, and on a cold night, that can mean losing part of the crop. For modern cranberry farmers, properly function-ing pumps, motors and sprinklers help ensure that their berry yield will be high. Without them, the berries are at the mercy of hostile climates that can cause crop-killing frost or destruc-tive heat.

Because of the fragile nature of the cranberry crop, Andersson needs an on-call electrician who can provide emer-gency repair service eff ectively and effi ciently enough to save the berries, sometimes in the middle of the night. Even more important, Andersson needs an electrician who can ensure through eff ective predictive maintenance that many of these emergencies do not happen at all. Andersson’s electrician is Joe Buchanan, project lead man and safety chairman at Kyle Electric, North Bend, Ore. Buchanan has been in the electric business 33 years; “since I was a pup,” he says. h roughout that career, he has made safety and customer satisfaction his per-sonal mantra.

Buchanan helps keep his customers happy by maintain-ing and repairing their equipment before it fails. Buchanan has worked with Andersson on the maintenance of the cranberry farm’s pump system for about six years.

Berry ParticularAndersson has 11 pump houses, each with between two and fi ve pumps and just as many motors for those pumps. h e motors range from 10 to 100 hp. All the fi elds have temperature sen-sors that relay back to the pump houses. If the temperature goes up or down too far, the pumps come on to start the sprinklers, which then use water to adjust the air temperature in the bogs.

h e equipment maintains the proper temperature of the fi elds 24 hours a day, 10 months each year. h e cranberry vines must stay within two or three deg of their ideal temperature, otherwise the crop is damaged and the yield is reduced.

“If they get frosted, they freeze. h at’s a throw away,” Andersson says. “If it gets too hot, it will cook them, and they will rot on the vine. Yield is all about temperature control.”

While high temperatures are less common in temperate, coastal Oregon, often the air and water on early spring nights can dip dangerously low. If a motor fails then, when the ambi-ent temperature is too high or low, Andersson could lose part or all of an entire fi eld before the pump is up and working again.

Since he started managing the farm in 1991, Andersson

Predictable Pump Motor Maintenance at a Cranberry BogChris Rayburn, Fluke Corporation

Due to the delicate nature of the cranberry, pump failure is not an option.

www.hyundai-elec.com

WPⅠ / WPⅡTEAAC

ㅣ330 East First Street, Mansfield, OH 44902, U.S.A. ㅣTel: 419-522-3611 ㅣOliver Kwon, [email protected]

ㅣ140-2 Gye-dong, Jongno-gu, Seoul, Korea 110-793ㅣTel: 82-2-746-7541ㅣAdrian Woo, [email protected]

TEFC

Our most efficient powerful Motor seriesgives you the utmost certainty and assurance

as we guarantee the best of the best in this field.For over 30 years,

Hyundai Motors have shown its Miraculous Power and Assurance.

circle 113 on card or go to psfreeinfo.com

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 31

has worked on his pump and motor system to maintain the nec-essary temperature for the berries in his fi elds. Buchanan began helping him six years ago when he installed the farm’s most recent pump house and its four 100-hp motors and pumps at a price of more than $100,000. Each pump can move as much as 1,500 gal of water per min to provide frost protection, irriga-tion, weed control and fl ooding of the bogs at harvest time or when otherwise necessary.

Water, Water, EverywhereMother Nature not only provides haz-ards for the berries, it can also cause abuse to the equipment. Buchanan must be mindful of those hazards during maintenance of the farm’s 27 motors. h e salt air eats through insulation, and the constant presence of water slowly corrodes the motors and relays. “Windings fail faster. h ere is corro-sion and insulation degradation ahead of schedule,” Buchanan says. However, equipment failure is not an option.

Buchanan has worked to eliminate failure by implementing a predictive maintenance plan. Each winter, he visits the farm for an annual inspection of motors, controls and pumps and checks for loosened terminals and connections and any damage from moisture or age.

On each predictive call, Buchanan looks for changes in readings, and he checks the insulation and lining around each motor. “We want to prevent criti-cal shut down,” he says. To do this, he compares all his readings against those he measured at the same time the pre-vious year. He also tests for any power dips, looks for any damage to the insu-lation or the lining of the motor, and ensures that no feedback or deteriora-tion is present.

“We’ve gone through it all, and it is now pretty much trouble free,” Andersson says. If a problem occurs in any of his pump houses, most com-monly, starters burn up or a relay fails.

The Bottom LineSafety is Buchanan’s top priority, and he says that the right tools can make a dif-ference. “Use quality tools and be a good craftsman.” h ese tips not only ensure safety but keep customers coming back, Buchanan says.

P&S

Marketing Manager for clamp meter, earth ground, and insulation test products, Chris Rayburn has an extensive background in aerospace with a masters of science in aero-nautics and astronautics from the University of Washington and an MBA from the same school. Prior to Fluke, Chris worked for Aerojet, Accenture and GE. You can contact him at christopher.rayburn@fl uke.com.

circle 129 on card or go to psfreeinfo.com

32 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

All About Water

Managers of water/wastewater facilities need to collect accurate information from remote assets

such as pumps, tanks and booster stations. Traditionally, this information is collected manually by collecting the chart record-ings. h is might be done monthly, weekly or daily, depending on available staffi ng.

While manual collection of this data is the norm, plants want to move to an automated process using a central station for all monitoring and control, which can reduce or eliminate the need for manual data collection. h is type of system is called a SCADA (Supervisory Control and Data Acquisition) system. h ese advanced networking SCADA systems can provide all the information from remote assets at a single location, improving the accuracy and timeliness of the operation.

A SCADA system requires a network with a secure communication path. Many diff erent technolo-gies—including dial-up, DSL, leased line and private radio—can provide this communications link. In water applications, networks must often reach areas where phone lines or tradi-tional wiring does not exist. Conduits can be trenched and wire can be laid, but this is often cost-prohibitive. Radio can provide access to these remote locations without the need for wires. When it comes to radio, there are a variety of options available. h is article examines the use of cellular technology in SCADA applications, how it can be implemented, the diff erent networking options available and security.

Cellular Network OptionsIn the world of cellular communications, two network options, voice and data, are available. Each has diff erent capabilities for SCADA applications. In this article, we will focus on the Global System for Mobile Communication (GSM) network

for voice communications and General Packet Radio Service/Enhanced Data Rates for GSM Evolution (GPRS/EDGE) for data communications, but the same principles exist for other cellular technology segments.

h e general diff erence between these types of networks is that the GSM network addresses all devices on the network by a phone number. On the GPRS/EDGE network, all devices are addressable via an IP address, making data communications easy.

Simple Control with the GSM Network for

SCADA applicationsh e GSM network connects with the Public Standard Telephone Network (PSTN), allowing communications from cellular devices to land-based modems using a phone number. h is is used for voice communication and Short Message Service (SMS), also known as text messaging.

Cellular Communications for SCADA ApplicationsIra Sharp, Phoenix Contact

Effective and secure cellular communications for remote data acquisition.

Cellular modem-to-modem text message communications can be used for autonomous

tank-level control

PUMPS & SYSTEMS www.pump-zone.com SEPTEMBER 2010 33

However, in the U.S., dial-up networking, where one modem calls another using the PSTN, is not permitted over the cellular infrastructure. h is limits the use of the GSM network for SCADA applications in the U.S. to SMS-only. Despite this limitation, the GSM network can be useful for simple control applications in a SCADA system.

For these simple control applications, modems can use a text message to take an event—such as a door alarm, high- or low-level tank alarm, or change in pump status—and report it to a control room or another modem for autonomous system opera-tion. In modem-to-modem commu-nications, when the second modem receives a command, it provides some action or status update. h e modems create an autonomous system that can control some part of an event-based process.

For example, Modem A receives a low-level alarm message from the tank. h is modem then sends a text mes-sage to Modem B, which turns on the pump and fi lls the tank. Once the water reaches an adequate level, Modem A sends another message to Modem B, requesting that the pump be turned off . While this process occurs, the modems also send the text message to a second number for the control room. h is pro-vides real-time updates to the control room SCADA system about the actions occurring on site.

If an autonomous system is not nec-essary, the facility can still use text mes-saging. h e modem can send informa-tion about the processes to the control room SCADA master, which will pro-vide the needed logic for control. It can also send a text message directly to the technicians who are responsible for the system. h e technicians can then make the necessary changes to the system. Text messaging can be an eff ective way to monitor and control simple processes.

Advanced Networking

with GPRS/EDGE for

SCADA ApplicationsFor applications that demand more than simple, event-based monitoring and control, the GPRS and EDGE networks off er additional capabilities. h e GPRS and EDGE networks can connect to a

private network or to the Internet using standard networking protocols. Since this allows for more information exchange from the remote assets, greater fl exibility is available for moni-toring, controlling, or even programming over the cellular infrastructure than the GSM network allows. When using the GPRS or EDGE network for data communications, you must decide if you will leverage a private network or use the standard

H{orz"zu"rgyz"ot"znk"suyz"k̃zxksk"gvvroigzouty4

X{mmkj4"Xkroghrk4"Xkgj’4

Mo¦k"{y"’u{x"zu{mnkyz2"suyz"k̃zxksk"v{svotm"gvvroigzout"gtj"}kÙrr"mo¦k"’u{"

g"iutzxur"yur{zout4"Ol"’u{"ng¦k"}gzkx3ngsskx2"}kÙrr"krosotgzk"oz4"Tkkj"yosvrk̃2"

j{vrk̃"ux"k¦kt"zxovrk̃"v{svotm"iutzxurE"Tu"vxuhrks4"Yvkkj"iutzxurE"Iutyojkx"

oz"jutk4"Krkizxoigr"otx{yn"vxuhrksyE"Yur{zouty"

gxk"u{x"yvkiogrz’4"Hktyng}"ullkxy"g"l{rr"rotk"ul"

l{rr"¦urzgmk"gtj"yuroj"yzgzk"yzgxzkxy"lxus"866"

zu"7;2666"¦urz"gtj"¦gxoghrk"yvkkj"jxo¦ky"lxus"

866"zu"<66"¦urz4

Zu"rkgxt"suxk"ghu{z"u{x"soyyout"ixozoigr"yur{zouty2"igrr":784?<>46766"ux"¦oyoz"nzzv@55hktyng}4i}li4ius

circle 133 on card or go to psfreeinfo.com

34 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

public network. Private networks off er a great deal of fl exibility. Just about

any network architecture can be realized, including host-ini-tiated communication, and all communications do not need to fl ow over the Internet. However, to create a private cellu-lar network, you must work with a carrier—such as AT&T, T-Mobile, Verizon, etc.—to defi ne how your network should

be constructed. h ese private networks typically charge a one-time setup fee to create the network. h is fee can range from hundreds to more than $2,500, depending on the type of net-work being constructed.

With this type network, you will also need to do some network management to ensure proper network use. Private networking can be ideal for larger cellular networks, but smaller

systems usually fi nd the public network more suitable.

h e public network does not require any special confi gurations. Service plans are easily accessible, and generally, no setup fees are required. However, all data communications will fl ow over the Internet, which heightens the chance of network security threats.

In addition, typical poll-response networks used in SCADA systems will not work over the public network with-out proper preparation. h e public net-work is designed for mobile-originated communications. In other words, the remote device talks, and the host receives the information. In most SCADA sys-tems, however, the host initiates the communication to the remote device. A VPN (virtual private network) can over-come both the security concerns and the remotely initiated communication issues.

Security with VPN

TunnelingA VPN tunnel is one simple way to ensure the security of the Ethernet traf-fi c over the Internet. To use a VPN tunnel, the modem must support VPN networks. A router that supports VPN networking must also be at the control room.

Leveraging the VPN tunnel to secure the communicated information also solves other cellular issues. As men-tioned earlier, cellular networks typically require that the remote modem initiate all data communications. Many indus-trial protocols, such as MODBUS and EtherNet/IP, however, are designed for poll response. h e SCADA master at the control room must initiate the commu-nications, not the remote modem.

By creating a VPN tunnel between the remote modem and the SCADA system, the modem will be available on demand. h is allows the SCADA master

All About Water

The MPT

family of self-

priming solids-

handling pumps

FamilyMattersWorthington ®

Durco ® IDP ®

It’s a lineage you can trust.

Worthington. Durco. IDP.

Three of the most respected names

in water resources, dewatering,

mining and general industry.

The new family of MPT self-priming

solids-handling pumps offers a robust

design with reliable and efficient

operation. Every MPT pump stems from

two centuries of experience found within

this Flowserve family of product brands.

Experience In Motion

Pedigree counts. Learn more

about the most distinguished

family tree in water and

general industry pumps at

www.flowserve.com.

circle 140 on card or go to psfreeinfo.com

• Superior Reliability

• Unmatched Quality

• Local Sales and Support

• Quickest Delivery Available

When it comes to industrial electric motors, power transmission products and drives, no other manufacturer offers more than Baldor...that is why Baldor is The Industrial Choice! Whether your application requires a fractional or 15,000 Hp motor, a variable frequency drive, mounted bearings or gearing, a pulley or sheave or even a standby generator, Baldor is the choice most preferred by industry.

When your next project demands the most reliable and energy efficient products available, look to Baldor as your one source for more industrial solutions.

baldor.com 479-646-4711

©2009 Baldor Electric Company

The Industrial Choice

® ® ®

circle 103 on card or go to psfreeinfo.com

36 SEPTEMBER 2010 www.pump-zone.com PUMPS & SYSTEMS

All About Water

to do the polling. h e modem will initiate communications at startup and will keep the tunnel up, making access of the con-nected devices easy.

Using this type of network in a water application means that a SCADA master located in a control room can poll a remote PLC, which monitors various aspects of a process, for information on demand, such as pump status. h is provides a

real-time look at the water process without the need for manual interaction. In addition, changing variables or programming is possible in the remotely located PLC over the cellular network, eliminating the need to visit each location for a system update.

Whether the application involves simple data collection, non-critical control, or remote programming capabilities, the cellular network provides the network access necessary. I/O modems with text message capabilities provide alarm notifi -cations based on a condition or control another device. Data modems provide data communications to remote assets. When used with a VPN, modem technology allows users to collect information, program controllers and access other critical information, all through a single secure wireless link.

P&S