Power Focus 4000 UK

Transcript of Power Focus 4000 UK

Power Focus 4000

A new level of tightening intelligence

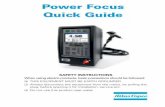

Presenting the Power Focus 4000 With your productivity in mind, we present the next generation of control systems for Tensor tools. The Power Focus 4000 is smarter and more intuitive than ever. Two versions, Graph and Compact, have all the functions you need to control Tensor electric nutrunners. The PF 4000 Graph offers a full user-interface with easyto-read colour display. The PF 4000 software includes a built-in Logic Congurator with PLC functions.

One model is all you need

tor charts and capability (Cpk) alarms. Alpha-numeric keys allow on-unit set-up and easy checking of traces and statistics. After listening to our customers, we made the PF 4000 much more compact as well. A standardized mounting plate ensures easy installation at every work station.PF 4000 Compact a handy alternative

The Power Focus 4000 is a new generation of control systems suitable for Tensor S, ST, DS and ETX models. Unlike its predecessor, the PF 3100, the PF 4000 is available in one model with two versions, Compact and Graph, that can handle all torque levels. This favours your maintenance budget, since fewer back-up units are required.PF 4000 Graph full-colour display, more compact design

Completing the range, the PF 4000 Compact has a basic operator interface with a six-button keyboard and LED display. Preprogrammed using ToolsTalk PF and with a PC as the interface, it offers the same functions as the Graph.Traceable, zero-fault process control

Once you start working with the new PF 4000 Graph, you wont want to work with any other controller. The easy-to-read LCD colour display gives you all the information you need. Statistical data is collected, analyzed and presented on the screen. Changes and trends in the assembly process are indicated by diagnostics and statistical alarms, such as SPC moni2 | P OW E R F O C U S 4 0 0 0

Advanced control functions built into the Power Focus 4000 prevent the operator deviating from the required process. When it receives assembly information, the programmed Job function automatically selects the correct tightening sequence and parameters. When combined with barcode scanning for component identification, the Job function offers traceable, zerofault process control.

smarter than ever beforePF 4000 can handle all Tensor toolsThe Tensor range of hand-held and fixtured electric assembly tools define the global benchmark in smart, cost-efficient and error-proof assembly management. Whichever tools you are running, Tensor S/SII/ST, DS or ETX, the PF 4000, with Unidrive, can handle them all.

When you want to connect a laptop

Plug & Play software functionality

No problem! The Power Focus 4000 is equipped with a handy USB connector for laptop access. It is located on the front of the unit for maximum accessibility. Communication is also possible over serial RS232, Ethernet TCP/IP and various field bus types. Networking is simple, both with external equipment and plant staff, or within the Power Focus production cell.

Why pay for more functionality than you need? You decide how much functionality the Power Focus 4000 will contain, and you can influence the system cost correspondingly. There are four standard software levels: DS, Bronze, Silver and Gold. With Atlas Copcos patented Rapid Back-up Unit, RBU, a combined program back-up unit and functionality key, you can tailor a hardware/software combination to your specific application using a plug and play approach.RBU concept minimizes downtime

Atlas Copcos RBU concept transfers functionality to the PF 4000 hardware and ensures the controller can easily be upgraded should functionality requirements change. It also acts as a back-up for programming and configuration. If a change of hardware is required, just fit the RBU to the new hardware, switch on the unit and youre ready. This cuts downtime to a minimum.

01 0

1

11 0 0 1 01 011

011 0

110 0 1

0

P OW E R F O C U S 4 0 0 0 | 3

Logic Congurator cuts costs and makes life simple

Built-in PLC functionality eliminates problems

Recognize this situation?

It couldnt be more convenient! The advanced Power Focus 4000 has an integrated Logic Configurator. This provides basic PLC functionality as an integrated part of the controller, without additional hardware components. You can now configure your PLC style signal flow between the line or the fixture, and the PF 4000, thus the need for an interface PLC is eliminated.It saves you time and money

Your tool controller needs to talk to the production process, but the controller doesnt quite fit the I/O signal specification. So you would be forced to acquire a PLC.

Work piece in place? Yes Activate cylinder, clamp work piece

The integrated Logic Configuarator cuts purchase, set-up and installation costs and simplifies system maintenance. It also saves you time and trouble.

Cylinder activated? Yes Enable tool, yellow light on Yes Job OK? No No Manual release? Yes

Green light on, release work piece

Release work piece

Logic Congurator eliminates PLCs in pre-assembly stationMotor vehicle industry discovers the benets of PF 4000

At a large automotive plant, to assure the tightening quality, a new pre-assembly station required communication between the Atlas Copco tightening system and the mechanical fixture. This would normally have required a PLC. The PF 4000, with its integrated Logic Configurator, solved the problem by offering basic PLC functions.Process description

When a workpiece is positioned, a proximity switch in the fixture detects its presence. The workpiece is held in position by an air cylinder. The position workpiece fixtured is detected by a second proximity switch. When the two proximity switches workpiece in place and workpiece fixtured are active, the tightening operation can begin. After finalizing the tightening operation, a green lamp lights and stays alight to indicate the OK result to the operator. If the job cant be finalized the operator can release the workpiece from the fixure manually.4 | P OW E R F O C U S 4 0 0 0

Improved ToolsTalk PF simplies QIF conguration

Improved ToolsTalk PF simplies QIF conguration

Atlas Copcos new, upgraded ToolsTalk PF software with improved graphics is more intuitive than ever before and thus highly user friendly. Using your PC as the interface, you can easily connect and configure the Quality Integrated Fastening (QIF) accessories below. All accessories are linked to the controller via a single cable using the built-in I/O bus. Stacklight Designed to provide continuous operator feedback on the tightening process. Operator Panel Equipped with command buttons and integrated lamps for operator feedback. A selector switch enables manual selection of programs displayed on the small, integrated screen.Stacklight Operator Panel

Socket Selector Determines the correct fastening parameter (P-set) for the specific application. I/O Expander Connected to the Power Focus, the I/O expander provides eight additional Inputs and Outputs for increased communication possibilities.I/O Expander Socket SelectorP OW E R F O C U S 4 0 0 0 | 5

New tightening strategies enhance production qualityAt last, SyncroTork for up to six spindles!

Available in the Power Focus 4000, SyncroTork allows continuous synchronization of up to six spindles during final tightening. This will improve assembly quality in the joints where an even clamp force build-up is critical, such as in U-bolt applications. The torque difference between the spindles, is minimized during the tightening stage, by adjusting the indiividual speeds. Synchronization of the tools is assured through high-speed communication via the proprietary Power Focus accessory bus. It should be noted that this function does not eliminate the need for a reaction bar, or similar, in higher-torque applications.Yield control get more from your fasteners

With the Power Focus 4000, it is possible to apply a Yield Control strategy for the cases where you need to get the most out of your fasteners.

While maintaining productivity, you can now make the fixtured tool shut off where each individual bolt yields, and not based on a firm torque or angle value. You can achieve substantial savings by always purchasing the correct sized fasteners for the application.

6 | P OW E R F O C U S 4 0 0 0

Hardware and software/Ordering numbers

Controller hardwareModel PF 4000-G-HW PF 4000-C-HW PF 4000-G-DN-HW PF 4000-C-DN-HW PF 4000-G-FLN-HW PF 4000-C-FLN-HW PF 4000-G-PB-HW PF 4000-C-PB-HW PF 4000-G-IB-HW PF 4000-C-IB-HW PF 4000-G-MB-HW PF 4000-C-MB-HW PF 4000-G-EIP-HW PF 4000-C-EIP-HW Version Field bus Graph Compact Graph DeviceNet Compact DeviceNet Graph FL-Net Compact FL-Net Graph ProBus Compact ProBus Graph Interbus Compact Interbus Graph ModBus Compact ModBus Graph Ethernet IP Compact Ethernet IP Ordering number 8433 6100 00 8433 6100 05 8433 6140 00 8433 6140 05 8433 6140 05 8433 6140 05 8433 6142 00 8433 6142 05 8433 6145 00 8433 6145 05 8433 6147 00 8433 6147 05 8433 6149 00 8433 6149 05

DSController functionality keysModel RBU-Bronze RBU-Silver RBU-Gold RBU-DS/DL Ordering number 8433 0010 10 8433 0015 20 8433 0020 20 8433 0005 10

Programming software (for PC)Model ToolsTalk PF licence 1 user ToolsTalk PF licence 5 user ToolsTalk PF licence 10 user ToolsTalk PF licence Plant ToolsTalk PF 1 user upgrade, W05 to W07 ToolsTalk PF 5 user upgrade, W05 to W07 ToolsTalk PF 10 user upgrade, W05 to W07 ToolsTalk PF Plant upgrade, W05 to W07 Ordering number 8433 1186 01 8433 1186 05 8433 1186 10 8433 1186 99 8433 1186 31 8433 1186 35 8433 1186 40 8433 1186 49

P OW E R F O C U S 4 0 0 0 | 7

We are committed to your superior productivity through interaction and innovation

www.atlascopco.com

9833 1754 01

Recyclable paper. Jetlag/Boardwalk 2008:1