PSAF

-

Upload

francisco-bone-tenorio -

Category

Documents

-

view

33 -

download

8

Transcript of PSAF

May 2006

PSAF for Windows User’s Guide and Reference Manual

Copyright CYME International T&D Inc.

All Rights Reserved

This publication, or parts thereof, may not be reproduced in any form, by any method, for any purpose. CYME International T&D makes no warranty, either expressed or implied, including but not limited to any implied warranties of merchantability or fitness for a particular purpose, regarding these materials and makes such materials available solely on an "as-is" basis. In no event shall CYME International T&D be liable to anyone for special, collateral, incidental, or consequential damages in connection with or arising out of purchase or use of these materials. The sole and exclusive liability to CYME International T&D, regardless of the form of action, shall not exceed the purchase price of the materials described herein. CYME International T&D reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product at all times in the future. The software described in this document is furnished under a license agreement. CYME International T&D Inc. 67 South Bedford Street, Suite 201 East Burlington, MA 01803-5177 1-800-361-3627 (781) 229-0269 FAX: (781) 229-2336 International and Canada: 1485 Roberval, Suite 104 St. Bruno QC J3V 3P8 Canada (450) 461-3655 Fax: (450) 461-0966

Internet : http://www.cyme.com E-mail : [email protected]

Windows 98 and Windows NT, 2000 & XP are registered trademarks of Microsoft. Autocad is a trademark of Autodesk Inc.

PSAF Basics & Editing – Users Guide and Reference Manual

TABLE OF CONTENTS 5

Table of Contents

Chapter 1 Getting Started.........................................................................................................1 1.1 Introduction ................................................................................................................1

1.1.1 About this Manual .........................................................................................1 1.1.2 The PSAF Users’ and Reference Manuals ..................................................1

1.2 Computer System Requirements ..............................................................................2 1.3 Installing PSAF for Windows .....................................................................................2 1.4 Running PSAF for Windows ......................................................................................3

1.4.1 PSAF Files....................................................................................................3 1.5 PSAF GUI ..................................................................................................................4

1.5.1 Network Window...........................................................................................4 1.5.2 Project View Sidebar ....................................................................................4 1.5.3 Detailed View Sidebar ..................................................................................5 1.5.4 Moving the Toolbars and Sidebars...............................................................7 1.5.5 Mouse Commands........................................................................................7

1.6 Using PSAF .............................................................................................................11 1.6.1 Using the Project view ................................................................................11 1.6.2 Creating a new project................................................................................11 1.6.3 Creating a network......................................................................................13 1.6.4 Building a network ......................................................................................15 1.6.5 How to Print the One Line Diagram............................................................16

Chapter 2 Menus and Toolbars..............................................................................................19 2.1 File Menu .................................................................................................................19

2.1.1 Import Wizard .............................................................................................21 2.1.2 Export Wizard .............................................................................................28 2.1.3 Preferences Settings ..................................................................................33

2.2 Edit Menu.................................................................................................................42 2.3 Network Menu..........................................................................................................44 2.4 View Menu ...............................................................................................................45 2.5 Database Menu .......................................................................................................47 2.6 Analysis Menu .........................................................................................................48 2.7 Report Menu ............................................................................................................49 2.8 Tools Menu ..............................................................................................................53 2.9 Windows Menu ........................................................................................................57 2.10 Help Menu................................................................................................................58 2.11 Toolbars ...................................................................................................................58

2.11.1 Standard Toolbar ........................................................................................58 2.11.2 Editing Toolbar............................................................................................59 2.11.3 Study Toolbar .............................................................................................60 2.11.4 O.L.D. Editing Toolbar ................................................................................61 2.11.5 Other Toolbars............................................................................................63

Chapter 3 Network Equipment Data ......................................................................................65 3.1 Overview of Dialog Boxes........................................................................................65

3.1.1 Database Dialog Boxes ..............................................................................65 3.1.2 Equipment Dialog Boxes ............................................................................66

3.2 Bus 69 3.3 Bus Tie.....................................................................................................................71 3.4 Bus Way...................................................................................................................72

3.4.1 Bus Way in the Network .............................................................................73 3.5 Cable........................................................................................................................74

3.5.1 Cables in the Network ................................................................................77 3.6 Series Compensation ..............................................................................................78

PSAF Basics & Editing – Users Guide and Reference Manual

6 TABLE OF CONTENTS

3.7 Generator, Synchronous .........................................................................................79 3.7.1 Generators in the Network..........................................................................80

3.8 Generator, Induction (IG).........................................................................................82 3.8.1 Induction Generator in network ..................................................................84

3.9 HVDC Line...............................................................................................................85 3.9.1 How HVDC Lines operate in CYMFLOWHow............................................86 3.9.2 HVDC Lines in the Network........................................................................86

3.10 Line ..........................................................................................................................89 3.10.1 Lines in the Network ...................................................................................92

3.11 Loads, Non-rotating .................................................................................................93 3.11.1 Loads in the Network..................................................................................94

3.12 Motor, Induction .......................................................................................................96 3.12.1 Induction Motors in the Network .................................................................98

3.13 Motor, Synchronous...............................................................................................101 3.13.1 Synchronous Motors in the Network ........................................................102

3.14 Network Protector ..................................................................................................103 3.15 Reactor, Series ......................................................................................................105

3.15.1 Series Reactors in the Network ................................................................106 3.16 SVC (Static Var Compensator)..............................................................................107

3.16.1 SVC’s in the Network................................................................................108 3.17 Switch ....................................................................................................................109 3.18 Switchable Shunt ...................................................................................................110 3.19 Transformer, Fixed-tap ..........................................................................................111

3.19.1 Zig Zag Winding for Transformers............................................................115 3.19.2 Fixed-Tap Transformers in the Network...................................................116

3.20 Inrush current model..............................................................................................117 3.20.1 Inrush current data....................................................................................118 3.20.2 Activation of the inrush current effect in the network................................119

3.21 Transformer, Phase-shifting ..................................................................................120 3.21.1 Phase Shifting Transformers in the Network............................................121

3.22 Transformer, Reactive power regulating ...............................................................122 3.22.1 Reactive Power Regulating Transformers in the Network .......................123

3.23 Transformer, Three-winding ..................................................................................123 3.23.1 Three-Winding Transformers in the Network ...........................................125

3.24 Transformer, Voltage-regulating (TCUL)...............................................................126 3.24.1 Voltage Regulating Transformers in the Network.....................................127

3.25 Utility Connection...................................................................................................128 3.26 Mutual Coupling between Lines or Cables in the Network....................................129 3.27 Grounding Transformer .........................................................................................130

3.27.1 Grounding Transformer in the Network ....................................................131 3.28 WECS-IG ...............................................................................................................132

3.28.1 WECS-IG in the Network..........................................................................133 3.29 WECS HVDC.........................................................................................................134

3.29.1 WECS HVDC in the Network....................................................................135 3.30 WECS DFIG...........................................................................................................136

3.30.1 WECS DFIG in the Network .....................................................................137 3.31 MCC (Motor Control Center) .................................................................................138

3.31.1 Normal Editing Mode ................................................................................140 3.31.2 Advanced Editing Mode............................................................................141 3.31.3 MCC Naming Convention.........................................................................142

3.32 Auto Transformer...................................................................................................143 3.32.1 Auto Xmer in the network .........................................................................144

3.33 Three-Winding Auto Xmer .....................................................................................146 3.33.1 Three-Winding Auto Xmer in the network ................................................147

3.34 Protection Devices.................................................................................................149 3.34.1 Fuse / LVCB / Recloser / Relay (all of them) / Miscellaneous..................150

PSAF Basics & Editing – Users Guide and Reference Manual

TABLE OF CONTENTS 7

3.34.2 Accessing a protective device through its connected equipment ............150 Chapter 4 Line and Cable Parameter Calculations............................................................153

4.1 Line Parameters Calculations................................................................................153 4.1.1 Line Parameters Calculation with HLINPAR ............................................153 4.1.2 Activate HLINPAR ....................................................................................154 4.1.3 HLINPAR Input Data.................................................................................155 4.1.4 Data Input in HLINPAR.............................................................................156 4.1.5 HLINPAR results.......................................................................................158 4.1.6 Data Input in HLINPAR.............................................................................161 4.1.7 HLINPAR results.......................................................................................163

4.2 Special Harmonic Line Models supported by HLINPAR .......................................163 4.2.1 LIN_3PB, Transposed 3-phase distributed ..............................................163 4.2.2 LIN_3PCB, Transposed 3-phase distributed, frequency dependent........164 4.2.3 LIN_3P, Untransposed N-phase distributed.............................................166

4.3 Typical Tower Layouts Supported in HLINPAR ....................................................167 4.4 Cable Parameters Calculations .............................................................................169

4.4.1 Cables Parameters Calculation ................................................................169 4.4.2 How to calculate cable parameters ..........................................................170 4.4.3 Cable Input Data.......................................................................................170

Chapter 5 Editing the Network.............................................................................................181 5.1 File extensions.......................................................................................................181 5.2 Overview of creation and editing ...........................................................................182 5.3 Opening a Network ................................................................................................182 5.4 One-Line View Mode .............................................................................................183

5.4.1 Creating a new Bus ..................................................................................183 5.4.2 Connect a New Equipment to the Network ..............................................184 5.4.3 Example: Connecting a Generator ..........................................................185 5.4.4 Edit an Equipment in the Network ............................................................186 5.4.5 Move an Equipment from One Bus to Another.........................................186 5.4.6 Move a Bus...............................................................................................187 5.4.7 Move Part of the Network .........................................................................187 5.4.8 Copy an Equipment ..................................................................................187 5.4.9 Copy and Paste Part of the Network ........................................................188 5.4.10 Delete an equipment.................................................................................188 5.4.11 Delete part of the network ........................................................................188 5.4.12 Undelete an equipment ............................................................................188 5.4.13 Disable/Enable an equipment without deleting it......................................189 5.4.14 Locate (Find) a Network component on the One-line-Diagram(OLD)......189 5.4.15 How Center the view on an equipment: ...................................................191 5.4.16 Hide parts of the One-line-Diagram(OLD)................................................191 5.4.17 Colors of the OLD.....................................................................................193 5.4.18 Title Block for the Network (User Defined Label) .....................................195

5.5 Table View Mode ...................................................................................................195 5.6 Input Data Report ..................................................................................................198

Appendix A – Representation of transformers in zero-sequence

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 1

Chapter 1 Getting Started

1.1 Introduction

CYME PSAF (Power Systems Analysis Framework) is a suite of modular analysis programs with a common database and network editing facility. The suite includes programs for topics such as Load Flow, Short Circuit, Harmonic and Transient Stability analyses of electrical networks.

The highly interactive graphical interface makes it easy to draw the network One-Line Diagram on the screen and define the parameters of its components. Additions, deletions and modifications are easily made during the process of creating the network. At any time, you may display (and edit) the data pertinent to any component on the screen by clicking with the mouse. As an alternative to the graphic method of entering the network description, PSAF allows you to enter data in tables.

You may choose which One-Line information is displayed on the screen while you work.

When you open a new window, you can drag and drop only the equipments that you want to see in the One-Line until the entire network. With this option you can divide a network in piece that you can see in different windows at the same time.

Calculation results may be displayed on the screen for specified components. Complete reports of the results may be saved in files and printed. You may design custom reports by selecting items from a menu. Undesirable load flow conditions such as overloads and under/over-voltages may be reported.

The auxiliary program CYMVIEW provides a common graphical display for results as a function of time (MOTOR-START or STABILITY) or frequency (HARMO).

1.1.1 About this Manual

The current manual covers the basics of PSAF. Chapter 1 includes an overview of the installation steps of the program and describes the graphical users’ interface. Chapter 2 lists and briefly describes all the commands available in the PSAF menus and its toolbars. Chapter 3, 4 and 5 provide tips about the creation of the network equipment data.

1.1.2 The PSAF Users’ and Reference Manuals

The following Users’ and Reference Manuals are also available from CYME for the registered users of the PSAF application modules:

• Basics of PSAF and overview of editing functions. (this manual)

• CYMFLOW, CYM-Motor-Start & CYM-AC Contingency, Users’ Guide and Reference Manual.

• Short-Circuit (ANSI & IEC), ARC Flash & CYMBREAK, User’s Guide and Reference Manual.

• CYMSTAB & UDM Library, User’s Guide and Reference Manual.

PSAF Basics & Editing – Users Guide and Reference Manual

2 CHAPTER 1 – GETTING STARTED

• CYMOPF, User’s Guide and Reference Manual.

• CYMVSTAB, Reference Manual.

• CYMHARMO, User’s Guide and Reference Manual.

• Importing/Exporting – Databases/Networks, Reference Manual.

1.2 Computer System Requirements

PSAF for Windows requires an IBM PC or compatible computer using Microsoft Windows NT 4.0, Windows 2000, Windows XP or Windows 2003 The minimum hardware requirements are:

• A Pentium III - based computer.

• 256 MB of extended memory (512 MB or more recommended).

• 150 MB of hard-disk space.

• 1024 X 768 screen resolution

• Any mouse, monitor and printer or plotter supported by Windows.

1.3 Installing PSAF for Windows

The PSAF package includes the installation CD and one protection key (if you have selected a hardware-type key), which plugs into the parallel or USB port on your computer. You cannot operate the program without the key in place. You can, however, install it. (In the case of a computer network installation, the key should be plugged into the server machine.)

Note: Installing a new version of PSAF on a drive where PSAF already exists will not overwrite the existing databases.

1. Start Microsoft Windows. 3. Insert the CYME CD into the CD-ROM reader. 4. The installation program should start automatically after a few seconds.

If it does not start by itself, use Windows Explorer to inspect the main directory of the CYME CD. Locate the icon “Setup” and double-click on it.

5. Click on the option to “Install Product”. 6. Choose PSAF (+ version #) from the list of software names.

7. Follow the prompts and screen instructions. (You will need the password.)

8. Insert the hardware key into the line printer port (e.g., LPT1) or in an empty USB port.

Please refer to the Appendix, "Setting Up the Protection Key", for further instructions.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 3

Users of Windows NT must also install the proper driver. Please refer to the Appendix.

1.4 Running PSAF for Windows

Having activated Windows, double-click on the PSAF program icon. The Main Menu and Toolbar will be displayed. Note that most of the icons will be disabled until you open a study (see section 1.5 PSAF GUI).

Since PSAF features more than 20 different modules, the program can take a long time to load-up (especially if you have a network type protection key). To accelerate the startup process, you can remove the initial validation on some of the simulation modules that you DON’T have. For more details on this option please see section 2.1 File Menu.

1.4.1 PSAF Files

A PSAF Network is the combination of a network (*.nwt) file, a study (*.stu) file and the use of a database directory. All of these are linked together through a “Project” to which the network belongs (see section 1.6.1 Using the Project view).

The databases store the intrinsic characteristics of the network equipment, such as

nameplate ratings.

The network (*nwt) file refers to items in the databases to establish the data that appear in the main tab of each equipment dialog box. See Chapter 3.

The study (*.stu) file refers to the databases to establish the supplementary data. (These data appear in the auxiliary tabs of each equipment dialog box. See Chapter 3.)

Examples: The rated MVA, voltage and impedances of a generator are stored in the network, but the choice of exciter model (if any) would be stored in the study.

The torque-speed characteristic for the load on an induction motor may be changed in a study, but the motor itself is part of the network.

PSAF Basics & Editing – Users Guide and Reference Manual

4 CHAPTER 1 – GETTING STARTED

1.5 PSAF GUI

1.5.1 Network Window

The screen is subdivided into four sections. These sections can be viewed only when a network has been opened.

1.5.2 Project View Sidebar

The Project View Sidebar (menu View > Project View) provides you quick access to your network views and to the gallery of symbols you can use in your one-line diagrams.

• The Projects tab, shows all projects that you have and all the networks for this project. Each network can contain one or more views that are displayed in the projects view in a tree-like fashion.

• The Symbols tab, shows all equipment that you can add in your network. Simply drag and drop one of them in one view to add it into the network. The symbols are grouped by categories that you can expand by clicking on the Category name. These include: General Equipment, Harmonic Equipment, Protective Devices and Tools.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 5

1.5.3 Detailed View Sidebar

The Detailed View Sidebar (menu View > Detailed View) provides a quick access to the network equipment. This sidebar is divided in three panes that can be displayed by clicking on the corresponding tabs:

• The Network tab shows you a list of every device present in the network. Equipment types with the green icon are present in the network. Equipment name shown with a red icon means that this equipment exists in the network but it is not currently displayed in the one-line diagram. You have access to four options by right clicking on a selected equipment:

1. Open (the Equipment dialog box). 2. Locate (the equipment will be centered in the one-line diagram window). 3. Hide (the equipment will be hided from the active view). 4. Delete (the equipment).

PSAF Basics & Editing – Users Guide and Reference Manual

6 CHAPTER 1 – GETTING STARTED

• The Database tab, shows every equipment database records available in the active database. You have access to two options by right clicking on an equipment:

1. Open (the equipment database dialog) 2. Delete (the record from the active database)

• The Option tab, includes one-line diagram coloring options. These options are

also available in the menu “Tools > Options” (from the Main toolbar) + “View > OLD filter” (See Hide parts of the One-line-Diagram(OLD), section 5.4.16.)

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 7

1.5.4 Moving the Toolbars and Sidebars

The Symbol Tool Bar is floating at the right instead of docked at the left.

1.5.5 Mouse Commands

1.5.5.1 Pan

• CLICK the RIGHT mouse button ONCE and HOLD IT DOWN.

• MOVE THE MOUSE and RELEASE THE BUTTON.

The drawing will move as though you had pulled it with the mouse. 1.5.5.2 Zoom

• Move the mouse to place the cursor at one corner of the desired area.

• DOUBLE-CLICK the RIGHT mouse button and HOLD IT DOWN.

• MOVE THE MOUSE so that the outline box surrounds the desired area.

• RELEASE THE BUTTON.

PSAF Basics & Editing – Users Guide and Reference Manual

8 CHAPTER 1 – GETTING STARTED

If your mouse is equipped with a scrolling wheel, you may rotate it to zoom in and out.

Hint: The Zoom buttons in the Editing Toolbar function as follows:

zooms out a little.

zooms out until the entire One-line is displayed.

zooms in a little.

Hint: The Center button in the Editing toolbar brings the selected equipment to the center of the Network window. Consider using it before zooming. The Find

function also has an option to place the selected item in the center.

1.5.5.3 Select an equipment

• Click the LEFT mouse button ONCE on the equipment symbol in the One-line. or

• Click the LEFT mouse button ONCE and HOLD IT DOWN.

• MOVE THE MOUSE to draw an outline box around the equipment symbol.

• RELEASE THE BUTTON. Hint: The selected symbol will be outlined in the color selected under Tools >

Options.

1.5.5.4 Show Dialog

• Select an equipment.

• Right-click on the symbol to display its context-menu and select the Properties option. (Other methods are available. See section 5.4.4 Edit an Equipment in the Network for more details)

1.5.5.5 Cancel

To cancel an editing activity, which is in progress, click on the cancel icon. You may also press the “Escape” key. You may cancel the following actions: Reconnect, New, Move, Copy, and Undelete.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 9

1.5.5.6 Context Menus

To see and use the context menu of a component, click right mouse button on it. Each of the following components has at least these options:

Properties To open the component dialog box.

Disable / Enable To disconnect or connect the bus.

Re-Connect Useful for reconfigurating selected component on a network.

Copy To copy the selected equipment to the clipboard.

Delete To eliminate an equipment.

Show / Hide Label To make the equipment-label visible or invisible, on the OLD.

Default all tags To reset the component tags to their default positions.

Hide component To make the component invisible on the OLD. If you want to see it again, simply drag and drop the corresponding component from de detailed view to the OLD.

The Bus context menu has one additional option: Show first ring; which is used to show all the connected equipment of this bus.

The Equipment context menu has one specific menu option: Auto-center, used to center the equipment in the current straight line.

PSAF Basics & Editing – Users Guide and Reference Manual

10 CHAPTER 1 – GETTING STARTED

The Protective Device context menu has one specific menu option, which is Switch To, to move the protective device on another side of the attached equipment.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 11

1.6 Using PSAF

1.6.1 Using the Project view

The Project tree view is used to manage all of your studies in a single, easy to find environment. Through its properties, the link between each of the files (section 1.4.1 PSAF Files) composing your cases are kept in the project definition. The following sections will tell you how to create a new project, how to associate the equipment database to it, how to create a network in this project.

To make a project active, simply right-click on its name and select the Set as Active Project command.

You may also add a network (1.6.3 Creating a network), rename a project, delete a project (with the possibility to delete all the associated files at the same time), import (2.1.1 Import Wizard) or Export (2.1.2 Export Wizard) the networks of this project. You may also change the properties of the project.

1.6.2 Creating a new project

The first step is to create a project to which you will link the network to be created. You can create any number of projects and each of them can contain one or more networks.

Select the File > New > Project menu item to display the Wizard that will guide you through the necessary steps. You can also access the Wizard through the Project View sidebar and by selecting the New Project shortcut, as shown below. You can display the Project View sidebar by using the View > Project View menu item.

PSAF Basics & Editing – Users Guide and Reference Manual

12 CHAPTER 1 – GETTING STARTED

Clicking on the New Project item will display the Project creation Wizard window:

At the first step “Project Settings”, you specify the directories that PSAF will use to store

the information related to the project you will create: Project name The name that you want to give to your project.

Project path The path where all the related networks will be saved.

Symbol file path The path where will be saved the .XML file containing your own

symbols (if you don’t have any, use the default one available with PSAF).

Click the Next button to display the next page of the Project creation Wizard: the Database settings.

Note: If you click the Finish button instead, then all others parameters will be filled in for you, using the available defaults.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 13

The Project creation wizard will display the default paths for the Equipment database and for the O.L.D. view database.

The Equipment database contains all the information about the available equipment. You might think of this as making an inventory of the network equipment as though it were all in a warehouse somewhere. Once an equipment has been defined in the database, you may insert multiple copies of it in the network. Conveniently, you may edit the databases even while editing the network One Line diagram.

Hints::

Initially, PSAF uses the databases that are stored in the directory called \DATABASE.vers# (e.g. \database.3.00 for PSAF version 3.00) as default database and will copy it to the specified DBF Folder. If you wish to change the default database, use the File > Preferences menu command in PSAF (see section 2.1.3 Preferences Settings).

The second path, O.L.D. view database, contains all the One Line Diagrams for this project. Each project can have multiple networks and each of them can have multiple O.L.D. views. All these views are saved in the MDB file.

At this time, you can press the Finish button and your project will be created.

1.6.3 Creating a network

The creation of a new network is done through the Network creation page of the Project creation Wizard. You have two ways to access it.

The first one is if you click the Next button (instead of the Finish button) once you are done with the Database settings. The Project Creation Wizard will take you to the next stage: the Network creation page that will allow you to specify the name of the network you wish to create in this project by typing it in and to select the template from which the network will be created from the drop down list below the name of your network. Once you click Finish, the wizard will disappear and a new One Line Diagram window will be displayed using the template you specified.

PSAF Basics & Editing – Users Guide and Reference Manual

14 CHAPTER 1 – GETTING STARTED

The second way is to click on the New Network shortcut in the Project view sidebar:

The Wizard that will be displayed will require specifying the name of the network and its template, and also specifying to which project it will be added (the Destination Project).

Once you click Finish, the wizard will disappear and a new One Line Diagram window

will be displayed using the template you specified.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 15

Note: If you create a network using the New Network shortcut in the Project view sidebar or the File > New > Network menu item, and that no project was previously specified, PSAF will display the Network creation Wizard that includes the steps of creating a new project.

1.6.4 Building a network

Once your network is created, you are now ready to define how the equipment is connected in the network. Do this by identifying points of connection between equipment and creating buses to represent them. Connect the equipment (to one or more buses) either by adding it to the One Line Diagram using the mouse and icons, or by entering data through tables. As you connect an equipment, define its service settings (e.g., primary tap position for a transformer).

Hint: You can choose colors to indicate buses of different voltage levels, etc. See the Tools > Options command. (see section 2.8 Tools Menu).

Having described the network, select an analysis to perform (e.g., loadflow). If necessary, you may specify parameters for the calculation (e.g., convergence tolerance). You may also choose the kinds of reports you would like to obtain, as well as the variables that will be featured in those reports. (PSAF remembers your choices from one analysis to the next.) Activate an analysis and view the results.

These steps are summarized below: 1. Describe generic equipment in the databases. 2. Connect equipment together. 3. Customize the equipment as you connect it. 4. Select an analysis to perform. 5. Define calculation parameters and select the reports desired. 6. Perform the analysis and view the reports.

PSAF Basics & Editing – Users Guide and Reference Manual

16 CHAPTER 1 – GETTING STARTED

The remaining chapters of this manual cover the activities related to the creating and editing a network and its components. The user will find in the CYMFLOW Users Manual the various analysis options of PSAF.

1.6.5 How to Print the One Line Diagram

To print the contents of the One Line Diagram (OLD): 1. Select the File > Print command, the Print / Preview dialog will appear. 2. Choose one of the three following option and Click Ok,

• “Output the whole network” prints the entire network even when you are seeing a part of the network on view window.

• “Output the network “as is” prints only what is visible in the view window. That means that if you zoom in on a part of the drawing, only the zoomed portion will be printed.

• “Output the selected print zone” prints one of specified zones of network.

This option allows the user to print multiple “Printing Zones” of a study. A “Printing zone” is a pre-defined view of a network. To define a printing zone:

A. Select Symbol toolbar > Tools > Define printing zone.

B. Left-click and hold the mouse on the Define printing zone icon and drag the cursor

onto the one-line diagram (OLD).

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 1 – GETTING STARTED 17

C. Click to select the label to make it active. Drag and drop the corners of the rectangle to define the extent of the printing zone.

D. PSAF automatically assigns a name to each Printing-Zone but you can change it. (The name is used by the Print command when selecting Printing zones.

By double-clicking the Printing-Zone border, PSAF displays the following dialog; where you can: change its name and border color, preview and print the zone.

PSAF Basics & Editing – Users Guide and Reference Manual

18 CHAPTER 1 – GETTING STARTED

You have the option to make PSAF print according one of above options without asking you, or to give you the choice to choose one of the options every time. See File > Preferences > General. (Section 2.1.3 Preferences Settings and illustration below )

Hints: Using color in the One Line Diagram (OLD)

You may find it useful to use different colors to distinguish buses of different base voltages. If you want to print the diagram in color, make sure to deactivate the option File > Preferences > General > Force all colors to black or white.

If you choose a dark background color for the network window, choose the option keep colors and make background transparent.

Note: Use File > Print Preview to confirm what will be printed.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 19

Chapter 2 Menus and Toolbars

2.1 File Menu

New

Project To display the Project creation Wizard, which will help you during the process of creating a new project.

Network To display the Network creation Wizard, which will help you during the process of creating a new network and adding it to a project.

Open Network/ Study file…

To display the Import Wizard, which will help you to use your old nwt/stu files. Refer to section 2.1.1 Import Wizard, for more details.

PSAF Basics & Editing – Users Guide and Reference Manual

20 CHAPTER 2 – MENUS AND TOOLBARS

Save

Network To save the current network (.NWT and .STU).

Network As To save the current network under another file name.

All Networks To save all opened networks.

View & Network

To save the current O.L.D. view in the mdb database and save the corresponding network (nwt and stu).

View As & Network

To save the current O.L.D. view using another name and to save the corresponding network (nwt and stu).

Save All To save all views and networks that are opened.

Close Network

To close the current network and all his views.

Close All To close all the files that currently opened. The program will prompt you to save any file that has been modified and not saved yet.

Import… To display the Import Wizard. Refer to section 2.1.1 Import Wizard, for more details.

Export… To display the Export Wizard. Refer to section 2.1.2 Export Wizard, for more details.

Tutorial To see what are a project, a network, an O.L.D view, an equipment database and a view database, click File Tutorial. This will create and open files for you. You will be able to access them from the Project View.

Preferences To access the dialog boxes to set directories, text fonts, text editor, etc. See section 2.1.3 Preferences Settings, below.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 21

Load Text Editor...

To open any text file using the text editor that you have specified in the Directory tab in the Preferences settings dialog, without leaving the PSAF environment. See section 2.1.3 Preferences Settings, below.

Note: You should not edit the network files (*.NWT) or the study files (*.STU) using the text editor.

Print To display the printer dialog box for your printer.

Note: It is recommended to the use Print Preview command instead

of Print. Print Preview

To display the image of the One Line diagram that will be printed. If it is acceptable, you may print it by clicking on the Print button within the Print Preview dialog box.

Hint: You can specify in the General tab of the Preferences settings dialog box the type of area PSAF will display when using the Print Preview command; i.e. only the portion of the diagram that is visible on the screen, or the entire diagram, or let you select on a case-by case basis. See section 2.1.3 Preferences Settings, below.

Print setup...

To specify a printer and its settings (e.g., Landscape orientation, etc).

Exit

To close the PSAF applications. PSAF will prompt you to save changes if you have not already done so.

2.1.1 Import Wizard

With PSAF, you have four import possibilities. The Import Wizard will help you go through all the steps related to your selection. To open the Import Wizard, click on the Import shortcut in the Project View or select the File > Import menu item.

PSAF Basics & Editing – Users Guide and Reference Manual

22 CHAPTER 2 – MENUS AND TOOLBARS

This wizard will open:

You can navigate through the steps using Next and Previous buttons or you can directly click on the desired step shown on the left. Each option is explained below.

2.1.1.1 Import existing network

With this option you can import any nwt/stu file that you have, like your old versions for example. Fill in the required information and if these files are related to a database, you can specify the database path that will be imported.

Next, you must specify the destination of your files. This can be a new project or an existing one. You also need to select the action to take in case of conflict.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 23

Once done, click on the Finish button, and you are ready to use this network. 2.1.1.2 Import zip archive

With this option you can import one zip file that was previously created by the Export function of PSAF.

Then choose the destination project and the action to take if there is a conflict when the database will be merged.

Once done, click on the Finish button, and PSAF will extract the zip file and import its content in the selected project.

PSAF Basics & Editing – Users Guide and Reference Manual

24 CHAPTER 2 – MENUS AND TOOLBARS

2.1.1.3 Import CYME DOS and other formats

Note: The following does not apply to the users of CYMBASE. For those, please communicate with CYME International; we will make the conversion to PSAF for you, free of charge.

Locate the file that you want to import, and then your destination project.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 25

Parameters for DOS conversion Select the File > Preferences > DOS Conversion menu item to specify how you want the network data to be converted into the PSAF format.

PSAF Basics & Editing – Users Guide and Reference Manual

26 CHAPTER 2 – MENUS AND TOOLBARS

DOS programs conversion options

To specify a number of options for converting old data files (used in CYME DOS programs such as CYMFLOW and CYMFAULT). PSAF will identify the network Buses using the bus number and/or bus name given in CYMFLOW and CYMFAULT. For example: Bus number: 2001 Bus-number-name: 2001-BOSTON Bus-name-number: BOSTON-2001

Hint: If you use Bus number, then PSAF will still keep the

name as the “Extra ID”. The Extra ID appears in the Bus dialog box and may be displayed on the One Line and in the reports. See File > Preferences > Study Config.

Default all line lenghts to 1

When activating this check box, the impedance of each Line will be imported as if it were the impedance per unit of length and the length will be made equal to 1 unit. Doing this makes it easy to compare data between the DOS file and the PSAF dialog box for Lines.

Default unknown zero sequence impedance to

Sets the following according to your choice:

Typical Values Same as CYMFAULT

Lines Z0 = 1.5 x Z1 Z0 = 0.001 p.u. Transformers Z0 = Z1

Winding connection Yg–D or D–Yg (Yg on higher voltage side)

Z0 = Z1 Winding connection Y-Y

Generators MVA = machine MVA kV = bus base kV X”d = 0.20 p.u., R”d = 0.0 p.u. X’d = 0.23 p.u., R’d = 0.0 p.u. Xd = 0.60 p.u., R = 0.02 p.u. X0 = 0.066 p.u., R0 = 0.0 p.u, Winding connection Yg

MVA = system MVA base kV = bus base kV X”d = 0.20 p.u., R”d = 0.0 p.u. X’d = 0.30 p.u., R’d = 0.0 p.u. Xd = 99 p.u., R = 99 p.u. X0 = 99 p.u., R0 = 99 p.u, Winding connection Y (ungrounded)

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 27

2.1.1.4 Import ASCII

Locate the adb file containing all the database information you want to import along with the corresponding nwt file, if there is one and if you want to import it as well.

Then, select the destination where the data will be imported and one network name if you have selected to import a nwt file.

PSAF Basics & Editing – Users Guide and Reference Manual

28 CHAPTER 2 – MENUS AND TOOLBARS

2.1.2 Export Wizard

With PSAF, you have five import possibilities. The Export Wizard will help you go through all the steps related to your selection. To open the Export Wizard, click on the Export shortcut in the Project View or select the File > Export menu item.

This wizard will open:

You can navigate through the steps using Next and Previous buttons or you can click on

the desired step shown in the list on the left of the window. Each option is explained in the following sections.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 29

2.1.2.1 Export Study

With this option you will export the networks that you want into a zip file. The first step is to select one or more networks to export.

Specify the zip path where all will be exported, and click Finish.

PSAF Basics & Editing – Users Guide and Reference Manual

30 CHAPTER 2 – MENUS AND TOOLBARS

2.1.2.2 Export PSS/E

This option will create the zero sequence (.seq) and the positive sequence (.raw) in PSS/E format version 27. First, select the network to export :

Specify the raw file to create. The seq file will be created in the same path.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 31

2.1.2.3 Export CYMFLOW – DOS (NND)

This option will create the entrance file for CYMFLOW Dos. First, select the network to export.

Then, specify the .nnd file that will be created.

CYMFLOW supports numeric ids only, if you check the box, the converter will try

to re-use all your bus ids as is until he will assign automatically new ids.

PSAF Basics & Editing – Users Guide and Reference Manual

32 CHAPTER 2 – MENUS AND TOOLBARS

2.1.2.4 Export one line diagram

Use this option to export one line diagrams to a format supported by AutoCAD™. First, select the view that you wish to export.

Specify the Dwg or Dxf file to create and the desired AutoCAD version :

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 33

2.1.2.5 Export ASCII

This option is used if you want to have your equipment database in a file. Select the project that contains the desired database.

Then, specify the .adb file path where the database file will be created.

2.1.3 Preferences Settings

The Preferences settings dialog box is composed of six tabs:

Directory To specify the default directories and files where PSAF reads and stores.

O.L.D. To specify the default thickness of lines and appearance of symbols in the one line diagrams.

Study Config

To specify a number of parameters about the study, for example the curve plotting option and the color options.

PSAF Basics & Editing – Users Guide and Reference Manual

34 CHAPTER 2 – MENUS AND TOOLBARS

General To specify miscellaneous basic defaults for the display of windows, file opening and printing; and set default values such as base and operating voltage and currency.

DOS-Conversion

To specify a number of options for converting old data files (used in CYME DOS programs such as CYMFLOW and CYMFAULT).

Advanced Provides options relating to the display of very large networks.

Directory Tab

Highlight the database type you wish to specify in the Directory selection list. Its description will be displayed in the Description group box. Select the path of the desired directory or application in the Path group box (use the browse button … ) and click the APPLY button once you have made your selection. Click OK to dismiss the dialog box once done.

Default database

Source database used when creating a new project.

Network Directory where all temproray files to communicate with engines will be saved.

UdmLibDir Folder containing all the UDM library files needed by the different networks opened in the application.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 35

ArcFlash Label Dir

Folder where the ArcFlash stylesheets for the labels (.xsl) are stored.

Editor Path to select a text editor application that will be used by the application to open various files. (This is especially useful in CYMSTAB for editing UDM files between simulations).

Projects File Path to the XML file where the contents of the Projects Tree will be saved.

O.L.D. Tab

The options available in this dialog box are described below. Click the APPLY button once you have made your selections. Click OK to dismiss the dialog box once done.

Thickness group box

To set the thickness of the symbols’ lines for Branches (line segments), Equipment Symbols (such as transformers) and Bus Symbols.

Bus Tags group box

You can specify default position of Bus ID and its solution voltage on the One Line Diagram (left, right or center) above Bus location.

PSAF Basics & Editing – Users Guide and Reference Manual

36 CHAPTER 2 – MENUS AND TOOLBARS

Symbol group box

You can select North American or European symbols for equipment (essentially transformers, lines and cables). Size Factor makes symbol of certain equipment types larger than others. To scale all symbols the same way, use Apply to all . To specify text font type, style and size of a label, double click on it or select the Tools > Tags properties menu item.

Mouse Wheel Invert the mouse wheel means that you switch the zoom direction when you go up or down with it.

Others group box

Don’t expand bus when moving an equipment: • With this option checked, when you move the

equipment further than the bus bound, the connection will remain on the border.

• When this option is not checked, when you move the equipment further than the bus bound, the bus bound will be increased.

Study Config Tab

The options available in this dialog box are described below. Click the APPLY button once you have made your selections. Click OK to dismiss the dialog box once done.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 37

Do not display reporting unit on one-line diagram

Activate this option if you don’t want to display every reporting unit for each equipment in the One Line Diagram.

Load flow group box

Activate this check box to display the Extra ID (description) instead of the Bus ID on the One Line and in Load Flow reports.

Load ID displayed

You can enter four differents ids for one load. Here you select which one you want to display on the One Line.

Curve plotting option

When you activate the Automatically ask me which curve I want to plot after each analysis; the Chart Selector dialog box (see below) will be automatically displayed after each Motor-Starting, Transient-Stability or Harmonic analyses to allow you specifying the desired solution curves. This Chart Selector is same as Chart Selector dialog box in CYMVIEW (CYMVIEW is covered in the CYMFLOW, MS-Start and AC Contingency Users Manual).

After you click on Done (above dialog), you can open CYMVIEW to plot other solution curve.

Color options In Tools > Options you can specify which color you want for a case of overload, underload, overvoltage and undervoltage. Here you specify if you want to display the specified color or use the default one.

PSAF Basics & Editing – Users Guide and Reference Manual

38 CHAPTER 2 – MENUS AND TOOLBARS

General Tab

When opening network, use the following mode:

To specify to open network file, by PSAF, in One-Line-Diagram mode (Graphic mode), in Tabular (spreadsheet) mode or no one. You can also ask PSAF to offer you the choice for each network you open.

Extent the print and the preview automatically to:

Four options are available. If you activate “Let me choose the extent”, PSAF will allow you to select one of first three options each time you print the network diagarm. (About the first 3 options, refer to section 1.6.5 How to Print the One Line Diagram.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 39

When printing network: You have three options: • Leave colors untouched: If you are using a

color printer you can activate this option. • Force all color to black and white: Prints

the drawing in black on a white background. This option is recommended if your printer is not a color printer, or if you are using a dark color for the One Line Diagram background, and also when PSAF is in black-and-white mode.

• Keep colors and make background transparent: This option would be useful when OLD background is colored and you need to print diagrams or tables on transparent sheet and you want to be sure, that the printer does not print background even by white color.

Enable equipment

mouse movement Activate this check box if you need to move equipment frequently on One Line Diagram.

Show errors and messages windows on startup

Activate this check box display the Messages window in the PSAF workspace when starting the application (see section 1.5.1 Network Window).

Select dialog box style for entering data

There are some differences between the North American and the European standard when you entered some data. Choose which one you prefer.

Auto-save study and topology

To activate the Auto-save function, so that at regular intervals PSAF will save your work, especially while you are building a Network. You may want to disable this function temporarily if you are no longer modifying the network, and just doing calculations.

Default Value for bus voltage

To set the default for the voltage of newly created buses.

Currency type You can use the system currency type or your own that you can specify here.

When copy diagram to clipboard

To select if the diagram will be copied with your defined colors or if you prefer to copy it in black and white.

Project tree view options

To show in the tree-view sidebar: • Simple: only the names of the projects, the

networks and the views. • Advanced: to show all names (projects,

networks and views) and all existing project paths and network paths.

PSAF Basics & Editing – Users Guide and Reference Manual

40 CHAPTER 2 – MENUS AND TOOLBARS

DOS Conversion Tab

To specify a number of default options for converting old data files (used in CYME DOS programs like CYMFLOW and CYMFAULT).

Please refer to 2.1.1.3 Import CYME DOS and other formats for more details.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 41

Advanced Tab

To set options relating to the display of very large networks.

Show network border

To see network borders on the one line diagram, activate this option and Show Volt Ctrld Relations (view-VCR) (from O.L.D. Editing Toolbar, section 2.11.4).

Default bus visibility

This has to do with not bothering to display uninteresting parts of large networks. If you open a network which contains more buses than the number you specify here, then PSAF will display a dialog through which you may decide which parts of the network to display continuously.

Show buses by group of ## buses

If you select the Show all option (section 2.11.4 O.L.D. Editing Toolbar) or if you decide to “re-arrange” the network (section 2.2 Edit Menu), and the network have more than ## buses you can use this option to arrange the buses on the one line diagram by groups of ## buses.

PSAF Basics & Editing – Users Guide and Reference Manual

42 CHAPTER 2 – MENUS AND TOOLBARS

Startup programs checking

To specify which engines you want to check for protection key on startup.

2.2 Edit Menu

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 43

Cut Copy Paste

Used for editing the One Line, but are also available when working with any text, such as tabular reports.

Copy Diagram to Clipboard

To place in the Windows clipboard an image of the One Line as displayed in the One Line. From the clipboard, you may paste the image into other opened document that support Windows clipboarding.

Select Equipment

To select the category of the equipment type (same function as the drop-down list described in section 2.11.2 Editing Toolbar.

Find Equipment (locate)

To search for a particular equipment. First select the type of equipment inside the Find dialog box, and then select the individual equipment by name. That equipment will be highlighted and centered on the screen for you. (See section 5.4.14 Locate (Find) a Network component on the One-line-Diagram(OLD)

Open Equipment Dialog

To display the dialog box of the selected equipment. Does the same thing as a right double-click on an equipment symbol. (See section 5.4.4 Edit an Equipment in the Network).

New Equipment

To connect a new equipment of the selected type. Note that the equipment tool bar can make this process easier than using this function. (See section 5.4.2 Connect a New Equipment to the Network)

Copy Equipment

To create a copy of the selected equipment allowing you to connect it elsewhere in the One-Line. (see section 5.4.8 Copy an Equipment).

Delete Equipment

To remove the selected equipment from the One Line. (see section 5.4.10 Delete an equipment).

Undelete Equipment

To reconnect the most recently deleted equipment. (see section 5.4.12 Undelete an equipment).

Move Component

Useful for moving Labels. The interface now makes it easy to select and move symbols on the One Line. (see section 5.4.6 Move a Bus).

Enable Equipment

Puts the status of an equipment in or out of service without deleting it. (see section 5.4.13 Disable/Enable an equipment without deleting it

Connect Equipment

To reconnect an equipment to another bus. (See section 5.4.5 Move an Equipment from One Bus to Another).

Rotate Equipment

To rotate an equipment symbol (usually a Bus) according to the mouse movement as you hold down the mouse button.

PSAF Basics & Editing – Users Guide and Reference Manual

44 CHAPTER 2 – MENUS AND TOOLBARS

Orthogonal To draw network branches automatically using perpendicular vectors. De-activate it if you want to draw diagonal vectors.

Lenghten Bus

To add one segment to the selected bus, starting at the right side (or bottom if vertical).

Shorten Bus

To remove one segment of the selected bus, starting at the right side (or bottom if vertical) if no equipment is connected there.

Rearrange Network

To redraw the One Line with the selected bus at the top of the diagram.

2.3 Network Menu

Edit Mutual Data

To define mutual impedances between cables and transmission lines (See Transformer, Voltage-regulating (TCUL), section 3.24.

Assign Area

To create areas out of one or more zones of buses, for the purpose of defining required active (MW) power flows between areas. See CYMFLOW, CYM-Motor-Start & CYM-AC Contingency, Users’ Guide and Reference Manual.

Network Stats

To display information about the network.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 45

2.4 View Menu

Toolbar To display / hide and customize the appearance of each tool bar. See also the Tools > Customize menu item. More details about the Toolbars in section 2.11.

Status Bar To display / hide the status bar at the bottom of the screen.

Viewspaces To display either (or both) of the Table view or the One Line view of the network. The Editing Toolbar (section 2.11.2) includes two buttons for the same functions. • Working with the Table View Mode is described in section 5.5. • Working with the One-Line View Mode is described in section 5.4.

Errors and Messages window

To display / hide the Message Window normally found at the bottom of the screen.

Project View

To display / hide the Project View sidebar. It is composed of two tabs: the Projects tab and the Symbols tab. See section 1.5.2 for all details about the Project View Sidebar.

Detailed View

To display / hide the Detailed View Sidebar, consisting of three tab: Network, Database and Options. See section 1.5.3 for all details.

Zoom To adjust the detail level of the One Line diagram - zoom to fit, zoom in and zoom out.

PSAF Basics & Editing – Users Guide and Reference Manual

46 CHAPTER 2 – MENUS AND TOOLBARS

Center Selection

To move the One Line diagram by placing the selected network component symbol at the center of the window. See 2.11.2 Editing Toolbar.

Filter OLD To hide parts of the One Line diagram. See section 5.4.16 Hide parts of the One-line-Diagram(OLD).

Monitor To display / hide the Monitor window (see Monitor for Load Flow Results, in the CYMFLOW Chapter of the CYMFLOW, CYM-Motor-Start & CYM-AC Contingency, Users’ Guide and Reference Manual.)

Images To add an image file to the OLD or create an image file of the OLD.

Show ID & Base Volt

To display /hide the ID and the base voltage of the buses on the One Line diagram.

Show Label To display / hide the label associated to the selected equipment, on the One Line.

Show Connected Controllers

To display / hide the letters next to Generator symbols that indicate the presence of control systems: “T” = turbine, “E” = exciter, “S” = stabilizer. (These controllers appear in CYMSTAB. For details, see the CYMSTAB Chapter in the CYMSTAB & UDM Library, User’s Guide and Reference Manual.)

Show Protective Devices

To display / hide the symbols and names of any protective devices attached to equipments.

Show Grid To display / hide the drawing grid (small dots at regular intervals).

Use Snap to Grid

To make the equipment and bus symbols align themselves with the grid, as an aid to drawing the One Line in User Mode.

Show solution

To display the various calculation results on the One Line.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 47

Show Volt Ctrld Relations (View VCR)

To display a dashed line between the buses and their VCR (AVR = Automatic voltage regulator). (e.g., voltage-controlled generator) Note that swing generators always control the bus-voltage to which they are connected. Therefore, no dashed line exists for these equipments.

Show Print Zones

To display / hide the border of the area in the one line diagram that has been specified as the Printing Zone (See section 1.6.5 How to Print the One Line Diagram).

2.5 Database Menu

Open Equip. DB Dialog

To display the Database dialog box of the equipment type currently selected on the Select Tool Bar (see section 2.11.2 Editing Toolbar).

New Blank Database Directory

To create a set of database files in a directory of your choice. To create a new directory, simply type its name in the Current folder field in the Browse for folder dialog. (The new database contains only default entries.)

Copy Active Database

To create a copy of all database files in the active directory and to place them in another directory of your choice. To create a new directory, simply type its name in the Current folder field in the Browse for folder dialog.

Pack & Reindex All

To remove excess blank entries in the database files. Usually, this command is used after modifications are made to the database files through a third-party software.

Merge Database To combine another database with the active one. After clicking on this option, enter the path of the database that you want to merge with the active one.

PSAF Basics & Editing – Users Guide and Reference Manual

48 CHAPTER 2 – MENUS AND TOOLBARS

Open UDM Library Manager

Applies to CYMSTAB. It allows you to edit and create User Defined Models for use in CYMSTAB simulations. Please refer to the CYMSTAB & UDM Library, User’s Guide and Reference Manual.

Note: Close all networks to edit UDM library.

Database Filter Manager

To specify filters for certain database types. When you open the database dialog of one of the filtered databases, it will only contain the data that follows the rules entered in the database filter manager.

Unlock All Networks of Current DB view

This applies to the network views database. When using the database in a multi-user environment, if more than one user is using the database, you will not be able to modify the data in the database as long as another user is connected. If a problem occurs or if you need to override this lock, you can use this option to clear all current connections to the database and, by doing so, unlock the database for modifications.

Note: The active database is the one that belongs to the project that is currently set as the active one. Refer to section 1.6.1 Using the Project view for more details.

2.6 Analysis Menu

Select Solver

To select the available analysis programs.

Study To set the calculation and the report parameters / options for the selected

analysis.) (Same as clicking on the icon.) (See also Study Parameters for Load Flow and for Short Circuit in following manuals: • CYMFLOW, CYM-Motor-Start & CYM-AC Contingency, Users’ Guide and

Reference Manual. • Short-Circuit (ANSI & IEC), ARC Flash & CYMBREAK, User’s Guide and

Reference Manual.

Solve To perform the selected analysis based on the parameters set. (Same as clicking

on the icon.)

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 49

Units... To set the units to express parameters and solution in the reports by using the

following dialog box. (Same as clicking on the icon.)

Reset LF Bus solution

To make all bus voltages equal to 1.0 p.u., 0 degrees. (This is accomplished automatically before you perform a load flow calculation - if you have activated the Flat Start option. See Solve for Load Flow, in the CYMFLOW, CYM-Motor-Start & CYM-AC Contingency, Users’ Guide and Reference Manual.

2.7 Report Menu

Show Text Report

To display the tabular report of the results of any analysis.

Export Results to CymLine

To write results to a file that can be read by CYMLINE. See: • CYMFLOW Chapter in the CYMFLOW, CYM-Motor-Start & CYM-AC

Contingency, Users’ Guide and Reference Manual. • Short-Circuit (ANSI and IEC) chapters in the Short-Circuit (ANSI & IEC),

ARC Flash & CYMBREAK, User’s Guide and Reference Manual.

PSAF Basics & Editing – Users Guide and Reference Manual

50 CHAPTER 2 – MENUS AND TOOLBARS

Input Data Report

This option produces a report of all the data that composes the network. It can produce this report on the one-line diagram and in a tabular format. In the Input Data Report dialog box, you may choose the unit for Impedances (Ohm or per-unit on the equipment base or on the system base), you may decide to combine the impedances or rated capacity for duplicated equipment, decide to report the total impedance of a line or cable instead of its “per length” value and you may decide to report the transient stability, harmonics or motor start extra information as well. The content of the information displayed on the one-line diagram is explained below in the Customize labels option.

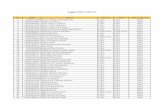

If the Show Tabular Reports check box is activated, clicking OK will display a spreadsheet report of all data pertaining to equipments and buses connected in the network. For example:

Sample Input Data Report (Bus page shown)

Start CYMVIEW

Opens the XY charts plotter companion program “CYMVIEW” in order to allow you to review previously generated curves. PSAF shows solution curves of Motor Starting, Transient Stability (CYMSTAB), Harmonic Analysis (CYMHARMO) and Arc Flash Hazard calculations.

Customize Keywords

Displays the list of all available keywords, via the Keyword modification dialog box. The keywords are classified in a tree-like fashion by types of equipment. The categories appear on the left side of the window. Click on + or – to expand and collapse the branches. Highlight the equipment of your choice to display the list of related keywords available.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 51

To modify the attributes of a keyword, double-click on the keyword, or select it and click the Properties button to display the Format editor. Once your changes are done, click OK.

Customize Labels

To change the contents of labels. Selecting this option displays the Label Customization dialog box.

Select an equipment in the tree list on the left side of the dialog box. The editing is done in the right hand part.

PSAF Basics & Editing – Users Guide and Reference Manual

52 CHAPTER 2 – MENUS AND TOOLBARS

You can enter a “ $ ” to see a menu of available keywords. These labels are completely user defined, i.e. you may specify the content, the number of decimals, you may add your own text, etc. You can also use the keywords to compute another value, simply put your equation between braces and use the normal math operators. See below for an example.

Enter a “ $ “ in the Content box to see active menu of available Keywords, from which you can choose and add desire keywords also you can enter description text.

Note: A Customized Label is a Label that has been changed from its default configuration. For example: a moved label is a customized label.

If Show Tabular Reports is not activated via Report > Input-Data-Report, and you click Ok, you will see label reports for all selected component on the OLD. Note: You can double click on the label of a component and edit it (through the tags-properties dialog).

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 53

2.8 Tools Menu

Customize The Customize dialog box that is displayed includes two tabs:

Toolbars To display / hide standard toolbars or to create new ones based on Windows standards. To create a new toolbar, click on the New… button, enter a name for it and click OK. This will display an empty toolbar in the working window. See the explanations in the Command tab below to learn how to add buttons to your new toolbar.

The four standard toolbars that are generally used in PSAF are: Standard, Editing, OLD editing and Study. The commands available in each are described in section 2.11 Toolbars.

PSAF Basics & Editing – Users Guide and Reference Manual

54 CHAPTER 2 – MENUS AND TOOLBARS

Commands

To add or remove icons in a toolbar.

To add a button to a toolbar: 1. Under the Categories list, select the name of a

toolbar; the icons of the commands associated to the category will be displayed in the Buttons group box to the right.

2. Left click on the icon of the button wanted and hold down mouse key.

3. Drag and drop the icon, from the Buttons group box onto a toolbar in your work window.

To remove an icon from a toolbar, drag and drop it out of the toolbar and release the mouse button.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 55

Shortcut To assign keyboard shortcuts to the available commands (macros).

1. Select a macro (command) in the list. 2. Click Create Shortcut to display the dialog box where you will specify

the keys you wish to assign. 3. Press and hold down Ctrl , Shift and/or Alt keys and press the key

(letter or number) that you want to finish your shortcut with. 4. Release all keys and click on OK.

Options To select the colors for displaying overloaded lines, under-voltage buses, buses of different voltage levels, as well as the background and text display colors, etc.

PSAF Basics & Editing – Users Guide and Reference Manual

56 CHAPTER 2 – MENUS AND TOOLBARS

Individual coloring is to apply a color for a specific item selected. Group coloring if for multiple components present in the One Line Diagram. You can assign one color for a zone that you have in your network, for one area that you have in your network or for a specific range of kv base. Use the Assign one Color per zone option when you want to assign color by zones, you can automatically assign one color for each zone that you have in your network by pressing on this button.

Tag Properties

To specify the categories of tags to be displayed, and the appearance (text, border and background) of all tags that can be shown on the one line diagram.

Equipment symbols

To specify your own symbols for each equipment. Double-click on the symbol that you want to change, and select the new one is the Symbol Selection dialog box that will be displayed.

PSAF Basics & Editing – Users Guide and Reference Manual

CHAPTER 2 – MENUS AND TOOLBARS 57

Symbol Editor

To draw your own symbols in the symbol editor application.

Refresh Symbol

To actualize all the symbols in all opened views with the changes that you have just done.

2.9 Windows Menu

New To open a new empty view for the currently activated network.

Close To close the active view.

Close All To close all the opened views.

Cascade To rearrange the windows so that they overlap, with all title bars

remaining visible. Tile Horizontal

To rearrange the windows so that they appear one above the other and be all of the same size.

Tile Vertical To rearrange the windows so that they appear side-by-side and be all the same size.

PSAF Basics & Editing – Users Guide and Reference Manual

58 CHAPTER 2 – MENUS AND TOOLBARS

<List of views>

The list of opened views appears at the bottom of the menu, below a menu separator. A check mark appears next to the currently active window. You can make any window the active one by clicking on its name in this list.

2.10 Help Menu

General PSAF Help Topics