Preview of “Old 17 foot page 3 | Otherpower” 3

-

Upload

oneshashplease -

Category

Documents

-

view

5 -

download

2

description

Transcript of Preview of “Old 17 foot page 3 | Otherpower” 3

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 1 of 7http://www.otherpower.com/17page3.html

Consulting Services Wind Power Solar Power Hydro Power Engine Power Power Systems Energy Storage Water Pumping Efficient LightingConservation Experiments Links

OTHERPOWERMAKE YOUR ELECTRICITY FROM SCRATCH!

Renewable EnergyAlternative Energy

Wind Power GeneratorsMicro Wind Turbine

ads

Search

WORKSHOPSClasses OfferedClass ScheduleCalendarWorkshop Photo DiariesOur Sponsors

ENERGY INFOConsulting ServicesWind Power

The Bottom Line AboutWind TurbinesBuild our 10 footdiameter wind turbine!Otherpower Wind TurbineUsers ManualTilt-up MET tower videos100-meter tilt-up METtowerOtherpower turbinepower curves for MidniteClassic MPPT controllerWind Data AcquisitionExample - SouthernIndiana, WirelessWind Turbine TowersScience Fair WindGeneratorsOur Homebrew WindTurbine Evolution7 Foot Diameter WindTurbine20 foot diameter windturbine

Home

WIND TURBINE STUFF FROM OUR ONLINE STORE!

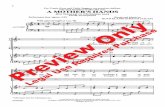

OLD 17 FOOT PAGE 3

Page 3

This page is about an older project of ours. We keep ALL of our projects up onthe internet for anyone that's interested...but we are no longer pursuing manyof these older ideas. Before starting this project, please check our main WindPower page to check for similar, more recent designs. These will be the top ofthe list and flagged with an "active project" tag. If you have any questionsabout what is current and what is not, or why we no longer work on certain

designs, first check out our Wind Turbine Evolution page for a detailed historyof how our designs have changed over the years. You can also Email us andwe'll fill you in as our email volume permits...check the Evolution page first.

PAGE 1Frame fabrication andalternator designprocedures

PAGE 2Frame finishing andalternatorfabrication

PAGE 3Alternator andblade assembly

PAGE 4Installation ontower andraising!

para Español This is 'part 3' of the project. The goal was to build a simple 17' windturbine, basically a scaled up version of earlier machines we've built which are verymuch inspired by Hugh Piggotts 'Axial Flux' wind turbine plans.

And, be sure to check out our book Homebrew Wind Power -- it has all the

FOLLOWOTHERPOWER

Like Be thefirst ofyourfriendsto likethis.

Home About Us Contact Us Discussion Board Online Store Calendar

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 2 of 7http://www.otherpower.com/17page3.html

17 foot diameter windturbineWind Generator TruckTestingThe Wood 103Wind Power GlossaryBicycle SpeedometerAnemometerEaster Egg AnemometerDyno Testing AlternatorsOlder Wind TurbineProjects

DanF's Wood A-XVolvo disk brakealternatorInduction MotorConversion Windmill14 Foot TurbinesLow-RPM Brake DiskAlternator400 watt 2 bladeVolvo Disk brakewind turbine9 foot DiameterBrake Disk Windmill10 foot DiameterBrake Disk WindmillOld 17 foot windturbine

Old 17 foot page2Old 17 foot page3Old 17 foot page4

Series - parallelswitch for windturbine alternatorsThe triplets - 10 footdiameter brake diskwind turbinesOld brake diskturbine, no furlingThe Wind Farm - 10foot brake disk windturbines

Alternator and GeneratorComparisonWind Turbine ConceptsDefined and Explained10 foot diameter brakedisk wind turbineTape Drive Motors forWind Turbines

information you need to build this turbine.

Here we're attaching the back magnet rotor to the hub. Again, we have to really becareful around these magnet rotors, the hub - wrenches... anything made of steel oriron is strongly attracted to these magnets. Notice how we're using nuts, and washersto serve as spacers between the magnet rotors. Better would be to machine aspacer, it can take time to get things perfect using nuts and washers.

Next we grease the wheel bearings, and mount the hub, with the back rotor to themachine. Then we can adjust the bearing and insert the cotter pin into the castlenut that holds it all on the spindle.

HomeAbout UsContact UsDiscussion BoardOnline StoreCalendar

OURSPONSORS

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 3 of 7http://www.otherpower.com/17page3.html

Wind Turbine DisastersHomebrew Wind PowerBook Blog

Solar PowerHydro PowerEngine PowerPower SystemsEnergy StorageWater PumpingEfficient LightingConservationExperimentsLinks

Single Phase ToThree Phasetripplite.com/PowerProt…300VA to 80kVA UPSSystems Home, Office,Data Center & more.

"Pure SineInverters"TheInverterStore.comLow Priced Inverters.Free Ship. Buy Here. Upto 7000 Watts. Call Us

WEG ElectricMotorswww.khvac.comAuthorized WebDistributor PremiumEfficiency Motors TEFC

Free Wind EnergyTrainingmesalands.edu/windTrain on a utility-scaleturbine. See if youqualify. Apply Now!

Premium DentalTurbineswww.theturbinesource.…OEM Price $300 * OurPrice $139-149 Factoryresults for 1/2 the price!

HOMEBREW WINDPOWER

We mount the stator so there's about a 3/32" gap between it and the back magnetrotor.

Pictured above you can see the 3 jacking screws we use to carefully lower the frontmagnet rotor into position. The magnet rotors must be aligned, so that wherever wehave a N pole on one rotor, there will be an opposing S pole on the other rotor.When we placed the magnets down on the disks, we ground an 'index mark' into thesides of each rotor so that we can be sure to get them together properly.

About oursponsors

Become a sponsor

WE SUPPORT

ENERGY PRICES

WTI Crude Oil$93.12 ▼ 0.36%

SOLAR / WIND

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 4 of 7http://www.otherpower.com/17page3.html

A VERY fine book on buildingyour own wind turbine fromscratch, with step-by-stepinstructions. We know, becausewe wrote it! Buy it here.

LATEST YOUTUBE80-meter MET tower lift80-meter MET tower lift80-meter MET towerHelicopter ride up theSkeena and Slamgeeshrivers

more

DISCUSSION BOARD -LATEST POSTS

Re: 48v turbine output toolowRe: Magnetic Saturation?Re: Magnetic Saturation?Re: 30m tower in tasRe: ART Turbine Peak V to3ph RMS V??? HelpRe: Magnetic Saturation?Re: Magnetic Saturation?Re: 30m tower in tasRe: Big dump loadresistors.Big dump load resistors.

more

So here we have a finished machine, except for the wooden parts! At this time wecould test it. The cut-in speed is about exactly 75 rpm so all is good! It's prettyimpressive how stiff an alternator of this size becomes when you short out all 3phases. If you spin it up by hand nice and fast... and then short it - there's animpressive flash (like a welder) and it 'bangs' to a dead stop instantly. Lots of fun...

I had my freind and neighbor Scott build my blades from laminated Cedar. He has anice wood shop, he can do them in a fraction of the time I can - and it saves a messin my shop! We came up with a very simple 'formula' for these blades so that they'dbe easy to make - and easy to replicate. They are 6" wide at the tips, about 14" wideat the widest point near the root and the taper is straight. They are 8 1/2' long tomake a total diameter of 17'. They are pitched 3 deg at the tip, and 6 deg at thehalfway point (radius =4.25'). This all makes the front of the blade a completely flatsurface, that can be made very easily on a planer with a simple jig.

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 5 of 7http://www.otherpower.com/17page3.html

NAVIGATIONFeed aggregator

Pictured above is the tips of the blades, you can see the very simple airfoil. Thethickest part of the airfoil is 1/8" as thick as the blade is wide, so at the tips we're3/4" thick, at the half way point we're about 1.5" thick, and it tapers to maximumthickness of 2" near the root of the blades.

The blades will be sandwiched between two plywood hubs. These hubs are 26" indiameter and made from 3/4" thick Baltic Birch plywood. Baltic Birch plywood issuper tough stuff... and it holds up well to the weather. It's much stronger thanordinary 3/4" plywood.

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 6 of 7http://www.otherpower.com/17page3.html

Here we're assembling the blades. I stained the hubs black and we coated everythingwith a thick coat of linseed oil. There are 3 bolts through the hub/blade assembly foreach blade - so a total of 9 bolts help hold the blades in and squeeze this whole'sandwich' together. First we assemble it all and just 'snug' the bolts up so that wecan still make adjustments to the position of the blades.

</ center> Here George and Scott and measuring tip to tip on the blades to makesure they're positioned properly. Once that's done, we can tighten up all the boltsand put in a bunch of wood screws. On this one, we have 15 wood screws into eachside of each blade - through the hubs, for a total of 90 wood screws in the wholeassembly.

I forgot to get pictures of the tail. The tail is kind of 'arrow shaped' - basicly its about2 1/2' wide and 5' tall, for about 12 square feet of total area. Its made from verystrong 1/4" thick Baltic Birch plywood, which we also stained black and coated withlinseed oil. It's bolted onto the tail boom with 4 bolts.

So there we have it, a finished machine!

5/1/13 2:01 PMOld 17 foot page 3 | Otherpower

Page 7 of 7http://www.otherpower.com/17page3.html

PAGE 1Frame fabrication andalternator designprocedures

PAGE 2Frame finishing andalternatorfabrication

PAGE 3Alternator andblade assembly

PAGE 4Installation ontower andraising!

Home Wind Turbines

100 Watt Solar Panel

Vertical Axis Wind Turbines

Solar Power Kits

Solar Panels for Your Home

Buy Solar Panels

Buy Solar Cells

Solar Panel Roof Tiles

Solar Power Systems

Energy Efficient Lighting

ads

All content copyright 2012 by Buckville Publications LLC. No dogs, cats or hamsters were harmed during the creation of this website.