Procurement Candidate Manual SS Online

description

Transcript of Procurement Candidate Manual SS Online

P u r c h a s i n g M a n a g e m e n t A s s o c i a t i o n o f C a n a d a

Professionals in Supply Chain Management

Enhanced. Exceptional.

Strategic S U P P L Y C H A I N M A N A G E M E N T

Leadership Program

Module

Procurement and Supply ManagementC A N D I D A T E M A N U A L : S E L F - S T U D Y

CPP SSCMLP Manual Covers 9/21/06 11:53 AM Page 1

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada i

Strategic Supply Chain Management Leadership Program

Module Two

Procurement and Supply Management

Candidate Manual

(Self Study)

Copyright © 2007 Purchasing Management Association of Canada. (Rel. 1) Revised October 2009.

No part of this material in this manual may be reproduced without the prior written consent of the Purchasing Management Association of Canada. 777 Bay Street, Suite 2701, P.O. Box 112, Toronto, Ontario M5G 2C8 Tel: (416) 977-7111 Fax: (416) 977-8886 Web Site: www.pmac.ca.

Use of this material is restricted to PMAC and its Provincial/Territorial Institutes for the express purpose of delivering the Strategic Supply Chain Management Leadership Program. No other use is authorized, express or implied. This material must be used in its entirety.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada ii

Table of Contents Information and Overview………………………………………………….…IO – 1 General Information…………………………………………………….. …IO – 2 Module Overview……………………………………………………….. …IO – 5 Module Materials………………………………………………………........IO – 8 Module Readings……………………………………………………….... ...IO – 9 Session and Reading Summary…………………………………………. …IO – 14 Candidate Evaluation……………………………………………………......IO – 17 Module Evaluation………………………………………………………. .....IO – 24 Session One – Tactical and Strategic Procurement…………………..…………S1 – 1 Session Two – Procurement Processes…………………………….……..……..S2 – 1 Session Three – Competitive Bidding and Negotiation…………..………..……S3 – 1 Session Four – Procurement and Supply Management Organization……..…….S4 – 1 Session Five – Make or Buy…………………………………………..………....S5 – 1 Session Six – Price and Cost Analysis………………………………….………...S6 – 1 Session Seven – Quality and Inventory…………………………………………..S7 – 1 Session Eight – Supplier Selection…………………………….…………………S8 – 1 Session Nine – Supplier Development and Certification…………..…………….S9 – 1 Session Ten – Services Procurement…………………………………………….S10 – 1 Session Eleven – E-Procurement………………………………………………...S11 – 1 Session Twelve – Involving Users and Suppliers………………………………..S12 – 1 Session Thirteen – Module Ending Examination………………………………...S13 – 1 Appendix: Fabritek, 1992 Sample Case and Report (see News section of community) Appendix: PowerPoint Slides

© Purchasing Management Association of Canada IO - 1

Introduction and

Overview

General Information

Module Overview

Module Readings

Schedule & Reading Summary

Candidate Evaluation

Module Evaluation

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 2

General Information

About the Program

The Strategic Supply Chain Management Leadership Program is PMAC’s C.P.P. Accreditation Program that has been redesigned and enhanced for 2007. This new Program is competency based and takes an integrated approach, shifting the focus of the profession from purchasing to strategic supply chain management in order to meet the evolving needs of the marketplace. The new C.P.P Accreditation Program is the most comprehensive program available in Canada, balanced to deliver advanced supply chain management knowledge and high-level business skills. The education component of the Program consists of eight modules which cover the foundational knowledge of supply chain management and six interactive workshops which address higher-level business skills. The Program is designed so that learning can be applied immediately in the workplace. This allows candidates to demonstrate their increased knowledge and value to their organizations as they progress through the program.

Program Modules

As stated above, there are eight modules which will be delivered over a 36-month period. There are four modules that are 13 sessions in duration and four modules that are seven sessions in duration. This is the second module of the Program – Procurement and Supply Management, a 13-session module. Below is a listing of all the modules so that candidates can see how they are progressing in the program and what they have to look forward to in the coming months.

Module Title

13-Session Modules

1 Supply Chain Management

2 Procurement and Supply Management

3 Logistics and Transportation

4 Operations and Process Management

7-Session Modules

5 Knowledge Management

6 Global Sourcing

7 Supply Chain Management for the Public Sector

8 Supply Chain Management for Services, Capital Goods and Major Projects

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 3

General Information, continued

Program Philosophy

PMAC’s philosophy for all of its modules and interactive workshops is that candidates learn by doing. Candidates who work thoroughly through the material to develop a good understanding of concepts and principles presented, and complete all the assigned readings, framework questions and assignments should have no trouble successfully completing the Program. Memorization of the materials is not as important as is: • careful preparation • being able to fully grasp the ideas and concepts presented, and • knowing where to go for the appropriate reference material. It is expected that candidates will be able to apply the appropriate concepts or techniques to the correct problem or decision at the right time.

Workload As a general rule, candidates should expect to spend an average of 10 hours of

preparation time for each session. Some sessions will require less work, while others may require more. Please note that the amount of time spent on each session will be influenced by present knowledge and experience, as well such factors as reading skills and comprehension skills.

Schedule This module has twelve sessions and a final exam session.

Candidates will receive a session schedule upon enrollment in the module. The session schedule includes the following information: - Assignment due dates - Assignment submission instructions - Information on the final exam - Information on marking Candidates who have not received this information should contact their local provincial or territorial institute.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 4

General Information, continued

Candidate Responsibilities

In order to be successful in this module it is important for all candidates to do the required work for each session. Candidates who do all the required work are prepared for writing the case report in the module exam. Many different assignments and learning activities are provided in this module in order to increase and reinforce transfer of knowledge. To ensure success candidates are expected to: • Do all the required readings for each session prior to completing the assignments • Read and prepare the assignments for submission, following the instructions provided • Through assignments, contribute relevant and timely information that will enhance

learning • Assume a strategic point-of-view when doing all readings and assignments

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 5

Module Overview

Introduction Procurement is the process of acquiring goods and services by organizations. Traditionally procurement has not been thought of in a strategic sense. As the share of production that is purchased goods has risen, so has the importance of procurement. Procurement is now one of the key strategic elements of an organization. The goal of this module is for candidates to better understand the strategic role of procurement, as well as tactical approaches that support the strategy.

About this Module

The focus of this module is on matters of strategic and tactical importance in procurement. The module starts with a discussion of strategic and tactical procurement, and goes on to consider key processes that support an organization’s strategic procurement goals. A comprehensive procurement strategy backed up by solid procurement tactics supports an organization’s goal of providing customers with highly valued products. Specific tactical matters are considered along the way. The sessions in this module are inter-related. Tactical and strategic purchasing delves into procurement processes (session 2), which leads to an examination of relationships and teams (session 4), and an exploration of the core competencies of the organization including make or buy decisions (session 5), price and cost analysis (session 6), supplier selection (session 8), and e-procurement (session 11). The cases examined in this module further apply the concepts and tools learned throughout the module. The module has a reading list with diverse but important topics. The articles provided are often theoretical, and explain complex methodologies. It is important when reading to focus on how the methodologies presented are applied. Avoid spending too much time on the theories themselves. Focus on the introductions, management implications and conclusions in the articles. Information gathered in readings can be applied to the activities and case analyses.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 6

Module Overview, continued

Module Objectives

Upon completion of this module candidates should be able to:

• Analyze case studies, and write case reports.

• Understand the elements of procurement strategy.

• Develop procurement strategy.

• Develop and apply tactics that support procurement strategy including those related to processes, organization, supplier selection and relationships, decision making, and technology.

• Analyze, or direct others in the analysis of make or buy decisions, price, cost,

quality, inventory, and total cost of ownership.

• Apply, or direct others in the application of tools to evaluate suppliers, and produce statements of work.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 7

Module Overview, continued

Module and Session Organization

This module consists of thirteen sessions. Each session’s workload is equivalent to that of a three-hour instructor-led class. The module objectives are covered in sessions one to twelve and the module ending examination is administered during session thirteen (a four-hour exam). This self-study module contains the equivalent workload and content as the instructor-led thirteen-week module.

Candidates will receive the following materials:

1. Candidate Manual (this manual): the guide for the module

2. Readings and Cases Manual: articles and cases for this module

3. Session Schedule: assignment due dates and instructions for submission Each session of this manual will contain the following sections as required:

• Agenda – a guide to each session’s format and content

• What You Already Know - a brief statement linking information in the session to any previous session (or to the candidate’s experience).

• Overview – a brief description of the contents of the session

• Objectives – a description of what candidates are expected to learn from the session

• Required Reading – reading assignments for the session

• Case Preparation – indicates the cases to be prepared for written reports

• Framework Questions – questions for framing each case analysis and report

• Exercises – instructions for preparing and submitting exercises

• Self-Assessment Activities – exercises to reinforce knowledge

• Session Notes – notes on the specific concepts or issues covered in the session

Learning Activities

Candidates will achieve learning in this module through the following learning activities: • Readings • Case study preparation • Written case reports • Exercises • Self-assessment activities

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 8

Module Materials

Module Materials

Materials included in this manual: The Introduction and Overview – contain the following: − General information and module overview − Information on readings and materials − Information on assignments − Guidelines for candidate evaluation Each Session contains the following – − Agenda for the session (the order of material and assignments in the session) − Readings, cases and assignment instructions − Session notes on the content and purpose of the session The Appendices contains – − Sample case and sample case report: Fabritek, 1992 − Printouts of the PowerPoint slides (from the Instructor-led version of the module) Materials included in the Readings and Cases manual: − Articles and cases Information included in the Session Schedule: − Assignment due dates − Assignment submission instructions − Information on the final exam − Information on marking Materials available on the Internet: − PMAC Code of Ethics (www.pmac.ca)

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 9

Module Readings

Module Readings

The readings for this module are drawn from business, professional and academic publications. Each reading is assigned a letter which is used in the Session Schedule and Reading Summary (see the following section) for your easy reference. They are as follows: A. Burt, Dobler and Starling (2003). World Class Supply Management, 7th edition, McGraw-Hill Irwin, New York. A1. Pages 239-246, 250-251 A2. Pages 41-49 A3. Pages 104-117 A4. Pages 304-315 A5. Pages 405-407, 409-411, 413-419, 426-430 A6. Pages 147-155

B. Leenders, Johnson, Flynn and Fearon, (2006) Purchasing and Supply Management, 13th Edition, McGraw-Hill Irwin, New York. Pages 59-77. C. Ritzman, Krajewski, Malhotra and Klassen (2007). Foundations of Operations Management, 2nd Canadian Edition, Pearson Canada Inc., Toronto. p.283-290, 305-6. D. Cavinato, Joseph, L. Fitting Purchasing to the Five Stages of Strategic Management. European Journal of Purchasing and Supply. #5, Issue 2. 1999. Pages 75-83. E. Heath, Stanley. Tackling Spend Analysis. Contract Management. January 2006. Pages 40-45. F. Zsidisin, George A. A Grounded Definition of Supply Risk. Journal of Purchasing and Supply Management. 2003. Pages 217-224. G. Wheeler, Michael (date). Negotiation Analysis: An Introduction. Harvard Business School. 9-801-156. H. Johnson and Leenders. The Supply Organizational Structure Dilemma. Journal of Supply Management, Summer 2001. Pages 4-11. I. Prahalad, C. K. and Hamel, Gary. The Core Competence of the Corporation. Harvard Business Review. May-June, 1990. J. Ellram, Lisa. Total Cost of Ownership: Elements and Implementation. National Association of Purchasing Management. October, 1993. Pages 3-11.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 10

Module Readings, continued

Module Readings, continued

K. Stuart, F. Ian and Mueller, P. Jr. Total Quality Management and Supplier Partnerships: A Case Study. International Journal of Purchasing and Materials Management. Winter, 1994, Pages 14-20. L. Genna, Albert. How do you find the right quality wavelength? Purchasing. Jan 16, 1997. Pages 45-46. M. Wilson, Elizabeth J. The Relative Importance of Supplier Selection: Review and Update. International Journal of Purchasing and Materials Management. Summer, 1994. Pages 35-41. N. Smytka, Daniel L and Clemens, Michael W. Total Cost Supplier Selection: A Case Study. International Journal of Purchasing and Materials Management. Winter, 1993, Pages 42-49. O. Cruz, Clarissa. Purchasing Pros Search for the Perfect Number of Suppliers. Purchasing. July 11, 1996, Pages 28 and 29. P. Carter, Phillip L., Monczka, Robert M., and Mosconi, Trish. Strategic Performance Measurement for Purchasing and Supply. CAPS: Center for Strategic Supply Research, 2005, Pages 10-27. Q. Krause, Daniel D. Supplier Development: Current Practices and Outcomes. International Journal of Purchasing and Materials Management. Spring, 1997. Pages 12-19. R. Lockhart, Marsetta and Ettkin, Lawrence. Vendor Certification: Seven Steps to a Better Product. Production and Inventory Management Journal. First Quarter 1993. Pages 65-69. S. Park, Hong Y., Reddy, S., C. Shin, G.-C. and Eckerle, C., Impact of Supplier Certification Program on U.S. Firms. European Journal of Purchasing and Supply Management. Volume 2, 1996. Pages 107-118. T. Sharland, Alex, Eltantawy, Reham, A. and Giunipero, Larry C. The Impact of Cycle Time on Supplier Performance and Subsequent Performance Outcomes. Journal of Supply Chain Management. Summer, 2003. Pages 4-12. U. Ellram, Lisa M., Tate, Wendy L. and Billington, Carey. Understanding and Managing the Services Supply Chain. Journal of Supply Management. Nov. 2004 Pages 17-32.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 11

Module Readings, continued

Module Readings, continued

V. Smeltzer, Larry R. And Ogden, Jeffrey A. Purchasing Professionals Perceived Differences Between Purchasing Materials and Purchasing Services. Journal of Supply Chain Management, Winter 2002. Pages 54-70. W. Service Level Agreements: Guidelines for Public Sector Organizations. New South Wales Premier’s Department, 1999. X. Porter, Anne Millen. A purchasing manager’s guide to the e-procurement galaxy. Purchasing. September 21, 2000. Pages S72 to S88. Y. Anonymous Author. Consultant’s Top 12 e-procurement tips. Purchasing. November 16, 2000. Pages 79 to 88. Z. Clark, Chris. Five Auction Steps. Purchasing. June 21, 2001. Pages 24 to 26. AA. Manciagli, Dana. A Supplier’s View. Purchasing June 21, 2001. Page 26. AB. Atkinson, William. IT Firm uses reverse auction for big contract labour buy. Purchasing, December 22, 2000. Pages 97 to 99. AC. Palmer. Richard J., Green, Leland D., and Ventura, Marie T. Are Corporate Procurement Cards for You? Management Accounting. September 1996. Pages 22-27. AD. Carbone, James. To save more distribute more cards study says. Purchasing. May 18, 2006. Page 29. AE. Gibley, Tracy. A guide to purchasing card success: overcoming 8 key hurdles. Treasury Management Association Journal. July/August 1999. Pages 47-50. AF. Waller, M, Johnson, M.E., and Davis.D., Vendor Managed Inventory in Retail Supply Chains, Journal of Business Logistics, #20, 1999. Page 183-187. AG. Dixon, Lance. JIT II: A New Approach to Supply Management. Center for Quality Management Journal. August 1992. Pages 15-19. AH. Pragman, Claudia, H. JIT II: A Purchasing Concept For Reducing Lead Times IN Time-Based Competition. Business Horizons. July-August 1996. Pages 54-58.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 12

Module Readings, continued

Module Readings, continued

Case Studies

• Blozis Company. Purchasing Agents Association of Connecticut. Inc. (Session 2)

• De Havilland Incorporated. Richard Ivey School of Business. #9A95B037.

(Session 3)

• Frich Turbo Engine Company. Harbridge House Inc. (Session 6)

• Placido Engine Company. Burt Dobler and Starling. World Class Supply Management. (Session 7)

• Platinum Box. Satyatas Consulting. (Session 8)

• Fisher and Paykel Limited. Richard Ivey School of Business #9A97D015.

(Session 9)

• Boeing Australia Limited: Assessing the Merits of Implementing a Sophisticated e-Procurement System. #HKU271. Centre for Asian Business Cases. (Session 11)

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 13

Module Readings, continued

Supplementary Readings and Websites

These are a selection of additional references on business mathematics that candidates may find useful. These are not required readings for the module. Note that Wikipedia provides information on various subjects. The web links below are suggested reading if you feel you need to review business mathematics and accounting. Also provided are some sites that describe some of the terminology and tools used in this module. • Financial Analysis definitions and terms: http://en.wikipedia.org/wiki/Financial_analysis • Financial Statements definition and terms: http://en.wikipedia.org/wiki/Financial_statements • Holding Costs definition: http://en.wikipedia.org/wiki/Holding_cost • Inventory definitions and terms: http://en.wikipedia.org/wiki/Inventory (then go to Business Inventory) • Return on Investment definition: http://en.wikipedia.org/wiki/Return_on_Investment • Strategic Profit Model Tool (a walk-through of the SPM): http://www.ism.ws/ismapps/cavinato/strat1.cfm • Cycle Time Reduction: a Worksheet for the Construction Industry http://www.toolbase.org/PDF/BestPractices/day_worth_worksheet.pdf

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 14

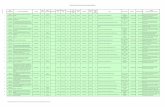

Session and Reading Summary

Introduction The table below provides a summary of all the readings, topics and activities in this

module for easy reference. A more detailed listing of the readings can be found on the preceding pages.

Session Topics and Activities Readings

1

Tactical and Strategic Procurement • Procurement and Supply Management • Strategic Stages of Purchasing • Tactical and Strategic Procurement • Spend Analysis / Procurement Risk • Cavinato’s 5 Stages of Strategic Management • Self-assessment activity: (not marked) Spend Analysis • Individual exercise: (marked – 5%) Goods Spend Analysis at Your

Organization

D,E,F

2

Procurement Processes • Steps in the Procurement Process • Importance of Description of Needs & Specifications • Types of Specifications & Specification Development • Potential Problems • Individual Written Case Report: (marked – 5%) Blozis Company

B, A1

3

Competitive Bidding and Negotiation • Factors related to choice of competitive bidding • Types of bids • Factors related to choice of negotiation. • Objectives of negotiation & steps in negotiation • Individual Written Case Report: (marked – 10%) De Havilland Inc.:

Applying Negotiation Analysis

G

4

Procurement and Supply Management Organization • Internal procurement relationships • Financial leverage effect • Cross functional teams • Organizing - centralized, decentralized and hybrid • Self-assessment activity: (not marked) Financial Leverage Effect • Individual exercise: (marked - 5%) Centralization versus

Decentralization

A2, H, A3

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 15

Session and Reading Summary, continued

Session Topics and Activities Readings

5

Make or Buy • Make or buy at the strategic and tactical level • Total cost of ownership: elements, benefits and implementation • Individual Written Case Report: (marked – 5%) Make or Buy and

Total Cost of Ownership: Happyland Construction

A4, I, J

6

Price and Cost Analysis • What is the Right Price? • Price Assessment • Market Conditions - Procurement • Leverage / Cost Analysis / Types of Costs / Profit • Learning Curves • Individual Written Case Report: (marked 5%) Frich Turbo Engine

Co. & Price Analysis

A5

7

Quality and Inventory • Factors Affecting Long Term Quality • Total Quality Management • Quality Training for Procurement Staff • Purposes of Inventory • Forecasting Demand • Inventory Models & Inventory Relationships • Self-assessment Activity: (not marked) Placido Engine Company • Individual exercise: (marked – 5%) ISO 9001:2000 and Your

Organization

A6, C, K, L

8

Supplier Selection • Sourcing: Finding Suppliers • Weighted Evaluation Systems & Product Attribute Considerations • Total Cost Approach • Single versus Multiple Sourcing & The Perfect Number of Suppliers • Individual exercise: (marked – 5%) Un-weighted Supplier

Evaluation Matrix: Platinum Box • Individual Written Case Report: (marked – 5%) Platinum Box

M, N, O

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 16

Session and Reading Summary, continued

Session Topics and Activities Readings

9

Supplier Development and Certification • Procurement performance monitoring • Approaches to supplier development • Objectives of supplier certification & Benefits of certification • Steps in supplier certification • Product development cycle times and supplier performance • Individual exercise: (marked – 5%) Supplier Certification • Self-assessment activity: (not marked) Fisher and Paykel Ltd.

P,Q,R, S,T

10

Services Procurement • Services are different • Procurement involvement: Services are the same • Services spend analysis • Specification: Statements of Work & Service Level

Agreements • Individual exercise: (marked – 5%) Services Spend Analysis

for Your Organization • Individual exercise: (marked – 5%) Services Procurement –

Statement of Work

U,V,W

11

e-procurement • Forms of e-procurement • Pros and cons of e-procurement • e-procurement knowledge areas / Implementing e-procurement • Reverse auctions • Individual Written Case Report: (marked – 10%) Boeing

Australia Limited

X,Y,Z, AA, AB,

AC

12

Involving Users and Suppliers

• P-Cards: Benefits • P- Cards: Considerations in Implementation • Vendor ( Supplier) Managed Inventory • Just in Time II • Wrap up

AD, AE, AF,AG,AH

13 Module Ending Examination • Case Analysis and Written Case Report (marked – 25%)

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 17

Candidate Evaluation

Introduction Candidates will be evaluated on individual performance using a variety of methods.

These include exercises, activities, written case reports and a module ending examination. Below is a breakdown of the mark allocation, as well as a description of each evaluation method.

Mark Allocation

The following table shows the allocation of marks for the different methods of evaluation used in this module.

Individual

Exercises (7) 35%

Written Case Reports (6) 40%

Module Ending Examination 25%

Individual Total 100%

Exercises There are a total of seven marked exercises. These exercises are in various forms.

Generally, the exercises require candidates to apply the concepts and tools learned in the session to their own organizations. Each of the marked exercises will be worth 5 percent of the candidate’s total mark. The seven marked individual exercises are:

1. Goods Spend Analysis (session 1) 2. Centralization versus Decentralization (session 4) 3. ISO 9001:2000 and Your Organization (session 7) 4. Un-weighted Supplier Evaluation Matrix: Platinum Box (session 8) 5. Supplier Certification (session 9) 6. Services Spend Analysis for Your Organization (session 10) 7. Services Procurement: Statement of Work (session 10)

Please see the Exercise section of each session for detailed exercise instructions. Candidates are provided with a separate session schedule with assignment due dates upon course enrolment. This schedule will indicate when each exercise is due.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 18

Candidate Evaluation, continued

Case Preparation

There are six cases to prepare as written case reports. The following are quick tips for reading case studies prior to writing case analyses:

1. Read the opening and closing paragraphs to identify issue(s) and challenges. 2. Examine tables and figures in the exhibits to determine what information is

useful in the decision-making process. 3. Examine the headings in the case to determine what information is available

for analysis. 4. Review the framework questions provided in each session of this module. 5. Read the first sentence of each paragraph, scanning for decisions made and

alternatives available. 6. Read closely, highlight issues, and make notes to gain a full understanding

of the case. 7. Decide what you would do if you were the decision maker in the case.

Written Case Reports: an Introduction

The six cases to be submitted as written case reports are:

1. Blozis Company (session 2, worth 5%) 2. De Havilland Inc.: Applying Negotiation Analysis (session 3, worth 10%) 3. Make or Buy and Total Cost of Ownership: Happyland Construction

(session 5, worth 5%) 4. Frich Turbo Engine Co. & Price Analysis (session 6, worth 5%) 5. Platinum Box (session 8, worth 5%) 6. Boeing Australia Limited (session 11, worth 10%)

For specific instructions on each case, refer to the session in which the case report occurs. Candidates will be evaluated on their ability to analyze and present information according to the Written Case Report Guidelines (see next section). When writing the paper connecting threads between thoughts must be present. For example issues, analysis, recommendations and implementation must flow from each other. Ideally all recommendation(s) will fall in line with the identified strategy. The main recommendation(s) should be aimed at fixing the system not the symptoms. The following section outlines the requirements for a case report. For further reference, A sample case, Fabritek, 1992, and a sample case report marking sheet have been provided in the Appendix for your reference. This case represents an example of how a response will be graded by applying the marking structure, it’s is not a sample of a model response.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 19

Candidate Evaluation, continued

Written Case Reports: an Introduction (continued)

In general, the objectives of a case analysis are: • to discover the issues in the case • to determine the criteria for making a decision • to analyze the options available (if applicable) • to decide the best plan of action • to present your findings in a written report Each of the cases present a procurement situation in which a decision must be made in a particular context, and in light of a number of tradeoffs and alternatives. While there are no right answers to a case, there are definite approaches that address the issues and recognize the trade-offs involved. For each of the cases there will be framework questions. These questions aid in discovering the important aspects of the case, and guide the preparation of the written case report. Candidates should be prepared to address these questions in the written report itself. It is important for the candidate to adopt the role of decision maker, and to address the real issues: "What should be done and why?", and “How do I plan to resolve the situation?” Candidates are provided with a separate session schedule with assignment due dates upon course enrolment. This schedule will indicate when each case report is due.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 20

Candidate Evaluation, continued

Written Case Reports

The written case reports should follow these guidelines: Audience: You will normally be writing your report to a specific person. Assume this person is already familiar with the facts of the case. Do not simply repeat the facts. Rather, use them, as required, to support your position. Style: Your report must be typed and double spaced. It must have at least 2.5 cm margins on all edges; and, it must be printed on white paper, complete with page numbers. Write in complete sentences. Do not use point form, except when providing a coherent list in a wider context. Resist the temptation to use too many new "tools" (e.g., clip art, colour printing). Black-on-white is all that is required. Font: The minimum acceptable font is 12-point for the report and 10-point for exhibits. Length: You are limited to a maximum of 1500 words; this does not include the title page, executive summary, key assumptions, or exhibits. You may have a maximum of three pages of exhibits. Major Components: The major components of your report should contain all of the elements associated with this structure but do not necessarily have to follow the exact format : Executive Summary

I. Process Elements II. List of issues with impact analysis III. Environmental and Root Cause Analysis IV. Alternatives or Options V. Recommendation(s) and Implementation VI. Monitor and Control VII. Judgement and Integration VIII. Written Communication: Format, Language and Style

b. Exhibits and/or Appendixes (if applicable) Title Page: This is a separate page that contains the name of the case, the module title, your marker’s name, your name and candidate number, and the date you submitted the report. Executive Summary: This is on a separate page, along with any key assumptions you have made. The executive summary is a short paragraph, consisting of your decision and the major elements and implications of your action plan. Begin with "My decision is to . . ." (You are required to make a decision to receive a mark for the report). The reader should be able to read your executive summary and understand the direction to be taken in implementing your decision. Do not outline background information or present your analysis in this section.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 21

Candidate Evaluation, continued

Written Case Reports (continued)

Process Elements: Are all of the process elements in place? Does your response include all of the elements? A sample of the type of content that should be included in this section is noted below and further detailed in the individual areas.

• Statement of Operating Environment (including assumptions) • Statement of Strategic intention • Issue Identification • Analysis of issue • Alternatives with Pro/Con analysis • Decision criteria / desired outcome • Recommendations • Implementation

List of Issue(s) with Impact Analysis: As the decision maker in the case, explain what you see as the main issue(s) to be addressed. Feel free to write in the first person. Explain, with reference to the data of the case, why the issue is important and/or sensitive. Demonstrate how the external and internal environments faced by the organization influence the issue. Identify one main issue – or just a few issues – not a long list of issues. Environmental and Root Cause Analysis: Your analysis should consist of outlining why your decision best addresses the issue(s) you have identified. Your analysis should flow logically, and rely on the facts of the case, and the criteria you have identified. A good analysis will consist of both qualitative and quantitative evidence. Quantitative (i.e. numerical) data more than a few lines long should be placed in an exhibit. Then, in the body of the report, be sure to explain the importance of the exhibit. Do not expect the reader to scan the exhibit for meaning. Alternatives and/or Options You are not required to present and analyze multiple alternatives. Many cases do not have mutually exclusive alternatives. Rather, they consist of complex problems, all of which may require attention (e.g., quality problems, supplier problems, employee problems, competitive problems, and etc.). Your analysis should argue for your chosen direction for any or all of these problems and include a pro/con analysis with quantitative support. However, some cases clearly require an analysis of mutually exclusive alternatives (e.g., purchase an automated line or hire more manual labour). For these cases, you should present and analyze the alternatives.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 22

Candidate Evaluation, continued

Written Case Reports (continued)

Recommendation and Implementation: Based on your analysis of the options, state what you would do (recommendation); then, outline the specific steps to be taken (implementation). Your analysis has explained why you made the decision, now provide the short- and long-term implementation details (who, what, where, when, and how). Set priorities or a timeline for a specific action, where applicable. Then, explain how you intend other stakeholders to buy into your decision; and how you intend to deal with any negative consequences of your decision; and how you intend to protect yourself from critical changes in the environment. The acid test is this: could your action plan be implemented without further study? (For example, an action plan is not complete if it recommends that a consultant or other expert determine the details of how to implement the decision.) Monitor and Control: State, where feasible, the method(s) you will use to determine if your recommendation and implementation plans are working. Some examples are use of budgets, regularly scheduled meetings, or scheduled reviews. The approach you use will depend on the nature of the recommendation. Exhibits: Exhibits may be used for such things as drawing process flow diagrams or showing detailed calculations. Remember that the report should stand alone; the exhibits provide supporting information only. An exhibit should be used when there are more than a few lines of quantitative material in the body of the report.

Judgement and Integration: Pay close attention to the logic, structure and clarity of the analysis. Is there a connecting thread or a sequence in the analysis or is it a potpourri or hodgepodge of ideas and calculations? How well have knowledge and concepts learned throughout the SSCMLP (concepts such as controls and procedures to be addressed, spending authority, information systems to facilitate data transfer, role and accountability of Supply Chain Management in organizational structure) been integrated?

Written Communication: Format, Language and Style: A report should contain titles, sentences and point form lists. It should demonstrate a professionl tone and be free of spelling and grammatical errors.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 23

Candidate Evaluation, continued

Written Case Report (continued)

Grading: The case studies will be graded as indicated in the below sample worksheet. Each section will carry an approximate weighting as indicated below. A completed is sample is available in the Appendix of the manual.

CASE ANALYSIS MARKS

AVAILBLE MARK

I. PROCESS ELEMENTS 10

II. LIST ISSUES WITH IMPACT ANALYSIS 10

III.ENVIRONMENTAL AND ROOT CASE ANALYSIS 20

IV. ALTERNATIVES AND/OR OPTIONS 15

V. RECOMMENDATIONS 5

VI. IMPLEMENTATION 10

VII. MONITOR AND CONTROL 10

OVERALL

JUDGEMENT AND INTERGRATION 10

WRITTEN ICOMMUNICATION: FORMAT 5

WRITTEN COMMUNIATION: LANGUGE AND STYLE 5

CASE TOTAL 100

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 24

Candidate Evaluation, continued

RACI Model Overview

The RACI model is tool used to identify roles and responsibilities of individuals and is often used by organizations when dealing with change management. The tool applies a responsibility assignment methodology that works by assigning a level of accountability to individuals. This model is an important strategic tool to use both when creating and presenting a procurement plan of action.

RACI Model The roles within the model consist of:

R= Responsible, the person who is responsible for the problem/decision/plan A= Accountable, the person who must sign-off or approve a decision/plan C= Consulted- the person who provides required information I= Informed- this person typically needs to be informed of a decision/plan The model is typically accompanied by a chart as illustrated below.

Finance IT Legal HR

Supplier Selection

A C R I

Contract Approval

R I A C

The model should be applied as you work through the various stages of your proposal to ensure that you have incorporated both internally and externally (vendor), the various people, departments and factors that should play a role in your assessment and final recommendation.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 25

Candidate Evaluation, continued

Self-Assessment Activities

Candidates will have the opportunity to review, test and reinforce their knowledge through self-assessment activities. These activities are not marked. Generally, the activities require candidates to apply the concepts and tools learned in the session to their own organizations, or to a case study. Candidates are strongly encouraged to complete the self-assessment activities, as these activities provide further coverage of the module content. The self-assessment activities are:

1. Spend Analysis (session 1) 2. Financial Leverage Effect (session 4) 3. Placido Engine Company (session 7) 4. Fisher and Paykel Ltd. (session 9)

Module Ending Examination

A four-hour module ending examination consisting of a case analysis will be administered during the final session (session 13) of this module. This examination is worth 25% of the total mark for the module. The candidate must arrange for exam invigilation through their provincial or territorial Institute.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada IO - 26

Module Evaluation

Module Evaluation Form

At the end of the module, candidates are required to submit an evaluation form for this module, rating the module content and format. To obtain the evaluation form, please access the PMAC site at http://www.pmac.ca. Then, click on the Education tab. Then, on the right-hand menu, click on New Accreditation Program The evaluation form will be in this menu. Please print the form, complete it, and mail it to the following address: Purchasing Management Association of Canada 777 Bay Street, Suite 2701 P.O. Box 112 Toronto, Ontario M5G 2C8 Email: [email protected]

© Purchasing Management Association of Canada S1 - 1

Session One

Tactical and Strategic Procurement

Procurement and Supply Management

“Strategic” Stages of Purchasing

Tactical and Strategic Procurement

Spend Analysis

Procurement risk

Strategic Management

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 2

Agenda for Session 1

Activity Directions

Module Overview Overview of module, objectives for module, and methods for candidate evaluation.

Read the Introduction and Overview chapter to understand the objectives for this module, and the methods of evaluation used in this module.

Session Overview and Objectives Objectives, and a brief overview of the session.

Read What You Already Know, the Session Overview and the Objectives found in this session. Review the PowerPoint slides for this session (see the Appendix of this manual. These slides are from the instructor-led version of this module.)

Session Notes: Strategic vs. Tactical Procurement Resources: - Session Notes in this session

Read the session notes for this section. Here are the key teaching points: • Evolution of procurement. • Modern perspective on procurement. • Difference between strategy and tactics. • Alignment of strategy and tactics with corporate level. • Procurement is strategic, but uses tactics to meet the

strategic purpose.

Session Notes: Cavinato’s 5 Stages of Strategic Procurement

Resources: - Cavinato, Joseph, L. Fitting Purchasing to the Five Stages of Strategic Management. - Session notes

Read the Cavinato article (see the Readings and Cases Manual). A summary of Cavinato’s 5 stages is in the session notes. Here are the key teaching points: • Review the differences in the stages. • Determine which of Cavinato’s stages your organization is

in. • Recommend how your organization can move from a lower

stage to a higher stage. • (If possible, provide your own examples of organizations in

each of the stages.)

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 3

Agenda for Session 1, continued

Activity Directions

Session Notes: Spend Analysis Resources: - Heath, Stanley. Tackling Spend Analysis - Session notes

Read the resources for this section. Key teaching points: • Defines spend analysis, and direct and indirect spend. • Monitor both $ and number of spends. • Review Heath’s triggers. • Review opportunities from spend analysis and barriers to

spend analysis. • Spend can support strategic goals of organization.

Self-assessment Activity: Spend Analysis (not marked) Resources: - Session Notes and readings in this session

Read and complete the self-assessment activity in this session.

Self-assessment Activity Evaluation When you are finished the self-assessment activity, review the Self-assessment Evaluation section in this session. Here are the key teaching points for the activity: • To reflect on spend analysis in your organization. • To develop a lists of benefits and constraints to spend

analysis.

Individual Exercise: Goods Spend Analysis at Your Organization (marked – 5%)

Read the requirements and complete the exercise in this session. Submit the exercise for evaluation. Refer to the Session Schedule provided for submission instructions.

Session Notes: Defining Supply Risk Resources: - Zsidisin. A Grounded Definition of Supply Risk - Session notes

Read the resources for this section. Key teaching points: • Definition of supply risk. • Sources of supply risk. • Importance of supply risk.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 4

Agenda for Session 1, continued

Review of Written Case Report requirements

Review the Written Case Reports section of the Introduction and Overview chapter. Review the requirements for the cases in sessions 3, 8 and 11. The purpose of this activity is to prepare you for the cases by giving you a preview of the requirements for each case. If you have any questions about case preparation or writing case reports, please contact your marker.

Session Wrap Up

Review this session’s objectives. View the topics and activities for the next session.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 5

Tactical and Strategic Procurement

What You Already Know

In Module 1, the focus was on supply chain management and relationship management between and within organizations to achieve organizational goals. In this module the focus is on a specific aspect of supply chain management – strategic procurement. Strategic procurement is the driver of the supply chain. It is through strategic procurement that the buying organization manages its supply chain. The field and practice of strategic procurement includes entering into arrangements with various suppliers including goods and service providers, logistics firms, information consultants (such as technology consultants or legal counsel), and asset disposal providers.

Overview

In this session candidates will be introduced to some of the underlying concepts of strategic procurement. It is important to remember that effective procurement is strategic, and that strategic procurement is the examination and formulation of all procurement activities and policies in alignment with the goals of the organization. This is the link between procurement and supply chain management: procurement that aligns with the goals of supply management at the organization, and with the organization’s goals as a whole. Strategic procurement drives the whole supply chain. In effect, strategic procurement “owns” the chain. Even at the strategic level (i.e. answering the questions “why” and “where”), procurement has tactical elements (i.e. answering the question “how”). As a warm up to this module, candidates should assess the situation in their own organization. The session examines some fundamental and strategic aspects of purchasing using Cavinato’s five stages of strategic management. Cavinato lists a large number of criteria for each stage of strategic management. For the purposes of this module, these criteria have been distilled down to a more manageable number. Then, the session examines spend analysis, which is a key tactical method for facilitating strategy. Spend and indirect spend are defined, as are opportunities and constraints to spend analysis. Using Heath’s approach, candidates are introduced to dimensions of spend, as well as triggers for spending. Candidates are required to perform an individual (marked) exercise on spend analysis. The final part of the session considers procurement risk. Procurement risks are important considerations in weighing strategies. There are also other risks to consider in formulating procurement policies. Zsidisin’s definition of supply risk is examined.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 6

Tactical and Strategic Procurement, continued

Objectives

Upon completion of this session candidates should be able to:

1. Describe the relationship between procurement and supply chain management. 2. Describe the relationship between tactical and strategic procurement 3. Describe and differentiate the five stages of strategic procurement management. 4. Define spend analysis including direct and indirect spend. 5. Understand why spend analysis is an important strategic purchasing function. 6. Prepare a goods spend analysis at their organization. 7. Recognize the opportunities from and barriers to spend analysis. 8. Identify types of supply risk.

Required Reading

Read the following: • Cavinato, Joseph, L. Fitting Purchasing to the Five Stages of Strategic

Management. European Journal of Purchasing and Supply. #5, Issue 2. 1999. Pages 75-83.

• Heath, Stanley. Tackling Spend Analysis. Contract Management. January

2006. Pages 40-45.

• Zsidisin, George A. A grounded definition of supply risk. Journal of Purchasing and Supply Management. 2003. Pages 217-224.

Framework Questions

Framework questions help you focus on the issues presented in the session. Answer the following questions as you complete the readings and activities in this session.

1. Where is your organization with respect to strategic purchasing? Is it tactical or

strategic? Is it both? 2. Is your organization acquiring greater strategic skills in its purchasing? 3. How will your organization move to become more strategic? 4. Does your organization use spend analysis? 5. What are the benefits and constraints to performing a spend analysis in your

organization? 6. What is an example in your organization of direct spend? Indirect spend? 7. Why is spend analysis important in your organization? 8. What are the supply risks in your organization? 9. How might you manage supply risks in your organization?

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 7

Tactical and Strategic Procurement, continued

Self-assessment Activity

Goods Spend Analysis (not marked) After completing the readings, answer the following questions: 1. Does your organization perform spend analysis? 2. What is an example in your organization of direct spend? Indirect spend? 3. What are the benefits and constraints to performing a spend analysis in your organization? 4. Why is spend analysis important in your organization? This activity is not submitted for evaluation. See below for instructions on self-evaluating this activity.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 8

Tactical and Strategic Procurement, continued

Individual Exercise

Goods Spend Analysis in Your Organization Describe components of a goods spend analysis for your organization. Please feel free to use any relevant information about your organization. (All information will be treated as confidential, and used for grading purposes only.) This exercise is worth 5% of the overall mark for this module. It must be typed and double spaced, with 2.5 cm margins on all edges, and be in 12-point font. This exercise is limited to a maximum of five pages. Remember to write in complete sentences; do not use point form, except when providing a coherent list in a wider context. Refer to your Session Schedule for instructions on submitting this assignment for marking. There are three components to the exercise that must be handed in: 1. Show the steps you would use to conduct a goods spend analysis for your

organization. 2. Describe specific key triggers and why you chose them. 3. Describe how spend analysis would fit within your current procurement strategy. In general, you will be evaluated on the following criteria: • Did you complete all the requirements of the assignment? • Did you apply the appropriate concepts and tools from this session? • Was your analysis realistic and achievable? • Was your analysis strategic (i.e. in alignment with your organization’s

procurement strategy, and the organization’s goals in general)? For more details on the characteristics and purposes of a goods spend analysis, refer to the session notes and readings for this session. General evaluation information for all exercises is available in Introduction and Overview: Candidate Evaluation.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 9

Self-Assessment Activity Evaluation

Goods Spend Analysis

The objectives of the activity are to familiarize the candidate with spend analysis terminology, and to promote a strategic view of the candidate’s organization’s spend analysis strategy. You do not have to submit this activity for marking; it is for self-evaluation purposes only. This activity is based on your own experience at your organization. The answers you provide depend on your experience and position within the organization. You should develop a list of reasons to adopt (or not adopt) spend analysis, and ways that the adoption of spend analysis will (or won’t) benefit your organization. If you have difficulties completing this exercise, or understanding the terminology used, refer to the session notes and readings in the session.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 10

Session Notes: Tactical and Strategic Procurement

Procurement and Supply Management

Purchasing, procurement, and supply management has been defined in a variety of ways by a variety of practitioners. In its earliest form, purchasing was seen as a function that provided the right input at the right place at the right time. This dated perspective still holds in some organizations. A modern view of procurement is that it is process-oriented, and concerned with the management of all supplies of an organization, giving rise to the term “supply management.” Supplies do not necessarily mean goods supplies such as metal, pens, paper, and the like. Supplies also mean supplies of services such as legal advice, and auditing, actuarial and engineering services, among others. The focus on all supplies places procurement at the leading edge of managing corporate supply chains. Through its processes, procurement determines the following: • what specifically is required • who will supply it • how it will move from its source to destination • how its performance or progression will be monitored • how used assets, waste, scrap and redundant supplies will be disposed of The role of procurement has expanded to encompass the lifecycle of the good or service being acquired. The overall goal, i.e. the strategic goal, is to provide value to the customer. Given the breadth of the procurement process, procurement plays a key role in relationships with other supply chain partners, as well as with the ultimate customer.

Strategic Stages of Purchasing

Procurement is of vital strategic interest to the organization. Procurement also provides tactical services to the organization. To better understand these roles, consider strategy as reflecting “where are we going” while tactics answer the question “how are we getting there”. An example of strategy is to require low-cost high-quality suppliers. An example of a tactic to achieve that strategy is to single source. Another tactic is to enter into an alliance with a key supplier. Strategic procurement is linked to the strategic goals of the organization. Purchasing strategies that are incongruent with corporate goals will be unsuccessful. Consider a situation where the corporate goal is to provide low-cost, low-quality products. Clearly a procurement strategy that focuses on low-cost and high-quality does not fit. Thus, any tactics derived from this procurement policy may also be at odds with the company’s goals. In this case, it may be more appropriate to have multiple suppliers who are competitive, as opposed to a single supplier.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 11

Session Notes: Tactical and Strategic Procurement, continued

Cavinato’s Five Stages of Strategic Management

To understand where an organization is strategically placed, we can examine Cavinato’s five stages of strategic management: Stage 1: Basic financial planning Stage 2: Forecast based planning Stage 3: Externally oriented planning Stage 4: Strategic management Stage 5: Knowledge based business The following table, abridged from Cavinato, highlights his staging with respect to procurement. Table 1.1 – A Summary of Cavinato’s Stages of Strategic Management

Stage Concept

of Field Concept of Strategy

Concept of Supply Chain

Range of Products and Services

Management Approach

Key Personal Skills

Key Measures

1 Buying Better price Production- purchasing

MRO, office supplies

Reactive Task-oriented Financial

2 Purchasing Maintain price

Supplier feeding production

Raw materials, MOR , office supplies

Reactive with some planning

Some management

Gap based

3 Procure-ment

Support line of business

Suppliers and suppliers’ suppliers to final product

Capital goods, MRO, office supplies, outsourcing

Fit to rest of organization

Managerial, analytical, interpersonal

Total product cost

4 Supply Entrepreneur-ial team

Innovator to final use and disposition

Product design in view of market

Pro-active Leadership of teams

Total supply chain costs

5 Network facilitation

Conduit and interpreter

Supplier’s capabilities through value to final customer

Unlimited Leadership Leadership, consultant, conduit

Total supply chain costs, comparative supply chain costs

Stage 1: Basic Financial Planning

In stage 1, an organization operates at the basic budgeting level. The major performance criterion is to conform to budget, and control is enforced by financial accounting entities within the organization. In stage 1 organizations, procurement’s role is “buyer” only. The strategic focus is finding the lowest price for an item (or driving the item price down). The supply chain as a whole is not considered, as procurement’s role is to buy goods for production. Value-creation (procurement’s value proposition) is to lower costs. Management is reactive and focuses on conformity. In stage 1 organizations, procurement’s authority is usually restricted to buying maintenance, repair and operational items. Management focuses on meeting the standards, not changing policy. Performance is measured exclusively in terms of financial targets.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 12

Session Notes: Tactical and Strategic Procurement, continued

Stage 2: Forecast-based Planning

In Cavinato’s stage 2, organizations start to develop a more sophisticated approach to planning. They determine desired financial results, and then design programs to move from the current financial situation to the desired situation (i.e. they conduct a gap analysis). Typically the future is defined as a simple trend, or extrapolated from past experience. In stage 2 the procurement role is expanded to include minimizing future costs with increased consideration of quality. This can be described as purchasing. The primary focus, however, remains on costs minimization or price maintenance. The procurement function’s value proposition is still to reduce the cost of goods and services. Some supply chain perspective has been adopted, in that suppliers are seen as critical to internal production. Management is focused primarily on process efficiency, and meeting standards. Managers have authority to react to events in the marketplace, but not to provide strategic direction for developing supply chain capabilities.

Stage 3: Externally-oriented Planning

In stage 3, procurement begins to step into a more strategic role with a focus on supporting lines of business. Procurement is managing a variety of supply chain activities in addition to basic acquisition. The supply chain view is holistic, from the supplier's suppliers to the final customer. At this stage, procurement becomes proactive and the organization works with partners within the business. Value-add is created by more integrated supplier management. The focus is on costs. To that end, the key measurement of success is total product cost. Management skills become less tactical and more strategic, as procurement managers work with lines of business to deliver total products. Management skills, such as analysis, are developed.

Stage 4: Strategic Management

In stage 4, procurement becomes strategic, and proactively creates value for the organization in line with the strategy of the organization. The measurement of procurement’s success is total supply chain costs. The supply chain from a procurement perspective ranges from innovating with suppliers in design, through satisfaction creation for the customer. Supply alliances become more common. Strategy focuses on entrepreneurship as a member of development teams. Management is proactive. Team leadership skills become important.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 13

Session Notes: Tactical and Strategic Procurement, continued

Stage 5: Knowledge-based Business

Stage 5 organizations use procurement as the driver of value creation from all elements of the supply chain through to the final customer. Strategy is viewed as being an interpreter of external and internal customer needs, and a conduit through which those needs are met. Procurement determines which needs are viable, and how to meet those needs. The supply chain is viewed as a network, with many other possible networks available. Management leads the organization in strategic supply chain development. Skills needed by procurement staff include the ability to consult, receive feedback, analyze, and implement (i.e. to act as a conduit between the organization and its suppliers in the best interest of the organization’s customers and overall strategy).

Spend Analysis

Spend analysis provides metrics to monitor organizational spending. Without accurate information on spending, it is difficult to manage spend tactically and even less likely that it will be managed strategically. Spend analysis provides information regarding what amount of funds or how many transactions are related to a particular good or service undertaken with a particular supplier or from a group within an organization. Without proper spend analysis, opportunities are missed. Spend analysis consists of direct and indirect spend: • Direct spend is for goods and services that end up in final products. An example is

sheet metal that is used to produce a car. • Indirect spend is spending that does not end up in the final product, that is, spending

on ancillary or overhead items. An example would be the cost of flying in sales representatives to a sales meeting to introduce a new car.

The Heath article (2006) refers to goods as commodities, and those who require spend as customers, and those receive spend as suppliers or contractors. Heath suggests that spend be analyzed by commodity, supplier and customer, and that ‘triggers’ be used to select procurement enhancement opportunities. The triggers are dollar-value and transaction-based. Suggested triggers for supplies to be considered for focus are:

• High dollar value of commodities or services • High number of transactions for commodities or services • High dollar value for suppliers • High number of transaction for suppliers • High dollar value for internal customers • High number of transactions for internal customers • High percentage of sole source for any of commodities, services, suppliers or

customers • A combination of any of these

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 14

Session Notes: Tactical and Strategic Procurement, continued

Spend Analysis: Opportunities and Barriers

Spend analysis can present performance-improvement opportunities. Once a trigger has been hit the potential opportunities include:

• Reducing cost through volume discounts • Reducing cost by leveraging bargaining position • Seeking better quality • Seeking better responsiveness from suppliers • Uncovering process improvements potential • Uncovering opportunities to enter into stronger relationships

There are barriers to spend analysis in many organizations, according to Heath these include:

• Disparate computer systems • Data problems (incomplete, inaccurate or inconsistent information) • Determining the appropriate classification plan for the analysis • Resistance to change • Inadequate resource levels • Setting unrealistic goals in terms of number of changes that can be made at once

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 15

Session Notes: Tactical and Strategic Procurement, continued

Procurement Risk

All procurement involves risk. Zsidisin’s article (2003) examines supply risk in a variety of organizations to develop a definition of this risk. The analysis suggests that supply risk emerges from two sources:

• Individual supplier failures: Cases where the supplier does not meet the requirements

• Market characteristics: Cases where there are market shortages or a non-competitive market

The article also considers the outcomes from procurement risk. The typical outcome is an inability of the purchasing organization to meet its customer’s requirements. This ranges from missed shipments to failure to meet specifications. The ultimate effect of failing to meet customer requirements is a negative effect on profits. The author also notes that in several cases, the effect of supply risk is the safety of ultimate customers. Using the results of the analysis, Zsidisin proposes that supply risk be defined as:

“the probability of an incident associated with inbound supply from individual supplier failures or the supplier market occurring, in which its outcome results in the inability of the purchasing organization to meet customer demand or causes threats to customer life and security”

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S1 - 16

Session Wrap Up: Tactical and Strategic Procurement

Review Objectives for this Session

Now that you have looked at tactical vs. strategic aspects of procurement, stages of procurement management, procurement risk, and completed activities on spend analysis, you should review the session’s objectives as restated here: Upon completion of this session candidates should be able to: 1. Describe the relationship between procurement and supply chain management. 2. Describe the relationship between tactical and strategic procurement 3. Describe and differentiate the five stages of strategic procurement management. 4. Define spend analysis including direct and indirect spend. 5. Understand why spend analysis is an important strategic purchasing function. 6. Prepare a goods spend analysis at their organization. 7. Recognize the opportunities from and barriers to spend analysis. 8. Identify types of supply risk. Candidates are encouraged to evaluate their learning by determining if they have achieved the objectives for this session as stated above.

Preview Next Session

In session 1 we explored the tactical and strategic aspects of procurement. In session 2, candidates will explore the procurement process in detail, and prepare a written case report for the Blozis Company.

© Purchasing Management Association of Canada S2 - 1

Session Two

Procurement Process

Key steps in the procurement process

Description of Needs: Specifications

Types of Specifications

Specification Development

Potential Problems

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S2 - 2

Agenda for Session 2

Activity Directions

Session Overview and Objectives Objectives and a brief overview of the session.

Read What You Already Know, the Session Overview and the Objectives found in this session. Review the PowerPoint slides for this session (see the Appendix of this manual. These slides are from the instructor-led version of this module.)

Session Notes: Steps in the Procurement Process Resources: - Leenders, Johnson, Flynn and Fearon, Purchasing and Supply Management 13th Ed. (page 61) - Session notes

Read the resources for this section. Here is the key teaching point: • Leenders’ 10 steps in the supply process (also see

summary in session notes).

Individual Reflection: Steps in Procurement Process

Ask yourself: - Which of these steps were you unaware of? - Which steps had you not previously considered as being related to procurement? - Do you consider all these steps to be important? Here is the key teaching point: • For procurement to be strategic it must encompass all

these steps, and be integral to the organization as a whole.

Session Notes: Needs Recognition and Description (Specification) Resources: - Leenders, Johnson, Flynn and Fearon, Purchasing and Supply Management (pages 62 and 63). - Session notes

Read the resources for this section. Here are the key teaching points: • Describe need recognition and specification. • Understand the importance of the specification stage.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S2 - 3

Agenda for Session 2, continued

Activity Directions

Session Notes: Supplier Selection, Ordering, Monitoring, Receipt and Inspection, Payment, Documentation, and Relationship Management Resources: - Leenders, Johnson, Flynn and Fearon, Purchasing and Supply Management (pages 65 to 73). - Course notes

Read the resources for this section. Here is the key teaching point: - Understand the processes: supplier selection, ordering, monitoring, receipt and inspection, payment, documentation and relationship management. (Some of these will be covered in more depth in later sessions.)

Individual Reflection: Follow up and Expediting (and other steps in the procurement process)

Provide one or more examples of follow-up and expediting from your experience. Key teaching points: • There are different levels and approaches of follow-up

and expediting. • There are different approaches to procurement at

different organizations. Session Notes: Types of Specifications Resources: - Burt, Dobler and Starling, World Class Supply Management, Chapter 11 (Pages 239-246, 250-251) - Session notes

Read the resources for this section. Key teaching points: • Simple specifications: Performance, Fit and function,

Brand or equal, Samples and grades • Complex specifications: Commercial, Design,

Engineering Drawings, Material & Method. • Understand the benefits of standardization. • Appropriate level of interaction interdepartmentally

needs to be considered. For simple buys this may be small, for large buys it may be significant.

• Appropriate level of interaction between supply organization and buying organization needs to be considered.

• Understand the common specification problems.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S2 - 4

Agenda for Session 2, continued

Activity Directions

Individual Case Report: Blozis (marked – 5%) Resources: − Blozis case − Introduction and Overview: Written

Case Reports (report guidelines) − Session notes in this session − Framework questions in this session − Required readings for this session − Fabritek, 1992 Sample Case and

Report (Appendix)

Analyze the case using the Case Preparation method described in the Introduction and Overview. Prepare the case report according to the instructions in this session. Also, use the guidelines in the Written Case Reports section of the Introduction and Overview. Submit the case report for evaluation. Refer to the Session Schedule for submission instructions. Key teaching points: • Pay close attention to the case requirements (as stated at

the end of the case). • Is the supply function organized properly? Is it strategic

or tactical in nature? • How would you revise purchasing procedures at Blozis

related to: specifications, purchase orders and receipt? • What problems are likely to occur with the

specifications as things now stand?

Session Wrap Up

Review this session’s objectives. View the topics and activities for the next session.

Module Two Strategic Supply Chain Management Leadership Program Procurement and Supply Management

© Purchasing Management Association of Canada S2 - 5

Procurement Processes

What You Already Know

In the last session we saw that while modern procurement focuses on strategy, there are also tactical elements. In this session the major procurement processes are considered, as these form the basis of tactics to meet the strategy. As specification of needs and requirements is a critical procedural step, candidates will prepare a case study related to a conflict in specifications (Blozis Co.). This case also encourages an analysis of the procedural elements of purchasing, and requires a restructuring of procedures.

Overview