PROMAX VOL 1108A.pdf · 3 IMPORTANT POINTS TO REMEMBER WHEN WORKING WITH PROMAX TOOLS. PROMAX End...

Transcript of PROMAX VOL 1108A.pdf · 3 IMPORTANT POINTS TO REMEMBER WHEN WORKING WITH PROMAX TOOLS. PROMAX End...

Winning The World OverOne Amazing Tool

At A Time

Specializing In High Performance Solid Carbide Cutting Tools

High Performance ProductsFor Shops That Seek Productivity

Vol. 1108A

VAR-A-TECH

PRO-4

SERIES 101 ROUGHER

SPECIALS

P R O M A XTools

“Feel The Edge”

2

INDEX

General InformationPg. 3 & 47

Technical InformationPg. 48 - 49

Roughing End MillsGeneral Purpose Series 100 pg. 20

Space Age Exotics Series 101 pg. 21

Light Alloys Series 102 pg. 25

Hardened Materials Series 103 pg. 44

Finishing End Mills5 Flute for Super Finishing Series 112 pg. 4

4 Flute Patented PRO-4 Series 190 - Square End pg. 5 Series 191 - Corner Radius pgs. 6 - 7 Series 192 - Ball End pg. 8

4 Flute VAR-A-TECH Series 155 - Square End pg. 9 Series 156 - Corner Radius pgs. 10 - 11 Series 157 - Ball End pg. 12

4 Flute for Steels & Alloys Series 111 - Square End pg. 14 - 15 Series 129 - Corner Radius pg. 16 - 17 Series 116 - Ball Nose pg. 13

3 Flute for High Speed Machining of Aluminum Series 110 - Square End pg, 22

3 Flute for Aluminum Series 109 - Square End pg. 23

3 Flute for Stainless Steel & High Temp Alloys Series 106 - Square End pg. 26 Series 113 - Ball End pg. 27

2 Flute for Aluminum Series 108 - Square End pg. 30 Series 115 - Ball End pg. 31

Roughing-Finishing End Mills5 Flute for Steels & High Strength Alloys Series 121 - Square End pg. 19

4 Flute for Stainless Steel & Titanium Series 120 - Square End pgs. 18 - 19

3 Flute for Stainless Steel & High Temp Alloys Series 117 - Square End pg. 28 Series 122 - Ball End pg. 29

3 Flute for Aluminum Series 119 - Square End pg. 24

Die & Mold ToolsDecimal End Mills Series 330 - 2 Flute Square pg. 32 - 33 Series 331 - 2 Flute Ball pg. 32 - 33 Series 332 - 4 Flute Square pg. 34 - 35 Series 333 - 4 Flute Ball pg. 34 - 35

2 Flute Taper with Ball End Series 250 - 254 pgs. 36 - 37

4 Flute Rib Tools Series 260 - 265 - Corner Radius pgs. 38 - 40 Series 270 - 275 - Ball End pgs. 41 - 43

Multi Flute for Hardened Materials Series 154 - Square End pg. 44

Additional ToolsCorner Rounding End Mills Series 137 - 2 Flute pg. 45 Series 138 - 4 Flute pg. 45

Chamfer Spotting Tools Series 132 & 133 - 60 Degree pg. 46 Series 134 & 135 - 90 Degree pg. 46 Series 130 & 131 - 120 Degree pg. 46

3

IMPORTANT POINTS TO REMEMBER WHEN WORKING WITH PROMAX TOOLS.

PROMAX End Mills• Climbmillingistherecommendedtechniqueofmilling.

• Workpiecerigidityisnecessaryforoptimumcuttingresults.

• Correctcoolantplacementandpressureisessentialforlubricationthrough thecutandtoassureefficientchipevacuationandalongertoollife.

• Horsepowertocubicinchremovalratioshouldbecheckedforoptimal performance.

PROMAX Roughers• Theminimumradialwidthofcutshouldnotbelessthanthecornerradiusoftheendmill.

• Whenslotting,theaxialdepthofcutshouldnotexceedthediameteroftheendmill.

• Feedsandspeedsarerecommendationsandshouldbeconsideredasstartingpointswithpossiblevariationstoachieve optimumresults.

• Workpiecerigidityshouldbecheckedtoassurethereisnovibration.

• Checkthehorsepoweravailabletocubicinchofmaterialremoval.

• Thepropercoolantflowandplacementwillwashthechipsoutofthecut,thuseliminatingtherecuttingof chips,anddamagetotheendmill.

“FEEL THE EDGE”TheNEWEDGEPREPisstandardonourPROMAXEndMills.Thisallowsyoutoforgothetediousandlongbreakperiodsneededonmosttoolsinorderreceivethemostproductionoutofyourtool.Combiningouredgeprepwithoursuperiorcoatingsandtheresultsareclear–longerrunningtoolswithfewertoolchangesperrunequalingsignificantcosteffectiveness.

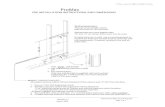

SUPERIOR TOOL DESIGN:PROMAXendmillsaremanufacturedfromhighstrength,ultrafineandsubmicrongraincarbidewithahighcobaltcontenttoproduceanextratoughendmillwhichhaveatransverserupturestrength(TRS)ashighas650,000psi.Ourendmillsareeccentricrelievedgivingthemthestrongestcuttingedgewhilerunningcoolerandsmoothertoproducebetterfinishes.WeofferTiCN,AlTiN&ZrNhardcoatingswhichincreasetoollifewhileenhancingchipflowandlubricitythroughthecut.WiththeadvancedPROMAXendmilldesign,youcanexpectyourproductivitytoincrease2to5timesoverconventionalcarbideendmills.

ECCENTRICRELIEF

RADIALRAKE

RELIEF

DIA.OFENDMILL

PROMAX Rougher-Finishers• PROMAXRougher-Finishersbridgethegapbetweenfullroughing andfinishing.

• ThePROMAXRougher-Finishercanbeusedwithanyradialdepth ofcut.

• Surfacefootagegenerallycanbeincreasedwiththerougher-finisher whenlightradialdepthsofcutsaremade.

4

CoolantSlot

5 Flute for Super Finishing

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”=+.000/-.002

HELIX ANGLE:h1/8”thru1”=40degrees

5 F

LU

TE

Series 112

FOR CHALLENGINGMATERIALThishighperformanceendmilldesignedformaximumproductioncapabilitiesiseccentricrelievedforasmootherrunningendmillwhenprofilingatmaximumspeeds.Engineeredtoaccommodatehightemperature,alloy&othermoredifficultmaterialswhileimprovingthesurfacefinishwhilereducingharmonicswith5flutegeometry.

“Feel The Edge”“Feel The Edge”DIA SHANK LOC OAL FLUTES TiCN AlTiN1/8 1/8 1/4 1-1/2 5 112-00822 112-00824

1/8 1/8 1/2 1-1/2 5 112-00812 112-00814

5/32 3/16 3/8 2 5 112-01022 112-01024

5/32 3/16 1/2 2 5 112-01012 112-01014

3/16 3/16 3/8 2 5 112-01222 112-01224

3/16 3/16 5/8 2 5 112-01212 112-01214

7/32 1/4 3/8 2 5 112-01422 112-01424

7/32 1/4 3/4 2-1/2 5 112-01412 112-01414

1/4 1/4 3/8 2 5 112-01622 112-01624

1/4 1/4 3/4 2-1/2 5 112-01612 112-01614

1/4 1/4 1-1/4 3 5 112-01632 112-01634

1/4 1/4 1-1/2 3-1/2 5 112-01642 112-01644

9/32 5/16 1/2 2-1/2 5 112-01822 112-01824

9/32 5/16 3/4 2-1/2 5 112-01812 112-01814

5/16 5/16 1/2 2-1/2 5 112-02022 112-02024

5/16 5/16 3/4 2-1/2 5 112-02012 112-02014

11/32 3/8 5/8 2 5 112-02222 112-02224

11/32 3/8 7/8 2-1/2 5 112-02212 112-02214

3/8 3/8 5/8 2 5 112-02422 112-02424

3/8 3/8 7/8 2-1/2 5 112-02412 112-02414

3/8 3/8 1-1/2 3-1/2 5 112-02432 112-02434

7/16 7/16 1 2-3/4 5 112-02812 112-02814

1/2 1/2 5/8 2-1/2 5 112-03222 112-03224

1/2 1/2 1-1/4 3 5 112-03212 112-03214

1/2 1/2 1-1/2 3-1/2 5 112-03232 112-03234

1/2 1/2 2 4 5 112-03242 112-03244

9/16 9/16 1-1/4 3-1/2 5 112-03612 112-03614

5/8 5/8 7/8 3 5 112-04022 112-04024

5/8 5/8 1-1/4 3-1/2 5 112-04012 112-04014

5/8 5/8 1-3/4 4 5 112-04032 112-04034

5/8 5/8 2-1/2 5 5 112-04042 112-04044

3/4 3/4 1 3 5 112-04822 112-04824

3/4 3/4 1-5/8 4 5 112-04812 112-04814

3/4 3/4 2-1/2 5 5 112-04832 112-04834

3/4 3/4 3-1/4 6 5 112-04842 112-04844

1 1 1-3/4 4 5 112-06412 112-06414

1 1 2-3/4 5 5 112-06432 112-06434

1 1 3-3/8 6 5 112-06442 112-06444

5

PR

O-4

DIA SHANK LOC LOR NECKDIA OAL FLUTES AlTiN

3/16 3/16 5/8 2 4 190-01214

1/4 1/4 3/8 2 4 190-01624

1/4 1/4 3/4 2-1/2 4 190-01614

1/4 1/4 3/4 2-1/8 .235 4 4 190-01664

5/16 5/16 3/4 2-1/2 4 190-02014

3/8 3/8 5/8 2 4 190-02424

3/8 3/8 7/8 2-1/2 4 190-02414

3/8 3/8 7/8 2-1/8 .355 4 4 190-02464

3/8 3/8 7/8 3-3/8 .355 6 4 190-02474

1/2 1/2 5/8 2-1/2 4 190-03224

1/2 1/2 1-1/4 3 4 190-03214

1/2 1/2 2 4 4 190-03234

1/2 1/2 1 2-3/8 .475 6 4 190-03264

1/2 1/2 1 3-3/8 .475 6 4 190-03274

1/2 1/2 1 4-1/8 .475 6 4 190-03284

5/8 5/8 7/8 3 4 190-04024

5/8 5/8 1-1/4 3-1/2 4 190-04014

5/8 5/8 1-1/4 2-3/8 .590 6 4 190-04064

5/8 5/8 1-1/4 3-3/8 .590 6 4 190-04074

5/8 5/8 1-1/4 4-1/8 .590 6 4 190-04084

3/4 3/4 1 3 4 190-04824

3/4 3/4 1-5/8 4 4 190-04814

3/4 3/4 1-5/8 2-1/2 .715 6 4 190-04864

3/4 3/4 1-5/8 3-3/8 .715 6 4 190-04874

3/4 3/4 1-5/8 4-1/8 .715 6 4 190-04884

1 1 1-3/4 4 4 190-06414

1 1 2-3/4 5 4 190-06434

1 1 1-3/4 2-1/2 .960 6 4 190-06464

1 1 1-3/4 3-3/8 .960 6 4 190-06474

1 1 1-3/4 4-1/8 .960 6 4 190-06484

Series 190PRO-4 Vibration Reducing - Square End

ThePatentedPRO-4solidcarbidehybridcuttercombinesthebestelementsofourFinishingEndMillandourRougher-Finisher.With8geometrieson4flutes,thePRO-4presentsanentirelyuniqueapproachtocommonproblemsinhigh-performancemachining.

Unique Hybrid Geometry

Cuttingedgechip-breakers&finishinggeometryappearinanalternatingpatternoneitherthelowerorupperhalfofeachflute.Intheresultingcuttingaction,achip-breakingedgeononehalfofthetoolononefluteisfollowedbyafinishingedgeinthesameregiononthefollowingflute.Thisgeometryaccomplisheswhatothergeometriesattemptthroughunequalindexingormultiplehelixes.

hEliminates Chatter & VibrationhRelieves Cutting Pressure Against The Tool With OD

Chip-Breakers While Delivering An Excellent FinishhEasy & Inexpensive To Regrind

Equallyindexedflutesrequirestandardfaceregrindingonly.NoODorspecialIndexing.hReady For Shrink-Fit Holders

hStandard With The Most Advanced Aluminum-Titanium-Nitride (AlTiN) Coating

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:3/16”thru1”:+.000/-.002

Patented

6

Series 191PRO-4 Vibration Reducing - Corner Radius

With SpecialEdge Prep

For Longer Tool Life

With SpecialEdge Prep

For Longer Tool Life

See Page 5 For PRO-4 Square End

Patented

See Page 8 For PRO-4 Ball End

PR

O-4

ThePatentedPRO-4solidcarbidehybridcuttercombinesthebestelementsofourFinishingEndMillandourRougher-Finisher.With8geometrieson4flutes,thePRO-4presentsanentirelyuniqueapproachtocommonproblemsinhigh-performancemachining.

Unique Hybrid Geometry

Cuttingedgechip-breakers&finishinggeometryappearinanalternatingpatternoneitherthelowerorupperhalfofeachflute.Intheresultingcuttingaction,achip-breakingedgeononehalfofthetoolononefluteisfollowedbyafinishingedgeinthesameregiononthefollowingflute.Thisgeometryaccomplisheswhatothergeometriesattemptthroughunequalindexingormultiplehelixes.

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:3/16”thru1”:+.000/-.002

DIA SHANK LOC LOR NECKDIA OAL .010 RADIUS

AlTiN.015 RADIUS

AlTiN.020 RADIUS

AlTiN.030 RADIUS

AlTiN.045 RADIUS

AlTiN.060 RADIUS

AlTiN.090 RADIUS

AlTiN.125 RADIUS

AlTiN

3/16 3/16 5/8 2 191-11214 191-21214 191-31214 191-412147/32 1/4 3/4 2-1/2 191-11414 191-21414 191-314141/4 1/4 3/8 2 191-11624 191-21624 191-31624 191-416241/4 1/4 3/4 2-1/2 191-11614 191-21614 191-31614 191-416141/4 1/4 3/4 2-1/8 .235 4 191-11664 191-21664 191-31664 191-416645/16 5/16 3/4 2-1/2 191-12014 191-22014 191-32014 191-420143/8 3/8 5/8 2 191-12424 191-22424 191-32424 191-424243/8 3/8 7/8 2-1/2 191-12414 191-22414 191-32414 191-424143/8 3/8 7/8 2-1/8 .355 4 191-12464 191-22464 191-32464 191-424643/8 3/8 7/8 3-3/8 .355 6 191-12474 191-22474 191-32474 191-424741/2 1/2 5/8 2-1/2 191-13224 191-23224 191-33224 191-43224 191-53224 191-632241/2 1/2 1-1/4 3 191-13214 191-23214 191-33214 191-43214 191-53214 191-632141/2 1/2 2 4 191-13234 191-23234 191-33234 191-43234 191-53234 191-632341/2 1/2 1 2-3/8 .475 6 191-13264 191-23264 191-33264 191-43264 191-53264 191-632641/2 1/2 1 3-3/8 .475 6 191-13274 191-23274 191-33274 191-43274 191-53274 191-632741/2 1/2 1 4-1/8 .475 6 191-13284 191-23284 191-33284 191-43284 191-53284 191-632845/8 5/8 7/8 3 191-14024 191-24024 191-34024 191-44024 191-640245/8 5/8 1-1/4 3-1/2 191-14014 191-24014 191-34014 191-44014 191-640145/8 5/8 1-1/4 2-3/8 .590 6 191-14064 191-24064 191-34064 191-44064 191-640645/8 5/8 1-1/4 3-3/8 .590 6 191-14074 191-24074 191-34074 191-44074 191-640745/8 5/8 1-1/4 4-1/8 .590 6 191-14084 191-24084 191-34084 191-44084 191-640843/4 3/4 1 3 191-14824 191-24824 191-34824 191-44824 191-64824 191-74824 191-848243/4 3/4 1-5/8 4 191-14814 191-24814 191-34814 191-44814 191-64814 191-74814 191-848143/4 3/4 1-5/8 2-1/2 .715 6 191-14864 191-24864 191-34864 191-44864 191-64864 191-74864 191-848643/4 3/4 1-5/8 3-3/8 .715 6 191-14874 191-24874 191-34874 191-44874 191-64874 191-74874 191-848743/4 3/4 1-5/8 4-1/8 .715 6 191-14884 191-24884 191-34884 191-44884 191-64884 191-74884 191-848841 1 1-3/4 4 191-46414 191-66414 191-76414 191-864141 1 2-3/4 5 191-46434 191-66434 191-76434 191-864341 1 1-3/4 2-1/2 .960 6 191-46464 191-66464 191-76464 191-864641 1 1-3/4 3-3/8 .960 6 191-46474 191-66474 191-76474 191-864741 1 1-3/4 4-1/8 .960 6 191-46484 191-66484 191-76484 191-86484

7

Series 191PRO-4 Vibration Reducing - Corner Radius

PR

O-4Patented

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:3/16”thru1”:+.000/-.002

See Page 16 - 17 For Series 129 4 Flute Corner Radius End Mills

DIA SHANK LOC LOR NECKDIA OAL .010 RADIUS

AlTiN.015 RADIUS

AlTiN.020 RADIUS

AlTiN.030 RADIUS

AlTiN.045 RADIUS

AlTiN.060 RADIUS

AlTiN.090 RADIUS

AlTiN.125 RADIUS

AlTiN

3/16 3/16 5/8 2 191-11214 191-21214 191-31214 191-412147/32 1/4 3/4 2-1/2 191-11414 191-21414 191-314141/4 1/4 3/8 2 191-11624 191-21624 191-31624 191-416241/4 1/4 3/4 2-1/2 191-11614 191-21614 191-31614 191-416141/4 1/4 3/4 2-1/8 .235 4 191-11664 191-21664 191-31664 191-416645/16 5/16 3/4 2-1/2 191-12014 191-22014 191-32014 191-420143/8 3/8 5/8 2 191-12424 191-22424 191-32424 191-424243/8 3/8 7/8 2-1/2 191-12414 191-22414 191-32414 191-424143/8 3/8 7/8 2-1/8 .355 4 191-12464 191-22464 191-32464 191-424643/8 3/8 7/8 3-3/8 .355 6 191-12474 191-22474 191-32474 191-424741/2 1/2 5/8 2-1/2 191-13224 191-23224 191-33224 191-43224 191-53224 191-632241/2 1/2 1-1/4 3 191-13214 191-23214 191-33214 191-43214 191-53214 191-632141/2 1/2 2 4 191-13234 191-23234 191-33234 191-43234 191-53234 191-632341/2 1/2 1 2-3/8 .475 6 191-13264 191-23264 191-33264 191-43264 191-53264 191-632641/2 1/2 1 3-3/8 .475 6 191-13274 191-23274 191-33274 191-43274 191-53274 191-632741/2 1/2 1 4-1/8 .475 6 191-13284 191-23284 191-33284 191-43284 191-53284 191-632845/8 5/8 7/8 3 191-14024 191-24024 191-34024 191-44024 191-640245/8 5/8 1-1/4 3-1/2 191-14014 191-24014 191-34014 191-44014 191-640145/8 5/8 1-1/4 2-3/8 .590 6 191-14064 191-24064 191-34064 191-44064 191-640645/8 5/8 1-1/4 3-3/8 .590 6 191-14074 191-24074 191-34074 191-44074 191-640745/8 5/8 1-1/4 4-1/8 .590 6 191-14084 191-24084 191-34084 191-44084 191-640843/4 3/4 1 3 191-14824 191-24824 191-34824 191-44824 191-64824 191-74824 191-848243/4 3/4 1-5/8 4 191-14814 191-24814 191-34814 191-44814 191-64814 191-74814 191-848143/4 3/4 1-5/8 2-1/2 .715 6 191-14864 191-24864 191-34864 191-44864 191-64864 191-74864 191-848643/4 3/4 1-5/8 3-3/8 .715 6 191-14874 191-24874 191-34874 191-44874 191-64874 191-74874 191-848743/4 3/4 1-5/8 4-1/8 .715 6 191-14884 191-24884 191-34884 191-44884 191-64884 191-74884 191-848841 1 1-3/4 4 191-46414 191-66414 191-76414 191-864141 1 2-3/4 5 191-46434 191-66434 191-76434 191-864341 1 1-3/4 2-1/2 .960 6 191-46464 191-66464 191-76464 191-864641 1 1-3/4 3-3/8 .960 6 191-46474 191-66474 191-76474 191-864741 1 1-3/4 4-1/8 .960 6 191-46484 191-66484 191-76484 191-86484

ExtendedLength

8

DIA SHANK LOC LOR NECKDIA OAL FLUTES AlTiN

3/16 3/16 5/8 2 4 192-01214

1/4 1/4 3/8 2 4 192-01624

1/4 1/4 3/4 2-1/2 4 192-01614

1/4 1/4 3/4 2-1/8 .235 4 4 192-01664

5/16 5/16 3/4 2-1/2 4 192-02014

3/8 3/8 5/8 2 4 192-02424

3/8 3/8 7/8 2-1/2 4 192-02414

3/8 3/8 7/8 2-1/8 .355 4 4 192-02464

3/8 3/8 7/8 3-3/8 .355 6 4 192-02474

1/2 1/2 5/8 2-1/2 4 192-03224

1/2 1/2 1-1/4 3 4 192-03214

1/2 1/2 2 4 4 192-03234

1/2 1/2 1 2-3/8 .475 6 4 192-03264

1/2 1/2 1 3-3/8 .475 6 4 192-03274

1/2 1/2 1 4-1/8 .475 6 4 192-03284

5/8 5/8 7/8 3 4 192-04024

5/8 5/8 1-1/4 3-1/2 4 192-04014

5/8 5/8 1-1/4 2-3/8 .590 6 4 192-04064

5/8 5/8 1-1/4 3-3/8 .590 6 4 192-04074

5/8 5/8 1-1/4 4-1/8 .590 6 4 192-04084

3/4 3/4 1 3 4 192-04824

3/4 3/4 1-5/8 4 4 192-04814

3/4 3/4 1-5/8 2-1/2 .715 6 4 192-04864

3/4 3/4 1-5/8 3-3/8 .715 6 4 192-04874

3/4 3/4 1-5/8 4-1/8 .715 6 4 192-04884

1 1 1-3/4 4 4 192-06414

1 1 2-3/4 5 4 192-06434

1 1 1-3/4 2-1/2 .960 6 4 192-06464

1 1 1-3/4 3-3/8 .960 6 4 192-06474

1 1 1-3/4 4-1/8 .960 6 4 192-06484

Series 192

PR

O-4

Patented

PRO-4 Vibration Reducing - Ball End

See Page 5 For PRO-4 Square End

See Pages 6-7 For PRO-4 Corner Radius

See Pages 18 - 19 For Series 120 4 Flute Rougher-Finishers

See Page 13 For Series 116 4 Flute Ball End Mills

hEliminates Chatter & Vibration

hRelieves Cutting Pressure Against The Tool With OD Chip-Breakers While Delivering An Excellent Finish

hEasy & Inexpensive To Regrind Equallyindexedflutesrequire standardfaceregrindingonly.No ODorspecialIndexing.

hReady For Shrink-Fit Holders

hStandard With The Most Advanced Aluminum- Titanium-Nitride (AlTiN) Coating

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:3/16”thru1”:+.000/-.002hBallRadius:+.001/-.001

9

DIA SHANK LOC LOR NECKDIA OAL FLUTES AlTiN

1/8 1/8 1/4 1-1/2 4 155-00824

1/8 1/8 1/2 1-1/2 4 155-00814

5/32 3/16 3/8 2 4 155-01024

5/32 3/16 1/2 2 4 155-01014

3/16 3/16 3/8 2 4 155-01224

3/16 3/16 5/8 2 4 155-01214

7/32 1/4 3/8 2 4 155-01424

7/32 1/4 3/4 2-1/2 4 155-01414

1/4 1/4 3/8 2 4 155-01624

1/4 1/4 3/4 2-1/2 4 155-01614

1/4 1/4 3/4 2-1/8 .235 4 4 155-01664

9/32 5/16 3/4 2-1/2 4 155-01814

5/16 5/16 1/2 2-1/2 4 155-02024

5/16 5/16 3/4 2-1/2 4 155-02014

11/32 3/8 7/8 2-1/2 4 155-02214

3/8 3/8 5/8 2 4 155-02424

3/8 3/8 7/8 2-1/2 4 155-02414

3/8 3/8 7/8 2-3/8 .355 4 4 155-02464

3/8 3/8 7/8 3-3/8 .355 6 4 155-02474

7/16 7/16 5/8 2-3/4 4 155-02824

7/16 7/16 1 2-3/4 4 155-02814

1/2 1/2 5/8 2-1/2 4 155-03224

1/2 1/2 1 3 4 155-03214

1/2 1/2 1 2-3/8 .475 6 4 155-03264

1/2 1/2 1 3-3/8 .475 6 4 155-03274

1/2 1/2 1 4-1/8 .475 6 4 155-03284

9/16 9/16 1-1/4 3-1/2 4 155-03614

5/8 5/8 7/8 3 4 155-04024

5/8 5/8 1-1/4 3-1/2 4 155-04014

5/8 5/8 1-1/4 2-3/8 .590 6 4 155-04064

5/8 5/8 1-1/4 3-3/8 .590 6 4 155-04074

5/8 5/8 1-1/4 4-1/8 .590 6 4 155-04084

3/4 3/4 1 3 4 155-04824

3/4 3/4 1-5/8 4 4 155-04814

3/4 3/4 1-5/8 2-1/2 .715 6 4 155-04864

3/4 3/4 1-5/8 3-3/8 .715 6 4 155-04874

3/4 3/4 1-5/8 4-1/8 .715 6 4 155-04884

1 1 1-3/4 4 4 155-06414

1 1 2-3/4 5 4 155-06434

1 1 1-7/8 2-1/2 .960 6 4 155-06464

1 1 1-7/8 3-3/8 .960 6 4 155-06474

1 1 1-7/8 4-1/8 .960 6 4 155-06484

Series 155VAR-A-TECH Vibration Reducing - Square End

VA

R-A

-TE

CH

VAR-A-TECHbyPROMAXwithVibrationReducingFluteGeometryhasalongertoolliferesultingingreaterproductivity.Userswillbenefitfromthereductioninchatterasitallowsformoreaggressivemachiningwithgreaterdepths-of-cutandheavierfeeds.ThisNewandexcitingtoolallowsroughingandfinishingatthesametimewhileachievingimprovedsurfacefinishes.EnjoygreatresultsinTitanium,otherHighTemperatureAlloysaswellasSteels,StainlessSteels,HighStrengthAlloysandCastIron.

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

Reduced Vibration with Special Edge Prep

UPON REQUEST:hCoolant Slots, 3/8” thru 1”hSet screw flats, 3/8” thru 1”

ExtendedLength

10

Series 156VAR-A-TECH Vibration Reducing - Corner Radius

.060 Radius

VA

R-A

-TE

CH

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002hRadius: 1/8”thru1”:+.000/-.001

Reduced Vibration with Special Edge Prep

UPON REQUEST:hCoolant Slots, 3/8” thru 1”hSet screw flats, 3/8” thru 1”

DIA SHANK LOC LOR NECKDIA OAL Flutes .010 RADIUS

AlTiN.015 RADIUS

AlTiN.020 RADIUS

AlTiN.030 RADIUS

AlTiN.045 RADIUS

AlTiN.060 RADIUS

AlTiN.090 RADIUS

AlTiN.125 RADIUS

AlTiN

1/8 1/8 1/4 1-1/2 4 156-10824 156-20824 156-308241/8 1/8 1/2 1-1/2 4 156-10814 156-20814 156-308145/32 3/16 3/8 2 4 156-11024 156-21024 156-310245/32 3/16 1/2 2 4 156-11014 156-21014 156-310143/16 3/16 3/8 2 4 156-11224 156-21224 156-31224 156-412243/16 3/16 5/8 2 4 156-11214 156-21214 156-31214 156-412147/32 1/4 3/8 2 4 156-11424 156-21424 156-314247/32 1/4 3/4 2-1/2 4 156-11414 156-21414 156-314141/4 1/4 3/8 2 4 156-11624 156-21624 156-31624 156-416241/4 1/4 3/4 2-1/2 4 156-11614 156-21614 156-31614 156-416141/4 1/4 3/4 2-1/8 .235 4 4 156-11664 156-21664 156-31664 156-416649/32 5/16 3/4 2-1/2 4 156-318145/16 5/16 1/2 2-1/2 4 156-12024 156-22024 156-32024 156-420245/16 5/16 3/4 2-1/2 4 156-12014 156-22014 156-32014 156-4201411/32 3/8 7/8 2-1/2 4 156-322143/8 3/8 5/8 2 4 156-12424 156-22424 156-32424 156-424243/8 3/8 7/8 2-1/2 4 156-12414 156-22414 156-32414 156-424143/8 3/8 7/8 2-3/8 .355 4 4 156-12464 156-22464 156-32464 156-424643/8 3/8 7/8 3-3/8 .355 6 4 156-12474 156-22474 156-32474 156-424747/16 7/16 5/8 2-3/4 4 156-328247/16 7/16 1 2-3/4 4 156-328141/2 1/2 5/8 2-1/2 4 156-13224 156-23224 156-33224 156-43224 156-53224 156-632241/2 1/2 1 3 4 156-13214 156-23214 156-33214 156-43214 156-53214 156-632141/2 1/2 1 2-3/8 .475 6 4 156-13264 156-23264 156-33264 156-43264 156-53264 156-632641/2 1/2 1 3-3/8 .475 6 4 156-13274 156-23274 156-33274 156-43274 156-53274 156-632741/2 1/2 1 4-1/8 .475 6 4 156-13284 156-23284 156-33284 156-43284 156-53284 156-632849/16 9/16 1-1/4 3-1/2 4 156-436145/8 5/8 7/8 3 4 156-14024 156-24024 156-34024 156-44024 156-640245/8 5/8 1-1/4 3-1/2 4 156-14014 156-24014 156-34014 156-44014 156-640145/8 5/8 1-1/4 2-3/8 .590 6 4 156-14064 156-24064 156-34064 156-44064 156-640645/8 5/8 1-1/4 3-3/8 .590 6 4 156-14074 156-24074 156-34074 156-44074 156-640745/8 5/8 1-1/4 4-1/8 .590 6 4 156-14084 156-24084 156-34084 156-44084 156-640843/4 3/4 1 3 4 156-14824 156-24824 156-34824 156-44824 156-64824 156-74824 156-848243/4 3/4 1-5/8 4 4 156-14814 156-24814 156-34814 156-44814 156-64814 156-74814 156-848143/4 3/4 1-5/8 2-1/2 .715 6 4 156-14864 156-24864 156-34864 156-44864 156-64864 156-74864 156-848643/4 3/4 1-5/8 3-3/8 .715 6 4 156-14874 156-24874 156-34874 156-44874 156-64874 156-74874 156-848743/4 3/4 1-5/8 4-1/8 .715 6 4 156-14884 156-24884 156-34884 156-44884 156-64884 156-74884 156-848841 1 1-3/4 4 4 156-46414 156-66414 156-76414 156-864141 1 2-3/4 5 4 156-46434 156-66434 156-76434 156-864341 1 1-7/8 2-1/2 .960 6 4 156-46464 156-66464 156-76464 156-864641 1 1-7/8 3-3/8 .960 6 4 156-46474 156-66474 156-76474 156-864741 1 1-7/8 4-1/8 .960 6 4 156-46484 156-66484 156-76484 156-86484

11

Series 156VAR-A-TECH Vibration Reducing - Corner Radius

VA

R-A

-TE

CH

DIA SHANK LOC LOR NECKDIA OAL Flutes .010 RADIUS

AlTiN.015 RADIUS

AlTiN.020 RADIUS

AlTiN.030 RADIUS

AlTiN.045 RADIUS

AlTiN.060 RADIUS

AlTiN.090 RADIUS

AlTiN.125 RADIUS

AlTiN

1/8 1/8 1/4 1-1/2 4 156-10824 156-20824 156-308241/8 1/8 1/2 1-1/2 4 156-10814 156-20814 156-308145/32 3/16 3/8 2 4 156-11024 156-21024 156-310245/32 3/16 1/2 2 4 156-11014 156-21014 156-310143/16 3/16 3/8 2 4 156-11224 156-21224 156-31224 156-412243/16 3/16 5/8 2 4 156-11214 156-21214 156-31214 156-412147/32 1/4 3/8 2 4 156-11424 156-21424 156-314247/32 1/4 3/4 2-1/2 4 156-11414 156-21414 156-314141/4 1/4 3/8 2 4 156-11624 156-21624 156-31624 156-416241/4 1/4 3/4 2-1/2 4 156-11614 156-21614 156-31614 156-416141/4 1/4 3/4 2-1/8 .235 4 4 156-11664 156-21664 156-31664 156-416649/32 5/16 3/4 2-1/2 4 156-318145/16 5/16 1/2 2-1/2 4 156-12024 156-22024 156-32024 156-420245/16 5/16 3/4 2-1/2 4 156-12014 156-22014 156-32014 156-4201411/32 3/8 7/8 2-1/2 4 156-322143/8 3/8 5/8 2 4 156-12424 156-22424 156-32424 156-424243/8 3/8 7/8 2-1/2 4 156-12414 156-22414 156-32414 156-424143/8 3/8 7/8 2-3/8 .355 4 4 156-12464 156-22464 156-32464 156-424643/8 3/8 7/8 3-3/8 .355 6 4 156-12474 156-22474 156-32474 156-424747/16 7/16 5/8 2-3/4 4 156-328247/16 7/16 1 2-3/4 4 156-328141/2 1/2 5/8 2-1/2 4 156-13224 156-23224 156-33224 156-43224 156-53224 156-632241/2 1/2 1 3 4 156-13214 156-23214 156-33214 156-43214 156-53214 156-632141/2 1/2 1 2-3/8 .475 6 4 156-13264 156-23264 156-33264 156-43264 156-53264 156-632641/2 1/2 1 3-3/8 .475 6 4 156-13274 156-23274 156-33274 156-43274 156-53274 156-632741/2 1/2 1 4-1/8 .475 6 4 156-13284 156-23284 156-33284 156-43284 156-53284 156-632849/16 9/16 1-1/4 3-1/2 4 156-436145/8 5/8 7/8 3 4 156-14024 156-24024 156-34024 156-44024 156-640245/8 5/8 1-1/4 3-1/2 4 156-14014 156-24014 156-34014 156-44014 156-640145/8 5/8 1-1/4 2-3/8 .590 6 4 156-14064 156-24064 156-34064 156-44064 156-640645/8 5/8 1-1/4 3-3/8 .590 6 4 156-14074 156-24074 156-34074 156-44074 156-640745/8 5/8 1-1/4 4-1/8 .590 6 4 156-14084 156-24084 156-34084 156-44084 156-640843/4 3/4 1 3 4 156-14824 156-24824 156-34824 156-44824 156-64824 156-74824 156-848243/4 3/4 1-5/8 4 4 156-14814 156-24814 156-34814 156-44814 156-64814 156-74814 156-848143/4 3/4 1-5/8 2-1/2 .715 6 4 156-14864 156-24864 156-34864 156-44864 156-64864 156-74864 156-848643/4 3/4 1-5/8 3-3/8 .715 6 4 156-14874 156-24874 156-34874 156-44874 156-64874 156-74874 156-848743/4 3/4 1-5/8 4-1/8 .715 6 4 156-14884 156-24884 156-34884 156-44884 156-64884 156-74884 156-848841 1 1-3/4 4 4 156-46414 156-66414 156-76414 156-864141 1 2-3/4 5 4 156-46434 156-66434 156-76434 156-864341 1 1-7/8 2-1/2 .960 6 4 156-46464 156-66464 156-76464 156-864641 1 1-7/8 3-3/8 .960 6 4 156-46474 156-66474 156-76474 156-864741 1 1-7/8 4-1/8 .960 6 4 156-46484 156-66484 156-76484 156-86484

12

DIA SHANK LOC LOR NECKDIA OAL FLUTES AlTiN

1/8 1/8 1/4 1-1/2 4 157-00824

1/8 1/8 1/2 1-1/2 4 157-00814

5/32 3/16 3/8 2 4 157-01024

5/32 3/16 1/2 2 4 157-01014

3/16 3/16 3/8 2 4 157-01224

3/16 3/16 5/8 2 4 157-01214

7/32 1/4 3/8 2 4 157-01424

7/32 1/4 3/4 2-1/2 4 157-01414

1/4 1/4 3/8 2 4 157-01624

1/4 1/4 3/4 2-1/2 4 157-01614

1/4 1/4 3/4 2-1/8 .235 4 4 157-01664

9/32 5/16 3/4 2-1/2 4 157-01814

5/16 5/16 1/2 2-1/2 4 157-02024

5/16 5/16 3/4 2-1/2 4 157-02014

11/32 3/8 7/8 2-1/2 4 157-02214

3/8 3/8 5/8 2 4 157-02424

3/8 3/8 7/8 2-1/2 4 157-02414

3/8 3/8 7/8 2-3/8 .355 4 4 157-02464

3/8 3/8 7/8 3-3/8 .355 6 4 157-02474

7/16 7/16 5/8 2-3/4 4 157-02824

7/16 7/16 1 2-3/4 4 157-02814

1/2 1/2 5/8 2-1/2 4 157-03224

1/2 1/2 1 3 4 157-03214

1/2 1/2 1 2-3/8 .475 6 4 157-03264

1/2 1/2 1 3-3/8 .475 6 4 157-03274

1/2 1/2 1 4-1/8 .475 6 4 157-03284

9/16 9/16 1-1/4 3-1/2 4 157-03614

5/8 5/8 7/8 3 4 157-04024

5/8 5/8 1-1/4 3-1/2 4 157-04014

5/8 5/8 1-1/4 2-3/8 .590 6 4 157-04064

5/8 5/8 1-1/4 3-3/8 .590 6 4 157-04074

5/8 5/8 1-1/4 4-1/8 .590 6 4 157-04084

3/4 3/4 1 3 4 157-04824

3/4 3/4 1-5/8 4 4 157-04814

3/4 3/4 1-5/8 2-1/2 .715 6 4 157-04864

3/4 3/4 1-5/8 3-3/8 .715 6 4 157-04874

3/4 3/4 1-5/8 4-1/8 .715 6 4 157-04884

1 1 1-3/4 4 4 157-06414

1 1 2-3/4 5 4 157-06434

1 1 1-7/8 2-1/2 .960 6 4 157-06464

1 1 1-7/8 3-3/8 .960 6 4 157-06474

1 1 1-7/8 4-1/8 .960 6 4 157-06484

Series 157VAR-A-TECH Vibration Reducing - Ball End

VA

R-A

-TE

CH

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002hCuttingRadius: 1/8”thru1”:+.001/-.001

UPON REQUEST:hCoolant Slots, 3/8” thru 1”hSet screw flats, 3/8” thru 1”

“Feel The Edge”“Feel The Edge”

VAR-A-TECHbyPROMAXwithVibrationReducingFluteGeometryhasalongertoolliferesultingingreaterproductivity.WiththisBallEndversionoftheVAR-A-TECH,userswillbenefitfromthereductioninchatterasitallowsformoreaggressivemachiningwithgreaterdepths-of-cutandheavierfeeds.ThisNewandexcitingtoolallowsroughingandfinishingatthesametimewhileachievingimprovedsurfacefinishes.EnjoyfantasticresultsinTitanium,otherHighTemperatureAlloysaswellasSteels,StainlessSteels,HighStrengthAlloysandCastIron.

ExtendedLength

13

DIA SHANK LOC LOR NECKDIA OAL FLUTES TiCN AlTiN

1/32 1/8 3/32 1-1/2 4 116-00212 116-00214

3/64 1/8 9/64 1-1/2 4 116-00312 116-00314

1/16 1/8 3/16 1-1/2 4 116-00412 116-00414

5/64 1/8 1/4 1-1/2 4 116-00512 116-00514

3/32 1/8 9/32 1-1/2 4 116-00612 116-00614

7/64 1/8 3/8 1-1/2 4 116-00712 116-00714

1/8 1/8 1/2 1-1/2 4 116-00812 116-00814

3/16 3/16 5/8 2 4 116-01212 116-01214

1/4 1/4 3/4 2-1/2 4 116-01612 116-01614

1/4 1/4 1-1/4 3 4 116-01632 116-01634

1/4 1/4 3/8 2-1/8 .235 4 4 116-01662 116-01664

5/16 5/16 3/4 2-1/2 4 116-02012 116-02014

5/16 5/16 7/16 2-1/8 .297 4 4 116-02062 116-02064

3/8 3/8 7/8 2-1/2 4 116-02412 116-02414

3/8 3/8 1-1/2 3-1/2 4 116-02432 116-02434

3/8 3/8 1/2 2-1/8 .355 6 4 116-02462 116-02464

3/8 3/8 1/2 3-3/8 .355 6 4 116-02472 116-02474

7/16 7/16 1 2-3/4 4 116-02812 116-02814

1/2 1/2 1-1/4 3 4 116-03212 116-03214

1/2 1/2 2 4 4 116-03242 116-03244

1/2 1/2 5/8 2-3/8 .475 6 4 116-03262 116-03264

1/2 1/2 5/8 3-3/8 .475 6 4 116-03272 116-03274

1/2 1/2 5/8 4-1/8 .475 6 4 116-03282 116-03284

9/16 9/16 1-1/4 3-1/2 4 116-03612 116-03614

5/8 5/8 1-1/4 3-1/2 4 116-04012 116-04014

5/8 5/8 2-1/2 5 4 116-04042 116-04044

5/8 5/8 3/4 2-3/8 .590 6 4 116-04062 116-04064

5/8 5/8 3/4 3-3/8 .590 6 4 116-04072 116-04074

5/8 5/8 3/4 4-1/8 .590 6 4 116-04082 116-04084

3/4 3/4 1-5/8 4 4 116-04812 116-04814

3/4 3/4 1 2-1/2 .715 6 4 116-04862 116-04864

3/4 3/4 1 3-3/8 .715 6 4 116-04872 116-04874

3/4 3/4 1 4-1/8 .715 6 4 116-04882 116-04884

3/4 3/4 3-1/4 6 4 116-04842 116-04844

1 1 1-3/4 4 4 116-06412 116-06414

1 1 1-1/4 2-1/2 .960 6 4 116-06462 116-06464

1 1 1-1/4 3-3/8 .960 6 4 116-06472 116-06474

1 1 1-1/4 4-1/8 .960 6 4 116-06482 116-06484

1 1 3-3/8 6 4 116-06442 116-06444

Series 1164 Flute Ball End Mills For Mild Steels & Alloys

HELICAL BALLRADIUSAneccentricreliefcuttingedge,&excellentchipflowreduceschatterinprofiling,pocketingandshallowslottingapplications.Designedforlowandhighcarbonsteels,stainlesssteel&high strength alloy materials.

HELIX ANGLE:h1/32”thru7/64”=30degreesh1/8”thru1”=40degrees

UPON REQUEST:hCoolantSlots,1/4”thru1”hSetscrewflats,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/32”thru7/64”=+.000/.0005 1/8”thru1”=+.000/-.002hBallRadius:+.001/-.001

With Special

Edge Prep

For Longer Tool Life

With Special

Edge Prep

For Longer Tool Life

4 F

LU

TE

14

DIA SHANK LOC LOR NECKDIA OAL FLUTES TiCN AlTiN

1/32 1/8 3/32 1-1/2 4 111-00212 111-00214

3/64 1/8 9/64 1-1/2 4 111-00312 111-00314

1/16 1/8 1/8 1-1/2 4 111-00422 111-00424

1/16 1/8 3/16 1-1/2 4 111-00412 111-00414

5/64 1/8 1/4 1-1/2 4 111-00512 111-00514

3/32 1/8 3/16 1-1/2 4 111-00622 111-00624

3/32 1/8 9/32 1-1/2 4 111-00612 111-00614

7/64 1/8 3/16 1-1/2 4 111-00722 111-00724

7/64 1/8 3/8 1-1/2 4 111-00712 111-00714

1/8 1/8 1/4 1-1/2 4 111-00822 111-00824

1/8 1/8 1/2 1-1/2 4 111-00812 111-00814

5/32 3/16 3/8 2 4 111-01022 111-01024

5/32 3/16 1/2 2 4 111-01012 111-01014

3/16 3/16 3/8 2 4 111-01222 111-01224

3/16 3/16 5/8 2 4 111-01212 111-01214

7/32 1/4 3/8 2 4 111-01422 111-01424

7/32 1/4 3/4 2-1/2 4 111-01412 111-01414

1/4 1/4 3/8 2 4 111-01622 111-01624

1/4 1/4 3/4 2-1/2 4 111-01612 111-01614

1/4 1/4 1-1/4 3 4 111-01632 111-01634

1/4 1/4 1-1/2 3-1/2 4 111-01642 111-01644

1/4 1/4 3/8 2-1/8 .235 4 4 111-01662 111-01664

9/32 5/16 1/2 2-1/2 4 111-01822 111-01824

9/32 5/16 3/4 2-1/2 4 111-01812 111-01814

5/16 5/16 1/2 2-1/2 4 111-02022 111-02024

5/16 5/16 3/4 2-1/2 4 111-02012 111-02014

5/16 5/16 7/16 2-1/8 .297 4 4 111-02062 111-02064

11/32 3/8 5/8 2 4 111-02222 111-02224

11/32 3/8 7/8 2-1/2 4 111-02212 111-02214

3/8 3/8 5/8 2 4 111-02422 111-02424

3/8 3/8 7/8 2-1/2 4 111-02412 111-02414

3/8 3/8 1-1/2 3-1/2 4 111-02432 111-02434

3/8 3/8 2 4 4 111-02442 111-02444

3/8 3/8 1/2 2-1/8 .355 6 4 111-02462 111-02464

3/8 3/8 1/2 3-3/8 .355 6 4 111-02472 111-02474

7/16 7/16 1 2-3/4 4 111-02812 111-02814

1/2 1/2 5/8 2-1/2 4 111-03222 111-03224

Series 1114 Flute End Mills For Steels & Alloys

HIGHER CHIP LOADSA4flutefinishingtoolforlow&highcarbonsteels,stainlesssteel&hightemperaturealloys,itwasdesignedwitheccentricrelief,creatinga25%strongercuttingedgewhilerunningsmootheratmaximumspeeds.Improvedsurfacefinishathigherchiploads.Duetothebalanceofthegeometry,substrate&coatingsthishighperformanceendmillwillachievelevelsneverthoughttobeattainable.

HELIX ANGLE:h1/32”thru7/64”=30degreesh1/8”thru1”=40degrees

UPON REQUEST:hCoolant,3/8”thru1”hSetscrewflats,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/32”thru7/64”=+.000/-.0005 1/8”thru1”=+.000/-.002

“Feel The Edge”“Feel The Edge”

4 F

LU

TE

15

DIA SHANK LOC LOR NECKDIA OAL FLUTES TiCN AlTiN

1/2 1/2 1-1/4 3 4 111-03212 111-03214

1/2 1/2 1-1/2 3-1/2 4 111-03232 111-03234

1/2 1/2 2 4 4 111-03242 111-03244

1/2 1/2 5/8 2-3/8 .475 6 4 111-03262 111-03264

1/2 1/2 5/8 3-3/8 .475 6 4 111-03272 111-03274

1/2 1/2 5/8 4-1/8 .475 6 4 111-03282 111-03284

9/16 9/16 1-1/4 3-1/2 4 111-03612 111-03614

5/8 5/8 7/8 3 4 111-04022 111-04024

5/8 5/8 1-1/4 3-1/2 4 111-04012 111-04014

5/8 5/8 1-3/4 4 4 111-04032 111-04034

5/8 5/8 2-1/2 5 4 111-04042 111-04044

5/8 5/8 3/4 2-3/8 .590 6 4 111-04062 111-04064

5/8 5/8 3/4 3-3/8 .590 6 4 111-04072 111-04074

5/8 5/8 3/4 4-1/8 .590 6 4 111-04082 111-04084

3/4 3/4 1 3 4 111-04822 111-04824

3/4 3/4 1-5/8 4 4 111-04812 111-04814

3/4 3/4 2-1/2 5 4 111-04832 111-04834

3/4 3/4 1 2-1/2 .715 6 4 111-04862 111-04864

3/4 3/4 1 3-3/8 .715 6 4 111-04872 111-04874

3/4 3/4 1 4-1/8 .715 6 4 111-04882 111-04884

3/4 3/4 3-1/4 6 4 111-04842 111-04844

1 1 1-3/4 4 4 111-06412 111-06414

1 1 2-3/4 5 4 111-06432 111-06434

1 1 1-1/4 2-1/2 .960 6 4 111-06462 111-06464

1 1 1-1/4 3-3/8 .960 6 4 111-06472 111-06474

1 1 1-1/4 4-1/8 .960 6 4 111-06482 111-06484

ExtendedLength

Series 1114 Flute End Mills For Steels & Alloys

See Page 16 - 17 For 4 Flute Corner Radius ToolsSee Page 13 For 4 Flute Ball Nose Tools

OurexperiencedandqualitySpecialsDepartment,withstate-of-the-artequipment,isreadytomeetyourspecificrequests.

4 F

LU

TE

16

Series 1294 Flute Corner Radius End Mills

StandardLength

4 F

LU

TE

.060 Radius

DIA SHANK LOC LOR NECKDIA OAL

.010 RADIUSTiCN

.010 RADIUSAlTiN

.015 RADIUSTiCN

.015 RADIUSAlTiN

.020 RADIUSTiCN

.020 RADIUSAlTiN

.030 RADIUSTiCN

.030 RADIUSAlTiN

.045 RADIUSTiCN

.045 RADIUSAlTiN

.060 RADIUSTiCN

.060 RADIUSAlTiN

.090 RADIUSTiCN

.090 RADIUSAlTiN

.125 RADIUSTiCN

.125 RADIUSAlTiN

1/8 1/8 1/2 1-1/2 129-10812 129-10814 129-20812 129-20814 129-30812 129-308143/16 3/16 5/8 2 129-11212 129-11214 129-21212 129-21214 129-31212 129-31214 129-41212 129-412141/4 1/4 3/4 2-1/2 129-11612 129-11614 129-21612 129-21614 129-31612 129-31614 129-41612 129-416141/4 1/4 3/8 2-1/8 .235 4 129-11662 129-11664 129-21662 129-21664 129-31662 129-31664 129-41662 129-416645/16 5/16 3/4 2-1/2 129-12012 129-12014 129-22012 129-22014 129-32012 129-32014 129-42012 129-420145/16 5/16 7/16 2-1/8 .297 4 129-12062 129-12064 129-22062 129-22064 129-32062 129-32064 129-42062 129-420643/8 3/8 7/8 2-1/2 129-12412 129-12414 129-22412 129-22414 129-32412 129-32414 129-42412 129-42414 129-62412 129-624143/8 3/8 1/2 2-1/8 .355 6 129-12462 129-12464 129-22462 129-22464 129-32462 129-32464 129-42462 129-42464 129-62462 129-624643/8 3/8 1/2 3-3/8 .355 6 129-12472 129-12474 129-22472 129-22474 129-32472 129-32474 129-42472 129-42474 129-62472 129-624741/2 1/2 1-1/4 3 129-13212 129-13214 129-23212 129-23214 129-33212 129-33214 129-43212 129-43214 129-53212 129-53214 129-63212 129-632141/2 1/2 5/8 2-3/8 .475 6 129-13262 129-13264 129-23262 129-23264 129-33262 129-33264 129-43262 129-43264 129-63262 129-632641/2 1/2 5/8 3-3/8 .475 6 129-13272 129-13274 129-23272 129-23274 129-33272 129-33274 129-43272 129-43274 129-63272 129-632741/2 1/2 5/8 4-1/8 .475 6 129-13282 129-13284 129-23282 129-23284 129-33282 129-33284 129-43282 129-43284 129-63282 129-632845/8 5/8 1-1/4 3-1/2 129-14012 129-14014 129-24012 129-24014 129-34012 129-34014 129-44012 129-44014 129-64012 129-640145/8 5/8 3/4 2-3/8 .590 6 129-14062 129-14064 129-24062 129-24064 129-34062 129-34064 129-44062 129-44064 129-64062 129-64064 129-74062 129-740645/8 5/8 3/4 3-3/8 .590 6 129-14072 129-14074 129-24072 129-24074 129-34072 129-34074 129-44072 129-44074 129-64072 129-64074 129-74072 129-740745/8 5/8 3/4 4-1/8 .590 6 129-14082 129-14084 129-24082 129-24084 129-34082 129-34084 129-44082 129-44084 129-64082 129-64084 129-74082 129-740843/4 3/4 1-5/8 4 129-14812 129-14814 129-24812 129-24814 129-34812 129-34814 129-44812 129-44814 129-64812 129-64814 129-74812 129-74814 129-84812 129-848143/4 3/4 1 2-1/2 .715 6 129-14862 129-14864 129-24862 129-24864 129-34862 129-34864 129-44862 129-44864 129-64862 129-64864 129-74862 129-74864 129-84862 129-848643/4 3/4 1 3-3/8 .715 6 129-14872 129-14874 129-24872 129-24874 129-34872 129-34874 129-44872 129-44874 129-64872 129-64874 129-74872 129-74874 129-84872 129-848743/4 3/4 1 4-1/8 .715 6 129-14882 129-14884 129-24882 129-24884 129-34882 129-34884 129-44882 129-44884 129-64882 129-64884 129-74882 129-74884 129-84882 129-848841 1 1-3/4 4 129-46412 129-46414 129-66412 129-66414 129-76412 129-76414 129-86412 129-864141 1 1-1/4 2-1/2 .960 6 129-46462 129-46464 129-66462 129-66464 129-76462 129-76464 129-86462 129-864641 1 1-1/4 3-3/8 .960 6 129-46472 129-46474 129-66472 129-66474 129-76472 129-76474 129-86472 129-864741 1 1-1/4 4-1/8 .960 6 129-46482 129-46484 129-66482 129-66484 129-76482 129-76484 129-86482 129-86484

SMOOTH AT MAXIMUM SPEEDSDesignedforfinishradiusapplications,theSeries129iseccentricrelievedandrunsexceptionallysmoothatmaximumspeeds.Theyalsoallowforimprovedsurfacefinishesinprofile&pocketapplications.

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

TOLERANCES:hDiameter: 1/8”thru1”=+.000/-.002hCornerRadius:+/-.001 HELIX ANGLE:

h1/8”thru1”=40degrees

With Special Edge Prep For Longer Tool Life

With Special Edge Prep For Longer Tool Life

17

Series 1294 Flute Corner Radius End Mills

ExtendedLength

4 F

LU

TE

Let PROMAX help you.Contact our Technical Service & Quotes Department

at 800-878-0502and receive your Specials with PROMAX Quality.

Special Needs . . .

Special Tools . . .

Modifications . . .

DIA SHANK LOC LOR NECKDIA OAL

.010 RADIUSTiCN

.010 RADIUSAlTiN

.015 RADIUSTiCN

.015 RADIUSAlTiN

.020 RADIUSTiCN

.020 RADIUSAlTiN

.030 RADIUSTiCN

.030 RADIUSAlTiN

.045 RADIUSTiCN

.045 RADIUSAlTiN

.060 RADIUSTiCN

.060 RADIUSAlTiN

.090 RADIUSTiCN

.090 RADIUSAlTiN

.125 RADIUSTiCN

.125 RADIUSAlTiN

1/8 1/8 1/2 1-1/2 129-10812 129-10814 129-20812 129-20814 129-30812 129-308143/16 3/16 5/8 2 129-11212 129-11214 129-21212 129-21214 129-31212 129-31214 129-41212 129-412141/4 1/4 3/4 2-1/2 129-11612 129-11614 129-21612 129-21614 129-31612 129-31614 129-41612 129-416141/4 1/4 3/8 2-1/8 .235 4 129-11662 129-11664 129-21662 129-21664 129-31662 129-31664 129-41662 129-416645/16 5/16 3/4 2-1/2 129-12012 129-12014 129-22012 129-22014 129-32012 129-32014 129-42012 129-420145/16 5/16 7/16 2-1/8 .297 4 129-12062 129-12064 129-22062 129-22064 129-32062 129-32064 129-42062 129-420643/8 3/8 7/8 2-1/2 129-12412 129-12414 129-22412 129-22414 129-32412 129-32414 129-42412 129-42414 129-62412 129-624143/8 3/8 1/2 2-1/8 .355 6 129-12462 129-12464 129-22462 129-22464 129-32462 129-32464 129-42462 129-42464 129-62462 129-624643/8 3/8 1/2 3-3/8 .355 6 129-12472 129-12474 129-22472 129-22474 129-32472 129-32474 129-42472 129-42474 129-62472 129-624741/2 1/2 1-1/4 3 129-13212 129-13214 129-23212 129-23214 129-33212 129-33214 129-43212 129-43214 129-53212 129-53214 129-63212 129-632141/2 1/2 5/8 2-3/8 .475 6 129-13262 129-13264 129-23262 129-23264 129-33262 129-33264 129-43262 129-43264 129-63262 129-632641/2 1/2 5/8 3-3/8 .475 6 129-13272 129-13274 129-23272 129-23274 129-33272 129-33274 129-43272 129-43274 129-63272 129-632741/2 1/2 5/8 4-1/8 .475 6 129-13282 129-13284 129-23282 129-23284 129-33282 129-33284 129-43282 129-43284 129-63282 129-632845/8 5/8 1-1/4 3-1/2 129-14012 129-14014 129-24012 129-24014 129-34012 129-34014 129-44012 129-44014 129-64012 129-640145/8 5/8 3/4 2-3/8 .590 6 129-14062 129-14064 129-24062 129-24064 129-34062 129-34064 129-44062 129-44064 129-64062 129-64064 129-74062 129-740645/8 5/8 3/4 3-3/8 .590 6 129-14072 129-14074 129-24072 129-24074 129-34072 129-34074 129-44072 129-44074 129-64072 129-64074 129-74072 129-740745/8 5/8 3/4 4-1/8 .590 6 129-14082 129-14084 129-24082 129-24084 129-34082 129-34084 129-44082 129-44084 129-64082 129-64084 129-74082 129-740843/4 3/4 1-5/8 4 129-14812 129-14814 129-24812 129-24814 129-34812 129-34814 129-44812 129-44814 129-64812 129-64814 129-74812 129-74814 129-84812 129-848143/4 3/4 1 2-1/2 .715 6 129-14862 129-14864 129-24862 129-24864 129-34862 129-34864 129-44862 129-44864 129-64862 129-64864 129-74862 129-74864 129-84862 129-848643/4 3/4 1 3-3/8 .715 6 129-14872 129-14874 129-24872 129-24874 129-34872 129-34874 129-44872 129-44874 129-64872 129-64874 129-74872 129-74874 129-84872 129-848743/4 3/4 1 4-1/8 .715 6 129-14882 129-14884 129-24882 129-24884 129-34882 129-34884 129-44882 129-44884 129-64882 129-64884 129-74882 129-74884 129-84882 129-848841 1 1-3/4 4 129-46412 129-46414 129-66412 129-66414 129-76412 129-76414 129-86412 129-864141 1 1-1/4 2-1/2 .960 6 129-46462 129-46464 129-66462 129-66464 129-76462 129-76464 129-86462 129-864641 1 1-1/4 3-3/8 .960 6 129-46472 129-46474 129-66472 129-66474 129-76472 129-76474 129-86472 129-864741 1 1-1/4 4-1/8 .960 6 129-46482 129-46484 129-66482 129-66484 129-76482 129-76484 129-86482 129-86484

“Feel The Edge”“Feel The Edge”

18

DIA SHANK LOC LOR NECKDIA RADIUS OAL FLUTES TiCN AlTiN

1/8 1/8 1/4 .010 1-1/2 4 120-00822 120-00824

1/8 1/8 1/2 .010 1-1/2 4 120-00812 120-00814

5/32 3/16 3/8 .010 2 4 120-01022 120-01024

5/32 3/16 1/2 .010 2 4 120-01012 120-01014

3/16 3/16 3/8 .010 2 4 120-01222 120-01224

3/16 3/16 5/8 .010 2 4 120-01212 120-01214

7/32 1/4 3/8 .020 2 4 120-01422 120-01424

7/32 1/4 3/4 .020 2-1/2 4 120-01412 120-01414

1/4 1/4 3/8 .020 2 4 120-01622 120-01624

1/4 1/4 3/4 .020 2-1/2 4 120-01612 120-01614

1/4 1/4 1-1/4 .020 3 4 120-01632 120-01634

1/4 1/4 1-1/2 .020 3-1/2 4 120-01642 120-01644

1/4 1/4 3/4 2-1/8 .235 .020 4 4 120-01662 120-01664

9/32 5/16 1/2 .020 2-1/2 4 120-01822 120-01824

9/32 5/16 3/4 .020 2-1/2 4 120-01812 120-01814

5/16 5/16 1/2 .020 2-1/2 4 120-02022 120-02024

5/16 5/16 3/4 .020 2-1/2 4 120-02012 120-02014

11/32 3/8 5/8 .020 2 4 120-02222 120-02224

11/32 3/8 7/8 .020 2-1/2 4 120-02212 120-02214

3/8 3/8 5/8 .020 2 4 120-02422 120-02424

3/8 3/8 7/8 .020 2-1/2 4 120-02412 120-02414

3/8 3/8 1-1/2 .020 3-1/2 4 120-02432 120-02434

3/8 3/8 7/8 2-1/8 .355 .020 4 4 120-02462 120-02464

3/8 3/8 2 .020 4 4 120-02442 120-02444

3/8 3/8 7/8 3-3/8 .355 .020 6 4 120-02472 120-02474

7/16 7/16 1 .020 2-3/4 4 120-02812 120-02814

1/2 1/2 5/8 .020 2-1/2 4 120-03222 120-03224

1/2 1/2 1-1/4 .020 3 4 120-03212 120-03214

1/2 1/2 1-1/2 .020 3-1/2 4 120-03232 120-03234

1/2 1/2 2 .020 4 4 120-03242 120-03244

1/2 1/2 1 2-3/8 .475 .020 6 4 120-03262 120-03264

1/2 1/2 1 3-3/8 .475 .020 6 4 120-03272 120-03274

1/2 1/2 1 4-1/8 .475 .020 6 4 120-03282 120-03284

9/16 9/16 1-1/4 .030 3-1/2 4 120-03612 120-03614

5/8 5/8 7/8 .030 3 4 120-04022 120-04024

5/8 5/8 1-1/4 .030 3-1/2 4 120-04012 120-04014

5/8 5/8 1-3/4 .030 4 4 120-04032 120-04034

Series 1204 Flute Rougher-Finisher for All Material Types

4 F

LU

TE

With Special

Edge Prep

For Longer Tool Life

With Special

Edge Prep

For Longer Tool Life

19

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1/4”:+.000/-.002 9/32”thru1”:+.000/-.003

DIA SHANK LOC LOR NECKDIA RADIUS OAL FLUTES TiCN AlTiN

5/8 5/8 2-1/2 .030 5 4 120-04042 120-04044

5/8 5/8 1-1/4 2-3/8 .590 .030 6 4 120-04062 120-04064

5/8 5/8 1-1/4 3-3/8 .590 .030 6 4 120-04072 120-04074

5/8 5/8 1-1/4 4-1/8 .590 .030 6 4 120-04082 120-04084

3/4 3/4 1 .030 3 4 120-04822 120-04824

3/4 3/4 1-5/8 .030 4 4 120-04812 120-04814

3/4 3/4 1-5/8 2-1/2 .715 .030 6 4 120-04862 120-04864

3/4 3/4 1-5/8 3-3/8 .715 .030 6 4 120-04872 120-04874

3/4 3/4 1-5/8 4-1/8 .715 .030 6 4 120-04882 120-04884

1 1 1-3/4 .030 4 4 120-06412 120-06414

1 1 1-3/4 2-1/2 .960 .030 6 4 120-06462 120-06464

1 1 1-3/4 3-3/8 .960 .030 6 4 120-06472 120-06474

1 1 1-3/4 4-1/8 .960 .030 6 4 120-06482 120-06484

Series 121

DIA SHANK LOC RADIUS OAL FLUTES TiCN AlTiN

3/4 3/4 2-1/2 .030 5 5 121-04832 121-04834

3/4 3/4 3-1/4 .030 6 5 121-04842 121-04844

1 1 2-3/4 .030 5 5 121-06432 121-06434

1 1 3-3/8 .030 6 5 121-06442 121-06444

Series 1204 Flute Rougher-Finisher for All Material Types

5 Flute for Steels & High Strength Alloys

GREAT SURFACE FINISH:Bridgingthegapbetweenfullroughing&finishingapplicationswhilemaintaininganexceptionalpartsurfacefinish,ourSeries120&121endmillsrelievetoolpressureduringmachining.Acornerradiusisstandardforimprovededgeprotection.ThesetoolsareperfectwhenmachiningInconel,Titanium&StainlessSteel.

HELIX ANGLE:h1/8”thru1”=40degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

4 F

LU

TE

5 F

LU

TE

SET SCREW FLATS:hStandardon3/8”thru1”hFlatsNOTincludedontoolswithLOR

20

DIA SHANK LOC OAL FLUTES TiCN AlTiN

3/16 3/16 3/8 2 3 100-01222 100-01224

3/16 3/16 5/8 2 3 100-01212 100-01214

1/4 1/4 3/8 2 4 100-01622 100-01624

1/4 1/4 3/4 2-1/2 4 100-01612 100-01614

5/16 5/16 1/2 2-1/2 4 100-02022 100-02024

5/16 5/16 3/4 2-1/2 4 100-02012 100-02014

3/8 3/8 5/8 2 4 100-02422 100-02424

3/8 3/8 7/8 2-1/2 4 100-02412 100-02414

7/16 7/16 1 2-3/4 4 100-02812 100-02814

1/2 1/2 5/8 2-1/2 4 100-03222 100-03224

1/2 1/2 1-1/4 3 4 100-03212 100-03214

1/2 1/2 1-1/2 3-1/2 4 100-03232 100-03234

9/16 9/16 1-1/4 3-1/2 4 100-03612 100-03614

5/8 5/8 7/8 3 4 100-04022 100-04024

5/8 5/8 1-1/4 3-1/2 4 100-04012 100-04014

5/8 5/8 2 4 4 100-04032 100-04034

3/4 3/4 1 3 4 100-04822 100-04824

3/4 3/4 1-5/8 4 4 100-04812 100-04814

3/4 3/4 2-1/4 5 4 100-04832 100-04834

1 1 1-3/4 4 5 100-06412 100-06414

1 1 2-5/8 5 5 100-06432 100-06434

Series 100

4 F

LU

TE

4 Flute General Purpose Roughing End Mill

ROUGHING APPLICATIONSSeries 100 Roughing End Mills are recommended for general purpose applications in material up to 50 Rc, including normalized carbon & alloy steels, cast steels, stainless steels, cast irons, brass and bronze.

HELIX ANGLE:h1/4”thru1”=30degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:+.000/-.005

CORNER RADIUS:(Tostrengthenendteeth)

h3/16”=.025/.035h1/4”thru5/16”=.040/.050h3/8”thru1”=.055/.065

SET SCREW FLATS:hStandardon3/8”thru1”

EachPROMAXToolhasSpecialEdgePreptoreduceoreveneliminatethetimelyBreak-Inprocess.

“FEEL THE EDGE”

21

DIA SHANK LOC OAL FLUTES TiCN AlTiN

3/16 3/16 3/8 2 3 101-01222 101-01224

3/16 3/16 5/8 2 3 101-01212 101-01214

1/4 1/4 3/8 2 4 101-01622 101-01624

1/4 1/4 3/4 2-1/2 4 101-01612 101-01614

5/16 5/16 1/2 2-1/2 4 101-02022 101-02024

5/16 5/16 3/4 2-1/2 4 101-02012 101-02014

3/8 3/8 5/8 2 4 101-02422 101-02424

3/8 3/8 7/8 2-1/2 4 101-02412 101-02414

7/16 7/16 1 2-3/4 4 101-02812 101-02814

1/2 1/2 5/8 2-1/2 4 101-03222 101-03224

1/2 1/2 1-1/4 3 4 101-03212 101-03214

1/2 1/2 1-1/2 3-1/2 4 101-03232 101-03234

9/16 9/16 1-1/4 3-1/2 4 101-03612 101-03614

5/8 5/8 7/8 3 4 101-04022 101-04024

5/8 5/8 1-1/4 3-1/2 4 101-04012 101-04014

5/8 5/8 2 4 4 101-04032 101-04034

3/4 3/4 1 3 4 101-04822 101-04824

3/4 3/4 1-5/8 4 4 101-04812 101-04814

3/4 3/4 2-1/4 5 4 101-04832 101-04834

1 1 1-3/4 4 6 101-06412 101-06414

1 1 2-5/8 5 6 101-06432 101-06434

Series 101

4 F

LU

TE

4 Flute Roughing End Mills for Space Age Exotics

ROUGHINGTHE EXOTICSSeries101RoughingEndMillsaredesignedforspaceageexoticmaterials,liketitanium&nickelbased/hightemperaturealloys(inconel,rene,wasploy,etc).Itshi-helix&fineprofilegeometryreducestoolpressure&generateslessheatwhileallowingheaviercutsatincreasedfeedrates.

HELIX ANGLE:h3/16”thru1”=40degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:+.000/-.005

CORNER RADIUS:(Tostrengthenendteeth)

h3/16”=.025/.035h1/4”thru5/16”=.040/.050h3/8”thru1”=.055/.065

SET SCREW FLATS:hStandardon3/8”thru1”

Withourowncoatingchamber,wearebetterabletomeetourcustomerneeds,includingfasterturnaroundtimesonspecialsaswellasmakingsuretheinventoryisonhand.

22

DIA SHANK LOC LOR NECKDIA RADIUS OAL FLUTES ZrN

1/4 1/4 3/8 .015 2 3 110-01626

1/4 1/4 3/4 .015 2-1/2 3 110-01616

1/4 1/4 3/8 2-1/8 .235 .015 4 3 110-01666

3/8 3/8 5/8 .015 2 3 110-02426

3/8 3/8 7/8 .015 2-1/2 3 110-02416

3/8 3/8 5/8 2-3/8 .355 .015 4 3 110-02466

1/2 1/2 5/8 .025 2-1/2 3 110-03226

1/2 1/2 1 .025 3 3 110-03216

1/2 1/2 5/8 2-3/4 .475 .025 4 3 110-03266

5/8 5/8 1-1/4 .030 3-1/2 3 110-04016

5/8 5/8 3/4 3-1/2 .590 .030 6 3 110-04076

3/4 3/4 1-5/8 .030 4 3 110-04816

3/4 3/4 1 3-1/2 .715 .030 6 3 110-04876

1 1 1-3/4 .030 4 3 110-06416

1 1 1-1/4 3-1/2 .960 .030 6 3 110-06476

Series 110

StandardLength

ExtendedReach

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

HELIX:h1/4”thru1”:35Degree

VERY AGGRESSIVESeries110,with3Flutegeometry,isdesignedforhighspeedmachiningofAluminum&LightAlloys.Standardwithcornerradius.

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/4”thru1”:+.000/-.002

3 Flute for High Speed Machining of Aluminum

3 F

LU

TE

Ourteamworkshard,soyourjobsrunsmooth.TheuseofCNCgrindingmachineskeepeachtoolwemakeconsistentwiththenext.Ourinspectorsverifyconsistencyandgeometrysothatourcustomersaresuretogetthesametooleverytimetheyorder.

23

DIA SHANK LOC OAL FLUTES AlTiN ZrN

1/8 1/8 1/4 1-1/2 3 109-00824 109-00826

1/8 1/8 1/2 1-1/2 3 109-00814 109-00816

5/32 3/16 3/8 2 3 109-01024 109-01026

5/32 3/16 1/2 2 3 109-01014 109-01016

3/16 3/16 3/8 2 3 109-01224 109-01226

3/16 3/16 5/8 2 3 109-01214 109-01216

7/32 1/4 3/8 2 3 109-01424 109-01426

7/32 1/4 3/4 2-1/2 3 109-01414 109-01416

1/4 1/4 3/8 2 3 109-01624 109-01626

1/4 1/4 3/4 2-1/2 3 109-01614 109-01616

1/4 1/4 1-1/4 3 3 109-01634 109-01636

1/4 1/4 1-1/2 3-1/2 3 109-01644 109-01646

9/32 5/16 1/2 2-1/2 3 109-01824 109-01826

9/32 5/16 3/4 2-1/2 3 109-01814 109-01816

5/16 5/16 1/2 2-1/2 3 109-02024 109-02026

5/16 5/16 3/4 2-1/2 3 109-02014 109-02016

11/32 3/8 5/8 2 3 109-02224 109-02226

11/32 3/8 7/8 2-1/2 3 109-02214 109-02216

3/8 3/8 5/8 2 3 109-02424 109-02426

3/8 3/8 7/8 2-1/2 3 109-02414 109-02416

3/8 3/8 1-1/2 3-1/2 3 109-02434 109-02436

3/8 3/8 2 4 3 109-02444 109-02446

7/16 7/16 1 2-3/4 3 109-02814 109-02816

1/2 1/2 5/8 2-1/2 3 109-03224 109-03226

1/2 1/2 1-1/4 3 3 109-03214 109-03216

1/2 1/2 1-1/2 3-1/2 3 109-03234 109-03236

1/2 1/2 2 4 3 109-03244 109-03246

9/16 9/16 1-1/4 3-1/2 3 109-03614 109-03616

5/8 5/8 7/8 3 3 109-04024 109-04026

5/8 5/8 1-1/4 3-1/2 3 109-04014 109-04016

5/8 5/8 1-3/4 4 3 109-04034 109-04036

5/8 5/8 2-1/2 5 3 109-04044 109-04046

3/4 3/4 1 3 3 109-04824 109-04826

3/4 3/4 1-5/8 4 3 109-04814 109-04816

3/4 3/4 2-1/2 5 3 109-04834 109-04836

3/4 3/4 3-1/4 6 3 109-04844 109-04846

1 1 1-3/4 4 3 109-06414 109-06416

1 1 2-3/4 5 3 109-06434 109-06436

1 1 3-3/8 6 3 109-06444 109-06446

Series 1093 Flute for Aluminum

See Page 27 For 3 Flute Ball Nose End Mills

ALUMINUM & LIGHT ALLOY FINISHINGThishighhelix,3flutefinisherisdesignedforaluminumandlightalloyfinishingapplications.

HELIX ANGLE:h1/8”thru1”=40degrees

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

3 F

LU

TE

24

DIA SHANK LOC RADIUS OAL FLUTES AlTiN ZrN

1/8 1/8 1/4 .010 1-1/2 3 119-00824 119-00826

1/8 1/8 1/2 .010 1-1/2 3 119-00814 119-00816

5/32 3/16 3/8 .010 2 3 119-01024 119-01026

5/32 3/16 1/2 .010 2 3 119-01014 119-01016

3/16 3/16 3/8 .010 2 3 119-01224 119-01226

3/16 3/16 5/8 .010 2 3 119-01214 119-01216

7/32 1/4 3/8 .020 2 3 119-01424 119-01426

7/32 1/4 3/4 .020 2-1/2 3 119-01414 119-01416

1/4 1/4 3/8 .020 2 3 119-01624 119-01626

1/4 1/4 3/4 .020 2-1/2 3 119-01614 119-01616

1/4 1/4 1-1/4 .020 3 3 119-01634 119-01636

1/4 1/4 1-1/2 .020 3-1/2 3 119-01644 119-01646

9/32 5/16 1/2 .020 2-1/2 3 119-01824 119-01826

9/32 5/16 3/4 .020 2-1/2 3 119-01814 119-01816

5/16 5/16 1/2 .020 2-1/2 3 119-02024 119-02026

5/16 5/16 3/4 .020 2-1/2 3 119-02014 119-02016

11/32 3/8 5/8 .020 2 3 119-02224 119-02226

11/32 3/8 7/8 .020 2-1/2 3 119-02214 119-02216

3/8 3/8 5/8 .020 2 3 119-02424 119-02426

3/8 3/8 7/8 .020 2-1/2 3 119-02414 119-02416

3/8 3/8 1-1/2 .020 3-1/2 3 119-02434 119-02436

3/8 3/8 2 .020 4 3 119-02444 119-02446

7/16 7/16 1 .020 2-3/4 3 119-02814 119-02816

1/2 1/2 5/8 .020 2-1/2 3 119-03224 119-03226

1/2 1/2 1-1/4 .020 3 3 119-03214 119-03216

1/2 1/2 1-1/2 .020 3-1/2 3 119-03234 119-03236

1/2 1/2 2 .020 4 3 119-03244 119-03246

9/16 9/16 1-1/4 .030 3-1/2 3 119-03614 119-03616

5/8 5/8 7/8 .030 3 3 119-04024 119-04026

5/8 5/8 1-1/4 .030 3-1/2 3 119-04014 119-04016

5/8 5/8 1-3/4 .030 4 3 119-04034 119-04036

5/8 5/8 2-1/2 .030 5 3 119-04044 119-04046

3/4 3/4 1 .030 3 3 119-04824 119-04826

3/4 3/4 1-5/8 .030 4 3 119-04814 119-04816

3/4 3/4 2-1/2 .030 5 3 119-04834 119-04836

3/4 3/4 3-1/4 .030 6 3 119-04844 119-04846

1 1 1-3/4 .030 4 3 119-06414 119-06416

1 1 2-3/4 .030 5 3 119-06434 119-06436

1 1 3-3/8 .030 6 3 119-06444 119-06446

Series 119

PROFILE & POCKET ROUGHER-FINISHINGSeries119isdesignedtoimproveperformanceinprofilingandpocketingrougher-finishingapplicationsinaluminumandlightalloys.Eccentricrelievedfora25%strongercuttingedgethatrunsexceptionallysmoothatmaximumspeeds.

HELIX ANGLE:h1/8”thru1”=40degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

SET SCREW FLATS:hStandardon3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

3 Flute Rougher-Finisher for Aluminum

3 F

LU

TE

25

DIA SHANK LOC OAL FLUTES AlTiN ZrN

3/16 3/16 3/8 2 3 102-01224 102-01226

3/16 3/16 5/8 2 3 102-01214 102-01216

1/4 1/4 3/8 2 3 102-01624 102-01626

1/4 1/4 3/4 2-1/2 3 102-01614 102-01616

5/16 5/16 1/2 2-1/2 3 102-02024 102-02026

5/16 5/16 3/4 2-1/2 3 102-02014 102-02016

3/8 3/8 5/8 2 3 102-02424 102-02426

3/8 3/8 7/8 2-1/2 3 102-02414 102-02416

7/16 7/16 1 2-3/4 3 102-02814 102-02816

1/2 1/2 5/8 2-1/2 3 102-03224 102-03226

1/2 1/2 1-1/4 3 3 102-03214 102-03216

1/2 1/2 1-1/2 3-1/2 3 102-03234 102-03236

9/16 9/16 1-1/4 3-1/2 3 102-03614 102-03616

5/8 5/8 1-1/4 3-1/2 3 102-04014 102-04016

3/4 3/4 1-5/8 4 3 102-04814 102-04816

3/4 3/4 2-1/4 5 3 102-04834 102-04836

1 1 1-3/4 4 3 102-06414 102-06416

1 1 2-5/8 5 3 102-06434 102-06436

Series 1023 Flute Rougher for Light Alloys

3 F

LU

TE

“Feel The Edge”“Feel The Edge”

AutomaticShelvingmakesshippingourproductamoreefficientprocess.

HELIX ANGLE:h3/16”thru1”=40degrees

ROUGHING APPLICATIONSSeries102RoughingEndMillsaredesignedforlightmaterialslikealuminum,brass,copper,etc.The3flutehi-helixroughinggeometryproducesamanageablechipthatallowsformaximumfeedratesinprofilingandslottingapplications.Alsousedingeneralpurposeapplicationsfordeepslotsandpockets.

CORNER RADIUS:(Tostrengthenendteeth)

h3/16”=.025/.035h1/4”thru5/16”=.040/.050h3/8”thru1”=.055/.065

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter:+.000/-.005

UPON REQUEST:hCoolantSlots,3/8”thru1”

SET SCREW FLATS:hStandardon3/8”thru1”

26

DIA SHANK LOC LOR NECKDIA RADIUS OAL FLUTES TiCN AlTiN

1/8 1/8 1/4 .010 1-1/2 3 106-00822 106-008241/8 1/8 1/2 .010 1-1/2 3 106-00812 106-008145/32 3/16 3/8 .010 2 3 106-01022 106-010245/32 3/16 1/2 .010 2 3 106-01012 106-010143/16 3/16 3/8 .010 2 3 106-01222 106-012243/16 3/16 5/8 .010 2 3 106-01212 106-012147/32 1/4 3/8 .020 2 3 106-01422 106-014247/32 1/4 3/4 .020 2-1/2 3 106-01412 106-014141/4 1/4 3/8 .020 2 3 106-01622 106-016241/4 1/4 3/4 .020 2-1/2 3 106-01612 106-016141/4 1/4 3/8 2-1/8 .235 .020 4 3 106-01662 106-016649/32 5/16 1/2 .020 2-1/2 3 106-01822 106-018249/32 5/16 3/4 .020 2-1/2 3 106-01812 106-018145/16 5/16 1/2 .020 2-1/2 3 106-02022 106-020245/16 5/16 3/4 .020 2-1/2 3 106-02012 106-020145/16 5/16 7/16 2-1/8 .297 .020 4 3 106-02062 106-0206411/32 3/8 5/8 .020 2 3 106-02222 106-0222411/32 3/8 7/8 .020 2-1/2 3 106-02212 106-022143/8 3/8 5/8 .020 2 3 106-02422 106-024243/8 3/8 7/8 .020 2-1/2 3 106-02412 106-024143/8 3/8 1/2 2-1/8 .355 .020 6 3 106-02462 106-024643/8 3/8 1/2 3-3/8 .355 .020 6 3 106-02472 106-024747/16 7/16 5/8 .020 2-3/4 3 106-02822 106-028247/16 7/16 1 .020 2-3/4 3 106-02812 106-028141/2 1/2 5/8 .020 2-1/2 3 106-03222 106-032241/2 1/2 1-1/4 .020 3 3 106-03212 106-032141/2 1/2 5/8 2-3/8 .475 .020 6 3 106-03262 106-032641/2 1/2 5/8 3-3/8 .475 .020 6 3 106-03272 106-032741/2 1/2 5/8 4-1/8 .475 .020 6 3 106-03282 106-032845/8 5/8 7/8 .030 3 3 106-04022 106-040245/8 5/8 1-1/4 .030 3-1/2 3 106-04012 106-040145/8 5/8 3/4 2-3/8 .590 .030 6 3 106-04062 106-040645/8 5/8 3/4 3-3/8 .590 .030 6 3 106-04072 106-040745/8 5/8 3/4 4-1/8 .590 .030 6 3 106-04082 106-040843/4 3/4 1 .030 3 3 106-04822 106-048243/4 3/4 1-5/8 .030 4 3 106-04812 106-048143/4 3/4 1 2-1/2 .715 .030 6 3 106-04862 106-048643/4 3/4 1 3-3/8 .715 .030 6 3 106-04872 106-048743/4 3/4 1 4-1/8 .715 .030 6 3 106-04882 106-048841 1 1 .030 3 3 106-06422 106-064241 1 1-3/4 .030 4 3 106-06412 106-064141 1 1-1/4 2-1/2 .960 .030 6 3 106-06462 106-064641 1 1-1/4 3-3/8 .960 .030 6 3 106-06472 106-064741 1 1-1/4 4-1/8 .960 .030 6 3 106-06482 106-06484

Series 106

HELIX ANGLE:h1/8”thru1”=35degrees

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

3 Flute for Stainless Steel

3 F

LU

TE

27

3 Flute Ball for Stainless Steel

3 F

LU

TE

DIA SHANK LOC LOR NECKDIA OAL FLUTES TiCN AlTiN

1/8 1/8 1/4 1-1/2 3 113-00822 113-00824

1/8 1/8 1/2 1-1/2 3 113-00812 113-00814

5/32 3/16 3/8 2 3 113-01022 113-01024

5/32 3/16 1/2 2 3 113-01012 113-01014

3/16 3/16 3/8 2 3 113-01222 113-012243/16 3/16 5/8 2 3 113-01212 113-012147/32 1/4 3/8 2 3 113-01422 113-014247/32 1/4 3/4 2-1/2 3 113-01412 113-014141/4 1/4 3/8 2 3 113-01622 113-016241/4 1/4 3/4 2-1/2 3 113-01612 113-016141/4 1/4 3/8 2-1/8 .235 4 3 113-01662 113-016649/32 5/16 1/2 2-1/2 3 113-01822 113-018249/32 5/16 3/4 2-1/2 3 113-01812 113-018145/16 5/16 1/2 2-1/2 3 113-02022 113-020245/16 5/16 3/4 2-1/2 3 113-02012 113-020145/16 5/16 7/16 2-1/8 .297 4 3 113-02062 113-0206411/32 3/8 5/8 2 3 113-02222 113-0222411/32 3/8 7/8 2-1/2 3 113-02212 113-022143/8 3/8 5/8 2 3 113-02422 113-024243/8 3/8 7/8 2-1/2 3 113-02412 113-024143/8 3/8 1/2 2-1/8 .355 6 3 113-02462 113-024643/8 3/8 1/2 3-3/8 .355 6 3 113-02472 113-024747/16 7/16 5/8 2-3/4 3 113-02822 113-028247/16 7/16 1 2-3/4 3 113-02812 113-028141/2 1/2 5/8 2-1/2 3 113-03222 113-032241/2 1/2 1-1/4 3 3 113-03212 113-032141/2 1/2 5/8 2-3/8 .475 6 3 113-03262 113-032641/2 1/2 5/8 3-3/8 .475 6 3 113-03272 113-032741/2 1/2 5/8 4-1/8 .475 6 3 113-03282 113-032845/8 5/8 7/8 3 3 113-04022 113-040245/8 5/8 1-1/4 3-1/2 3 113-04012 113-040145/8 5/8 3/4 2-3/8 .590 6 3 113-04062 113-040645/8 5/8 3/4 3-3/8 .590 6 3 113-04072 113-040745/8 5/8 3/4 4-1/8 .590 6 3 113-04082 113-040843/4 3/4 1 3 3 113-04822 113-048243/4 3/4 1-5/8 4 3 113-04812 113-048143/4 3/4 1 2-1/2 .715 6 3 113-04862 113-048643/4 3/4 1 3-3/8 .715 6 3 113-04872 113-048743/4 3/4 1 4-1/8 .715 6 3 113-04882 113-048841 1 1 3 3 113-06422 113-064241 1 1-3/4 4 3 113-06412 113-064141 1 1-1/4 2-1/2 .960 6 3 113-06462 113-064641 1 1-1/4 3-3/8 .960 6 3 113-06472 113-064741 1 1-1/4 4-1/8 .960 6 3 113-06482 113-06484

Series 113

HELIX ANGLE:h1/8”thru1”=35degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”=+.000/-.002hBallRadius:+.001/-.001

SLOTTING & POCKETINGAPPLICATIONSThe3fluteSeries106&113withtheir35degreehelixwereengineeredforslottingofstainlesssteelandalloymaterials.Designedwithaneccentricrelief,theseSerieshavea25%strongercuttingedgethatrunsextremelysmoothatmaximumspeeds.WiththeadditionofAlTiNcoating,forhighheatapplications,thesetoolscombinechipclearanceandstrengthforthemostdifficultslottingandpocketingapplications.

28

DIA SHANK LOC RADIUS OAL FLUTES TiCN AlTiN

1/8 1/8 1/4 .010 1-1/2 3 117-00822 117-00824

1/8 1/8 1/2 .010 1-1/2 3 117-00812 117-00814

5/32 3/16 3/8 .010 2 3 117-01022 117-01024

5/32 3/16 1/2 .010 2 3 117-01012 117-01014

3/16 3/16 3/8 .010 2 3 117-01222 117-01224

3/16 3/16 5/8 .010 2 3 117-01212 117-01214

7/32 1/4 3/8 .020 2 3 117-01422 117-01424

7/32 1/4 3/4 .020 2-1/2 3 117-01412 117-01414

1/4 1/4 3/8 .020 2 3 117-01622 117-01624

1/4 1/4 3/4 .020 2-1/2 3 117-01612 117-01614

9/32 5/16 1/2 .020 2-1/2 3 117-01822 117-01824

9/32 5/16 3/4 .020 2-1/2 3 117-01812 117-01814

5/16 5/16 1/2 .020 2-1/2 3 117-02022 117-02024

5/16 5/16 3/4 .020 2-1/2 3 117-02012 117-02014

11/32 3/8 5/8 .020 2 3 117-02222 117-02224

11/32 3/8 7/8 .020 2-1/2 3 117-02212 117-02214

3/8 3/8 5/8 .020 2 3 117-02422 117-02424

3/8 3/8 7/8 .020 2-1/2 3 117-02412 117-02414

7/16 7/16 5/8 .020 2-3/4 3 117-02822 117-02824

7/16 7/16 1 .020 2-3/4 3 117-02812 117-02814

1/2 1/2 5/8 .020 2-1/2 3 117-03222 117-03224

1/2 1/2 1-1/4 .020 3 3 117-03212 117-03214

5/8 5/8 7/8 .030 3 3 117-04022 117-04024

5/8 5/8 1-1/4 .030 3-1/2 3 117-04012 117-04014

3/4 3/4 1 .030 3 3 117-04822 117-04824

3/4 3/4 1-5/8 .030 4 3 117-04812 117-04814

1 1 1 .030 3 3 117-06422 117-06424

1 1 1-3/4 .030 4 3 117-06412 117-06414

Series 1173 Flute Rougher-Finisher for Stainless Steel

3 F

LU

TE

AGGRESSIVE SLOTTING & POCKET MILLINGSamehighperformancegeometryastheSeries106endmill,onlywithadvancedchipbreakersdesignedforaggressiveslottingandpocketmillinginlowandhighcarbonsteels,stainlesssteels,titaniumandhightemperaturealloys.K-landcornerradiusisstandardforcorneredgeprotection.Aneccentricreliefcuttingedgefor25%morestrengthmakesthesetoolsrunextremelysmoothatmaximum speeds.

HELIX ANGLE:h1/8”thru1”=35degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

SET SCREW FLATS:hStandardon3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

CoolantSlot

See Page 24 For 3 Flute Rougher-Finisher for Aluminum

With Special

Edge Prep

For Longer Tool LifeWith Special

Edge Prep

For Longer Tool Life

29

DIA SHANK LOC OAL FLUTES TiCN AlTiN

1/8 1/8 1/2 1-1/2 3 122-00812 122-00814

5/32 3/16 1/2 2 3 122-01012 122-01014

3/16 3/16 5/8 2 3 122-01212 122-01214

7/32 1/4 3/4 2-1/2 3 122-01412 122-01414

1/4 1/4 3/4 2-1/2 3 122-01612 122-01614

9/32 5/16 3/4 2-1/2 3 122-01812 122-01814

5/16 5/16 3/4 2-1/2 3 122-02012 122-02014

11/32 3/8 7/8 2-1/2 3 122-02212 122-02214

3/8 3/8 7/8 2-1/2 3 122-02412 122-02414

7/16 7/16 1 2-3/4 3 122-02812 122-02814

1/2 1/2 1-1/4 3 3 122-03212 122-03214

5/8 5/8 1-1/4 3-1/2 3 122-04012 122-04014

3/4 3/4 1-5/8 4 3 122-04812 122-04814

1 1 1-3/4 4 3 122-06412 122-06414

Series 1223 Flute Ball Rougher-Finisher for Stainless Steel

3 F

LU

TE

AGGRESSIVE SLOTTING & BALLPOCKET MILLINGLiketheSeries117,theSeries122hasthesamehighperformancegeometryastheSeries113endmill,onlywithadvancedchipbreakersdesignedforaggressiveslottingandpocketmillinginlowandhighcarbonsteels,stainlesssteels,titanium&hightemperaturealloys.Aneccentricreliefcuttingedgefor25%morestrengthmakesthesetoolsrunextremelysmoothatmaximum speeds.

HELIX ANGLE:h1/8”thru1”=35degrees

UPON REQUEST:hCoolantSlots,3/8”thru1”

SET SCREW FLATS:hStandardon3/8”thru1”

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002hBallRadius:+.001/-.001

PROMAXnetworksautomaticgrindingmachineswithanopticalmeasuringsystemthataccuratelyusesmultiplelightsensorstomeasurecomplextoolgeometrieswithouthumancontact.Thisprocessestablishesasystemthatfocusesonprecisionandconsistencyinourmanufacturingenvironment.

30

DIA SHANK LOC OAL FLUTES ZrN

1/8 1/8 1/4 1-1/2 2 108-008261/8 1/8 3/8 1-1/2 2 108-008165/32 3/16 5/16 2 2 108-010265/32 3/16 9/16 2 2 108-010163/16 3/16 5/16 2 2 108-012263/16 3/16 9/16 2 2 108-012167/32 1/4 3/8 2 2 108-014267/32 1/4 3/4 2-1/2 2 108-014161/4 1/4 3/8 2 2 108-016261/4 1/4 3/4 2-1/2 2 108-016161/4 1/4 1-1/4 3-1/2 2 108-016369/32 5/16 7/16 2-1/2 2 108-018269/32 5/16 13/16 2-1/2 2 108-018165/16 5/16 7/16 2-1/2 2 108-020265/16 5/16 13/16 2-1/2 2 108-020165/16 5/16 1-1/4 4 2 108-020365/16 5/16 2-1/8 4 2 108-0204611/32 3/8 1/2 2-1/2 2 108-0222611/32 3/8 1 2-1/2 2 108-022163/8 3/8 1/2 2-1/2 2 108-024263/8 3/8 1 2-1/2 2 108-024163/8 3/8 1-1/2 4 2 108-024363/8 3/8 2-1/2 6 2 108-02446

13/32 7/16 9/16 2-3/4 2 108-0262613/32 7/16 1 2-3/4 2 108-026167/16 7/16 9/16 2-3/4 2 108-028267/16 7/16 1 2-3/4 2 108-028167/16 7/16 2 4 2 108-0283615/32 1/2 5/8 2-1/2 2 108-0302615/32 1/2 1-1/4 3 2 108-030161/2 1/2 5/8 2-1/2 2 108-032261/2 1/2 1-1/4 3 2 108-032161/2 1/2 2 4 2 108-032361/2 1/2 3 6 2 108-032465/8 5/8 3/4 3 2 108-040265/8 5/8 1-5/8 3-1/2 2 108-040165/8 5/8 2-1/2 5 2 108-040365/8 5/8 3-3/4 6 2 108-040463/4 3/4 1 4 2 108-048263/4 3/4 1-5/8 4 2 108-048163/4 3/4 3 6 2 108-048363/4 3/4 4 7 2 108-048461 1 1-1/4 4 2 108-064261 1 2 5 2 108-064161 1 3 6 2 108-064361 1 4-1/8 7 2 108-06446

Series 1082 Flute End Mill for Aluminum

FOR ALUMINUMThe SERIES 108 end mill was designed to be a workhorse in milling ALUMINUM and other non-ferrous materials. Thistool comes standard withZirconium Nitrate (ZrN)coating.

HELIX ANGLE:h1/8”thru1”=40degrees

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/8”thru1”:+.000/-.002

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

2 F

lute

31

AtPROMAXweknowthatAccuracyandPrecisionarekeyinproducingaqualityendproductthatcustomerscandependon.Thatiswhyweinvestinthemostcurrentmeasuringequipment-soourcustomerscandependonusandtheircustomerscandependonthem.

2 Flute Ball for Aluminum

2 F

lute

DIA SHANK LOC OAL FLUTES ZrN

1/4 1/4 3/8 2 2 115-01626

1/4 1/4 3/4 2-1/2 2 115-01616

1/4 1/4 1-1/4 3-1/2 2 115-01636

5/16 5/16 7/16 2-1/2 2 115-02026

5/16 5/16 13/16 2-1/2 2 115-02016

5/16 5/16 1-1/4 4 2 115-02036

3/8 3/8 1/2 2-1/2 2 115-02426

3/8 3/8 1 2-1/2 2 115-02416

3/8 3/8 1-1/2 4 2 115-02436

7/16 7/16 9/16 2-3/4 2 115-02826

7/16 7/16 1 2-3/4 2 115-02816

7/16 7/16 2 4 2 115-02836

1/2 1/2 5/8 2-1/2 2 115-03226

1/2 1/2 1-1/4 3 2 115-03216

1/2 1/2 2 4 2 115-03236

5/8 5/8 3/4 3 2 115-04026

5/8 5/8 1-5/8 3-1/2 2 115-04016

5/8 5/8 2-1/2 5 2 115-04036

3/4 3/4 1 4 2 115-04826

3/4 3/4 1-5/8 4 2 115-04816

3/4 3/4 3 6 2 115-04836

1 1 1-1/4 4 2 115-06426

1 1 2 5 2 115-06416

1 1 3 6 2 115-06436

Series 115

CoolantSlot

FOR ALUMINUMTheallNEWSERIES115BALLNOSEendmill,likeit’ssquareendcounterpart,wasdesignedtobeaworkhorseinmillingALUMINUMandothernon-ferrousmaterials.ThistoolcomesstandardZirconiumNitrate(ZrN)Coating.

HELIX ANGLE:h1/4”thru1”=40degrees

TOLERANCES:hShank:-.0001/-.0004hCuttingDiameter: 1/4”thru1”:+.000/-.002hBallRadius:+/-.001

UPON REQUEST:hCoolantSlots,3/8”thru1”hSetscrewflats,3/8”thru1”

“Feel The Edge”“Feel The Edge”

32

DIA SHANK LOC OAL SQUARE END

BALL END

0.005 1/8 .008 1-1/2 330-00520

0.005 1/8 .015 1-1/2 330-00510

0.006 1/8 .009 1-1/2 330-00620

0.006 1/8 .018 1-1/2 330-00610

0.007 1/8 .011 1-1/2 330-00720

0.007 1/8 .021 1-1/2 330-00710

0.008 1/8 .012 1-1/2 330-00820

0.008 1/8 .024 1-1/2 330-00810

0.009 1/8 .014 1-1/2 330-00920

0.009 1/8 .027 1-1/2 330-00910

0.010 1/8 .015 1-1/2 330-01020 331-01020

0.010 1/8 .030 1-1/2 330-01010 331-01010

0.011 1/8 .017 1-1/2 330-01120

0.011 1/8 .033 1-1/2 330-01110 331-01110

0.012 1/8 .018 1-1/2 330-01220

0.012 1/8 .036 1-1/2 330-01210 331-01210

0.013 1/8 .020 1-1/2 330-01320

0.013 1/8 .039 1-1/2 330-01310 331-01310

0.014 1/8 .021 1-1/2 330-01420

0.014 1/8 .042 1-1/2 330-01410 331-01410

0.015 1/8 .023 1-1/2 330-01520 331-01520

0.015 1/8 .045 1-1/2 330-01510 331-01510

0.016 1/8 .024 1-1/2 330-01620

0.016 1/8 .048 1-1/2 330-01610 331-01610

0.017 1/8 .026 1-1/2 330-01720

0.017 1/8 .051 1-1/2 330-01710 331-01710

0.018 1/8 .027 1-1/2 330-01820

0.018 1/8 .054 1-1/2 330-01810 331-01810

0.019 1/8 .029 1-1/2 330-01920

0.019 1/8 .057 1-1/2 330-01910 331-01910

0.020 1/8 .030 1-1/2 330-02020 331-02020

0.020 1/8 .060 1-1/2 330-02010 331-02010

Series 330 & 331

DIA SHANK LOC OAL SQUARE END

BALL END

0.021 1/8 .032 1-1/2 330-02120

0.021 1/8 .063 1-1/2 330-02110 331-02110

0.022 1/8 .033 1-1/2 330-02220

0.022 1/8 .066 1-1/2 330-02210 331-02210

0.023 1/8 .035 1-1/2 330-02320

0.023 1/8 .069 1-1/2 330-02310 331-02310

0.024 1/8 .036 1-1/2 330-02420

0.024 1/8 .072 1-1/2 330-02410 331-02410

0.025 1/8 .038 1-1/2 330-02520 331-02520

0.025 1/8 .075 1-1/2 330-02510 331-02510

0.026 1/8 .039 1-1/2 330-02620

0.026 1/8 .078 1-1/2 330-02610 331-02610

0.027 1/8 .041 1-1/2 330-02720

0.027 1/8 .081 1-1/2 330-02710 331-02710

0.028 1/8 .042 1-1/2 330-02820

0.028 1/8 .084 1-1/2 330-02810 331-02810

0.029 1/8 .044 1-1/2 330-02920

0.029 1/8 .087 1-1/2 330-02910 331-02910

0.030 1/8 .045 1-1/2 330-03020 331-03020

0.030 1/8 .090 1-1/2 330-03010 331-03010

0.031 1/8 .047 1-1/2 330-03120

0.031 1/8 .093 1-1/2 330-03110 331-03110

0.032 1/8 .048 1-1/2 330-03220

0.032 1/8 .096 1-1/2 330-03210 331-03210

0.033 1/8 .050 1-1/2 330-03320

0.033 1/8 .099 1-1/2 330-03310 331-03310

0.034 1/8 .051 1-1/2 330-03420

0.034 1/8 .102 1-1/2 330-03410 331-03410

0.035 1/8 .053 1-1/2 330-03520 331-03520

0.035 1/8 .105 1-1/2 330-03510 331-03510

0.036 1/8 .054 1-1/2 330-03620

0.036 1/8 .108 1-1/2 330-03610 331-03610

2 FLUTES UNCOATED

DE

CIM

AL

Series 330 - Square End

Series 331 - Ball End

TOLERANCES:

hShank:+.0000/-.0003hCuttingDiameter:+.000/-.0005

2 FLUTES UNCOATED

2 Flute Decimal End Mills

33

DIA SHANK LOC OAL SQUARE END

BALL END

0.037 1/8 .056 1-1/2 330-03720

0.037 1/8 .111 1-1/2 330-03710 331-03710

0.038 1/8 .057 1-1/2 330-03820

0.038 1/8 .114 1-1/2 330-03810 331-03810

0.039 1/8 .059 1-1/2 330-03920

0.039 1/8 .117 1-1/2 330-03910 331-03910

0.040 1/8 .060 1-1/2 330-04020 331-04020

0.040 1/8 .120 1-1/2 330-04010 331-04010

0.041 1/8 .062 1-1/2 330-04120

0.041 1/8 .123 1-1/2 330-04110 331-04110

0.042 1/8 .063 1-1/2 330-04220

0.042 1/8 .126 1-1/2 330-04210 331-04210

0.043 1/8 .065 1-1/2 330-04320

0.043 1/8 .129 1-1/2 330-04310 331-04310

0.044 1/8 .066 1-1/2 330-04420

0.044 1/8 .132 1-1/2 330-04410 331-04410

0.045 1/8 .068 1-1/2 330-04520 331-04520

0.045 1/8 .135 1-1/2 330-04510 331-04510

0.046 1/8 .069 1-1/2 330-04620

0.046 1/8 .138 1-1/2 330-04610 331-04610

0.047 1/8 .071 1-1/2 330-04720

0.047 1/8 .141 1-1/2 330-04710 331-04710

0.048 1/8 .072 1-1/2 330-04820

0.048 1/8 .144 1-1/2 330-04810 331-04810

0.049 1/8 .074 1-1/2 330-04920

0.049 1/8 .147 1-1/2 330-04910 331-04910

0.050 1/8 .075 1-1/2 330-05020 331-05020

0.050 1/8 .150 1-1/2 330-05010 331-05010

0.051 1/8 .077 1-1/2 330-05120

0.051 1/8 .153 1-1/2 330-05110 331-05110

0.052 1/8 .078 1-1/2 330-05220

0.052 1/8 .156 1-1/2 330-05210 331-05210

0.053 1/8 .080 1-1/2 330-05320

0.053 1/8 .159 1-1/2 330-05310 331-05310

0.054 1/8 .081 1-1/2 330-05420

0.054 1/8 .162 1-1/2 330-05410 331-05410

0.055 1/8 .083 1-1/2 330-05520 331-05520

0.055 1/8 .165 1-1/2 330-05510 331-05510

0.056 1/8 .084 1-1/2 330-05620

0.056 1/8 .168 1-1/2 330-05610 331-05610

0.057 1/8 .086 1-1/2 330-05720

0.057 1/8 .171 1-1/2 330-05710 331-05710

DIA SHANK LOC OAL SQUARE END

BALL END

0.058 1/8 .087 1-1/2 330-05820

0.058 1/8 .174 1-1/2 330-05810 331-05810

0.059 1/8 .089 1-1/2 330-05920

0.059 1/8 .177 1-1/2 330-05910 331-05910

0.060 1/8 .090 1-1/2 330-06020 331-06020

0.060 1/8 .180 1-1/2 330-06010 331-06010

0.061 1/8 .092 1-1/2 330-06120

0.061 1/8 .183 1-1/2 330-06110 331-06110

0.062 1/8 .093 1-1/2 330-06220

0.062 1/8 .186 1-1/2 330-06210 331-06210

0.063 1/8 .095 1-1/2 330-06320

0.063 1/8 .189 1-1/2 330-06310 331-06310

0.064 1/8 .096 1-1/2 330-06420

0.064 1/8 .192 1-1/2 330-06410 331-06410

0.065 1/8 .098 1-1/2 330-06520 331-06520

0.065 1/8 .195 1-1/2 330-06510 331-06510

0.070 1/8 .105 1-1/2 330-07020 331-07020

0.070 1/8 .210 1-1/2 330-07010 331-07010

0.075 1/8 .113 1-1/2 330-07520 331-07520

0.075 1/8 .225 1-1/2 330-07510 331-07510

0.080 1/8 .120 1-1/2 330-08020 331-08020

0.080 1/8 .240 1-1/2 330-08010 331-08010

0.085 1/8 .128 1-1/2 330-08520 331-08520

0.085 1/8 .255 1-1/2 330-08510 331-08510

0.090 1/8 .135 1-1/2 330-09020 331-09020

0.090 1/8 .270 1-1/2 330-09010 331-09010

0.095 1/8 .143 1-1/2 330-09520 331-09520

0.095 1/8 .285 1-1/2 330-09510 331-09510

0.100 1/8 .150 1-1/2 330-10020 331-10020

0.100 1/8 .300 1-1/2 330-10010 331-10010

0.105 1/8 .158 1-1/2 330-10520 331-10520

0.105 1/8 .315 1-1/2 330-10510 331-10510

0.110 1/8 .165 1-1/2 330-11020 331-11020

0.110 1/8 .330 1-1/2 330-11010 331-11010

0.115 1/8 .173 1-1/2 330-11520 331-11520

0.115 1/8 .345 1-1/2 330-11510 331-11510

0.120 1/8 .180 1-1/2 330-12020 331-12020

0.120 1/8 .360 1-1/2 330-12010 331-12010

Series 330 & 331

DE

CIM

AL

2 Flute Decimal End Mills2 FLUTES UNCOATED 2 FLUTES UNCOATED

34

DIA SHANK LOC OAL SQUARE END

BALL END

0.005 1/8 .008 1-1/2 332-00520

0.005 1/8 .015 1-1/2 332-00510

0.006 1/8 .009 1-1/2 332-00620

0.006 1/8 .018 1-1/2 332-00610

0.007 1/8 .011 1-1/2 332-00720

0.007 1/8 .021 1-1/2 332-00710

0.008 1/8 .012 1-1/2 332-00820

0.008 1/8 .024 1-1/2 332-00810

0.009 1/8 .014 1-1/2 332-00920

0.009 1/8 .027 1-1/2 332-00910

0.010 1/8 .015 1-1/2 332-01020 333-01020

0.010 1/8 .030 1-1/2 332-01010 333-01010

0.011 1/8 .017 1-1/2 332-01120

0.011 1/8 .033 1-1/2 332-01110 333-01110

0.012 1/8 .018 1-1/2 332-01220

0.012 1/8 .036 1-1/2 332-01210 333-01210

0.013 1/8 .020 1-1/2 332-01320

0.013 1/8 .039 1-1/2 332-01310 333-01310

0.014 1/8 .021 1-1/2 332-01420

0.014 1/8 .042 1-1/2 332-01410 333-01410

0.015 1/8 .023 1-1/2 332-01520 333-01520

0.015 1/8 .045 1-1/2 332-01510 333-01510

0.016 1/8 .024 1-1/2 332-01620

0.016 1/8 .048 1-1/2 332-01610 333-01610

0.017 1/8 .026 1-1/2 332-01720

0.017 1/8 .051 1-1/2 332-01710 333-01710

0.018 1/8 .027 1-1/2 332-01820

0.018 1/8 .054 1-1/2 332-01810 333-01810

0.019 1/8 .029 1-1/2 332-01920

0.019 1/8 .057 1-1/2 332-01910 333-01910

0.020 1/8 .030 1-1/2 332-02020 333-02020

0.020 1/8 .060 1-1/2 332-02010 333-02010

0.021 1/8 .032 1-1/2 332-02120

Series 332 & 333

DIA SHANK LOC OAL SQUARE END

BALL END

0.021 1/8 .063 1-1/2 332-02110 333-02110

0.022 1/8 .033 1-1/2 332-02220

0.022 1/8 .066 1-1/2 332-02210 333-02210

0.023 1/8 .035 1-1/2 332-02320

0.023 1/8 .069 1-1/2 332-02310 333-02310

0.024 1/8 .036 1-1/2 332-02420

0.024 1/8 .072 1-1/2 332-02410 333-02410

0.025 1/8 .038 1-1/2 332-02520 333-02520

0.025 1/8 .075 1-1/2 332-02510 333-02510

0.026 1/8 .039 1-1/2 332-02620

0.026 1/8 .078 1-1/2 332-02610 333-02610

0.027 1/8 .041 1-1/2 332-02720

0.027 1/8 .081 1-1/2 332-02710 333-02710

0.028 1/8 .042 1-1/2 332-02820

0.028 1/8 .084 1-1/2 332-02810 333-02810

0.029 1/8 .044 1-1/2 332-02920

0.029 1/8 .087 1-1/2 332-02910 333-02910