Proposal A

-

Upload

pulkit-aggarwal -

Category

Documents

-

view

216 -

download

4

description

Transcript of Proposal A

ENACTUS ST. STEPHENSPROJECT PROPOSAL - 2014An Enactus St Stephen’s initiative.

Enactus St Stephen’s:

• We, at Enactus St Stephen’s are a fledgling organization. Enactus was set up in St. Stephen's College in October 2013. We aim to bring the best minds together to start projects which create an impact in as many lives as possible. Being one of the premier colleges of the country that produces leaders and innovators at a formidable rate, Enactus is the perfect platform to begin our service to the community at large. Any projects undertaken will be the first of their kind at Enactus St Stephen’s. Thus our pilot project needs wings to take off.

• We acknowledge the importance of social entrepreneurship in today’s world and are committed to the values of Enactus.

• The Enactus St Stephens college team comprises of 75 members and we are one of the very few diverse society’s in St Stephens College with participation from students of all courses in our college.

• We have students from various disciplines of study such as English, Mathematics, Economics, History, and various Sciences.

Potential Project Ideas:

1. Biogas Digester

BIOGAS DIGESTER

CONCEPTION:

A bio-digester is an airtight closed container that is used to digest organic waste material and turn it into bio-gas that can in turn be relayed directly from the bio-digester to a stove for cooking gas, or to a gas heater for heat. It can also generate electricity, and even possibly later be bottled and sold for use by consumers.

The idea is to make the bio-digesters from materials that are available and relatively cheap, like recycled plastic containers, bricks or even mud and that the waste material must be adapted to local availability.

Biogas technology provides an alternative source of energy mainly from organic wastes. It is produced when bacteria degrade organic matter in the absence of air. Biogas contains around 55-65% of methane, 30-40% of carbon dioxide and small quantities of hydrogen, nitrogen, carbon monoxide, oxygen and hydrogen sulphide. The calorific value of biogas is appreciably high (around 4700 kcal or 20 MJ at around 55% methane

content).

DEMAND SIDE Demand for power in the capital broke all records in

2013 touching an all-time high of 5,653 Megawatt, triggering long power cuts in several areas due to tripping of distribution network following increased load.

The price of cooking gas cylinders is increasing in the capital.

The amount of organic waste in the capital is increasing.

TARGET COMMUNITY:

• The community is geographically located near Punjabi Bagh metro station.

• Women - work at houses near by and work as daily wage workers.

• Men - Drivers, Watchmen, Daily wage workers.

• Average income - 200 rupees per day.

• They are willing to work and accept change.

CHALLENGES FACED BY THE TARGET COMMUNITY:

• Drainage/sewage problem.

• Mosquitos, Diseases.

• They cant go to near by clinic as they demand ESI card 1 govt. toilet in locality, not clean, no water in toilets.

• 4-5 pipes in locality with irregular supply of water, sometimes dirty water.

• There is a small school , called "NAVYUVAK", but no teacher there. Have to pay 100 bucks per person to use the washroom/toilet per month.

BUSINESS MODEL

The basic plan is to make a cheap Biogas Digester systems that has minimum number of components in it (to reduce the cost).

We will then look for reliable and efficient suppliers that can provide the components, required to assemble the Biogas Digester Systems, directly to the community.

The community will then be provided with intensive training regarding the assemblage process. This will involve interaction with experts who will equip the community with adequate skills and safety guidelines simultaneously.

We will also establish a supply chain in the market to provide biogas digesters

One of our main aims and also one of the most important objectives is to keep the cost of the Biogas Digester System as low as possible such that it does not increase the financial burden on the target community.

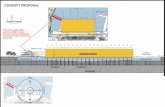

Biogas Digester Blueprint

Materials 200 ml blue plastic barrels Plastic garbage bin PVC pipes and fittings PV hoses and fittings Silicon sealer

Design

A biogas digester requires an input pipe (a place to deposit fresh feedstock), and an output pipe of some kind (for contents to be displaced out of). Design the barrel in such a way that both the input and output pipes should enter the

barrel through the top of the barrel, through the lids, and the biogas output should also be located at the top of the barrel. The biogas digester is designed to be gas-tight, so that no biogas can escape the unit except through the gas-out valve, which is a simple polytube irrigation valve. However, if for some reason pressure should build up in the system, it will simply push the contents out through one or both of the input/output pipes. The input pipe runs through one of the lids of the blue plastic barrel, and extends almost to the bottom of the barrel. This means that fresh feedstock will enter the digester at the bottom. The output pipe runs only to the centre of the barrel, which means that as fresh feedstock enters, existing liquid will be displaced from the centre of the barrel, and exit the unit into an effluent bucket. Since solid particles of organic matter usually either float or sink, it will be mostly only liquid which comes out as effluent, leaving the larger particles in the digester to break down further. Set the output pipe almost at the level of entry into the barrel, which leaves a pocket inside the dome of the top of the barrel for biogas to collect, and it is at the very top of the barrel that the gas-out valve is fixed. This means that at any given time there will be very little biogas stored in the digester – the digester will be almost completely filled with liquid, and almost all biogas will be expelled via the gas-out valve to the collector. The collector is a blue plastic barrel with its top cut off, 3/4 filled with water, with a plastic garbage bin inverted and submerged, with a gas input and a

gas output valve fitted to it. Biogas produced by the digester will collect in the garbage bin, and as the garbage bin filled, it will rise out of the water. If the unit becomes too filled with biogas, biogas will simply leak out the side.

CHALLENGES

We need to ascertain the market for the biogas digester systems: we can sell it to small business houses which need electricity supply or we can look into other options.