Protective Clothing

description

Transcript of Protective Clothing

Dr. V. K. KothariDepartment of Textile Technology, IIT, Delhi

Schematic of classifications of Protective Textiles

Flame retardant o Kermel® and Kermel® / Viscose

fabrics for flight suits, station wear and turnout gear.

o Nomex® for military applications o Molten Aluminum splash protective

fabric. o Electrical Arc

Ballistic protection o p – Aramid woven fabric for hard

and soft ballistic applications Lint free antistatic

o Continuous filament polyester / carbon fabrics

Medical textiles o Systemic and non systemic

antibacterial and antistatic fabrics for surgeons gowns, scrubs and warm up jackets.

Chemical protection o Liquid chemical protective fabrics

UV protection o Fabrics that offer a UPF rating for

the wearer. Industrial work wear

o Component fabrics for chain saw protection

o freezer suits o waterproof clothing

Military textiles o Uniformso Parachutes

Materials & Technologies

Processing technologies for specific protective clothing are different, the main processes generally include:

Material manufacturing or selection; Producing fabrics and other related items; Finishing, and Clothing engineering.

Schematic of materials and technologies for manufacturing protective textiles

Steps in selection of protective clothing materials

Step 1: Assess hazards

Type of hazard(s) Severity of the hazard

Step 2: Identify relevant standards, specifications, or guidelines

With well defined performance requirements Not well defined performance requirements

Steps in selection of protective clothing materials

Step 3 Screen materials based on protection performance of fabrics, e.g.

• Cold climate protection performance• Chemical protection performance• Biological protection performance• Flame and thermal protection performance• Mechanical protection performance

Step 4 Select materials based on other major factors

• Job performance• Comfort• Cost• Durability• Use, care & maintenance

AGENDALook at some aspects related to: Extreme old protection Chemical & Biological protection Radiation protection Electrical protection Heat & Flame protection Mechanical protection High visibility Protection

Extreme COLD PROTECTIVE CLOTHING

Hazards of Extreme Cold Climate Increased incidence of Arthritis,

Rheumatism and Bronchitis Cold metal injury Hypothermia - one of the serious

hazards of cold exposure Frostbite

Comfort & Survival Factors in Cold Protective Clothing

1. Physiological Factors – Metabolic heat output – Perspiration rate

2. Environmental Factors – “Wind Chill”– Relative Humidity or Dampness of the

Environment

3. Fabric Factors – Thermal insulation– Air permeability– Moisture vapour permeability

4. Design of the Fabric Assembly

The human heat balance equation

Appropriate protection against cold is provided when the human body is in heatbalance at acceptable levels of body temperatures (for example skin and coretemperatures).

This implies that heat losses are equal to metabolic heat production.

The following equation describes the heat balance.

where S is the rate of change in body heat content, M is the metabolic heat production, C is the convective heat exchange, R is the radiative heat exchange,E is the evaporative heat exchange,and RES is the respirative/airway heat loss, all in W/m2.

Thermal insulation

Evaporative resistance

Wind resistance

Water resistance

Measurements of clothing performance

Category of Fibres which provides Thermal Insulation

A. Heat Insulating - to entrap as much air as possible. - Low compressibility and high resilience - Conventional fibres, hollow fibres & high

bulk fibres

B. Heat Absorbing

- to maintain the microclimate inside the clothing

- Solar radiation absorbing fibre and fibres containing ceramic particles to absorb IR radiation

C. Heat Storing

- Phase change materials

Types of Layer- Combination Outer layer should provide adequate

resistance to wind penetration & should be water vapour permeable

Next-to-skin layer of the garment should wick the liquid sweat away from the body rapidly

Middle layer(s) should provide the main insulation. Body heat should be reflected back using a inner reflective layer.

Structural Model of a Cold Weather Protective Clothing

Laminates with Aluminum Film

Engineered Fibres• An unique polyester fibre such as Primaloft • Air pockets increases the thermal resistance and

help it to resist the passage of water while allowing body moisture in form of water vapour to escape

Insulation through Incorporation of Integrated Heating Panels

• Light weight, washable heating panels

powered by batteries are laminated in the fabric

Smart Polymeric Membranes

• Laminated fabrics made from monolithic breathable membrane which react to build up of heat and moisture

• As the microclimate temperature rises, the openings between the polymer molecules in the membrane expand, thereby increasing the fabric moisture permeability. As the temperature drops the pores in the fabric close, thereby trapping heat.

Chemical Protection

Chemical Hazard

• Affects human based on its characteristics and mode of entry

• Chemicals present a variety of hazards such as toxicity, corrosiveness, flammability, reactivity, and oxygen deficiency

• Routes of chemical entry into the human body are oral, respiratory, and dermal

• Dermal exposure considered primary mechanism of chemical entry through human body

Chemical Resistant Clothing

• It provides an effective barrier between the chemicals used & area of the body to be protected• No single material will protect against all chemicals

Appropriate chemical resistant clothing must demonstrate:

No penetration

No significant degradation

Low permeation rate

Chemical/Biological (CB) warfare agents and their effects

To design and to fabricate effective CB protective clothing, it is necessary tohave an understanding of the hazardous threats that must be prevented fromreaching the wearer.

CWAs are defined as natural or synthesized chemical substances, whethergaseous, liquid or solid, which might be employed because of their direct toxiceffects on man, animals and plants. BWAs are microorganisms (viruses and bacteria) or toxins derived fromliving organisms.

They are used to produce death, or incapacitation in humans, animals, or plants. Typical effects of selected CWAs are listed in Table given in the next slide.

Chemical and biological protection

Typical effects of toxic chemicals, microorganisms, and toxins

There are basically four different types of CB Protective Materials. Figure illustrates the differences in their protective capabilities.

Different types of protective materials

Examples of Chemical Protective Clothing

Three layers outer fabric, sorptive layer and inner layer

Layers of Protective Clothing

• Outer shell is water repellent layer protecting from liquid chemicals• Sorptive layer is soul of protective clothing absorbing liquid & air borne chemicals• Inner layer provides comfort to the wearer

Development of Chemical Protective Clothing

Polyester fabricCotton NonwovenActivated carbon Cotton NonwovenCotton fabric

• Formed by five layers• Outer shell made of polyester as it has low absorption of 2% & provides good strength to the fabric and polyester has a good resistance to lab grade chemicals• Inner layer is made up of cotton fabric as it gives good absorbency and comfort• Middle layer comprises of activated carbon sandwiched in cotton nonwoven

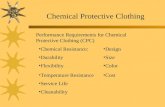

Chemical Protective Clothing

CPC Garment materials

• Textiles

• Unsupported rubber or plastics

• Microporous film basics

• Adsorbent-based fabrics

• Coated fabrics

• Plastic laminates

• Combinations

The use of excellent protective materials, effective closures, and ergonomic survival equipment for an individual will be meaningless and unproductive without proper garment designs.

There are different garment designs given as follows:

Coverall or one-piece garments

Two-piece garments

Undergarments

Multilayered garments

Closure system, components, and systems

Clothing system designs

UV exposure and human skin

Effect of UV rays on different types of skin

Radiation Protection

Ultraviolet radiation band

UVA(320 to 400 nm)

UVB(290 to 320 nm)

UVC(200 to 290 nm)

Causes little visible reaction on skin but decrease immunological response of skin cells

Responsible for development of skin cancers

Totally absorbed by atmosphere & doesn’t reach the earth

Radiation Protection

Fabric's ability to block UVR dependent on several parameters:

Principal Parameters

Fiber Chemistry Fabric Construction Moisture content Wet Processing History

WeightThicknessPorosity

Dye Concentration

FluorescentWhitening Agents

UV-absorbers

Textiles as protection from ultraviolet radiation

Schematic representation of a textile as a barrier to UV radiation

Electrostatic Protection

The term `electrostatic' or `static electricity' refers to the phenomenon associated with the build up of electrical charges generated, for example, by contact and/or rubbing of two objects. Static electricity is generated by unbalancing the molecular configuration of relatively non-conductive materials.

Discharge of static electricity

In principle, there are three methods for neutralizing charges on insulators:

conductance through the bulk of the material conductance along the surface of the material the attraction of oppositely charged ions from the air

Measurement techniques

There have been two main approaches to assessing the electrostatic propensity of textile materials.

One is to measure the charge built up on a clothed person or the electrical capacitance of a body (human-body model)

The second is to measure some electrostatic characteristics of textiles (e.g., surface resistivity, charge decay rate, peak potential, etc.) in small-scale tests.

The most common way to confer anti-static properties on a fabric is to incorporate conductive fibres/yarns.

Common conductive elements used in

fabrics include carbon, copper, silver, stainless steel or metallic salts.

The choice of conductive product will

partly depend on the end use and the required level of static protection.

Modern ESD-textiles

• Many ESD-garments are made of heterogenous composite fabrics where a grid or stripes of conductive threads are present inside an insulating matrix of cotton, polyester or mixtures of these materials.

• The conductive threads are more and more frequently made by composites, i.e. by a mixture of conductive and insulating fibres.

• There are several variations in both fabric and thread structures.

Gore-tex: Antistatic

Source: AVANTEX 2000