Professor Jonghwan Suhr Professor Jae-Do Nam … 3D Printing Center...SKKU-Dassault Systemes...

Transcript of Professor Jonghwan Suhr Professor Jae-Do Nam … 3D Printing Center...SKKU-Dassault Systemes...

1

Professor Jonghwan SuhrProfessor Jae-Do Nam

Sungkyunkwan University (SKKU)

International Forum on Open Innovation 2018

2018/5/25

2

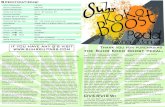

SKKU 3D Printing Hive Center (since 2015)

R&D, Education, Consulting, Networking, Design & Printing Service, New Business Dev.

4

Cross-Interdisciplinary R&ED Infrastructure

Structuralcomposites EMIshieldmaterials Thixotropicmaterials Flexibleelectronics

EHDprinting Nozzlesystem PrintingS/W

Reverse-engineering Processsimulation Optimum design

6

Researchinstitute

Company

Localgovernment

University

SKKU3D Printing

HIVE

LG Electronics

2nd Research ComplexRm#83158 (300m2)

Best Location for Close Collaborations with Industries !

Location!

Gyoenggi Province

Automobile, IT, NT, BT industries within 30km

8

2018.03.29

Collaborations on materials & systems of metal 3D printing Joint R&D projects Exchange visits, training and talent cultivation

SKKU-SITI Metal 3D Printing Joint Research Center

9

SKKU-Chiang Mai University

2016. 10. 18

Collaborations on Environmentally Friendly 3D Printing Materials Joint Lab in Step Science Park Exchange visits/Share experties

10

2016. 07. 28.

SKKU-Dassault Systemes

Dassault Systems Providing famous & useful Engineering software (SIMULIA, CATIA, ABAQUS, etc.) Plan the joint project for 3D Printing materials in polymer & metal materials Technical information exchange & workshop Joint Publications: Conference and journal papers

12

Development of EMI shielding composites

Development of high resolution 3D printing system

Rheology controlprinting system

Thixotropy controlprinting system

Before After

Shield effectiveness analysis

Smart Phone with EMI Shielding

3D Printing for Smart Phone Applications

Development of thixotropic material

Mechanical properties analysis

Thixotropy control

13

* Kelly-Tyson model equation

Mechanical properties characterization

Composite fiber length measurement

Composite design & critical fiber length

* Rule of mixture

Critical length (um) 743.97

3D Printable Composite Filament Design

14

Line width & height control

Rheological properties control

Mechanical property control

3D Printing for Fuel Cell Electric Vehicle

Customized 3D printable Ink development(PI, Epoxy, etc.)

3D Printable Materials/Hardware & Structural Design

15

3D Printing Consulting for Hyundai Motors

Battery coverMaterial: NylonPrinter type: SLS

Front bumperMaterial: ResinPrinter type: Industrial SLS

Air conditioning ductMaterial: NylonPrinter type: SLS

Suspension wishboneMaterial: NylonPrinter type: DMLS

Head light prototypeMaterial: ResinPrinter type: SLA

16

3D Printing for Nuclear Power Plant

“Equipment obsolescence”“Part Aging”

Reverse-engineering

3D printing simulation& parameter optimization

Reliability verification* Neutron irradiation test

Standardization

* DED (Direct Energy Deposition)MX-1000, 1,000/800/650 (mm)

* PBF (Powder Bed Fusion)SLM 500, 500/280/365 (mm)

Metal 3D Printing

Period: 2017~2022Budget: $13 million

“Metal 3D printing for nuclear power plant parts"

17

3D scan datageneration

Reverse-engineering

3D printing & 3D scanning

Drawing

* Inventor

3D CAD model generation

* Artec spiderRes.: 0.1 mm

* Polyjet 3D printerConnex350, Stratasys Co.

Target part: 3 inch control valve bodyPart size: 500/300/300 (mm)

3D Printing for Nuclear Power Plant

18

Printing process simulation

Max. distortioncomparison

Material model development Printing process analysis

Laser power

Laser speed

Laser spot size

Laser pathProcess

Horizontal printing Vertical printing

Max. effectivestress

(N/mm2)

Max.distortio

n(mm)

Max. effectivestress

(N/mm2)

Max.distortion

(mm)

After printing 462.75 0.55 448.63 0.45

Simple cutting 370.93 0.61 395.12 0.42

Support removal

327.32 0.94 299.87 0.57

Vertical printinganalysis

Horizontal printinganalysis

3D Printing for Nuclear Power Plant

3D printing analysis

19

Intermolecular networkby hydrogen-bond

High Speed & Resolution with Thixotropy

* H. Sun, et al. J. of Mater. Chem. C, (2018)

20

Curing Characteristics & Anisotropic Properties

<Connex 350>

<Curing degree vs Irradiation time>

<Uniaxial Tensile Test>

0.0 0.2 0.4 0.6 0.8 1.0

260

270

280

290

300

310

320

330

340

DPC and DSC results

Printed Specimen

DiBenedetto Fitting

Gla

ss T

ran

sitio

n T

em

pe

ratu

re (

K)

Degree of cure (α)

Mechanical Analysis

<DSC & DPC>

<Dibenedetto analysis>

<Size dependently increasing tensile properties>

UV-Curable 3D Printing Materials

Experimental

<Electron Beam Treatment>

* S.Y. Hong, et al. Polymer (2018)

Thermal Analysis

Electron Beam Treatment

22

with

“Technical support of 3D printed temporal bone prototype”

Temporal bonemodel request

Optimal material &3DP process derivation

SKKU3D Printing

HIVE

3D Printing for Biomedical Applications

23

Beginner Course K-12

Advanced/Customized Courses

Education & Training Programs

Capstone Design for Undergrads

24

Education - R&E Program w/ Local High School for Gifted

Pre-mixing by mini extruder

Composite filament manufacturing

3D printing & material properties measurements

Electrical conductivity Tensile property

“ Development of CNT-PLAf composite filament for FDM”