PowerPlant Chemistry · PDF file408 PowerPlant Chemistry 2008, 10(7) PPChem PowerPlant...

Transcript of PowerPlant Chemistry · PDF file408 PowerPlant Chemistry 2008, 10(7) PPChem PowerPlant...

408 PowerPlant Chemistry 2008, 10(7)

PPChem PowerPlant Chemistry Interview

Victor, please give our readers a brief overview of yourpower plant.

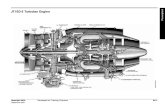

Orot Rabin PS is the largest energy producing site inIsrael. It is located at the midpoint of the seaside roadthat connects the ports of Haifa and Tel-Aviv. On sitethere are four 360 MW units commissioned in the early80s (Units 1–4) and two 575 MW units commissioned inthe middle of the 90s (Units 5–6), amounting to a total of2 590 MW (about 25 % of the total installed capacity).The annual electricity production is around 19 millionkWh (equivalent availability higher than 90 % andalmost 40 % of total production). Both types of unitsburn almost exclusively bituminous coal. The drum boil-ers produce main steam of 13.5 MPa (Units 1–4) and17.5 MPa (Units 5–6). All units are equipped with elec-trostatic precipitators and gas monitoring equipment.Low sulfur (0.43 % average) and low NOx generatingcoal is used. Flue gas desulfurization and NOx reduc-tion (primary and SCR) plants will be added in the com-ing years.

The bottom ash removal system operates with seawater (Units 1–4) and tap water (Units 5–6), while fly ashis pneumatically transferred. All ash is sold for applica-tions in road and housing projects.

The chemical control is based on equilibrium phosphatetreatment (EPT) in the smaller units and on oxygenatedtreatment in the larger ones (which switched to thattreatment from EPT about two years ago).

The pH in the feedwater is different from unit to unit inaccordance with the metallurgy (copper free, almostcopper free and with copper tube heaters). The units aresea water cooled, with all condensers made of titaniumtubing. Units 1–4 still use a small amount of hydrazine.The makeup water is produced by ion exchange. TheGE generator stators are water cooled and the turbinecontrol fluid is a phosphate ester.

What are the main tasks of the Chemistry and EnvironmentGroup?

– We are in charge of choosing, defining, applying andchecking the type of chemical control. Our groupreports to the production superintendent and worksclosely with the shift people (which include a shiftchemical operator). In defining strategically importantdecisions we work together with the CentralHeadquarters Chief Chemist's Department.

– We coordinate the maintenance of the chemicalplants: demineralized water production, chemicaldosing, wastewater treatment plant, and the chemi-cal analyzer room.

– We are in charge of the safe handling of hazardouschemicals and report to various official controlgroups on environmental protection (chemicals, seaand air discharge, spillage on ground or water).

– We perform a wide range of analytical activities forthe Operations, Electrical and Mechanical Depart-ments (water, oil, coal and ash). We maintain theautomatic analyzers (together with the ControlDepartment).

© 2008 by PowerPlantChemistry GmbH. All rights reserved.

PowerPlant Chemistry Interview

PowerPlant Chemistry talks with Dr. Victor Marcu, the senior chemist of the Israel Electric Corporation's (IEC) OrotRabin power station, Hadera, Israel, and asks him some questions about the power plant and the chemist's functionsin this utility.

Heft2008-07 20.07.2008 14:17 Uhr Seite 408

409PowerPlant Chemistry 2008, 10(7)

PPChemPowerPlant Chemistry Interview

– We are in charge of operatingthe wastewater treatmentplant (one of the first to oper-ate in the country).

– We take part in solving prob-lems and suggest improve-ments for existing processes.

– We are in charge of orderingchemicals and resins for rou-tine operation, outages anddevelopment projects. Wecheck suppliers' offers for ourfield and represent the plantat the bidding committee.

– We are part of the variousprojects in the "green energy"field.

– We are part of the plant'sworkgroups for ISO 9001 andILO (a safety standard pro-gram).

– We supply some of our serv-ices to outside clients (forinstance, to gas turbine oper-ators).

– We are in charge of cooperation with the PlanningDivision for the commissioning of all chemistry-related equipment.

– We take part in various emergency drills and chemi-cal instruction for other departments in the company.We accompany visitors to our "Visitors' Center"according to our plant manager's requests. We takepart in community activities when needed.

– One of our group's members is the so-called "Mr.Combustion," a liaison person between the coal sup-pliers, operations and maintenance people in regardto any coal mill, burner, and precipitator problems.

– During outages we inspect the pipes and vesselstogether with the maintenance people.

– We take part in the activities of knowledge exchangegroups like FOMIS, VGB, EPRI, NACE, and EUR-ELEC.

How many people work in your group?

Thirteen. That is 0.5 people per 100 MW.

We thank your for your time and willing responses to ourquestions. We are sure that we will receive comments onthis interview from our readers. They will all be passed onto you. Thanks again, Victor.

Victor Marcu (M.Sc., Physical Chemistry, PolytechnicalInstitute of Bucharest, Romania, Ph.D., Chemistry, Weiz-mann Institute, Rehovot, Israel) has 18 years of powerplant experience in commissioning water treatment instal-lations, in management of chemical labs and as envi-ronment group leader during the last 5 years. He has coauthored over 30 papers in the fields of semiconductorphotoelectrochemistry, kinetics of solids and power plantwater treatment.

CONTACT

Dr. Victor MarcuOrot Rabin Power StationOperations DivisionPOB 2062Hadera 38386Israel

E-mail: [email protected]

Heft2008-07 20.07.2008 14:17 Uhr Seite 409