Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

-

Upload

mehmet-soysal -

Category

Documents

-

view

218 -

download

0

Transcript of Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

1/18

PTT PUBLIC COMPANY LIMITED RATCHABURI WORLD COGENERATIONCOMPANY LIMITED

GAS PIPELINE AND GAS METERING AND REGULATING STATION PROJECT

DOCUMENT TITLE: WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT)

DOCUMENT NO.: PR-W-1102.21-4012-004 REVISION: A

REVIEW STAMP COMMENTS

E. Work may proceed.

F. Work may proceed. Submit for Construction

Documents.

G. Revise and Resubmit. Work may proceedSubject to incorporation of changes indicated.

H. Revise and Resubmit. Work may not proceed.

I. Review not required. Work may proceed.

Acceptance in any of these categories shall be in no wayrelieve the Contractor/Supplier of its responsibility for thedue and proper performance of the Work in accordancewith the Contract/Purchase Order.

Name:

Sign:

Date:

A 25/03/13 Issued for Approval WS JR NP

Rev. Date DescriptionPrepared

ByChecked

ByApproved

By

CONTRACTOR:

SIAM RAJATHANEE JOINT VENTURE

CONSULTANT:

UNITY ENGINEERING AND CONSULTANCY

SERVICES CO.,LTD.

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

2/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 2 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

DOCUMENT CHANGE RECORD

Rev Date Prepared/

Revised

By

ReviewedBy

ApprovedBy

Description

A 25/03/13 WS JR NP Issued for Approval

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

3/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 3 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

TABLE OF CONTENTS

ARTICLE PAGE

1. PURPOSE ...................................................................................................................................... 4

2. SCOPE ........................................................................................................................................... 4

3. DEFINITION ................................................................................................................................... 4

4. RESPONSIBILITY .......................................................................................................................... 5

5. RECORDING WELDING PARAMETERS DURING WPQR .......................................................... 6

5. QUALIFICATION OF WELDING ................................................................................................... 7

7. WELDING CONSUMABLE CONTROL ......................................................................................... 8

8. WELDER IDENTIFICATION .......................................................................................................... 8

13. ACCEPTANCE CRITERIA ............................................................................................................. 8

14. RANGE QUALIFIED ...................................................................................................................... 9

15. REFERENCE DOCUMENT(S) .................................................................................................... 12

16. ATTACHMENT ............................................................................................................................ 12

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

4/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 4 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

1. PURPOSE

This Procedure is for the Welding of Gas Pipeline and Gas Metering and Regulating Station Project.

The Material of Pipe used is under standard of ASTM A36, ASTM A53 for Structural Steel. The

applied Welding Procedure are SMAW for Steel Structure in accordance with AWS D1.1

2. SCOPEFor Steel Structure welding SMAW process (manual) can be selected. The Steel Structure weldersshall be qualified based on the approved Welding Procedures Specifications and ProcedureQualification Records.

3. DEFINITION

Owner means Ratchaburi World Cogeneration Company Limited.

Advisor means PTT Public Company Limited.

Project means Gas Pipeline and Gas Metering and Regulating Station

Project.

Consultant means Unity Engineering and Consultancy Services Co., Ltd

Contractor means Siam Rajathanee Joint Venture Co., Ltd.

HSS&E means Health, Safety, Security and Environment

JSEA means Job Safety and Environment Analysis

WPS means Welding Procedure SpecificationWPQ means Welder Performance Qualification

PQR means Procedure Qualification Record

WPR means Welding Procedure Record

PCN means Personnel Certification for NDT.

CSWIP means Certification Scheme for Welding Inspection Personnel

ASNT means American Society of Non Destructive Testing

AWS means American Welding Society

QA means Quality Assurance

QC means Quality Control

NDT means Non Destructive Testing

PT means Penetrant Test

RT means Radiographic Testing

QC Manager means Quality Control Manager

Welding Supervisor means Controls and Coordinates all of the site welding activities

Welding Forman means Controls the specific day to day welding activities for one or

more welding location

Welding Inspector means Inspects the activities related to welding

Quality Control Engineer means Writes, Runs and approves the welding procedures and

WPS for the Contractor

Subcontractor means The party to which Contractor has sub-contracted a portion

of the Work under the Contract

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

5/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 5 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

4. RESPONSIBILITY

4.1 Quality Control Manager

The QC Manager shall report to the Project Manager, and his duties include, but are notlimited to:

Implementation of the Contractors Quality Specifications and Procedures relevant topipeline inspections.

Complete inspection, witness monitoring verification activities in accordance with the

Contractors Inspection and Test Plan and Procedures.

Ensure inspection personnel are issued with approved Procedures and adequateinspection equipment

Review and complete (where applicable) all required documentation and obtain allnecessary approvals and signatures.

Review destructive and non-destructive examination reports including interpretationof weld radiographs.

Prepare all Quality Control documentation, i.e. Procedure Qualifications for Welding,NDT and Coating etc. for acceptance.

Prepare all pre-construction documentation with respect to Control of Welding, NDTand Coating.

Liaise with the Owner/Consultant Inspectors during pipeline fabrication andinstallation to resolve any Quality related problems.

Co-ordinate Welding, NDT Coating and Installation Inspection personnel, including:

Welding Inspectors

Erection QC Inspectors4.2 Welding Supervisor

The Welding Supervisor shall report to the Construction Manager, and his duties include, butare not limited to:

Coordinating welding activities

Ensure that the welding foreman is fully conversant with the welding techniques andprocedures.

Ensures that the welding consumables are available and complied with approvedProcedure Qualification Records.

Liaise with the Contractors Welding Inspector on a daily basis to resolve any relatedproblems.

Ensure non-destructive examination requests are progressed.

4.3 Welding Foreman

The Welding Foreman shall report to the Welding Supervisor, and his duties include, but arenot limited to:

Ensure welding plant equipment is maintained in good order.

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

6/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 6 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

Implementing the approved weld procedures; supervise all welding personnel andensure their competence. Ensure that all welders are approved for the welds they

have to perform.

Ensure that all welders are issued with the correct consumables and equipment, andare familiar with, and understand, all welding parameters.

Ensure that welding is carried out under the correct conditions and suitable weatherprotection is available.

Liaise with the ContractorsWelding Inspector on a daily basis to resolve any relatedproblems.

Ensure non-destructive examination requests are progressed.

Ensure the WSP parameters I.E. voltage, travel speed, current are correct

4.4 Welding Inspector

The QC Inspector / welding inspector reports to the QC Manager and is shall be responsibleto ensure all inspection and testing activities are conducted, reported and recorded inaccordance with the relevant procedures.

4.5 Quality Control Engineer

The Quality Engineer shall be responsible for assisting Quality Control Manager to preparethe proposed WPS, running the procedure qualification tests, arranging and witnessing themechanical testing, preparing the weld procedure qualification records and final WPS.

5. RECORDING WELDING PARAMETERS DURING WPQR

The procedure to be employed for recording welding parameters and calculating heat input shall beas follows:

One recorder shall record each half of a weld joint

Amperage and voltage shall be set within the range specified in the WPS

Travel speed shall be measured by a stop watch using the stop / start method i.e. the stop

watch shall be started at the start of an arc and shall stop whenever the arc is broken. As

soon as the welder restarts welding the stop watch shall also restart.

The total time recorded shall be reflective of actual arc time The voltage and amperage readings taken shall be averaged out

The travel speed and heat input shall be calculated

The welding supervisor shall give guidance to the welders in his team based on the informationgenerated during monitoring and recording. The method for management and control of travel speedand hence heat input is further illustrated below (See figure 1)

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

7/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 7 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

5. QUALIFICATION OF WELDING

Preparation and welding of test pieces are to be carried out in accordance with the WPS and underthe general condition of production welding which it represents.

Welding of the test assemblies and testing of test specimens are to be witness by third party

If tack welds and/or starts and stops points are conditions of the weld process they are to be fusedinto the joint and are to be included in the test assemblies.

Butt weld

Assembly of test pieces

The test assembly is to be of a size sufficient to ensure a reasonable heat distribution and according

with the minimum dimensions:

Plate

- Width = 3xt, min 150 mm.

- Length = 6xt, min 350mm.

- Position 3G+4G

Pipe

- OD. = 2 in,Thicknss3.91 mm.

- OD. = 6 in, Thickness 9.53 mm.

- Position 6G

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

8/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 8 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

Examination and tests

Test assemblies are to be examined non-destructively- Visual testing 100%

- Radiographic 100%

7. WELDING CONSUMABLE CONTROL

Welding consumables (electrodes), shall be controlled by the following measures :

Cntaliz contoll y stoag aa Issuance of electrodes shall be controlled by the welding supervisor, and the minimum

amount of electrodes, shall be in use at all times

Electrode containers shall only be opened sufficiently to extract electrodes and to prevent as

far as practical the ingress of water and contaminants

Electrodes shall be kept dry and clean at all times during use

Open, partially used electrode containers shall be returned to the central store every evening

Electrodes that become contaminated, shall not be used and shall be removed and discarded

8. WELDER IDENTIFICATIONWelders shall be identified by issuance of identification cards stating:

Wls nam, photogaph an signatu Wl I/D no. Wling pocus an positions qualifi Dat of WQT Ca issu numb

All welder I/D cards shall be approved, and signed by welding supervisor, reviewed and initialed by

QA / QC manager prior to issuance to the welders. The I/D cards shall be controlled by issue number

and shall be traceable to the register of steel structure welders.

Recommended pass sequence

Refer to PR-W-1102.21-4012-002 - Welding Procedure Specification For Steel Structure (WPS).

13. ACCEPTANCE CRITERIA

All welds shall be subject to 100% visual and Radiographic Test in accordance with AWS D1.1.Any welder whose welds have passed visual and Radiographic Test will be certified as qualifiedwelder.

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

9/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 9 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

14. RANGE QUALIFIED

Position

AWS D1.1Table 4.9Welder QualificationProduction Welding Positions Qualified by Plate, Pipe and Box Tube Tests(See 4.18.1.1)

Qualification Test Production Plate Welding Qualified

Weld Type Positions1 Groove CJP Groove PJP Fillet

PLATE Groove2

1G2G3G4G

3G+4G

FF, H

F, H, VF, OH

All

FF, H

F, H, VF, OH

All

FF, H

F, H, VF, H, OH

All(Note 8)

TUBULARGroove2

(Pipe or Box)

1G Rotated2G5G6G

2G + 5G(Note 9)

FF, H

F, V, OHAllAll

FF, H

F, V, OHAllAll

FF, H

F, V, OHAllAll

(Note 8)

6GR(Fig. 4.27)

All AllAll

(Note 8)

6GR(Fig. 4.27 &

4.28)All All

All(Note 8)

CJPComplete Joint Penetration; PJPPartial Joint Penetration

Notes (notes shown at the bottom of a column box apply to all entries):

1. 6 digus e., e.e, e.r an e.S

2. Groove weld qualification shall also qualify plug and slot welds for the test positions indicated.

3. Only qualified for pipe over 24 in. [600 mm] in diameter with backing, back gouging, or both.

4. Not qualified for joints welded from one side without backing, or welded from two sides

without back gouging.

5. Not qualified for welds having groove angles less than 30 (see 4.12.4.2)

6. Qualification using box tubing (Figure 4.27) also qualifies welding pipe over 24 in [600 mm] in

diameter.

7. Pipe or box tubing is required for the 6GR qualification (Figure 4.27). If box tubing is used per

Figure 4.27, the macro etch test may be performed on the corners of the test specimen

(similar to Figure 4.28)

8. See 4.25 and 4.28 for dihedral angle restrictions for plate joints and tubular T-, Y-, K-

connections.

9. Qualification for welding production joints without backing or back gouging shall require using

the Figure 4.24 joint detail. do ling pouction joints

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

10/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 10 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

Thickness and Diameter

AWS D1.1 Table 4.10Welder and Welding Operator QualificationNumber and Type of Specimens and Range ofThickness and Diameter Qualified (Dimensions in Inches)(see 4.18.2.1)

(1) Test on Plate Qualified Dimensions

Production Groove or Plug WeldsNominal Plate, Pipe or Tube

Thickness Qualified, in.

Type of Test Weld (Applicable Figures)Nominal Thickness of Test

Plate (T) in.Min Max

Groove (Fig. 4.30 or 4.31) 3/8 1/8 3/4 max4

Groove (Fig. 4.21, 4.22 or 4.29) 3/8 4 > 3/8 (Note 5) Unlimited 3/16 Unlimited

Production T-, Y-, or K-Connection CJPGroove Welds

Nominal Pipe or Tube SizeQualified, in.

Nominal Wall or Plate Thickness3

Qualified, in.

Type of

Test Weld

NominalSize of

Test Pipe,in.

NominalTest

Thickness,in.

Min Max Min Max

PipeGroove

6 O.D. 1/2 4 Unlimited 3/16 Unlimited

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

11/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 11 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

5. The minimum pipe size qualified shall be the test diameter or 4in., whichever is greater.

6. See Table 4.9 for appropriate groove details.

7. Two plates required, each subject to the test specimen requirements described. One plate shall be welded inthe 3F position and the other in the 4F position.

8. For dihedral angles < 30, see 4.26.1.

Essential VariableAWS D1.1 Table 4.11

Welding Personnel Performance Essential Variable Changes Requiring Requalification

Essential Variable Changes to WPQR RequiringRequalification

Welding Personnel

Welders2

WeldingOperators

2,3

TackWelders

(1) To a process not qualified (GMAW-S is considered aseparate process X X X

(2) To an SMAW electrode with an F-number (see Table4.12) higher than the WPQR electrode F-number

X X

(3) To a position not qualified X X X

(4) To a diameter or thickness not qualified X X

(5) To a vertical welding progression not qualified (uphill ordownhill)

X

(6) The omission of backing (if used in the WPQR test) X X

(7) To multiple electrodes (if a single electrode was used inthe WPQR test but not vice versa

X1

General Notes:

An x indicates applicability for the welding for the welding personnel; a shaded area indicatesnonapplicability.

WPQR = Welding Performance Qualification Record.

See Table 4.9 for positions qualified by welder WPQR

Note:1. Not for ESW or EGW.

2. Welders qualified for SAW, GMAW, FCAW or GTAW shall be considered as qualified welding operators

in the same process(es) and subject to the welder essential variable limitations.

3. A groove weld qualifies a slot weld for the WPQR position and the thickness ranges as shown in Table

4.10.

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

12/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 12 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

15. REFERENCE DOCUMENT(S)ASTM A36 - Standard Specification for Carbon Structural Steel

ASTM A35 - Specification for Pipe, Steel, Black and Hot-Dipped Zinc

Coated Welding and Seamless Pipe

AWS D1.1 - Structural Welding Code

SP-S-1102.21-010-001 - Specification for Line Pipe

SP-S-1102.21-010-002 - Standard for Welding of Pipelines and Related Facilities

PL-A-1102.21-4012-002 - Project Execution Plan

PR-W-1102.21-4012-002 - Welding Procedure Specification For Steel Structure (WPS)

16. ATTACHMENT16.1 Attachment 1Visual Inspection report

16.2 Attachment 2Welder Identity

16.3 Attachment 3Welders Qualification Register

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

13/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 13 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

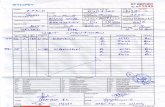

ATTACHMENT 1 VISUAL INSPECTION REPORT

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

14/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 14 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

15/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 15 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

ATTACHMENT 2 WELDER IDENTITY

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

16/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 16 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

17/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 17 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

\

ATTACHMENT 3 WELDERS QUALIFICATION REGISTER

-

8/12/2019 Pr-w-1102.21-4012-004 Rev a Welder Qualification Testing for Steel Structure (Wqt) - Sw

18/18

WELDER QUALIFICATION TESTINGFOR STEEL STRUCTURE (WQT)

GAS PIPELINE AND GAS METERING ANDREGULATING STATION PROJECT

Document No. PR-W-1102.21-4012-004

Rev. A Page 18 of 18

PR-W-1102.21-4012-004 Rev.A(WELDER QUALIFICATION TESTING FOR STEEL STRUCTURE (WQT))

![MANUFACTURER'S DATA RECORD [ M.D.R.] · Assembly and Dimensional Check Form Final QA Check ... WQT, Welder Register & ... Material Certificate No. Manufacturer Test Report No. (if](https://static.fdocuments.us/doc/165x107/5ae3a1487f8b9a90138dded8/manufacturers-data-record-mdr-and-dimensional-check-form-final-qa-check-.jpg)