profit H10 Professional nesting solution - Felder...

Transcript of profit H10 Professional nesting solution - Felder...

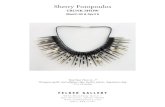

Professional nesting solution

profit H10

www.format-4usa.com

Flexibility

Preci

sion

Productivity

Various materials: Wood, Plastic, Alucobond, mineralised material, packaging material

Panel Processing CentreCNC Cutting – CNC Drilling – CNC Nesting – CNC Milling• Minimum waste, maximum material yield • Highest cutting quality - no requirement of further processing • Maximum throughput with job specific sizing cut capacity • Tomorrow‘s technology for today‘s productivity and profit

www.format-4usa.com

3x 230 V motor voltage, 60 Hz ■Automatic central lubrication system ■Router electrospindle 10 kW HSK F63 ■

Electroandmechanicalpneumaticpreperationofthedrillinghead ■

8-piece tool changer on side of machine chassis ■1 compressed air connection at front of machine ■Teleservice support package via internet ■

Hand-heldremotecontrolunitforthemachine ■

Wood Flash Programming software ■2 vacuum pumps with 147 CFM (250 m³/h) each ■AutomaticlengthmeasurementsystemsfortoolinZaxis ■

Technical data, equipment options to suit your requirements:

profit H10 16/38 standard optional

CNC Cutting• Load panel, start working.

Once loaded, the profit H10 works without an operator. No additional manipulation is required.

• Highly precise cut edges, shaping cut = format cut

CNC Drilling • Material does not need to be

transported to CNC or drill-ing machine

• Significant time savings thanks to a combination of CNC cut-ting and CNC drilling in just one work cycle

CNC Nesting(nesting) • Any desired shape can be

used. Minumum waste thanks to nesting software

• Significant time savings thanks to a combination of CNC cut-ting, CNC drilling and CNC nesting in just one working cycle

CNC Milling • Grid table can be fitted with

vacuum pods; CNC milling operations can be carried out just as in standard CNC machines

The two-sided driven portal design of the profit H10 guar-antee the highest precision and repeatability of your processing. The rack and pinion drive in the X and Y direction ensures for maximum driving speeds for the shortest processing times and tool changing times.

Panel cutting, drilling and milling in any shape desired, all in one process!

Edge processing

Block vacuum pads for edge milling on the bottom side of the tool. The horizontal drilling unit can be used without limit.

Screw taps

Metric threads or fine threads. Simple programming - perfect results.

Cutting foam

The large Z-direction stroke enables the use of special units. Any type of foam up to 80 mm can be processed in highest quality.

Lamello

By using the 5-motionplus units, manual angle settings are a thing of the past. Tools, such as the Lamello spindle moulder tool can be used.

Doors

The C-axis enables highest flexibility and the optional use of units. Complete pro-cessing of doors in the shortest processing time is possible.

Chip deflector

The interpolating rotary motion of the chip-ping deflector is controlled via the C-axis. Thus, the resulting chippings are guided in the direction of the extraction channel, especially with processing edges.

3D-Milling machine

Simplest 3-axis application with impressive results. There is no limit to your creativity.

Template

Using the template connections on the left or right sides of the matrix table, you can extend your application spectrum. The tem-plate connections ensure maximum vacuum performance, even with small contours.

Engraving

Your future field of application is not only limited to wood. Special equipment fea-tures also allow the processing of Aluco-bond.

www.format-4usa.com

DH 16 4H 2S

Positioning toolVacuum cups - Positioned quickly

Quick and easy positioning of the suction pods, suitable for every workpiece sizeThe raster geometry of the matrix table makes handling and positioning the vacuum cups easy. Additionally a distributor can be used, in order to establish a dual-circuit vacuum system.

Drill headLongitudinal measurement system

Vacuum cups, drill head, ...

The hand-held terminal activates and positions the cross laser.The distribution of positioning tools over the complete table support you with handling the base board.

Positioning laser that travels along for precise vacuum suction pad positioning.

Regardless whether the machine will only be used for cabinet manufacturing or as an all-rounder. You decide which drill-head configuration is the right one for you. Choose between, a head with only vertical drilling spindles or spindles with a grooving saw for vertical and horizontal processing.

Setting the parametres of your tools made easy: every tool length is stored in the tool database accurately to one hundredth of a millimetre.

Tool changerThe linear tool changer ensures a rapid tool change and minimises the compressed air consumption. The use of aggregates that have larger tool diameters for increased performance of your profit H10. Up to 36 tool and ag-gregate positions are available.

HSK F63 Lock housing ag-gregate with two compressed air nozzlesOrder no. 300-24-017

HSK F63 Floating unit with tracer for vertical routing of exact milling depths HSK F63Order no. 300-24-010

5-motion/5-motionplus

Automatically fully adjustable! With the 5-motion/5-motionplus tilting aggregate your CNC machining centre becomes a 4 1/2 axes machine.

Aggregate examples

HSK F63 Fourfold angle cutter head Order no. 300-24-015

HSK F63 Dual angle head Max. Ø 180 mm Order no. 300-24-012

CNC-Aggregates

Cut, push-off and labelThe integrated unloading unit on the portal pushes the finished workpieces off after processing and cleans the table at the same time. Any remaining chippings are extracted via the under table extractor. During the unloading process, the first label is printed out and the corresponding workpiece is shown in colour on the the screen, indicating to which workpiece it belongs. This process is then repeated workpiece for workpiece.

Cut, push-off and label

Software from Format-4 the self explanatory user interface, guarantees a high level of productivity

WoodflashPlanning, drawing, constructing = Programming

FlashNest ProImport the data including optimisation, with only a few clicks of your mouse. Any contours are interlaced and optimised as per the users specifications. Visual repre-sentation of the Nesting and the informa-tion on the total surface usage. Labels can also be generated with individual, specific information..

Flash3DThree dimensional furniture planning and visualisation

3D simulatorOption: Accurate representation of your ma-chine as a 3D model incl. collision control

Software

21

21

Assembly times

Prod

uctiv

ity

Craftsman's skill Competitiveness/Profitability

Programmer competence

Competitiveness/Profitability

Material competence

Construction competence

Finishing competence

Machine competence

PrecisionFlexibility

Programmer competence

On the basis of a carpenters skill the CNC broadens the current and future competitiveness and profitability of every workshop, in every market and in every sector.

Craftsman's skill

How big is the step up?

3

g

g

g

g

www.format-4usa.com

95 of 100rationaliseFocus: Revenue potential

32 of 100expandFocus: Market potential

75 of100innovateFocus: Performance potential

Type of company• Established• Dynamic

Company size

Market • Competition• Customers• Dynamic

Performance area

Changing the way we think is the biggest challenge.

The mechanization of the workshop has been advancing for decades.

When will your workshop take the next step?

34 of100optimizeFocus: Business potential

Furniture/KitchensDoorsInterior decorationWindowStaircasesJob order productionTenders

The CNC triangle provides 4 key focus directions for your business ways in which to maximise profitability regardless of the market conditions.

It is now commonplace for all woodworkers to setup and operate various types of machines with a range of tools in order to produce a finished product.The CNC operates along the same lines, but with an important difference: The production processes are merged together. Programmed by the operator and performed by the CNC.

100 of 100 CNC users: “... CNC has become crucial to my work”

87 of 100 CNC users: “... my CNC expectations were exceeded”

Can one compete against CNC workshops without a CNC? 81 of a 100 say “no”

“Easier to program than expected”: 78 out of a 100

6 reasons to invest in a CNC! Today many cabinetmakers are fulfilling their dream of owning a CNC

“CNC is the standard machine of tomorrow!” The things that seem difficult to us today, will become clear tomorrow! CNC machines are already playing a key role in

every workshop. A CNC machine will enable umlimited options and possibilities for your workshop in the future.

Programming within 3 daysAnyone with basic computer knowledge, who can draw their product and knows the required produc-

tion steps, can develop a solid CNC pro-gramming base within 3 days.

Founded on capentary skills!The foundation on which the programming of a CNC is built, is carpentry skill. Programming becomes a new and

additional skill in a industry renowed for first class, innovative, artistic and design oriented practice

CNC requires big changesCNC changes the carpenter trade significantly.The CNC redefines a cabinet-maker‘s work!

CNC-Power is 3 dimensional! CNC broadens the competitiveness, as well as profitability over three central dimensions. It is a common misconception

to view a CNC simply as a way to increase the speed of production.

Batch production efficient from the very first piece!Once a cabinet has been programmed, the CNC will manufacture it faster and to a much better quality

standard than a regular machine. Once, twice, a hundred times ...

1. The standard machines of tomorrow.

3.CNC = flexibility = individuality

4.Core competencies and profitability

5.CNC is

3 dimensional!

6.In summary

2.Easy to learn

programming.

profit H10 (16/38)

Technical data, equipment options to suit your requirements:

Axis X-axis 12 ft (4650 mm) Y-axis 5 ft (1530 mm) Z-axis 11“ (280 mm)Table size X-axis 12 ft (3670 mm) Y-axis 5 ft. (1550 mm)Speed X-axis 330 ft/min. Y-axis 330 ft/min. Z-axis 100 ft/min. Vector speed XY 460 ft/min.Drill head Vertical drilling spindles 12/16 Horizontal drilling spindles 2+2 Grooving saw 1+1 Speed 1.000–6.000 rpmMain spindle HSK F63 10/12/12 kW FK Speed 1.000–24.000 rpmPneumatics Connection ½-inch Pressure in supply pipe 8 Bar

Pressure in the machine 6 Bar Air-consumption 400 Nl/minVacuum pump Motor 2x 300 m³/hDust extractors Vacuum connection Ø 200 mm Volume flow 2200 m³/h Air speed 20 m/sec Vacuum 1000 PaElectrics Power supply 3x 208/230 V Frequency 60 Hz Total power consumption 26–31 kWSoftware PC Dell Flat screen monitor 19” Programming software Wood Flash, Flash 3D, Option: FlashNestProWeight Machine (total) approx. 10.250 lbs

Basic modelL..................24 ft. (7400 mm)W .............. 14 ft. (4260 mm)H ...................8 ft. (2510 mm)

L..................33 ft. (9960 mm)W ............... 14 ft. (4260 mm)H ...................8 ft. (2510 mm)

unloading station

L = Length, W = Width, H = Height

loading-unloading station

Combination with Panel storage

L...............44 ft. (13.310 mm)W ............... 15 ft. (4450 mm)H ...................8 ft. (2510 mm)

W ............... 15 ft. (4450 mm)H ...................8 ft. (2510 mm)Individual machine configu-ration available on request

www.format-4usa.com

Space requirements and technical specifications

Your profit H10 - In different configuration levels depending on your requirements

... in combination with panel storage... with loading and unloading station

... with unloading stationBasic model

profil45 profil45M profil45Mx-motion

kappa550e-motion kappa550x-motion kappa550

kappa400x-motion kappa400

dual51 plan51 plan51L exact63 exact51

RL300 RL250 RL200 RL160 RL125

Jointer-Planers/Jointers/Planers

Panel Saws

The program

Shapers

Dust Extractors

NEW NEW

NEW NEW

NEW

kappaautomatic55/75 kappaV60 HVPfinish1302/1102GIANT

perfect710e-motion/perfect710x-motion

perfect812e-motion/perfect812x-motion

perfect608x-motionplus

profitH10 profitH08

profitH24/H24L

profitH22/H22L

profitH20

profitH30/H30L

profitH50

c-express920

www.format-4usa.com VIEwALLVIdEos

Industry Panel Saws Wide Belt Sanding Machines Heated Veneer Press

Edgebanders

CNC Machine Centers

NEWNEW

NEW5 axes CNC

NEW

FELDER-GROUP USAEast: 2 Lukens Drive, Suite 300, NEW CASTLE, DE 19720, [email protected]. Cal: 3006 Beacon Blvd., WEST SACRAMENTO, CA 95691, [email protected]. Cal: 26060 Acero Suite 103, MISSION VIEJO, CA 92691, [email protected]

www.format-4usa.com

DE: 866-792-5288N. Cal: 800-572-0061S. Cal: 866-714-6005 866-922-8879

... inhouse manufacturing ensuringhighest quality standards

... 60 years of experience in building fine woodworking machinery

FORMAT-4Quality and precision

from AUSTRIA

... family ownership

QualitY, reliaBilitY, PreCision based on ...

MADE IN AUSTRIAmeans for you ...

© AH 06/2013 · FELDER KG · KR-Felder-Straße 1, A-6060 HALL in Tirol, Tel. +43(0) 05223/58 500, Fax +43(0) 05223/56 130, [email protected] Specifications subject to alterations. Felder is not to be held responsible for syntax or printers errors.