Presentation to IWAI Workshop November 2014

Transcript of Presentation to IWAI Workshop November 2014

A joint venture between Jindal Saw and SULA

SULA is a partnership between Nautilus, USA owned by Capt.

Rajesh Mehrotra and the SMT Group (www.smtshipping.com)

The Partnership focuses on loading or unloading large ships

without parcel size restriction.

Deliver 10,000 to 60,000 MT++ discharge/day even in shallow river

waters

The Partners

• It is Not a floating Crane!

• Highly flexible, self contained, floating & mobile cargo handling unit with its own built-in storage

• Capable of a self sustaining operation well away from the shores presently operating about 70 Miles offshore from Haldia Port

• It’s the lynchpin of waterborne/ integrated logistics supply chains.

Trans-Shipper/Trans-Loader

Highlights

•Sandheads : Distance to Farakka 642 km

•KanikaSands : Distance to Farakka 750 km

•Capex : INR 780CR

•Employment : Around 500+

•Cargo : 3 MTPA

Highlights

By August 2015 Cargo Movement : ~9-12 Million MTPA Capex deployment : ~1400 CR Flotilla Transhippers : 2-3 Barges : 42-54 Shuttle vessels : 3 x 13,000 DWT Daughter Vessels : 5 x 70,000 DWT Tugs : 2 Service Boats : 2 Shore Infrastructure - Shore Cranes : 2 - Jetties : 2 - Conveyor system : 1.5 KM

Kanika Sands – All Weather National Transshipment Zone

• The MOS has formalized Kanika sands location for transhipment purposes.

• In October 2014 the first 72,000MT coal parcel was discharged at KS despite resistance

• Kanika sands is available for use and can develop into an year round operation

• Transhipment potential – about 15 MTPA

• National Transhipment Zones (“NTZ”) can increase port throughput by 100

MTPA without the need to spend huge amounts on CAPEX.

All weather working is possible

Predominant Sea & Swell During SW Monsoon

Sheltered Water s

Rough weather position at Kanika Sands

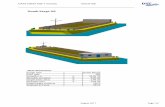

JH-1

JH-2

Conveyor G

176 m

Conveyor A

Schematic Layout – Fixed Infrastructure Farakka

Conveyor C

Cranes

All Figures in Millions US$ SUL Advantage© $$$$ Benefit in US$/MT

Two Port call ~$ 2

Shore Logistics advantage ~$ 2

Reduced Spillage ~$ 0.35

Reduced Demurrage Cost ~$ 0.45

Parcel Size Optimization benefit ~$ 3 to $ 7/PMT

Less Transshipment costs ~ $ 3

Landed costs $$$$ Benefit ~ $ 5 MT or around INR 90+ CR for 3 MTPA every year

GREEN Solution Save Environment + Great CSR!!

SUL ADVANTAGE© FOR NTPC PROJECT

• Leap-frog infrastructure shortcomings

• Low Cost & Swift deployment

• Deliver 10,000 to 60,000 MT++ bulk cargo / day

• Millions of $$$ savings

• Ideal for shallow water ports & complements Major Ports

• Clean – Green – Smart – save over 200,000 Truck moves / year

SELF UNLOADER ADVANTAGE ©

Conventional

Inefficient

Low Weather Threshold

Low Volume

Slow

Internet photo and credits are acknowledged

SELF UNLOADER BASED TRANSSHIPMENT

State of the Art

Safe & Efficient

Economical

Reliable

Internet photo and credits are acknowledged

COST EFFECTIVE FLOATING JETTY SOLUTIONS

• Dramatically reduce

jetty building costs

• Avoid and or Minimize

Dredging costs

• Environment friendly

• Rapid deployment

• Manufactured locally

• Fast Loading/Unloading

• If adopted for captive

RIL barge jetty will

dramatically slash jetty

building costs

Can be designed as a fully enclosed system to eliminate spillage and or pollution concerns

Trans-ship or Trans-load

No Terminal? No Problem!! No Floating crane High speed load High Speed Discharge to 60,000MT/day!!

Self Discharge

No Shore equipment

No Ship related cargo spill = $$$$

Environment friendly

High speed – to 60,000mt/day

Pinpoint Discharge

• Keep Port pollution free with pin point discharge and save $$$$

• Movable hopper and Targeted discharge

Versatile

• SUL Advantage© solution provides direct bottom line saving

• Examples to maximize vessel size and minimize Jetty impact

Ship board equipment

Full Loading and unloading equipment on board to save $$$$ and bring efficiency

A mini – floating terminal capable of discharging even high moisture content cargoes

GROWTH DRIVERS

• Access to $$$$$$ and easier credit norms

• Duty free fuel for such national projects

• Streamlining of customs and port processes

• Tax Incentives to Coastal Seafarers

• Shipbuilding and repair facility in the waterways

• Setting of National Transshipment Zones