Preventing Leakage in Down Filled · PDF filePreventing Leakage in Down Filled Jackets This is...

Transcript of Preventing Leakage in Down Filled · PDF filePreventing Leakage in Down Filled Jackets This is...

Preventing Leakage in Down Filled Jackets

This is a guide to aid with the manufacturing process of down jackets and advise on how to prevent downand feather leakage. Leakage that occurs through the fabric is a direct result of the materials used.

Preventing Leakage in Down Filled Jackets

Contents

Introduction

What is a down jacket?

What are the problems associated with down jackets?

Why does down leakage occur?

Manufacturing process guidance for down jackets

Preventing Leakage in Down Filled Jackets

Introduction

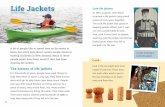

There is nothing better on a cold winter’s day than putting on your favourite winter jacket knowing that thematerials used in its construction will offer protection from the cold.

The materials that are used in the outer layer and filling of jackets vary depending on the look, fit, pricepoint and technical specification. Some outer material will be able to block wind, allow moisture to escapeand be tough enough to withstand tears and abrasions while other options may merely be wind or waterresistant.

The materials used for filling these jackets may consist of synthetic or natural fibres. Synthetic fillinggenerally has the advantage that it does not leak through the fabric openings as easily, but down fillingprovides greater warmth.

Preventing Leakage in Down Filled Jackets

What is a down jacket?

Down provides a higher degree of insulation. The fluffier the down inside the jacket, the more air that istrapped which in turn keeps out the cold. Most down jackets are not made of pure down but are oftenfilled with a mix of other materials such as feathers.

Preventing Leakage in Down Filled Jackets

What are the problems associated with downjackets?

There is, however, nothing more annoying than buying a new jacket only to have to pull out downfeathers that appear for no apparent reason every few days. Leakage that occurs through the fabric is adirect result of the materials used. This could be either due to the quality of the down feather or the outerlayer fabric. This outer layer material should be made in such a way to prevent penetration of down andtested accordingly prior to manufacture. Testing should conform to BS EN standards to confirm suitability.

Preventing Leakage in Down Filled Jackets

Why does down leakage occur?

There are a number of reasons why down leakage occurs which include:

• The fabric selection is unsuitable and allows the feathers or down to penetratethrough the fabric weave

• Additional processes that occur after final garment make up that cause agitationof the filling

• Needle holes caused by stitching together fabric pieces or by sewing seams tohold the down/feathers in place within the garment. This could relate to either theneedle size or point or even the deflection of the needle as it penetrates throughthe fabric

• The needle or sewing machine throat plate is be larger than necessary. If aneedle hole is too large it allows the fabric to flag (move up and down within theneedle hole) which can pull the down or feathers through the fabric during thesewing operation

• The sewing thread is either too hairy or too coarse which allows the down orfeather materials to attach to the thread and pull through the fabric surfaceduring sewing

• Other factors such as stitch balance and static build up contribute to the downattaching itself to the needle/thread

Preventing Leakage in Down Filled Jackets

Manufacturing process guidance for down jackets

The following can be used as a guide during the manufacturing process:

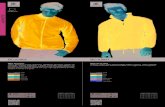

• Needles should be changed on a regular basis during sewing as damage to aneedle point will in turn cause damage to the fabric and increase the chance ofdown leakageNeedle point

• Select a good quality needle as needle vibration/movement could cause theneedle hole to increase in size. This vibration will also increase at highermachine speeds. A sewing machine speed of 3,500 rpm or less should beconsideredNeedle selection

•• Needle deflection may occur due to moving parts on the sewing machinebrushing past or hitting the needle. The result of higher vibration or deflection willbe that the needle hole will be a larger size and less neat (round) in shapeallowing down or feathers to enter more easily than when not deflected. It mayalso be an idea to control the maximum machine speed on these types of fabricsto help reduce deflection

Needle deflection•• A fine/thin needle size should be used; the finer/thinner the better. A needle point

should also be chosen that allows the fabric to be pushed aside as the needle

Preventing Leakage in Down Filled Jackets

penetrates the fabric rather than one that has to punch through the fabric. Aneedle with an acute round point such as an SPI, R or RS point would be a goodchoice. A metric needle size of Nm 60-65 should be considered for threads thatare Tkt 180-120 moving to a size Nm 70-80 for Tkt 80Needle size

•• A lower stitch density will give less opportunity for the down/feather to passthrough holes made by the needle. Ensure that the seam tear tests areacceptable and other quality requirements are met. A higher stitch density ismore likely to have down leakageStitch density

•• A smoother thread will attract less down/feathers than a hairier thread and willalso look neater in the sewn seam. A suitable thread type would be a continuousfilament polyester thread such as Coats Gral. Thread types

••• Ensure the correct stitch balance is set and maintained. Try to keep the tensionas low as practical to avoid thread bedding into the fabricSewing tension

•• Joining seams prior to filling or using narrow interlinings to help prevent holescan help reduce down leakageSeam type

On-site Technical Support / Training

Pre-bulk can be made available along with on-site training which will help to resolve these issue of downleakage during the sewing process.

Preventing Leakage in Down Filled Jackets