Product Improvement Test of Nonmetallic Fuel Tanks for Trucks

Transcript of Product Improvement Test of Nonmetallic Fuel Tanks for Trucks

RDTE PROJECT NO./FSN

TEST AGENCY PRaJECT NO.

TEST SPONSOR Ys - nd

TEST SPONSOR PROJECT-.NO,

TRADOC AC NO.

U S m m T a dOah:t a

PRODUCT IMPROVEMENT TEST OF NONMETALLIC FUEL TANKS

FOR - TRUCKS, M151 AND M715 SERIES

(PHASE I ) I

FIRST LlX"l'ER REPORT DUGWAY PROVING GROUW

BY T ~ H N L C A L LIBRARY -0 a: JUAN A. SUAREZ

JUNE 1 9 7 4

DISTRIBUTION LIMITED TO US GOVERNMENT AGENCIES ONLY; TEST AND EVALUATION; JUNE 1 9 7 4 . OTHER REQUESTS FOR THIS DOCUMENT MUST BE REFERRED TO US ARMY TANK-AUTOMOTIVE COMMAND, WARREN, MICHIGAN 4 8 0 9 0 .

U. S. ARMY YUMA PROVING GROUND

Dootroy t h i r roport when no longer needed. Do not nt* it to tho oris;inator.

Tho findin80 i n t h i r report are not t o be conrtruad u an o f f i c i a l Dapartmont of the Army posit ion unless ro doaiyutod by othor authorlawid documento.

Tho tam of trade namem i n t h i s report does not con- r t i t u t e an o f f i c i a l endorsement o r approval of the w o of ruch comorcial hardware o r roftware. This n p o r r u y not be c i ted fo r purpose of advertisement.

DISCLAIMER NOTICE This document may contain

pages which do not reproduce legibly.

Inconsistent page numbers are due to omittance of blank

pages.

Unclassif ied LCURITY CLASSIFICATION O? TMIS r r o c F a n D r . Entor*@

Tanks f o r Trucks, M151 and M715 Se r i e s (Phase I )

b RePORTDOCUMENTATtONPAGE . REPORT NUMBER 2. OOVT A C C I U I O N NO.

USAYPG Report 193 1 . T I T L E ( m d Sublltle)

Product Improvement Test of Nonmetallic Fuel

READ MM'RUCTIONS BEFO- COYPL-Q FORM

3. R L C I P I L N T ' ~ CATALOQ NUMIER

S. TYPE O? RePORT 6 CLAOO C O V L M O

F i r s t Le t t e r Report, 17 April

'. AUTHOR(a)

ATTN: STEYP-MTM I

8. CONTRACT OR GRANT N U M I L W ~ )

JUAN A. SUAREZ I. PERFORMING ORGANIZATION NAME AND ADDRESS

US Army Y u m a Proving Ground 10. PROORAM ELEMENT PR JECT, TASK

AREA * WORK UNIT * N ~ M ~ I M

US Army Tank-Automotive Command ATTN: AMSTA-RHT

Y u m a , Arizona 85364 1. CONTROLLING OFFICE NAME AND ADDRESS

J u 1974 13. NUMBER OF PAGES

12. REPORT DATE

Warren, Michigan 48090 I 14. MONITORING AGENCY NAME 13 ADDRESS(1f dlfforent from Controlling Offlc*) I 15. SECURITY CLASS. (of thle t.poH)

US Army Test and Evaluation Command ATTN: AMSTE-BB US Army Aberdeen Proving Ground, Maryland 21005

I NA 6. DISTRIBUTION STATEMENT (of L i e Roporl)

Dis t r ibu t ion l imi ted t o US Government Agencies only; Test and Evaluation; June 1974. Other reques t s f o r t h i s document must be re fe r red t o US Army Tank-Automotive Command, Warren, Michigan 48090

7. DlSTRleUTlON STATEMENT (of th* abalract .nt*red I n Block 10, 11 dlll*rent from Roport)

8. SUPPLEMENTARY NOTES

9. KEY WORDS (Continuo on raveroe d d o I f necoaauy and Identlfy by block number)

0. ABSTRACT (Contlnu* on rovorae aide I f nec*ae.ry m d Id*ntlfy by block number)

A Product Improvement Test of Nonmetallic Fuel Tanks f o r Trucks, M151 and M715 Se r i e s was conducted by US Army Yuma Proving Ground during the period 17 Apr i l 1973 through 10 May 1974. The purpose of t he test was t o determine the s u i t a b i l i t y of t h e nylon f u e l tanks f o r N151 and M715 s e r i e s t rucks un- der deser t environmental conditions. The t e s t items were i n s t a l l e d i n M151 and M715 s e r i e s t rucks. These t rucks were operated under rou t ine , adminis- t r a t i v e operation on gravel , paved and cross-country t e r r a i n a t US Army Yuma

EDITION OF 1 NOV 65 IS OBSOLETE

SECURITY CLASSIFICATION OF THIS PAGE ( m e n D.1. Enlered)

I 'the nylon f u e l tanks are sui table f o r use i n the M715 and M151 s e r i e s truck

It was recammended tha t :

(1) To preclude fur ther f u e l tank support bands slippage, one of the followSng act ions must be implemented: ( a ) Change the nylon f u e l tank design t o provide molded depressions, o r (b) join the support bands by in- s t a l l i n g two metal banding s t raps between them.

(2 ) Incorporate the operational procedure of grounding the f u e l pump and the f u e l sending uni t i n pertinent technical manuals.

Unclassified SKCURITY CLASSIFICATION OF THIS PAGE(Whrr Data k t -

DEPARTMENT OF THE ARMY M r . J . A . Suarez/mjt/899-2929 US Army Yuma Proving Ground

Yuma, Arizona 85364

STEYP-MTM

SUBJECT: F i r s t L e t t e r Report on Product Improvement Tes t o f Nonmetallic Fuel Tanks f o r Trucks, MI51 and M715 S e r i e s , TECOM P r o j e c t No. 1-VG-123-000-001 (Phase I )

Commander US Army Tank-Automotive Command ATTN: AMSTA-RHT Warren, Michigan 48090

Dates of Tes t : 17 Apr i l 1973 through 10 May 1974

1. REFERENCES

a. L e t t e r , Headquarters, US Army Tes t and Evaluat ion Command, AMSTE-BB, da ted 1 3 A p r i l 1972, s u b j e c t : Customer Tes t D i rec t ive : Product Improvement Test of Non-Metallic Fuel Tanks f o r Trucks, M151 and M715. -

b . Customer Test D i rec t ive , AMSTA-RPT, dated 28 March 1972, p l u s inc lo- s u r e l e t t e r , dated 14 March 1972, s u b j e c t : Tes t Program of Non-Metallic Fuel Tanks.

c . L e t t e r , US Army Tank-Automotive Command, AMSTA-RPT, dated 1 5 November 1 9 7 2 , s u b j e c t : Product Improvement Test of Non-Metallic Fuel Tanks.

d . I , e t t e r , Headquarters, US Army Tes t and Evaluat ion Command, AMSTE-BB, dilted 1 5 December 1972, s u b j e c t : Product Improvement Test o f Non-Metallic l 'ucl Tanks f o r Trucks, M151 and M715.

1

e . Customer Test D i rec t ive , AMSTA-RPT, da ted 4 December 1972, p l u s i n c l o s u r e l e t t e r , dated 1 6 November 1972, s u b j e c t : Revised Tes t Program for Non-Metallic Fuel 'iaa?ks.

f L e t t e r , US Army Test and Evaluat ion Command, AMSTE-BB, da ted 23 February 1973, s u b j e c t : Rescheduling of Non-Metallic Fuel Tank Tes ts .

C

STEYP-MTM SUBJECT: F i r s t L e t t e r Report on Product Improvement Tes t of Nonmetallic

Fuel Tanks f o r Trucks, M151 and M715 Ser ie s , TECOM Pro jec t No. 1-VG-123-000-001 (Phase I )

g. L e t t e r , US Army Tank-Automotive Command, AMSTA-RHT, dated 6 Novem- be r 1973, sub jec t : Product Improvement Test of Non-Metallic Fuel Tanks.

2. BACKGROUND

Nonmetallic f u e l tanks have c e r t a i n advantages over m e t a l l i c tanks i n s o far as they a r e not prone t o corros ion, a r e l i g h t weight and are somewhat l e s s expensive than metal f u e l tanks. US Army Tank-Automotive Connnand has been i n t h e process of securing from p r i v a t e indust ry , under c o n t r a c t , a quant i ty of nylon, high dens i ty polyethylene,and cross-l inked polyethylene f u e l tanks. Since t h i s ma te r i a l is r e l a t i v e l y new, t h e Army has e s t ab l i shed a program t o f i e l d t e s t them i n a l l environments ( h o t , co ld , dry , humid) f o r a t least 1 year t o determine t h e i r s u i t a b i l i t y t o m i l i t a r y app l i ca t ion . A t e s t program, Reference b , was i n i t i a t e d and its genera l plan was t o test a quan t i ty of nonmetallic f u e l tanks a t t h e arctic, d e s e r t , and t r o p i c test s i t e s . Due t o unresponsive bidding from manufacturers, and, later, t o de lay i n obta in ing t h e necessary t o o l i n g requi red i n manufacturing t h e t e s t i tems, t h e o r i g i n a l t e s t program was rev i sed and rescheduled by Referencesc through g. I n i ts rev i s ion , Reference e a l s o includes t e s t - ing t h e items a t t h e temperate test s i t e . Because t h e test items could - not a r r i v e a t t h e d i f f e r e n t test sites a t t h e same time, TACOM decided t o d iv ide t h e progran. i n t o two phases. Phase I of t h e test (nylon f u e l tanks) was t o start between March and Apr i l 1973 a t t h e arctic, d e s e r t and temperate test s i t e s ; Phase I1 of t h e t e s t (high dens i ty polyethylene and cross-l inked polyethylene f u e l tanks) was t o s t a r t between January and Apr i l 1974 a t a l l four of t h e previously mentioned t e s t sites.

This r e p o r t is based on t h e r e s u l t s obtained during Phase I o f t h e t e s t ( r o u t i n e , adminis t ra t ive opera t ion of t h e M151 and M715 s e r i e s with t h e i n s t a l l e d nylon f u e l tanks on g rave l , paved and cross-country t e r r a i n ) a t US Army Yuma Proving Ground.

I

3. OBJECTIVE

To determine the s u i t a b i l i t y of t h e nylon f u e l tanks f o r t h e M151 and M715 s e r i e s t r u c k s under d e s e r t environmental condit ions.

4. PROCEDURES AND RESULTS

Sixteen nylon f u e l tanks (one each f o r e igh t M715 and one each f o r e igh t M151 series t rucks ) were received f o r t e s t . Each t e s t item was inspected;

STEYP-MTM SUBJECT: F i r s t L e t t e r Report on Product Improvement Test of Nonmetallic

Fuel Tanks f o r Trucks, M151 and M715 Ser ie s , TECOM Projec t No. 1-VG-123-000-001 (Phase I)

no damage o r i r r e g u l a r i t i e s were found. The conventional t e r n e p l a t e tank was removed from each of t h e f a c i l i t y t rucks and s to red f o r f u t u r e r e in - s t a l l a t i o n . The t e s t i tems were i n s t a l l e d i n t h e above f a c i l i t y t rucks i n accordance with t h e i n s t a l l a t i o n and s a f e t y procedures out l ined i n TM 9-2320-218-20 (Organizat ional Maintenance Manual f o r M151 s e r i e s t rucks ) and TM 9-2320-244-20 (Organizat ional Maintenance Manual f o r M715 s e r i e s t r u c k s ) . Since t h e M151A1 t ruck conta ins a self-grounded submerged f u e l pump i n t h e t e r n e p l a t e f u e l tank, t h e f u e l pump i n t h e nylon f u e l tank a s we l l a s t h e f u e l sending u n i t had t o be grounded. The mileage of each t ruck was then recorded. The 16 t rucks were operated f o r 1 year under rou t ine , adminis t ra t ive operat ion on gravel , paved and cross-country t e r r a i n . During t h e 1-year period, a s circumstances permitted, t h e f u e l tanks were checked f o r f u e l leakage, cracking, bulging, e t c . When a problem developed, it was inves t iga ted and then temporari ly correc ted by USAYPG t o expedite t e s t i n g . Af ter the one-year t e s t period was completed, t h e mileage of each t ruck was recorded again t o e s t a b l i s h t o t a l t e s t miles on each nylon f u e l tank. The nylon f u e l tanks were inspected before and a f t e r removal from the t rucks . No damage o r i r r e g u l a r i t i e s were found i n t h e t e s t items ex- cept f o r some thermal expansion of t h e f u e l tanks which was expected of t h i s mater ia l . No co lo r changes, cracking o r craz ing were found during t h i s inspect ion .

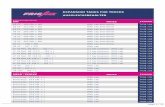

Date of i n s t a l l a t i o n and removal of each t e s t item, i d e n t i f i c a t i o n of each t r u c k , t o t a l t e s t miles accumulated on each t e s t i tem, and p e r t i - nent remarks can be found i n Inclosure 1. Photographs i l l u s t r a t i n g t h e nylon f u e l tank a s i n s t a l l e d on t h e t ruck can be found i n Inclosure 2. I

Meteorological da ta a t USAYPG from Apri l 1973 through Apr i l 1974 a r e in- cluded f o r information purposes i n Inclosure 3.

'The following inc idents occurred with the M715's nylon f u e l tanks during t h e 1 year of t e s t :

I a. After 116 days of operat ion and 2087 accumulated t e s t miles on t h e nylon f u e l tank which was i n s t a l l e d i n t ruck USA Reg No. 03B00469, the sup- p o r t bands were found t o have s l ipped o f f (due t o road v ib ra t ions ) allowing the f u e l tank t o f a l l t o t h e ground. The f u e l l i n e s and t h e gage wire were r ipped loose. The f u e l tank i t s e l f sus ta ined minor scra tches but d id not rupture. The f u e l tank was then r e i n s t a l l e d . A t t h i s time, two metal band- ing s t r a p s were i n s t a l l e d joining t h e two support bands t o keep them from separa t ing .

P STEYP-MTM SUBJECT: F i r s t Letter Report on Product Improvement Test of Nonmetallic

Fuel Tanks f o r Trucks, M151 and M715 Ser ie s , TECOM Projec t No. 1-VG-123-000-001 (Phase I )

b. Another inc ident similar t o t h e one mentioned i n t h e above para- graph occurred with t r u c k USA Reg No. 03543568 a f t e r 119 days of operat ion and 1652 accumulated t e s t miles. Two metal banding s t r a p s were then i n s t a l l e d jo in ing t h e two support bands.

c . A last inc ident similar t o t h e ones i n t h e above paragraphs occurred with t ruck USA Reg No. 03E92768 a f t e r 125 days of operat ion and 761 accumu- l a t e d t e s t miles. However, t h e inc ident was noticed before t h e f u e l tank could f a l l o f f , preventing poss ib le damage t o t h e f u e l tank o r any of its components. Metal banding s t r a p s were i n s t a l l e d a s explained above.

During t h e inspect ion o f a l l t h e above inc iden t s , it was found t h a t t h e nu t s on t h e end of t h e support bands could not be t ightened fu r the r . However, t h e r e was an inc ident with M715 t ruck USA Reg No. 03M41668 where one of t h e n u t s on t h e end o f a support band loosened and f e l l o f f , allowing t h e support band t o loosen and t h e tank t o near ly f a l l o f f , The support bands were put back i n place and t h e nut was t ightened.

Af ter t h e support band s l ippage inc ident occurred i n t h r e e separa te t rucks , two metal banding s t r a p s were i n s t a l l e d on each of t h e nylon f u e l tanks on t h e r e s t of t h e M715 s e r i e s t rucks .

I l l u s t r a t i o n s of t h i s modification can be found i n Figures 3 and 4, Inclosure 2.

5. CONCLUSIONS

The nylon f u e l tanks a r e s u i t a b l e f o r use i n t h e M715 and M151 s e r i e s t rucks under d e s e r t environmental condit ions.

6. RECOMMENDATIONS

. To preclude f u r t h e r f u e l tank support bands s l ippage , one of the following a c t i o n s must be implemented:

(1) Change t h e nylon f u e l tank design t o provide molded depres- s ions , o r

( 2 ) Jo in t h e support bands by i n s t a l l i n g two metal banding s t r a p s between them (See Fig 3 and 4 of I n c l 2 ) .

STEW-MTM SUBJECT: First Letter Report on Product Improvement Test of Nonmetallic

Fuel Tanka for Trucks, MI51 and M715 Series, TECOM Proj~ect No. 1-VG-123-000-001 (Phaae I)

b. Incorporate the operational procedure of grounding the fuel pump and the fuel rending unit in pertinent technical manula.

FOR THE COMMANDER:

4 Incl 1. Test Data 2. Photographs 3. Meteorological Data 4. Distribution List

BAElON J. HEICK Acting Director of Materiel Teat

TEST DATA NYLON FUEL TANKS

1 Dates I Truck USA pns ta l la t ion I Removal ( Reg No.

18 Apr 73 6 May 74 03E92768

20 Apr 73 7 May 74 03F50668

23 Apr 73 6 May 74 3D67368

24 Apr 73 29 Apr 74 03543568

25 Apr 73 30 Apr 74 03502260

26 Apr 73 7 Hay 74 03B00469

Type of Truck

U5lA1, %-Ton 415lA1, %- on TI. 5 lAl . 36- Ton

I'otal Tesi Miles Remarks

The submerged f u e l pump and f u e l sending uni t must be grounded. Incorporation of t h i s opera- t iona l procedure i n the per t inent technical manuals is required.

(1) After 127 days of operation and 1101 accu- mulated t e s t miles, the nut on the end of a support band loosened and f e l l o f f . The supporl band loosened and the tank nearly f e l l off . (2) Two metal banding s t r aps were added on 23 --- - -

Aug 73 a f t e r 1169 ac&nula&d test miles. (1 ) After 125 days of operatior, and 761 accu- mulated t e s t miles, t he support bands began t o s l i p o f f . The f u e l tank d id not f a l l off . (2) Two metal banding s t raps were added on 21 August 1973 a f t e r 761 accumulated t e s t miles. (1) Two metal banding s t r aps were added (no - .- - record of date and mileage). (2) Vehicle remained parked s ince 29 Jan 74 waiting f o r power t r a i n r e p a i r par ts . Two metal banding s t r aps were added on 27 AunB - a f t e r 3343 accumulated t e s t m i l e s . Two metal banding s t raps were added on 23 AugZ - a f t e r 432 accumulated t e s t m i l e s . (1) After 119 days of operation and 1652 accu- mulated t e s t miles, t h e support bands slipped o f f . The f u e l tank f e l l o f f . (2 ) Two metal banding s t r aps were added on 23 Aug 73 a f t e r 1652 ac&ulated t e s t miles. Two metal banding s t r aps were added on 22 AUR 7 - a f t e r 991 accumulated test miles. (1) After 116 days of operation and 2087 accu- mulated t e s t miles, t he support bands slipped of f . The f u e l tank fel l of f . (2) Two metal banding s t r aps were added on 17 Aug 73 a f t e r 2687 accumulated t e s t miles.

. y . < : . : . ,. " r ;...:: p?..e.. :::2 ,%.y3.$3~ ?$$g?. 3 i&:: $4;~ . ixk.T&. .3:.~& .s , .~ is.y2 %?-.-].,.% ;$,-z.J&. yg2gi $mp$; 6 g3g&.;f3g '.

&+:.-.--- 2..A. ,......., .,.. A,..w. *& .<...A.U ,c.w':: .... .,.. &3.2g. <zpizz:ge;2. %&333. ~ ; . ~ ~ ~ ; ; $ ~ zki3t && 2~ be- ~.:~;~:$~;~.~~.~j.~.ij ~ ~ : < ~ ~ ~ . . . a? 2 <:~2r2*ggziE;~;~~~tzi2~~~ g2393.3:~- ' & : ~ ~ ~ & g ~ $paB; ~ g p ~ p ~ ~ ~ ~ $ G g ~ e * h

METEOROLOGICAL SUMMARY FOR APRIL 1973

AVERAGE DAILY SKY CONDITION C - CLEAR P - PARTLY CLOUDY & CLOUDY

r i l l -

I ~ I I I I I I I I I I I ~ I I I I I I I I I I I C C C C C C C C P P C e c C P c C C C . P C C C C C C C C P

60 *

AV6RAbC HOURLY SOLAR RADIATION (OM CAI./CMJ *

50

1

40 I

Incl 3 Page 1 of 14

v I

3 0

20. 6 -

N

2 0

15

10

5

0

I AVERAGE HOURLY S O U R RADIATION (QM CAL / C M ~

I

DAILY Pl?EVAlLING WIND SpEEO [ M P ~ , AND DIRECTION

AVERAGE DAILY SKY CONDITION C-CLEAR P-PARTLY CLOUDY & CLOUDY

C I I I ~ I I I I I I I I I I I I I I I I . I I I I . I I I I I I C C C O C C C C C C C P C C C C C C C C C . ' C C C C P C P . P C C Incl 3

METEOROLOGICAL SUMMARY FOR JUNE 1973

Incl 3 Page 3 of' 1 4

METEOROLOGKAL SUMMARY- FOR JULY 1973

MAXIMUM AND M I N I M U M DAILY AMBIENT

TEMPERATURE (OF)

AVERAGE HOURLY S O U R RADlATlO

1

AVERAGE DAILY SKY CONDITION C - CLEAR, P S A R T L Y CLOUDY & CLOUDY

U C P C C C C C C

Incl 3 Page 4 of 14

I

METEROLOGICAL SUMMARY FOR AUGUST 1973

N

20 DAILY PREVAILING W I ~ D (SPEED ( M P N AND DIRECTION)

I

15

10 - I -1

AVERAGE DAILY SKY CONDI'IION C - CLEAR P - PARTLY CLOUDY & CLOUDY

~ I I I I I I I I I I I I I I I I I I I I I I I I . I I I I ~ ~ C P P P C C C C c C C c P P P P P P c P c C C C C c c C C P C

Incl 3 Page 5 of' 14

JOD ,DPCt