PT Fundamentals

-

Upload

mamdouhalhanafy -

Category

Documents

-

view

49 -

download

0

Transcript of PT Fundamentals

Product Training ManualPower Transmission Fundamentals for V-Belt Drive Systems

• Basic calculations to assist in installation and problem-solving • Belt Drive Advantages • Product Types • Balancing Standards • Installation & Maintenance

1

INDEX

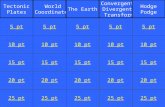

Chapter 1 - Power Transmission Fundamentals1.1 Calculation of the Circumference of a Circle ...................................................................................................... 31.2 Force ....................................................................................................................................................................... 5 1.2.1Definition .............................................................................................................................................................5 1.2.2Motion ................................................................................................................................................................ 6 1.2.3TorqueCalculation ............................................................................................................................................. 71.3 Work .......................................................................................................................................................................121.4 Speed and Velocity .............................................................................................................................................. 141.5 Power .....................................................................................................................................................................161.6 Efficiency ...............................................................................................................................................................191.7 Ratio .......................................................................................................................................................................201.8 Service Factors ....................................................................................................................................................23

Chapter 2 - Drives: Belts, Bushings & Sheaves 2.1 What are the Advantages of a Belt Drive System? ........................................................................................... 252.2 Belts ..................................................................................................................................................26 V-BeltClassifications .............................................................................................................................................27 2.2.1.1 Lightduty&Fractionalhorsepower(F.H.P)V-Belts .....................................................................................27 2.2.1.2 ClassicalV-Belts ...........................................................................................................................................28 2.2.1.3 DeepWedge/GrooveorNarrowV-Belts .....................................................................................................29 2.2.1.4 Cogged/Raw-EdgeV-Belts .........................................................................................................................30 2.2.1.5 BandedBelts ................................................................................................................................................30 2.2.1.6 V-Ribbed/PolyV-Belts .................................................................................................................................31 2.2.1.7 Double/HexagonalV-Belts ..........................................................................................................................31 2.2.1.8 VariableSpeedBelts.....................................................................................................................................32 2.2.2 OtherBeltTypes ...........................................................................................................................................32 2.2.2.1 StandardFlatbelts ........................................................................................................................................32 2.2.2.2 Standard/TrapezoidalSynchronousBelts ...................................................................................................33 2.2.2.3 H.T.B./CurvilinearSynchronousBelts .........................................................................................................34 2.2.3 BeltLength ..................................................................................................................................................35 2.2.3.1 Parallelaxis,uncrossedbeltdrive ................................................................................................................36 2.2.3.2 Arcofcontact ................................................................................................................................................372.3 Drive Components Materials ................................................................................................................................38 2.3.1 Gray/CastIron ..............................................................................................................................................38 2.3.2 DuctileIron ..................................................................................................................................................38 2.3.3 SinteredMetal ...............................................................................................................................................39 2.3.4 TableofMechanicalProperties .....................................................................................................................392.4 Bushings ..................................................................................................................................................40 2.4.1 QD(QuickDetachable)InterchangeableBushings ......................................................................................40 2.4.2 Taper-Lock/BoreBushings ..........................................................................................................................43 2.4.3 SplitTaperBushings .....................................................................................................................................43

2

2.5 Sheaves ..................................................................................................................................................44 2.5.1 SheaveBody ................................................................................................................................................45 2.5.2 SheaveClassifications&Terminology ..........................................................................................................46 2.5.2.1 LightDutyFixed&BushTypes .....................................................................................................................46

2.5.2.2 Adjustable/F.H.P&Integral ..........................................................................................................................47 2.5.2.3 Classical&NarrowBeltDrives .....................................................................................................................50 2.5.2.4 ApplicationTablebyClasses ........................................................................................................................51 2.5.3 BalancingStandards(MPTA)........................................................................................................................52 2.5.3.1 GeneralInformation ......................................................................................................................................52 2.5.3.2 StaticorSingle-PlaneBalancing ..................................................................................................................52 2.5.3.3 DynamicorTwo-PlaneBalancing .................................................................................................................55

Chapter 3 – Drive Selection Program

PleaseseeourOn-lineProgramforthissectionatwww.maskapulleys.com

Chapter 4 - Installation & Maintenance

4.1 Bushing Mounting .................................................................................................................................................57 4.1.1 TypesofMounting ........................................................................................................................................57 4.1.2 Tightening ..................................................................................................................................................584.2 V-Belts & Sheaves .................................................................................................................................................59 4.2.1 MountingStructure .......................................................................................................................................59 4.2.2 CenterDistanceAdjustment .........................................................................................................................59 4.2.3 V-BeltInstallation ..........................................................................................................................................60 4.2.4 Tensioning ..................................................................................................................................................63 4.2.4.1 MeasuringTechniques ..................................................................................................................................64 4.2.4.2 Run-inPeriod ................................................................................................................................................67 4.2.5 IdlerPulleys ..................................................................................................................................................68 4.2.6 Maintenance .................................................................................................................................................69 4.2.7 BeltStorage ..................................................................................................................................................694.3 Typical Problems ..................................................................................................................................................70 4.3.1 DriveMisalignment .......................................................................................................................................70 4.3.2 SheaveCrackedinHub ................................................................................................................................70 4.3.3 Vibrations ..................................................................................................................................................71 4.3.4 OverTension .................................................................................................................................................71 4.3.5 HighRatiowithShortCentertoCenterDistance .........................................................................................724.4 Couplings ..................................................................................................................................................73 4.4.1 FlexibleCouplingTypes ................................................................................................................................73 4.4.2 ShaftMisalignment .......................................................................................................................................75 4.4.3 ElastomericElementCouplings ...................................................................................................................76

3

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Chapter 1POWER TRANSMISSION FUNDAMENTALS

Inthisfirstchapterwewillendeavortofamiliarizeyouwithconceptsrelatedtodifferenttransmissionapplications.Variousnotionsofmechanicsandgeometryrequiredtomakeagoodselectionofdrivecomponentswillbepresented.Thesefundamentalcalculationbasicsareoftenfoundinengineeringreferencemanualsbuttheyhavebeenincludedtoshowhowtheycanbeappliedtoproblem-solvingwithbelttransmissionapplications.Youarethereforeencouragedtoexaminethischapteranddotheaccompanyingexercisesasgroundworkforcalculatingcriticalfactorsencounteredwheninstallingdrivecomponents.

1.1 Calculation of the Circumference of a Circle

Oneof themostcommonbasicgeometricfiguresusedwhendesigning a power transmissioncomponent isthecircle. Thecircle is thegeometrical shapeonwhich theentirepower transmissionprocess isbased.Thecircumferenceisdefinedasthemeasurementofthecircle’scontour;asimplemethodofobtainingthisdimensionisbymeasuringtheexactlengthofstringneededtogoaroundthecircle.

Circumference (C)

Circle Center

Radius (R)

Diameter (D)

Fig. 1.1: Illustration of a Circle’s Main Geometric Parameters

Tocalculateacircle’scircumference,wemustknowthattheratiobetweenthecircumferenceandthediameterisaconstant.ThisconstantisnamedPi(π,Greekletter).Itsvalueis 3.1416.

4

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Formulastocalculatethecircumference( C )ofacircleare:

C = � • D or C = 3.1416 X D

also, C = �(2R) ⇒ C = 2�R knowingthat D representsthediameterand Rtheradiusofacircle(Fig.1.1)

Example 1.1 Calculateacircle’scircumferenceifthediameteris4".

Answer: C = �D = 3.1416 X 4 = 12.566 inches

Ifa4"diskwasrolledonaflatsurface,adistanceof12.566"wouldbecoveredwitheach completeturn.

5

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.2 Force

1.2.1Definition

Forceisdefinedastheactionthatonebodyhasonanotherbody.Whenanappliedforceonanobjectisgreaterthananyexistingforce,thiscanresultinadisplacementofastaticbody,accelerateanddecelerateabodyinmovementorresultinadistortionofsomekind.Thisisreferredtoasactionandreaction.

Forcecanbeaccuratelydeterminedwhenthemagnitude,directionandthepointofcontactareindicated.Inthefollowingdiagrams,theforce’sdirectionandpointofcontactarerepresentedbyavector(arrow)(seeFig.1.2).ThemeasurementunitofforceintheEnglishSystemispoundandtheunitsymbolis “lb”.Inthisexample,theweightofoneunitofmassisequaltooneunitofforce.

NOTE:ThisprincipledoesnotapplywhenusingtheMetricSystem.

When torque is not taken into consideration, all parallel forces can be subtracted if they are from opposingdirections, or combined if they are in the samedirection, to obtain a single force: resultant force. Whencalculatingtheresultantforce,itisimportanttokeepinmindthestatusofeachappliedforce(+or-)asthiswilldirectlyinfluencetheresultsobtained.However,referencetothepositiveornegativestatusisneededonlywhencalculatingmathematicalequations(Example1.2);itismorepracticaltodrawasimplediagramoftheappliedforces.(Ref.Fig.1.3)

Magnitude

Application point Direction

20 lb

Fig. 1.2: Diagram of a force

20lbs 20lbs 40lbs 20lbs

20lbsResultant=0

Fig. 1.3: Addition of collinear forces (Example 1.2)

6

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Example 1.2 Infigure1.3,forceisappliedtoeachsideofablock.(Inthisdiagram,thearrowrepresentsthepointofapplicationandtheforce’sdirection)Calculatetheresultantforceforeachdiagram,assumingthatthereisnofrictionbetweentheobjectandtheground.

Answer:

The leftdiagramhasa resultant forceofzero (20 lb.–20 lb.=0 )and thus remainsmotionless.Thelawofstaticdictatesthatthetotalsumofforcesmustequalzero.

Therightdiagramhasaresultantforceof20lb.(40lb.–20lb.=20lb.),thuspushingtheblocktotheright.Inthisexample,theblockmovesinthedirectionoftheresultantforceandonlyanopposingforce,likefriction,couldstopthemovement.

1.2.2 Motion

Twomajortypesofmotionexist;theyarelinearandangularmotions.Themovementofatrainonarailwaytrackis anexample of linearmotion. On theother hand, a turningpulley is a goodexample of angularmotion.Mechanicalpowertransmissiongenerallyimpliesthereforeangularmotionandtheusageofrotatingelements,suchas:shafts,couplings,gearreducers,chaindrives,sheavesandbelts.

Motionalwaysrequiresanexternalforceorenergy.However,motioncanbemeasuredwithoutreferencetotheinitialforce.Forexample,youcancalculatethespeedofanobjectevenifyoudon’tknowtheforceusedtopowerit.Theinteractionbetweenmotionandforceareveryimportantconceptstounderstandinanytransmissiondrivesystem,aswewillseelateron.

Linear Motion Angular Motion

Fig. 1.4: Linear and angular motion

7

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.2.3 Torque Calculation

Intheprecedingsubheading,wesawthatforcecancauseanobject tomovelinearly(example1.2)but itcanalsomakeitturn.Torquecorrespondstoatwistingforceandresultsfromtheactionofanappliedforceonabodyatacertaindistancefromthecenteraxis.Thedistancebetweenthepointwhereforceisappliedandtherotarycenterisusuallycalledtheleverarm.Sothetendencyforanysystemsubmittedtotorqueistoturnonit’srotationaxis(example:tighteninganutwithawrench,pushingthepedalsonabicycle,abeltturningapulley,etc.).

Torqueiscalculatedbymultiplyingthemagnitudeoftheforcebytheleverarm.

Tocalculatetorque ( T ),usethisformula:

T = F x ror

T = F x R

knowingthatF=forceandr=theleverarm(youcanreplacerbytheradiusRforacircularbody,suchasapulley,whenforce isappliedontheoutercircumference). For thisreason, torque isexpressed inpounds-inches (lb.-in).Hence,torqueresultsfromthedirectionandmagnitudeoftheappliedforceandtheleverarm.

Important: The component force of torque must be at a 90o angle with the lever arm via the point of contact and the rotary center (Fig. 1.5).

Fig. 1.5: Diagram of torque force

centeraxis

TR

F

8

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

r=10in

15lbs

150lb.-in

Example 1.3 A5"diameterpulleyisinstalledonashaft.Thepulleybearsaweightof10pounds (Fig.1.7).Whatistheinducedtorque?

Answer: Theleverarmmeasures2.5inches(diameterdividedbytwo).Thedistancebetweenthepointof contactandtherotarycentercorrespondstotheradiusofapulley.Theweightistheonlyforce producingtorque.

T = F x R

T = 10 [pounds] x 2.5 [inches] = 25 lb./ in.

D

Torque

10pounds

Fig. 1.7: Torque from a suspended weight on a pulley (Example 1.3)

Fig. 1.6: Virtual lever arm

9

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Example 1.4 Usingthesameexample,supposewewanttocalculatetheleverarm;theforceandtorqueareknown.Iftheinducedtorqueis50lb.-inandthesameweight(10lb.)issuspendedonthepulley,howlongshouldtheleverarmbe?

Answer: UsethesameformulatocalculatetheR(leverarm)thistime:

R= T

= 50 [lb • in] F 10 [lb]

R = 5"

Thisillustratesthesignificanceoftheleverarm.Thesameweightsuspendedfromapulleytwicethesize(thusdoublingtheleverarmlength),requirestwiceasmuchtorqueasinexample1.3.

Atthispoint, itwillbeusefultoexaminethenotionofresultanttorque,aswedidwithresultantforce.Multipletorquecanbeaddedorsubtracteddependingontheirdirection,butmustbeonthesamecenteraxis.Theconventionsignusedforthedirectionofatorqueis(+)foraclockwisedirectionand(-)foracounterclockwisedirection(Fig.1.8).Thefollowingexamplewillhelpyoutounderstandhowresultanttorqueworks.

Clockwise ( + ) Counter - Clockwise ( - )

Fig. 1.8: Torque convention sign

10

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Example 1.5 Calculatethetorquefromtherotatingpointofthebeamintheillustrationbelow(Fig.1.9).Afterapplyingtheweights,towhichsidewillthebeamtiltaccordingtotheresultingtorque?

Answer:Torquefromleftweightappliedoncenteraxis(counterclockwise-): T = F x R = 100[pounds] x 30[inches] = 3000 lb•in

Torquefromrightweight(clockwise+): T = F x R = 30[pounds] x 50[inches] = 1500 lb• in

TheresultantTorqueiscounterclockwise: T = 1500[lb• in] – 3000[lb• in] = – 1500 lb• in Thebeamwilltilttotheleft.

Fig. 1.9: Example 1.5

100lb. 30lb.

50"30"

Example 1.6 With reference to Fig. 1.9, at what distance from the rotary point would a 50-lb.weighthavetobeplacedtobalancethebeamhorizontally?

Answer:First,example1.5indicatedthatthesystemhasacounterclockwiseresultanttorque.Inthiscase,theonlywaytostabilisethebeamwouldbetoplaceaweighttotherightsideoftherotarypoint.Thetotalsumofalltorquemustequalzerotoattainequilibrium,aswasseenwiththestaticlawofforce(example1.2).

Resultant Torque = 1,500[lb.• in] – 3,000[lb.• in] + 50[lb.] x d = 0

11

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

50[lb] x d = 3000[lb • in] – 1500[lb • in]

d = 3000[lb• in] - 1500[lb.• in] d = 30"

50 [lb]

*** Even if a body doesn’t move, it could have an induced torque.***

12

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.3 Work

Inthecontextofthismanual,worksignifiestheactioncarriedoutwhenaforcecausesanobjecttomove.Workequals thedegreeof forceapplied toabody,multipliedby thedistancecovered inmovement. Nowork isrecordedintheabsenceofmovement.Notethatenergyisalsoconsideredaformofworkbutshouldnotbeconfusedwiththenotionofpower(ref.Section1.5.)

Inlinearmotion,workresultsfromthedegreeofforceappliedtoanobjectandthedistancecovered.Ontheotherhand,angularmotionresultsfromthetorqueappliedtoanobjectandtheangularmovement.

Workisusuallyexpressedinft.-lb.orin.-lb.Torquehasthesameunitsofmeasure,butinvolvesthedistancefromtherotarycenter to thepointofcontactwhereaswork iscalculatedbymeasuring thetotaldistancecoveredbetweentheinitialandfinalposition.

Theformulasare:

Linear system: Work resulting from a force U = F x d or

Rotational system: Work resulting from a torque U = T x θ

knowingthatU=work,F=force,T=torqueandd =thedistancecoveredbyonebodysubjectedtoagivenforce.Tocalculatetheworkresultingfromatorque,displacementismeasuredbytheangle

(θ )inradians(1radian=57.3degreesor1800/π).

Example 1.7 Afilingcabinetispushedonawoodenfloor(Fig.1.10).Theforceappliedtomovethefilingcabinet is10 lb. Thedistancecoveredis120inches. What is theworkvalue?

Answer:

U = F x dU = 10 lb. x 120 inU = 1,200 in- lb.

13

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

10lb.

120"

Fig. 1.10: Example 1.7

Example 1.8 Youhavetotightenanutonastructure.Youuseatorquewrenchwithtwoarms,6incheslongoneachside.Ifyouappliedaconstantforceof6lb.totheextremityofeacharmandturnedthenut900(¼ofaturn),calculatehowmuchworkisinvolved.

Answer:

1.Calculatingtorqueononearm T1 = F x d T1 = 6 lb. x 6 in = 36 lb.-in

2.Calculatingtheresultanttorque T = T1 + T2 = 36 [ lb.- in ] + 36 [ lb.-in ] = 72 lb.-in

3.Converttheangletoradians π rad = 180o

π/2 rad = 90o

3.Calculatingtheworkinvolved U= T x θ U= 72 [ lb.-in] x (π/2) U= 72 [ lb.-in] x (1.57) = 113 lb.-in

14

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.4 Speed and Velocity

Oncethenotionofmovementhasbeenunderstood,itisimportanttodetermineandquantifythespeedanobjectmoves.Todoso,wehavetocalculatethevelocity(speed)ordistancethatanobjectmovesinagivenunitoftime.Inlinearmotion,thedisplacementequalsthedistancecoveredandinangularmotionthedisplacementisanangle.

Theformulastocalculatevelocityare:

linear velocity (v):

v = d t

whered=distance,t =timeandvisexpressedinin/secorft/sec.

and angular velocity (ω):

ω = θ t

whereωisexpressedinrad/sec.Anothermorepracticalformulatocalculatethespeedforangularmotionistocountthenumberofrevolutionsper

minute(rpm).However,tangentialspeed(vT)isanotherimportantmeasurementtounderstandwhendesigningabelt-drivesystemorchoosingaV-belt.Itisusuallyexpressedinfeetperminuteandcorrespondstothebeltvelocity.Whenabeltispulley-driven,thespeedatthepointofcontactisdifferentfromtherotaryspeedofthepulley.Forexample,ifusingabicycleonatreadmillmachineyoucouldcomparethemovingconveyortoabeltandthebicyclewheeltoapulley.Thebicyclistdoesnotneedtoknowtherotaryspeedofthebicyclewheelstocalculatethesurfacespeedorthebeltspeedbecauseasaspeedometercanindicatethistohim.However,whendesigningabeltdrivesystemyouusuallyhavetodeterminetherimspeed.Todoso,thesamemethodofconversionmustbeappliedasthatusedbyacarorbicyclespeedometer.

Hereareseveralpracticalformulastoknowinordertocalculatetangentialvelocityorbeltspeed.

TherelationbetweenVTandωis:

ω [rad / min] = 2� x RPM&

vT= ω x R vT = 2� x R x RPM = � x D x RPM

Withreferencetoabelt drive system,theformulatofindbeltspeedis:

Belt Drive velocity[ft/min]=Pulley Diameter[in]x π x RPM x 1/12 [ft/in]or

FPM=Pulley Diameter[in]x 0.2618 x RPM

15

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Please note that the fraction 1/12 hasbeenaddedtotheformulatoconvertthepulleydiameterintofeet.Youalsoneedtorememberthattheoutsidediametershouldnotbeusedforcalculatingbeltspeedwhenworkingwithvariablepulleys,astheradialpositionwillvary

Belt speed

Fig. 1.11: Belt Speed

Example1.9 Calculatethebeltspeeddrivenbya5inchpulleywitharotaryspeedof2,000rpm.

V-beltdrive[ft/min]=5[in]x3.1416x2000[rpm]x1/12[ft/in]V-beltdrive[ft/min]=2,618ft/min

16

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.5 Power

Inmechanicalengineering,powerisameasureofperformanceorcapacityandisdefinedastheamountofworkperformedinagiventime.Themostworkaccomplishedintheleastamountoftime,equalsgreaterpower.TheformulastocalculatePower(P)are:

P = U

t

or

P = T x ω P = F x v

KnowingthatU=work,t =time,v=linearvelocity,T=torqueand F=Force.Theunitsofmeasurementforpowerareusuallyin-lb./sec,ft.-lb./sec,butcouldvarydependingontheunitsusedintheformula.

Example 1.10 Calculatethepowerrequiredtolifta500lb.weight20ft.in60seconds.(Fig.1.12)

Answer:

P = U = F x d t t

P = 500[lb] x 20 [ft] X 12 [in]= 2000 in•lb 60 [sec] [ft] sec

500lb.

20ft

Fig. 1.12: Example 1.10

17

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

IMPORTANT

InthePTindustry,thetermhorsepowerisoftenusedasapowerunit,commonlycalledforce.Evenifthis

expressioniscurrentlyused, itshouldnotbeconfusedwiththedefinitionofforcethathasalreadybeen

given. Inordertoavoidconfusion,itisbettertousethecorrecttermofpower.

TheformulastocalculatePowerinhpare:

HP = U [ft·lb] = P[ft·lb/sec] 550·t[sec] 550

or

HP = U [ft·lb] = P[ft·lb/min] 33000·t[min] 33000

Example1.11 Usethepreviousexample(Fig.1.12)tocalculatepowerexpressedinhp.Answer:

HP = P [ft-lb.] 550 t [sec]

HP = 500[lb.] x 20[ft] 550 x 60 sec

HP = 0.303 hp

Inthecaseofangularmotion,thereisobviouslyaformulatocalculatepoweraswell.Thepreviouslydiscussedformulasoftorqueandangularvelocityareinvolved.

18

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Hereistheformulatocalculatepowerusingspeedrevolution(RPM) ornumberofrotationsa minuteandtorque (T):

P = 2π x T x RPM

Therefore, the power in hp (HP) can be calculated using the following formulas:

HP = T[lb·ft]·RPM

5252

or

HP = T[lb·in]·RPM

63025

Example 1.12: AV-beltdrivensystemispoweredbya2hpelectricmotor.Themotorhastwooperationalspeeds:1,140rpmand570rpm.Calculatethetorqueatbothspeeds. Hint:Rewritetheequationtofindthetorque.

Answer:Speed 1- 1,140 rpm

HP = T[lb·ft]·RPM 5252

T[lb·ft] = 5252·HP= 5252x2 = 9.21 lb ·ft RPM 1140

Speed 2- 570 rpm

T[lb·ft] = 5252·HP= 5252x2 = 18.4 lb ·ft RPM 570

19

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.6Efficiency

Inmosttransmissionsystems,frictionforcesandheatdissipationaccountforaconsiderablelossofpower.InthecaseofaV-beltdrivensystem,aconsiderablelossisexperiencedfrombeltslip.Mechanicalefficiencyismeasuredintermsofinputandoutputpower,where100%equalsmaximumperformanceorzeropowerloss.Theformulaformechanicalefficiencyis:

Example 1.13 Calculatetheefficiencyofatransmissionthathasaninputpowerof10hpand9hpattheoutput.

Answer:Efficiency(%)=HPOutputx100 HPInput

Efficiency(%)=9hpx100 10hp

Efficiency(%)=90%

20

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.7 Ratio

Aratioisaproportionalfactorbetweentwosimilarobjectsofdifferentsizes.Inabeltdrivesystem,aratioisusedtodeterminethespeedrelationbetweentwopulleys.Thespeedratiowouldbestableifslippagedidnotoccur;howeverasbeltslipisinevitable,theratiovaries.Iftheratiois>1werefertoaspeedupsystem;iftheratiois<1itisaspeedreductionsystem.Inbothcases,theratioisobtainedusingthedimensionsoftheinputdrive(driver)pulleyandtheoutput(driven)pulley.

Rs =

ω1 = RPM1 = D2

ω2 RPM2 D1

whereRSisthespeedratio,D1diameterofdriverpulley,D2diameterofdrivenpulley.

***FOR V-BELT DRIVES, REPLACE DIAMETER(D) BY THE PITCH DIAMETER(PD)***

Example 1.14: Calculatetheratiobetweena2inchdriverpulleyanda5inchdrivenpulley.Answer:

Rs

=

D2 =5 2.5 : 1 D1 2

Example 1.15: Calculatethespeedratiobetweenadriverpulleyturningataspeedof500rpmandadrivenpulleyat2,000rpm.Ifthedrivingpulleyis4inchesindiameter,whatisthedimensionofthedrivenpulley?

Rs

= 500 1: 4

2000

Whenthedriverpulleyhascompletedonerevolution,thedrivenhasturned4times.

Rs

= 500 =

D2 D2= 500 x 4" = 1" 2000 4" 2000

21

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Ratioscannotbeaddedorsubtracted;onlymultipliedordivided.Forexample,todeterminethespeedratioofadrivenpulleyinacompounddrivewithfourpulleys(seeFig.1.13),ratiosaremultipliedtomaketheconnectionbetweentheinputpulleyD1andoutputpulleyD4.

However,thediameterofthefourpulleyscanbecalculatedonlyinacompounddrivewherethespeedsofthedrivingpulleyandthedrivenpulleyareknown.Inthiscase,seethefollowingsteps(ref.Example1.16):

1. The first step is to form a fraction with the driving pulley speed as thenumeratorandthedrivenpulleyspeedasthedenominator.

2. Afterthat,reducethisfractiontoitslowestterms.3. Dividethenumeratorandthedenominatorintotwopairsoffactors(apair

beingonefactorinthenumeratorandoneinthedenominator).4. Ifnecessary,multiplyeachpairbyatrialnumberthatwillgivepulleysof

suitablediameters(seeexample1.16).Thistrialnumberhasaninfluenceonthecost,soitshouldbereducedasmuchaspossiblewhileretainingthepowerrequired.

Example 1.16: Inthecompounddriveabove,ifthespeedofpulleyD1is575rpm,andthespeedofpulleyD4is1,200rpm,whatisthediameterofthefourpulleys?

(Step 1) Rs =

575 1200

(Step 2)reducethefractiontoitslowestterms

23 48

(Step 3) Divideintotwofractions

23 = 1x2348 2x24

(Step 4)multiplybytrialnumber8and1 (1x8) x (23x1) = 8x23

(2x8) x (24x1) 16x24

Thevalues8and23inthenumeratorrepresentthediametersofthedrivenpulleys,D2andD4,andthevalues16and24representthediametersofthedriverpulleys,D1andD3..Thepulleydiametersmustrespectthedesign.D3>D4>D1>D2;verify24>23>16>8.

Note:Whenthedimensionsobtainedarenotstandardmanufacturersizes,thepulleyscanbereducedbydividingthediameterofeachonebythesamenumbersoastoobtainastandarddimension.Thissignifiescostsavingsandareductioninthedesignspacerequired.JustbesurethattheystillmeettherequiredHPrating.

D3

D2

D4

D1

Fig. 1.13: Example 1.16

22

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

Example 1.17: IfthediameterofthepulleysD1=40,D2=15,, D3=36, and D4=48andthespeedofpulleyD1is695,findthespeedofthedrivenpulleyD4.

D2 X D4 = RPM1 N4 = D1 x D3 X RPM1 =

40 x 36 X 695 = 1390 rpmD1 D3 RPM4 D2 x D4 15 x 48

Hence,theoverallratiobetweentheinputdriveD1andoutputdriveD4isequalto:

RPM1

= 695 = D2 X

D4 = 1 : 2RPM4 1390 D1 D3

23

Pow

er T

rans

mis

sion

Fu

ndam

enta

ls

1.8 Service Factors

When designing components formanufacturing industries, engineersmust take into account factory inducedfactorssuchasoperatingtimes,thetypeofdrivingunitandtheload.Thisservicefactorisusedtoadjustthehorsepowerrequirementstoreflectactualhorsepowerneedsinordertoensurenormalservicelife.Aservicefactorcanbecomparedtoasafetyfactororsafetyprecaution.

Manufacturingcompaniesdecided tousea formulabasedonproductioncondition factors to foreseepossible

abuse throughexcessivewearand tear andadapt their transmission systemsaccordingly.Various tablesbasedonproductionconditionsarereferredtowhendesigningpowertransmissionsystems.Environmentalfactors(heat,abrasivedust)arenottakenintoconsiderationbutcertainlyaffectthelifeofadrivesystem.You’llseehowtheseservicefactortablesareusedwhendesigningabeltdrivesysteminchapter3.

Theformulaforcalculatingaservicefactoris:

Ks = P'

P

KnowingthatKSrepresentstheservicefactor,P’thedesignpowerandPtherequirementpower

Example1.18 Ifabeltdrivesystemhasaservicefactorof1.4,andtherated(required)poweris40hp,howmuchpowerisneeded?

Answer:

Ks = P'

P

P' = P · Ks = 40[hp] · 1.4 = 56hp

24

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Chapter 2DRIVES: BELTS, BUSHINGS & SHEAVES / PULLEYS

Hex

agon

al B

olt

Shea

veSq

uare

Key

QD

Bus

hing

V-Be

lt

25

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.1 What are the Advantages of a Belt Drive System ?

InChapter1itwasillustratedthatforceandpowercanbetransmittedindifferentmanners.Themostcommonlyusedsystemstotransmitpowerfromadrivershafttoadrivenshaftarebelt-drivesystems(Fig.2.2a),gear-drivesystems(Fig.2.2b)andchain-drivesystems(Fig.2.2c).

(a) (b) (c)

Fig. 2.2: Illustration of different drive systems

Thereareanumberofadvantagestousingabeltdrivesystemascomparedtoothersystems.Itisalsoreferredtoasa“frictiondrive”aspoweristransmittedasaresultofthebelt’sadherencetothepulley.Amongthedifferentbeltdrivesystems,the“V”beltdriveisaveryeconomicalspeedreducingoptionthatiscommonlyusedinindustrial,automotive,commercial,agriculturalandhomeapplianceapplications.Thelistbelowpresentstheadvantagesofabeltsystemwhenitiswell-designedandusedinaproperenvironment.

Advantages of “V” belt drives are:

* Easyandeconomicalinstallation.

* Nolubricationrequired.

* Clean&lowmaintenance.

* Elasticityofbeltshelpsshockloaddampening.

* Quiet,smoothoperation.

* Longlifeexpectancywhenwelldesigned.

* Goodmechanicalefficiency. In addition, should a rotational component become blockedwhile in operation, considerable damage can be

causedtotheentirepowertransmissionsystem.Thisriskcanbegreatlylessenedwithabeltdrivesystem,

26

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

asabeltwillslipifthesystemblocks,thusreducingtheriskofbreakage;thisadvantageisnotavailablewithachainorgearsystem.However,thisadvantageisoffsetbythefactthatstandardfrictiondrivescanbothslipandcreepandsodonotofferexactvelocityratios,norprecisiontimingbetweeninputandoutputshafts.Itisthusveryimportanttochoosetherightdrivedesignbasedontheapplication.

2.2 Belts

BeltdrivesareoneoftheearliestpowertransmissionsystemsandwerepopularduringtheIndustrialRevolution.Atthetimeflatbeltswereusefulforconveyingpoweroverlargedistancesandweremadefromleather.However,due to thedemands formorepowerfulmachinery,and thegrowthof largemarketssuchas theautomobileindustry,newtypesofbeltsweredesigned.Inordertomeethigherstandardsofperformance,V-belts,withatrapezoidalor“V”shape,andmadefromrubber,neoprene,urethaneorsimilarsyntheticmaterials,replacedflatbelts.

• Thebelt’sinsidesurfacemustbemadefromamaterialthatensuresadherencetothepulleygroovethroughfrictionforceandreducesthebelttensionrequiredtotransmittorque.

• Thetoppartofthebelt,calledthetensionorinsulationsection,containsfibercordsforincreasedstrengthasit carries the loadof the traction force,whereas thebottom,or compressionsection,hasbeendesigned towithstandcompression.

(1) PROTECTIVE COVERGenerallya toughandelasticcovermade fromaspecial rubber-impregnated fabricthatisslip-resistantanddurable.Thisheatresistantlayerservestoprotectthebelt’sinnercomponents.(2) INSULATION SECTIONThissectionhelpsholdsthetensionmembersinplaceandactsasabinderforgreateradhesionbetweenthecordsandtheothersections.Inthismanner,heatbuild-upisreducedresultinginextendedbeltlife.(3) TENSION MEMBERSPre-stretched cords (polyester, aramide, steel, fiberglass,..) provide high tensilestrengthandminimizestretch.(4) COMPRESSION SECTIONMadefromatoughrubbercompoundthatexertsawedgingforceagainstthepulleygroovetoincreaseadherencewithoutdeformation.

Thetorqueobtaineddependsonthebelt’sresistancetotheappliedtensionandthedegreeofadherencetotheinnerwallsofthepulleygroove.Forthisreason,abeltdrivesystemshould never be lubricatedasitdependsonfrictiontotransmitpower,incontrasttochainorgearsystemsthatfunctionthroughpurecontactpressure.Theinsidefaceofthebeltshouldnevertouchthebottomofthegroove(Ref.SeeFig.2.4)

Fig. 2.3 V-Belt

27

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1V-BeltClassifications

All belt sizes are classified by cross-section and length dimensions. Thebeltidentificationnumberincludesaletter,indicatingthecross-section,followedbyup to3digits. Thecross-section indicates the topwidth,depthand“V”angledimensionsofVbelts.Industrialbeltsaremeasuredin terms of outside and inside (pitch) lengths (section 2.2.2.2). ThedifferenttypesofV-Beltsmentionedbelowareininches.Todeterminebelt nomenclature in metric, youmust refer to a belt manufacturer’scatalog.

Fig. 2.4: Sheave Cross-Section 2.2.1.1 Light duty & Fractional horsepower (F.H.P) V-Belts

ThistypeofV-beltwasdesignedforlight-dutyapplicationsoflessthan1hp,whichiswhytheyarereferredtoasF.H.P.or fractionalhorsepower. TheV-shape results in improvedperformance for conventional speedoperations inamore compact format, as compared to flat pulleys. Thesebeltsareusedonlywith small1-groovepulleysforsingle-beltpowertransmission.

Fig. 2.5: Light duty V-Belt Cross-sections

ForthistypeofV-belt,thecross-sectionisidentifiedbytheletter “L”precededbyupto5figures(1to5),whichwhendividedby8indicatesthetopwidth.Thisis trueforallbeltsexceptthe“5L”,ofwhichthewidthisnot5/8butrather21/32.Itisinterestingtonotethatthereisacorrespondingheightforeverytopwidth.Thenumberthatfollowstheletter“L”indicatestheoutsidelengthmultipliedby10.

Fig. 2.6: Light duty 3D Cross-sections

Example 2.1 Whatarethedimensionsofa4L990V-belt?Answer: 4/8=½-inchtopwidth,5/16-inchheightand99inchesoutsidelength

28

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1.2 Classical V-Belts

ClassicalV-beltsareusedasmuchinheavy-dutyaslightduty(A&B)applicationsbecauseofthelargeselectionofcross-sectionsavailable.Theyareavailableindifferentbelttypesandmaterials.AllclassicalV-beltswithidenticalcross-sectionswilloperate insheaveswithgrooves for thatparticularcross-section. Baldor•Maskaoffersacompleteselectionofclassicalsheaves.

1/2" 21/32"

13/32"5/16"

7/8"

17/32"

1 1/4"

3/4"

1 1/2"

1"

40o 40o 40o 40o 40o

A B C D E

Fig. 2.7: Classical V-Belt Cross-sections

ClassicalV-beltsareidentifiedby5letters:A, B, C, D, & E.Unlikemostbelts,thecross-sectionisidentifiedbyasingleletter,followedbytheapproximateinsidelength.

4Land5LV-beltsarerespectivelyinterchangeablewithtypeA&Bbelts,althoughtheBbeltisslightlyhigherthanthe5L.TypeAandBbeltsareavailableinalargervarietyofsizesthanthe4Land5L.Pleasenotehoweverthatdifferentbelttypesshouldnotbecombinedonthesamepulleywithseveralgrooves.

AllclassicalV-beltscanbeusedaloneorcoupledwithotheridenticalcross-sectionbeltstotransmituptohundredsofhpunits.

Example 2.2 WhatarethedimensionsofaB228V-belt?Answer: 21/32-inchtopwidth,13/32-inchthickand228inchesinsidelength.

29

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1.3 Deep Wedge / Groove or Narrow V-Belts

NarrowV-beltsare recommended fordrivesystems that requirecompactdesign,higherspeedand increasedhorsepower.Theyhaveamorepronounced“V”shapeandareusedinapplicationssimilartothoseofmultipleclassicalV-belts.Theyhaveagreaterhorsepowercapacitythanconventionalbeltsduetoincreasedsurfacecontactwiththepulleywall.

Fig. 2.8: Narrow V-Belt Cross-sections

3/8"

5/16"

5/8"

17/32"

1"

7/8"

3V 5V 8V

Threestandardcross-sectionscover theentire rangeofdrive requirements, as compared to five for classicalV-belts.Thisresultsinreducedinventoryforthistypeofbeltandpulley.3VbeltsareusedwithA&Bsheaves,5VdealswithB&Csheavesand8VcoversD&Ecross-sections.

Since greater horsepower capacity can be obtained, the drivesystem can be designed with shorter centers and smallersheaves. Overall drive dimensions can be reduced by asmuchas40%.Smaller,lightweightdrivesystemsreflectcostsavingsthroughreducedsizecomponentsorcantransmituptotwicethehorsepowerofclassicalsectionbeltswithinthesamespace.

Aswith light duty belts, the initial number, when divided by 8,indicates the topwidth. The last numbermultipliedby tenindicatestheoutsidecircumference.

Example 2.3 Whatisthebeltidentificationnumberofa140incheslengthnarrow V-beltwitha3/8inchwidth?

Answer: 3V1400

Fig 2.9: Narrow V-Belt (3D Cross-section) Fig. 2.9: Narrow V-Belt (3D Cross-section)

30

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1.4 Cogged / Raw-Edge V-Belts

CoggedV-beltsareofferedasafeatureonbothclassicalandnarrowconfigurations.Theletter“X”isaddedtothecross-sectionidentificationletter(ex.AX,BX,CX&3VX,5VX).

The notches that are cut in the underside render the beltmore flexible, resulting in increased surface contact.For this reason, cogged belts are especially useful for highperformance,highspeedapplicationsoperatingwithsmallersheaves. When subjected to difficult operating conditions,theuseofcoggedbeltsallowsforincreasedsurfacecontact,resultinginimprovedheatdistribution.

• Usedinheavytrucksandbusesbecauseoflongerservicelifeandreducedbendingstress.

• Increasedtorquecapacityeveninhigh-speedoperations.

• Lessslippage.

2.2.1.5 Banded Belts

BandedV-beltsareidentifiedbytheletter“R”placedbeforethecross-sectionidentificationletter.Thestandardcross-sectionidentificationfor classical bandedV-belts is: RB-RC-RD. The standard cross-section identification for narrow V-belts is: R3V-R5V-R8V. TheadvantagesofclassicalordeepwedgeV-beltsaremultipliedbythestrengthofseveralbeltsinone.

Advantages & Features:

• Recommendedforapplicationswithvertically-mountedshaftsorextendedcenter-to-centerdistances.

• Assureslateralrigidityandguidesthebeltsintothepulleywallsinastraightline.

• Designedforheavy-dutydriveswhereshockloadingisaproblemandwheremultiplematchedsinglebeltstendtorolloverorjumpoff.

Fig. 2.10: Narrow V-Belt (3D Cross-section)

31

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1.6 V-Ribbed / Poly-V Belts

V-ribbedbeltsareacombinationdesignofflatandV-shapedbelts.Youcanthusbenefitfromthebestofbothworlds–increasedV-beltpowertransmissioncoupledwiththeflexibilityofflatbeltsthatfunctionwellathigherspeeds.Themultipleribsprovidemuchmorestabilitythanaflatbelt.

ThebelttensionmustbealittlehigherthanwithclassicalV-belts,butperformsupto30%morepower.Thistypeofbeltisrecommendedwhendriveratiosareashighas40:1andrequiresmallpulleys.Somecross-sectionV-ribbedbeltsarecapableoftransmittingupto1,000hp.

Advantages & Features:

• ThemultipleV-ribbeddesignprovidesmoreeffectivesurfacecontactareathanconventionalV-belts.

• Theuseofsmaller,lessexpensivesheaveswithshortercenterdistances.

• Flexibilityallowsmulti-pulleydrives.

• Highspeedcapabilityinserpentinedriveswithlimitedspace

2.2.1.7 Double / Hexagonal V-Belts

DoubleV-beltsareusedonequipmentwherethedrivenshaftsrotateinadirectionoppositetothatofthedrivingshaft.Usuallythedriveranddrivenshaftsrotateinthesamedirection;anexampleofsuchanexceptionisthatofserpentinereversebenddrives,wherethis typeofV-beltisused.

ThedoubleV-beltdrivesfromboththetopandbottomsurface.Thecross-sectionsareidenticaltoclassicalV-beltsbutwith twodriving surfaces. StandarddoubleV-beltsare identifiedbyduplicate letters in thebelt codefollowedby theinsidelength.

Fig. 2.15: Doubled V-BeltDoublesidedV-beltsare generallyfoundinagriculturalandtextileapplications.

Fig 2.12: Poly-V Belt

Fig. 2.13: Serpentine Drive

Fig. 2.14: Doubled V-Belt cross sections

32

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.1.8 Variable-Speed Belts

Variable or adjustable V-belts are uniquely designed to transmit powerin applicationswhere there is a varying speed-ratio. This is the casewhenworkingwithadjustablepulleysthathavebeendesignedwithtwomoveableflangesthatcanbeadjustedinwidth.

Variable-speedbeltshavecross-wiserigidityandlengthstabilityforoptimumperformancebecauseoftheincreased

widthatthetopofthebeltinproportiontothethickness.Variablespeed beltsalsorequirelengthwiseflexibilitytobendaroundsmallsheaveswithoutexcessstrainthatcouldshortenbeltlife.

Advantages & Features:

• IndustrialapplicationsofvariablespeedV-beltsarepumps,fans,blowers,conveyors,&mixers.Consumerapplicationsincludemotorcycles,snowmobilesandgolfcarts.

• Thebeltadjustseasilywithinthepulleygroove,thusallowingforawiderangeofspeedratios.

2.2.2 Other Belt Types

2.2.2.1 Standard Flat belts

FlatbeltshavebeenreplacedbyV-beltsinmostindustrialapplicationsbecauseofimprovedresistanceandreducedsize.However,theflatbeltisstilloneofthebestsolutions forhighspeedapplicationsasgreatas15,000ft./min.Duetotheirheightandweight,V-beltsaresubjecttoincreasedcentrifugalforcewhereaslighterflatbelts,whosecenterofgravityisclosertothepulley’ssurface,maintainbettersurfacecontactathigh speeds.

Pulleysusedwithflatbeltsmusthavealargersurfaceareatotransmitthesameamountofpower.Infact,inordertoattaintheequivalentcoefficientoffriction,flatbeltsmustbeconsiderablylargerastheyaremuchthinner.(SeeFig.below)

Thesmallbendingcross-sectionoftheflatbeltcauseslittlebendingloss.Thisfact, togetherwitheven runningand theabsenceof pulleywedgeeffects,leads tohigherflatbeltefficiency.Themaximumefficiencyattainedbyflatbeltsis98%compareto96%forV-belts.

Advantages & Features:•Flatbeltsarecapableoftransmittingpoweroverlongdistances.

•Theyarestillusedbecauseoftheirflexibilityinserpentinedrivesandinapplicationswherebeltsmustbetwistedtoachievereverseshaftrotation.

•Increasedflexibilityresults inlessbendingloss.

Fig 2.16: Variable speed V-Belt Fig 2.16: Variable speed V-Belt

Fig 2.17: Standard flat Belt sections

Flat Belts

33

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.2.2 Standard / Trapezoidal Synchronous Belts

Usedprimarilywherethemotionof inputandoutputshaftsmustbepreciselymatched,synchronousbeltsarealsoknownastimingbeltsorpositive-belts.Transmissionisproducedthroughevenlyspacedteethontheinsidesurfaceofthebeltthatengagematinggroovesinapulley. There isnobeltslipandthespeedratio isconstantandprecise.Thoughvisually similar,thistypeofbeltisnottobeconfusedwithcoggedbelts.AswithV-belts, therearedual-sided timingbeltswith teethonbothsides forreversed-motionandserpentinedrives.

Thesebeltsarefoundinawidevarietyofprecisiondriveapplicationsincludingrobots,machinetoolsandplotters.High-volumeapplicationsincludedrivingandtimingoverheadcamshaftsinautomotiveengines.Speedsvaryfromafewinchesperminutetomorethan16,000FPMandloadcarryingcapacitycanvaryfromfractionaltohundredsofhorsepower.

240 / L / 075 Belt Pitch Length Tooth Pitch Belt width (24.0 inches) (3/8 inch) (0.75 inches)

• Smoothengagementofbeltwithpulleyallowshighspeedoperations.

• Idealwhereback-lash,noiseandmaintenanceofchaindriveswouldbeundesirable.

• Timingbeltsweighonlyafractionascomparedtoalternativemethodsforthesamehorsepowerrequirements.

• Thecleanoperationisidealforcontaminationsensitiveenvironments,suchasindustrialfoodprocessing.

Fig 2.18: Synchronous belt Fig 2.18: Synchronous belt

34

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Belt PitchesOnsynchronousbelts,pitchisthedistancebetweenthecenteroftwoadjacent

teethasmeasuredalong thepitch line. Thepulleypitch linemust bethe same as the belt pitch line in order to be synchronized. For thisreason, thepulley’spitch is thedistancebetweengroovecenters,andthepulleypitchcircleismeasuredmidwaybetweentheareasoftensionandcompressionofthebelt.

Thebeltpitchline(simplycalledpitchfornarrowv-belts)islocatedwithinthetensionmemberandcoincideswiththepitchcircleofthepulleymatingwithit.ThedistancebetweenthepitchlineandtheoutsideofthepulleyiscalledthePitchLineDifferential.Anychangeinbeltconstructionthataltersthepitchlinedifferentialrequiresacorrespondingchangeinthepulleydiameters.Timingbeltsmustberunwithpulleyswithanidenticalpitch.

Belts-inordertohandleawiderangeofloads,speedsandapplicationsathighestpossibleefficiencies-aremadein

fivestockpitches.Consequently,whendesigningbeltdrives,aswithgearorchaindrives,circularpitch(usuallyreferredtoaspitch)isafundamentalconsideration.

2.2.2.3 H.T.B. / Curvilinear Synchronous Belts

H.T.B.isanabbreviationforHighTorqueBeltsandfollowsthesamedrivedesignrulesasthetimingpulley.Theseroundedformbeltsallowforalltheadvantagesthatcomefromsynchronousrubberbeltsonapplicationsthatpreviouslycalledforrollerchainsandgeardrives.

Thestandard-trapezoidal tooth timingbeltpresentedaboveperformspoorly inhightorqueapplicationsandhighpowerdrivesatlowerspeeds.Toovercomethisdrawback,theHighTorqueBelt(HTB)wasdevelopedusingamoreefficienttoothprofile.

HTBtimingbeltsareclassifiedbytoothprofile,beltpitchlength,toothpitchandbeltwidthinmillimeters.

720 / 8M / 30 Belt Pitch Length Tooth Pitch Belt width (mm) (mm) (mm)

Among the advantages are :

*Highertorquetransmissionatlowerspeeds*Highpowertransmissionoverawidespeedchange*Improvedmeshingtoreducetoothjump*Higherresistancetotoothshear*Lesstoothwearduetofriction

Fig. 2.20: High torque belt

PitchDiameter

BeltPitchLine

SprocketPitchDiameter

OutsideDiameter

Fig 2.19: Synchronous Drive

35

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.3 Belt LengthThebeltlengthequalsthesumofthelengthofbothstraightsectionsandbothlengthsincontact

withthesheaves.

C

D2

D1

02

01

Fig 2.21: Diagram to calculate belt length

The variables of this system are:

D1:Datumdiameterofthedrivingpulley/sheave(in)D2:Datumdiameterofthedrivenpulley/sheave(in)C: Distancebetweensheaves’rotaryaxis(centerdistance,in)θ1etθ2:Arcofcontactbetweenthebeltand,respectively,thedrivingandthedrivensheaves(degreeor

radius(ifindicated))

36

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.3.1 Parallel axis, uncrossed belt drive

Thisisthemostcommonbeltsystemset-upintheindustry.Theinstallationmethodisillustratedbelow.(Fig.2.21)

Thearcofcontactforthesmallersheaveis:

θ1 = 2 cos-1 D2 - D1

2C

or

θ1 ≈ 180 - 60·(D2 -D1 ) C

Thearcofcontactforthelargersheaveis:

θ2 = 360 - 2 cos-1 D2 - D1

2C

or

θ2 ≈ 180 + 60·(D2 -D1 ) C

Therefore,theformulatocalculatethetotallengthis(anglesareinradians):

L=√4C 2 - (D2 -D1 )

2 + 1 (D2 θ2 -D1 θ1 )

2

Toacceleratethecalculation,thefollowingformulacanalsobeused:

L≈2C + π (D2+D1 ) + (D2 -D1 )2

2 4·C

or

L≈2C + 1.57(D2+D1 )+ (D2 -D1 )2

4·C

Theaboveformulaappliestounequalpulleys(differentdiameters);theformulatocalculatethebeltlengthforequalpulleys(samediameters)is:

L≈2C + D·π or L≈2C + D·3.1416

37

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.2.3.2 Arc of contactThearcofcontact(θ1etθ2Fig.2.21)determinestoagreatextentabelt-drivesystem’scapacitytotransmitpower.

Forefficientoperation,theminimumbeltwrap,orarcofcontact,ofthesmallestpulleyshouldbe120o.Themaximumarcofcontactthatcanbeobtainedis180o.Thisisachievedwhenthetwopulleysareofequaldiameter.

Theformulasusedinsections2.2.3.1.illustratethatthearcofcontactincreaseswiththecentertocenterdistance.Theminimumarcofcontactnecessaryinapowertransmissionsystemthushasadirectinfluenceonthedesignofthecentertocenterdistanceofthepulleys.

38

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.3 Drive Components Materials

BeforeconsideringtheremainingprincipalcomponentsofaV-beltdrivesystem,suchasbushingsandsheaves,wewilldiscusstheimportanceofselectingthepropermaterialwhendesigningthepart.

Oneofthemostcommonferrousmetalsusediscastiron.Thisisacost-efficientmaterialthatadaptswelltothemoldingprocess,andisrecommendedevenforcomplexparts.ThefollowingisadescriptionofthemechanicalandphysicalpropertiesofthetwomaintypesofcastironthatBaldor•Maskaworkswith.

2.3.1 Gray/Cast Iron

Thepropertythatdifferentiatesgraycastironfromplaincarbonsteelisthepresenceofpuregraphiteintheformofflakes.Duringthemoldingprocess,althoughmostofthecarbonmixeswithiron,theremainingelementsformgraphite.Thepresenceofgraphitecontributestograycast iron’s high vibration absorption andwear resistance.On the other hand, the graphiteflakescreateweaknessplaneswhichresultinslightlyreducedtensilestrength.Grayironalsohasgreatercorrosion resistanceundermostconditionscompared toplainsteel. For thosereason,coupledwithawiderangeofcastingproperties,machineframesandengineblocksaremanufacturedfromthismaterial.

ThemajorityofBaldor•Maskapulleysusedinstandardapplicationsaremanufacturedfromgraycastiron;howevertheyarenotrecommendedforoperationsthatareatriskofexperiencingexcessiveshockloadsorhighspeed.Forthisreason,certainitemsaremadefromductileironforimprovedstrength.

2.3.2 Ductile Iron

Ductile iron has greater resilience and ductility, as it’s name denotes, than gray cast iron.Graphite is present in a nodular (small, round lumps) rather than flaky form. Corrosionresistanceiscomparabletothatofgray.

This stronger material is recommended for operations that could experience occasionaljolting.Comparedtogray,ductileironcannotbemachinedaseasily.Italsohaslessvibrationabsorbency. However, themechanical properties are similar to steel and it is used in theproductionofgears,crankshafts,wheelhubs,etc.

Inaddition,otheradvantagesofductileironascomparedtogray,isthatitallowsforareductioninsizeandweightofthepart,andhasaddedresistancetoimpactfailure.Baldor•MaskaisoneoftheonlycompaniesthatoffersabroadrangeofQDBushingsinductileiron.

Fig 2.22: Cast iron

Fig 2.23: Ductile iron

39

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.3.3 Sintered Metal

Sinteredmetalprocessinghasbecomeverypopularinthelast20years.Easilyadaptedtomassproduction,thisprocesshasbeenusedintheautomobileindustryandcanproducecomplexpartswithhightolerancesandverylittlewasteduringmolding.Inaddition,theferrousalloysavailablehaveexcellentmechanicalpropertiesatacompetitiveprice,duetoeconomicalprocessingmethods.

Whereascastedmetalsmustbebrought to themeltingpoint, this rawmaterial isapre-determinedmixtureofdifferentalloysinafine,granularform(powder)ofwhichsmallamountsundergohighpressurecompactingfrompressesequippedwithasetofmatrixesandpunchesthatdeterminetheshape.Atthisstage,thepartusuallyhastherequiredshape,butnotthemechanicalresistancerequired.

Inordertoacquirethenecessaryresiliencefoundincastedmetal,theparticlesneedtobebindedtogether.Thisisdonebyheating thepartsoveraspecificperiodof timecalledsintering,at temperatures justunder themeltingpoint.Thecontrolledtemperaturegeneratesmetallurgicalbinderswithinthepartwithoutalteringtheshapeduetoexcessiveheat.Uponcomingoutofthefurnace,thepartisafinishedproduct,unlessspecialmachiningortreatmentsareneeded.

Auniqueadvantageofthissinteringprocessisthepossibilityofadjustingthebasicpowder“recipe”to includespecial additives that can either increase corrosive resistance, improved machinability or increased partdensity.Althoughsinteredmetalhasdifferentmechanicalpropertiesthanthatofcastedmetal,theresultsarenonethelessverycompetitive.Baldor•Maskawasoneofthefirstcompaniestomarketandtakeadvantageofsinteredmetalprocessingforcertainproductlines.

2.3.4 Table of Mechanical Properties

MATERIAL GRADETENSILE

STRENGTHMIN. ( PSI )

YIELD STRENGTHMIN. ( PSI )

ELONGATION ( PERCENT )

MODULUSOF ELASTICITY

( X 106 PSI)Grey cast iron 30 30,000 30,000 <1.0 13-16.4Ductile iron 65-45-12 65,000 45,000 12 24Sintered Metal FC-0205-40 40,000 40,000 <1.1 17.5

40

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.4 Bushings

Allpowertransmissioncomponentsmusteitherbeattachedorconnectedtoashaft.Abushingistheintermediaryelementusedtomountorattachasheave/pulleytoashaft.Inbelttransmissiondrivesystems,thebushingisinstalledinthehubofthepulleyandissecuredwithscrews,thusexertingapressureonthehub.Thispressureiscreatedbyatapergeometryprinciplethatcanalsobeobservedwhenamaleconicalobjectisinsertedintothematingsurfaceofthecorrespondingfemalepart.Thebushinghasathinslitdownthesidethatenablesittobecompressedevenlyaroundtheshaftduringinstallation,whichresultsfromtheaxialforceappliedwhenfittingthebushingintothesheavehub.Mosttaperedbushingscompensatefornormalvariationsinshaftandcomponentdimensionaltolerances.

Bushingsareavailable inanumberofdifferentboresizes forvariousshaftdimensionsandsafelypermitpowertransmissionasthego-betweentheshaftandthesheave.Theygreatlyreducethenumberofstandardsheavesrequiredorhavingtomachinethepartforeverydifferentshaftsize.(Fig.2.1)

2.4.1 QD (Quick Detachable) Interchangeable Bushings

QDbushingshavea straight borewitha taperedbarrel on theouter surface thatmatchesthepulleyhub.QDbushingshaveafullsplitthroughtheflangeandbarreltopermitatightclampingactionontheshaft.Theyareeasytoinstall,eliminatefrettingcorrosionbetweentheboreandtheshaftandareanexcellentchoiceforV-beltdrivesystems.

Capscrewsareusedtotightenandsecurethebushingontotheshaft.Toassemble,thebushingandsheaveareslippedovertheshaft.Whenthetaperedsurfacesfirstmeet,thefitbetweenthebushingboreandtheshaftisrelativelyloose.Whenthecapscrewsaretightened,thesplitclosespartiallyandthebushinggripstheshafttightly.

Baldor•MaskaoffersaninterchangeableQDBUSHING(QDisaregisteredtrademarkandmanufacturedunderlicense).

• PrecisionmachiningofthetaperedboreinthehuboftheQDsheaveandthetaperedmatingsurfaceofthebushinginsureasnugandprecisionfitbetweenthesheaveandthebushing.

• Thesplitisfull(notpartial).Asthecapscrewsaretightened,atremendouspressureisgenerated,withagripequivalenttothatofapressfit,ontheshaft.

• Bushingsshouldnotbere-boredastheconcentricity(perfectcenter)willbelost.However,thismaybepossibleforapplicationswithaverylowRPM,.

• ItisveryIMPORTANTnottouseanytypeoflubricantonanysurfaceofthebushingormatinghub.

2.24: QD Bushing

41

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Baldor•Maska,andallotherM.P.T.A.members,manufacture“QD”bushingsconformtostandardiseddimensionsinordertoassuretotalinterchangeability.

Illustration of QD Bushing SD - 1 ¾ Bushing“SD” StockBore1¾ Keyseat3/8x1/8**

SK - 40

Bushing“SK” StockBore40(metricsystem) Keyseat12x8

Insomecases,astheboreincreasesindiameter,ashallowkeyseatisprovidedduetoinsufficientmetalthickness.Thisdoesnotaffect thebushing’sability to transmit the load.Therectangularkey,onflatkeyas it isalsoreferredto,fitsintothestandardkeywayintheshaft.

SK 1-3/4 Bushing“SK” StockBore1-3/4 Keyseat3/8X3/16

**Shallow Keyseat.

Bushing “L”

(“H” - Cross Reference)

Bushing “JA to J” Inclusive

Bushing “M to W” Inclusive

Bushing “S” Taper 3/4" per FT on Diameter - B -

42

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Standard Keyseat Shallow Keyseat

Fig. 2.26: Keyseat

Types of Keyseat

Note:Themetricsystemdoesnot refer tokeyseatorkeywaydimensions,asdoes the Imperialsystem; instead,dimensionsaregivenforthekeyitself,whichisrectangularinshape.ThismeetsISOstandards.

Formoreexplanationsaboutbushingmountingandproperwrenchtorque,pleaseconsulttheInstallation&MaintenanceChapter.

Important

English System: Square key -

rectangular keyway

Metric System: Rectangular key -

square keyway

Baldor•Maskaoffers threedifferent typesof bushings. Thedifference is basedon the shaft diameter and thenumberofholesintheflange.BushingsLtoJhavethesamenumberofholesandtappedholes.Asthenumberofholesincreases,theadmissibletorqueonthesheaveincreases.OnlybushingsMtoShavetappedholestosecuremounting.

43

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.4.2 Taper-Lock / Bore Bushings

Withmorethanamillionpresentlyinoperation,andinitiallylimitedtoEurope,manycompaniesworld-widenowconsider“TaperLock”bushingsasstandardmounting components in the PT industry. This type of bushing does nothaveaflange,resultinginacompact,neatdesignthatispreferredincertainapplications.

They are not interchangeable with QD type bushings as the taper has adifferentangleandtappedholesinthehubarenotinthesameposition(asplitholeontheinsideoftheTaperlockhubvs.completeholesinthesideoftheQDhub).Theyareinstalledontotheshaftwithsetscrewsinsteadofstandardbolts,aswithQDBushings.

Taper Lock Installation

1. LineupthesmoothholesoftheTaperLockbushingwiththethreethreadedholesinthesheavehub.2. Threadthecapscrewsintothesheavehub.Note:Thethreadedholesinthebushingareusedtoremovethe

bushing.

Asthecapscrewsaretightened,thebushinguniformlysupportsthehubalongtheentirecircumference.

* Frequentlymatchedwithsprockets,gearsandtimingbelts;notnecessaryinV-Beltdrives(“over-design”)

* Suitablewhenexcessivetorqueisapplied(H.T.D.).Shearforces,thatactonthescrewswhensubmittedtoaexcessivetorque,dosooveralargersurfacearea(diameterXlength)insteadofactingonthescrewssectionarea,asisthecasewithQDbushings.

2.4.3 Split Taper Bushings

AscomparedtoQDstyle,Splittaperbushingsweredesignedwithtwodifferentfeatures.First,thereisakeywayonbothsidesofthebarrel;theadditionalkeythatfitsintothehubbearsthepressureofshearingforceswhentorqueisappliedtothepulley,ratherthanactingonthesetscrewsaswithQDstylebushings.Secondly,theSplittaperbushing,asit’snamerefers,issplitonlythroughthebarrelortaper,andnotthroughtheflange.

Splittaperbushingsareavailablewithasimpleordoublesplitbarrel.Shafttolerancesonapplicationshavetobe tighter with this type of bushing, as comparedtoQDbushings,whichhavegreaterflexibilityandmoreuniformclampingforce.

Fig. 2.27: Taper-Lock

Fig. 2.28: Split Taper-Lock

44

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5 Sheaves

AsheaveisdefinedasaV-groovedwheelusedtotransmitpowerormotioninconjunctionwithaV-belt.Sometermsassociatedwithsheavesareexplainedandillustratedbelow.

Groove Shapedportionofasheave;width,depthandanglearedeterminedbythebeltsection used.Groovesaremachinedtomeetstandardtolerances.

Face Width Distancemeasuredacrossgrooves-definedas«F»dimensionintheBaldor•Maskacatalog.

Outside DiameterDimensionmeasuredaroundtheoutersheavediameter- definedasO.D.intheBaldor•Maskacatalog.

Pitch Diameter Dimensionmeasuredaroundthesheavewherethebeltpitch linemeetsthesheavegroovewall-definedasP.D.inthe Baldor•Maskacatalog.(seeFig.2.29)

Datum System

AnewstandardforclassicalV-beltsandsheaveshasbeenrecentlyestablishedwhereinthetitle“DatumSystem”replacedthedesignation“PitchSystem”,and“PitchDiameter”became“DatumDiameter”.Withreferencetoclassicalsheaves,thenew“PitchDiameter”valueequalsthesheave’soutsidediameterseeingasthetopofthebeltarrivesatthesameheight.Theonlyexceptionisthatofan“A”beltfittedwitha“B”sheave,asthetopofthebeltisbelowtheO.D.The“DatumSystem”isacompromisethattheMPTAchoseasthemostaccurateapproximatevalueofthe“PitchLine”thatservesasthestandardforallbeltmanufacturers,soastocompensatefortheslightdifferencesbetweenthedifferentcompanies.

F

O.D.P.D.

Fig. 2.29: Sheave nomenclature

45

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.1 Sheave Body

Thestructureofthesheavebodydifferswithsize.Largersheavesdonotneedtobesolidorfullinordertomeetthemechanical requirements. Forexample,a30-inchsolid sheavewouldbeveryheavyandexpensive.Baldor•Maskaengineersdeterminetheamountofmaterialnecessaryintheconstructionofeachpartforhigh-qualityperformanceandsecuritythatmeetsindustrystandards.

Sheavescomeinseveralforms,beingeithersolid,webbedorarmdesign,dependingontheoutsidediameter.The typeof design is indicated in theBaldor•Maskacatalog in the column “T” (type). TheBaldor•Maskanomenclatureorlistingforthethreeclassificationsisasfollows:

TYPE B - Block Diameter ~ 0" to 6"

TYPE W - WebDiameter ~ 6" to 14"

TYPE A – ArmDiameter ~ Over 14"

Fig. 2.30: Sheave body

46

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.2SheaveClassifications&Terminology:

Sheavesmustbedesignedtoworkefficientlywithbeltssoastodeliver thenecessarypower. Oneof themostimportantfactorsisthedesignofthegroove,asthisisthebeltcontactzone.Standardidentificationclassificationforpulleysincludethebeltcross-section,numberofgrooves,anddiameter.AllBaldor•Maskasheavescanbegroupedintothreefamily-types.

2.5.2.1 Light Duty Fixed & Bush Types

Typicalapplicationsforthistypeofsheavesarepumps,mixers,compressors,conveyors,fansandblowersdrivenbymotorsupto10HP.Baldor•Maskadoesnotmanufactureordistributepulleysfor2Lbeltsastheydonotneedtobemadefromcastiron.

PartClassificationNumber:

MA80X1/2 1groovefixedbore MBL77 1groovebushtype(3L)&A(4L)V-belts A(4L)&B(5L)V-beltsO.D.=8.0in Lbushing½Boresize O.D.=7.7in.

2MA80X1/2 2groovesfixedbore 2MBL77 2groovesbushtypeA(4L)V-belts A(4L)&B(5L)V-beltsO.D.=8.0in Lbushing½Boresize O.D.=7.7in.

47

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.2.2 Adjustable/ F.H.P & Integral

Adjustable sheaves offer the flexibility of adapting to varying driving shaftspeedsthroughexpansionofthepulleywalls.Inthisway,thebeltpitchusedvariesdependingontheadjustedwidthofthesheave,resultinginthepossibilityofdifferentspeedratios.

Adjustablespeedsheaveshaveoneortwogrooveswithflangesthatcanbeadjustedinwidth,sothebeltmovesinaradialmovementwithinthegroove(seeillustrationbelow).Theprincipleoftheadjustablepitchsheaveisthatone of the discs forming theV-shaped groove (inwhich the belt rides)ismovable.When thedisc ismovedcloser, thebelt rideshigher in thegrooveandthepitchdiameterofthesheaveislarger.Whenthediscismovedapart,thebeltrideslowerandthepitchdiameterbecomessmaller,therebyproducingaspeedandratiochange.

Fig. 2.32: Ratio variation – Close and Open

Important

Baldor•Maskaadjustablespeedsheavesareusedonlyforstaticpitchdrivedesign.

• AdjustableLightDuty(H.V.A.C.)MVL

Thisadjustablesheaveismadetoaccommodate“3L”,“4L”,or“5L”belts.

MVLadjustablelightdutysheavesaredesignedtobeusedwithF.H.P.(fractionalHP)motors.

Fig. 2.31: Adjustable sheave

48

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

•AdjustablePitchV-BeltSheaves(8000series)

Baldor•MaskavariablepitchV-beltsheavesareprecisionmachinedcast toprovidemaximumstrength,andalsoensuresmoothandquietoperation.Groovesareaccuratelymachinedandsmoothlyfinishedtoprovideproperbeltseating.Theyareusedwith“4L”or“A”and“5L”or“B”V-belts.

Thedatumdiameterof thesheave isadjustedby loosening thesetscrews in the

hubsandturningthethreadedflangeto thedesiredsetting, thenre-tighteningthesetscrews.

Bothsingleanddoublegrooveadjustablesheavespermitvariationsofasmuchas30%inspeed.

Bothsingleanddoublegroovesofthe8000seriesaresuitablefordrivesupto25hp.

•AdjustablePitchV-BeltSheaves(MVS)

TheMVSsheaveoffersseveralsignificantadvantages.Thissheaveisavailablein6sizesandisdesignedfor“A”-”B”or“5V”belts.Capacitiesrangeupto40hpat1,750rpm.

Thespeedisinfinitelyvariable,andasonlyonescrewcontrolsbothmovableflanges,accurategroovespacingisassuredatalltimes.Nolubricationisneeded.

Adjustable Pitch V-Belt Sheaves

Fig. 2.33: 2 groove 8000 series

O.D.

H

E F E

L

INBO

ARD

OU

TBO

ARD

Fig. 2.34: MVS series

49

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Step pulleys (MAS)

- Combinationof3stepsupto5(equalnumberofpossiblespeedratios)

- DesignedforA,4L&3LV-Belts.- From2to6inchdiameters.- Commonlyusedforvaryingspeedswithdrillpresses&wood

lathes.

Fig. 2.35: Step pulleys

50

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.2.3 Classical & Narrow Belt Drives

Classical(conventional)V-Beltsareavailableindifferenttypesanddesigns.AllclassicalV-beltswiththesamecross-sectionwilloperateinsheaveswithgroovesforthatparticularcross-section.Baldor•Maskaoffersacompleteselectionofclassicalsheaves.ThisfamilyincludessheavesforclassicalV-beltsandnarrowV-belts.Inaddition,A/BCombination(codeB)sheavescanbeusedwitheither“A”(4L)or“B”(5L)V-belts.

Part Designation number:

2B64-SDS 2grooves 1-3V8.00-SDS 1grooveA(4L)&B(5L)V-belt 3V-beltP.D.=6.4in O.D.=8.0inBushingsizeSDS (P.D.=7.95in)

BushingsizeSDS

1C110-SF 1groove 3-5V4.40-SDS 3grooves“C”V-belt 5V-beltP.D.=11in O.D.=4.4inBushingsizeSF (P.D.=4.30in)

BushingsizeSDS

4D150-F 4grooves 4-8V44.5-M 4grooves“D”V-belt 8V-beltP.D.=15in O.D. =44.5inBushingsizeF (P.D.=44.3in)

BushingsizeM

ImportantDuetothemechanicalpropertiesofgreyandductilecastiron,partsmadefromgrayironcanoperateuptomaximum

rimspeedsof6,500feetperminute.SpeedsinexcessofthisrateMUSTusepartsmadefromductileiron,whichhasamaximumsafeoperatingspeedof9,500feetperminute.

51

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.2.4 Application Table by Classes

TableshowingallsheavefamiliesmanufacturedbyBaldor•Maskawithalimitedlistofindustrialapplications.

FAMILY SHEAVES APPLICATIONS

Light Duty Fixed & Bush Types

MFAL

Fans,Blowers,H.V.A.C.,WoodProcessingEquipment,Pumps,Conveyors,PrintingMachines,MachineTools,MixersandCom-pressors

Upto3hp

MA-MB-MAL-MBL

Fans,Blowers,H.V.A.C.,WoodProcessingEquipment,Pumps,Conveyors,PrintingMachines,MachineTools,MixersandCom-pressors

Upto10hp

Adjustable/ F.H.P & Integral

MVL

Fans,Pumps,Conveyors,Ma-chineTools,MixersandCompres-sors

Upto2hp

8000

Fans,Pumps,Conveyors,Ma-chineTools,MixersandCompres-sors

Upto25hp

MVS

WoodProcessingEquipment.,AirMovingEquipment,ConveyorsSystems,BottlingPlant

Upto40hp

Classical & NarrowV-Belt Drives A/B-C-D-3V-5V-8V

PulpandPaperMillsEquipment,SawMillEquipment,MiningEquip-ment,Crushers,Pumps,Compres-sorsScreens,Extruders

Upto500HP

52

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

2.5.3 Balancing Standards (MPTA)

2.5.3.1 General Information

When a unit turns in a circular path, a hypothetical inertia force known ascentrifugal forceexertsapulling influenceon theelementaway from thecenterduringtherotationalmovement.Thiscanbeillustratedbytyinganobjecttooneendofaropeandtheotherendtoarotatingaxisofthecenterofthepart.Asthespeedincreases,theobject is liftedintotheairuntil itattainsahorizontalposition.

Inpowertransmissionsystems,ifthemassofarotatingbodyisunevenlydistributedaroundtherotationaxis,thecentrifugal forceswillbeunbalanced. Thiscausesvibration,noiseand reducedcomponentsservice life. Asecondaryoperationcalledbalancingiscarriedouttominimizetheseeffectsbyalteringthecenterofgravitytocorrespondwiththeaxisofrotationofthecenterofthepartsoastobeevenlydistributed.

Every rotating component is eventually unbalanced to somedegree; partsmanufacturedwith absolute balancewouldbeacostlyprocessfortheconsumer.Forthisreason,itmustbedeterminedtowhatdegreeasheavemustbebalancedfortheindustrialapplicationinquestion.WewillnowconsiderthetwotypesofbalancinginuseintheindustryandapprovedbyMPTA:single-planeanddouble-planeoperations.

2.5.3.2 Static or Single-Plane Balancing

Single-planebalancing isabasicsecondaryoperationandcommonlyusedmethod that is recommended forallproducts. Aone-planeabsolutebalancedsystemcanbe illustratedbyauniformdiskwith thecentermassperfectlyalignedwiththeshaftaxis.

Fig. 2.37: Balanced Force on shaft

Balanced Forceon Shaft Axis of rotation

(Shaft)

Center of gravityconcentric with the axis of rotation

M

Fig 2.36: Centrifugal force

53

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

However,shouldthediskhaveaholeatacertaindistancefromthecenter,thesystemwouldbeunbalanced.Toillustrate,ifarodwithanironballwasattachedtoonesideofashaft,theballcouldbecomparedtoexcessweightononesideofthedisk.

Fig. 2.38: Unbalanced Force on shaft

Unbalanced Forceon Shaft

Unbalanced Equivalent Mass

Axis of rotation(Shaft)

Hole in Disk Shifts Center of Gravity to the Opposite Side

Astherotationalspeedincreases,thecentrifugalforcecausestheshafttofeelthepullofthenon-balanceddisk.Inordertooffsetthesituation,acounterweightmustbeaddeddirectlyoppositetotheextramass.Inthiscase,anidenticalamountofmassmustbeeliminatedbyboringanotherholeoppositethefirstone.

Fig. 2.39: Balanced Force on shaft

Unbalanced Forceon Shaft

Unbalanced Equivalent Mass

Balanced Mass

Axis of rotation(Shaft)

Hole in Disk Shifts Center of Gravity to the Opposite Side

Drilled Hole for Balanced

Themethodfordeterminingwheretheholeshouldbeboredinordertobalancethepartorsheaveconsistsofplacingitonanhorizontalshaftsuspendedfromtwocarefullylevelledverticalsupports,asillustratedinFigure40.Ifthesheaveisnotbalanced,theshaftwillturnuntiltheheaviersideisonthebottom.Ahole(orholes)is(are)boreduntilthesheaveisinstaticbalance,orremainsmobileregardlessofwhatpositionitisplacedin.

A A

Fig. 2.40: Balancing – Vertical position

54

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

A second method thatisalsousedtobalanceasheaveconsistsofmountingthesheavehorizontallyonaverticalarborplacedontableB,whichissupportedbyaknife-edgebearing.ApendulumCissuspendedfromtableB.Totestthestaticbalanceofthesheave,itiscounter-balanceduntiltheindicatorisstableinthecenterofthestationaryscaleD.Thereareseveralotherdevicesfortestingstaticbalancethataresimilarindesigntothesestandardprinciples.

Thenomographbelowshowsthemaximumspeedlimit(inRPM)forstandard statically balanced sheaves of a given diameter andfacewidth.

To use the nomograph, lay a straightedge ruler between thediameterandfacewidthreadingsandtakethemaximumRPMrecommended for standard balance where the ruler edgecrossestheslantedline.IftheRPMoftheapplicationexceedsthe maximum recommended, two-plane balancing should becarriedout.

64

60

55

50

45

40

35

30

28

26

24

22

20

18

16

14

12

109

8

7

6

5

4 1.5

2

2.5

3

3.5

4

4.5

5

6

7

8910

12

1416182024283236

MAX RPM RECOMMENDEDFOR STANDARD BALANCE

FACE

WID

TH IN

INCH

ES

50004600

44004200

3800

3400

30002800

26002400

2200

2000

1800

1600

1400

12001100

1000

900

800700

600

500

640

725

860

960

1460

1750

2900

3500

1160

Fig. 2.42: Nomograph-Max RPM for one-plane balancing

B

C

D

Fig 2.41: Balancing – Horizontal position

55

Driv

es: B

elts

, B

ushi

ngs

& S

heav

es

Todeterminewhetherdynamicbalancingisrecommended,thefollowingformulacanalsobeused:

RPM = 15500 √D • F

DistheDiameterininchesFisFaceWidthininches

TheresultantRPMisthemaximumrecommendedoperatingRPMforsheaveswithasingleplanebalance.

Example 2.4 Ifa20in.x10in.diameterfacewidthsheaverunsfasterthan1,100rpm, dynamicbalancingisrecommended.Theresultobtainedwiththe formulais1,096rpm.

2.5.3.3 Dynamic or Two-Plane Balancing

Asheavemayhaveundergonesingle-planebalancingandyetnotbesufficientlybalancedforcertainoperations,suchaswhenthesheaverotatesathighspeedsandhasarelativelylargefacewidth.Undertheseconditionsadifferenttypeofbalancingisnecessary.