Process Layout

-

Upload

jessie-radaza-tutor -

Category

Documents

-

view

17 -

download

0

description

Transcript of Process Layout

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 1/31

© 2007 Pearson Education

D D

D D

G G

G G

G G

M M

M M

M M

A A

A A

L

L L

L L

L L

L

Process Layout

Chapter 8

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 2/31

© 2007 Pearson Education

How Process Layout

f i ts the Operat ions Management

Phi losophy

Operations As a Competitive

Weapon

Operations StrategyProject Management Process Strategy

Process Analysis

Process Performance and Quality

Constraint Management

Process Layout

Lean Systems

Supply Chain Strategy

Location

Inventory Management

Forecasting

Sales and Operations Planning

Resource Planning

Scheduling

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 3/31

© 2007 Pearson Education

Layou t Plann ing

Layout planning is planning that involves decisions

about the physical arrangement of economic activity

centers needed by a facility’s various processes.

Layout plans translate the broader decisions about the

competitive priorities, process strategy, quality, and capacity

of its processes into actual physical arrangements.

Economic activity center : Anything that consumes

space -- a person or a group of people, a customer reception area, a teller window, a machine, a

workstation, a department, an aisle, or a storage

room.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 4/31

© 2007 Pearson Education

Before a manager can make decisions

regarding physical arrangement, four

questions must be addressed.

1. What centers should the layout include?

2. How much space and capacity does

each center need?

3. How should each center’s space be

configured?

4. Where should each center be located?

Layou t Plann ing

Quest ions

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 5/31

© 2007 Pearson Education

Strateg ic Issues Impact and Implications

Layout choices can help communicate anorganization’s product plans and competitivepriorities.

Altering a layout can affect an organization and howwell it meets its competitive priorities in the followingways:

1. Increasing customer satisfaction and sales at a retail store.

2. Facilitating the flow of materials and information.

3. Increasing the efficient utilization of labor and equipment.4. Reducing hazards to workers.

5. Improving employee morale.

6. Improving communication.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 6/31

© 2007 Pearson Education

Types o f Layouts

Flexible-flow (process) layout: A layout thatorganizes resources (employees) and equipment byfunction rather than by service or product.

Line-flow (product) layout: A layout in whichworkstations or departments are arranged in alinear path.

Hybrid layout: An arrangement in which someportions of the facility have a flexible-flow andothers have a line-flow layout.

Fixed-position layout: An arrangement in whichservice or manufacturing site is fixed in place;employees along with their equipment, come to thesite to do their work.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 7/31

© 2007 Pearson Education

A Flexib le Flow Layou t

FoundryMilling

machines

LathesGrinding

Painting Drills

Office

Welding

Forging

A job shop has a flexible-flow layout.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 8/31

© 2007 Pearson Education

Line Flow Layout

Station 1 Station 2 Station 3 Station 4

A production line has a line-flow layout.

i

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 9/31

© 2007 Pearson Education Ch 7 - 9© 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e

ompar ison

Produc t And Process

Layouts PRODUCT LAYOUT PROCESS LAYOUT

1. Description Sequential arrangement Functional grouping

of machines of machines

2. Type of Process Continuous, mass Intermittent, job shop

production, mainly batch production,

assembly mainly fabrication

3. Product Standardized Varied,

made to stock made to order

4. Demand Stable Fluctuating5. Volume High Low

6. Equipment Special purpose General purpose

7. Workers Limited skills Varied skills

i

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 10/31

© 2007 Pearson Education Ch 7 - 10© 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e

ompar ison

Produc t And Process

Layouts PRODUCT LAYOUT PROCESS LAYOUT

8. Inventory Low in-process, High in-process,

high finished goods low finished goods

9. Storage space Small Large

10. Material Fixed path Variable pathhandling (conveyor) (forklift)

11. Aisles Narrow Wide

12. Scheduling Part of balancing Dynamic

13. Layout decision Line balancing Machine location

14. Goal Equalize work at Minimize material

each station handling cost

15. Advantage Efficiency Flexibility

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 11/31

© 2007 Pearson Education

Performance Cri ter ia

Customer satisfaction

Level of capital investment

Requirements for materials handling

Ease of stockpicking

Work environment and “atmosphere”

Ease of equipment maintenance

Employee and internal customer attitudes Amount of flexibility needed

Customer convenience and levels of sales

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 12/31

© 2007 Pearson Education

Creat ing Hyb r id Layouts

Layout flexibility is the property of a facility to

remain desirable after significant changes occur or to

be easily and inexpensively adopted in response to

changes.

A One-worker, multiple-machines (OWMM) cell is

a one-person cell in which a worker operates several

different machines simultaneously to achieve a line

flow.

A Cell is two or more dissimilar workstations located

close together through which a limited number of

parts or models are processed with line flows.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 13/31

© 2007 Pearson Education

Machine

1

Machine

2Machine

3

Machine

4Machine

5

Materials in

Finished

goods out

One Worker,

Mult ip le Mach ines

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 14/31

© 2007 Pearson Education

Group Techno logy (GT)

Group Technology (GT) is an option for

achieving line-flow layouts with low-volume

processes; this technique creates cells not

limited to just one worker and has a unique

way of selecting work to be done by the cell.

The GT method groups parts or products

with similar characteristics into families and

sets aside groups of machines for their

production.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 15/31

© 2007 Pearson Education

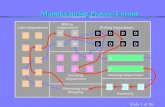

Before Group Techno logy

Drilling

D D

D D

Grinding

G G

G G

G G

Milling

M M

M M

M M

Assembly

A A

A A

Lathing

Receiving and

shipping

L

L L

L L

L L

L

Jumbled f lows in a job sho p w ithout GT cells

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 16/31

© 2007 Pearson Education

App l ied Group Techno logy

Line f lows in a job shop w ith three GT cel ls

Cell 3

L M G G

Cell 1 Cell 2

Assembly

area

A A

L M DL

L MShipping

D

Receiving

G

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 17/31

© 2007 Pearson Education

Source: Organization for Industrial Research Inc.

Class i f icat ion and Cod ing

System

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 18/31

© 2007 Pearson Education Ch 7 - 34© 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e

Original Process

Layout

12

1

2

3

4

5

6 7

8

9

10

11

A B C Raw materials

Assembly

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 19/31

© 2007 Pearson Education Ch 7 - 37© 2000 by Prentice-Hall Inc Russell/Taylor Oper Mgt 3/e

Cel lu lar Layou t

Solut ion

12

12 3

4

5

6

7

8 910

11

A BCRaw materials

Cell1Cell 2 Cell 3

Assembly

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 20/31

© 2007 Pearson Education

Warehouse Layouts

Out-and -back Pattern

The most basic warehouse layout is the out-and-back pattern.

The numbers indicate storage areas for same or similar items.

Dock Aisle

Storage area

Storage area

3 5 5 6 4 2 7

1 5 5 4 4 2 7

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 21/31

© 2007 Pearson Education

Warehouse Layouts

Zone Sys tem

Click to add t i t le

Zones Zones Control

station Shipping

doors

Tractor

trailer

Tractor

trailer

Overflow

Feeder

linesFeeder

lines

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 22/31

© 2007 Pearson Education

Off ice Layou ts

Most formal procedures for designing office layouts

try to maximize the proximity of workers whose jobs

require frequent interaction.

Privacy is another key factor in office design.

Four common office layouts:

1. Traditional layouts

2. Office landscaping (cubicles/movable partitions)3. Activity settings

4. Electronic cottages (Telecommuting)

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 23/31

© 2007 Pearson Education

Designing

Line-Flow Layou ts

Line balancing is the assignment of work to

stations in a line so as to achieve the desired output

rate with the smallest number of workstations.

Work elements are the smallest units of work thatcan be performed independently.

Immediate predecessors are work elements that

must be done before the next element can begin.

Precedence diagram allows one to visualizeimmediate predecessors better; work elements are

denoted by circles, with the time required to perform

the work shown below each circle.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 24/31

© 2007 Pearson Education

Line Balanc ing Examp le 8.3

Green Grass, Inc., a manufacturer of lawn & garden equipment,

is designing an assembly line to produce a new fertilizer spreader,

the Big Broadcaster. Using the following information, construct a

precedence diagram for the Big Broadcaster.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 25/31

© 2007 Pearson Education © 2007 Pearson Education

Line Balanc ing Green Grass , Inc.

6

E

20

H

18

I

40

D

30

B

25

F

50

C40

A

15

G

A Bolt leg frame to hopper 40 None

B Insert impeller shaft 30 A

C Attach axle 50 A

D Attach agitator 40 B

E Attach drive wheel 6 BF Attach free wheel 25 C

G Mount lower post 15 C

H Attach controls 20 D, E

I Mount nameplate 18 F, G

Total 244

Work Time Immediate

Element Description (sec) Predecessor(s)

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 26/31

© 2007 Pearson Education

Desired Outpu t and

Cyc le Time

Desired output rate, r must be matched to the

staffing or production plan.

Cycle time, c is the maximum time allowed for

work on a unit at each station: 1

r c =

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 27/31

© 2007 Pearson Education

Theoret ical Minimum

Theoretical minimum (TM ) is a benchmark or goal

for the smallest number of stations possible, where

total time required to assemble each unit (the sum of

all work-element standard times) is divided by the

cycle time. It must be rounded up

Idle time is the total unproductive time for all

stations in the assembly of each unit.

Efficiency (%) is the ratio of productive time tototal time.

Balance Delay is the amount by which efficiency

falls short of 100%.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 28/31

© 2007 Pearson Education

Outpu t Rate and Cyc le Time

Example 8.4

Green Grass, Inc. Desired output rate, r = 2400 /week

Plant operates 40 hours/week

r = 2400 /40 = 60 units/hour

Cycle time, c = 1/60

= 1 minute/unit

= 60 seconds/unit

1

r

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 29/31

© 2007 Pearson Education

Calcu lat ions for

Examp le 8.4 cont inued

Theoretical minimum (TM ) - sum of all work-element

standard times divided by the cycle time.

TM = 244 seconds/60 seconds = 4.067

It must be rounded up to 5 stat ions

Cycle time: c = 1/60 = 1 minute/unit = 60 seconds/unit

Efficiency (%) - ratio of productive time to total time.

Efficiency = [244 /5(60)]100 = 81.3%

Balance Delay - amount by which efficiency falls short of 100%.

(100 − 81.3) = 18.7%

G G I

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 30/31

© 2007 Pearson Education © 2007 Pearson Education

S1

S2

S3

S5S4 6

E

20

H

18

I

40

D

30

B

25

F

50

C40

A

15

G

Green Grass , Inc.

Line Balanc ing Solut ion

c = 60 seconds/unit

TM = 5 stations

Efficiency = 81.3%

The goal is to cluster the work elements

into 5 workstations so that the number of

work-stations is minimized, and the cycle

time of 60 seconds is not violated. Here

we use the trial-and-error method to find

a solution, although commercial software

packages are also available.

7/15/2019 Process Layout

http://slidepdf.com/reader/full/process-layout-5633826ff0a4b 31/31

© 2007 Pearson Education

Other Considerat ions

In addition to balancing a line, managers must alsoconsider four other options:

1. Pacing: The movement of product from one station

to the next as soon as the cycle time has elapsed.2. Behavioral factors of workers.

3. Number of models produced: A mixed-model line produces several items belonging to the samefamily.

4. Cycle times depend on the desired output rate, andefficiency varies considerably with the cycle timeselected. Thus exploring a range of cycle timesmakes sense.