Powder metallurgy

-

Upload

mohit-ostwal -

Category

Engineering

-

view

108 -

download

1

Transcript of Powder metallurgy

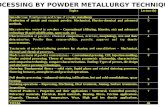

UNIT IVPowder Metallurgy3ME4A

Er. Mohit OstwalAssistant ProfessorDepartment of Mechanical EngineeringJodhpur Institute of Engineering and Technology, Jodhpur

Topics to be covered• Introduction• Properties of Powder Processed Materials• Powder Manufacturing• Mechanical Pulverization• Sintering• Electrolytic Process• Chemical reduction• Atomization• Properties of Metal Powders• Compacting of Powders sintering• Advantages and Application

Introduction – Powder Process• Process of producing metal powders and making finished

/semi finished objects from mixed or alloyed powders with or without the addition of nonmetallic constituents.

• Powder metallurgy (PM) is a metal working process for forming precision metal components from metal powders. The metal powder is first pressed into product shape at room temperature. This is followed by heating (sintering) that causes the powder particles to fuse together without melting.

Why Powder Processing ?• The parts produced by PM have adequate physical and mechanical

properties while completely meeting the functional performance characteristics.

• The cost of producing a component of given shape and the required dimensional tolerances by PM is generally lower than the cost of casting or making it as a wrought product, because of extremely low scrap and the fewer processing steps.

• Parts can be produced which are impregnated with oil or plastic, or infiltrated with lower melting point metal. They can be electroplated, heat treated, and machined if necessary.

• The rate of production of parts is quite high, a few hundreds to several thousands per hour.

Process in Powder Metallurgy1. Mixing (Blending)2. Compacting3. Sintering

Fig.1. Basic steps in Powder Metallurgy process

Process in Powder Metallurgy

Fig.2. Typical Set for Powder Metallurgy Tools

Production of Powders (Powder Manufacturing)• Widely used Metal Powders

Pure Metals AlloysAluminum Aluminum-ironAntimony Brass

Beryllium Copper-zinc-nickel

Bismuth Nickel-chromium

Cadmium Nickel-chromium-iron

Cobalt Nickel-copper

Copper Nickel-iron

Iron Silicon-iron

Lead, Molybdenum Solder

Manganese, Zinc Stainless steel

Molybdenum, Tungsten Composites

Nickel, Silicon, Tin, Titanium etc. Borides, Carbides, Nitrides etc.

Metal Powder Characteristics• Apparent Density - The apparent density or specific gravity of a powder is expressed

in kg/m3. It should be kept constant. This means that the same amount of powder should be fed into the die each time.

• Compressibility - Compressibility is the ratio of the volume of initial powder to the volume of the compressed piece. It varies considerably and is affected by the particle-size distribution and shape. Compressibility affects the green strength of a compact.

• Fineness - Fineness refers to the particle size and is determined by passing the powder through a standard sieve or by microscopic measurement.

• Flow ability – It is the characteristic of a powder that permits it to flow readily and conform to the mold cavity. It can be described as the rate of flow through a fixed orifice.

• Particle Size Distribution – It refers to the amount of each standard particle size in the powder. It influences the Flowablity and apparent density as well as porosity of the product.

• Sintering ability - It is the suitability of a powder for bonding of particles by the application of heat.

1. Mechanical MethodMechanical forces such as compressive forces, shear or impact to facilitate particle size reduction of bulk materials.

Milling: a. Impact – Striking of one powder particle against another.b. Attrition - production of wear debris due to the rubbing action

between two particles.c. Shear – Cutting of particles resulting in fracture.d. Compression forces – Particles broken into fine particles -squeezing.

Mechanism of Millinga. Microforging - particles are impacted repeatedly so that they flatten with very less

change in mass.b. Fracture - Individual particles deform and cracks initiate and propagate resulting in

fracture.c. Agglomeration - Mechanical interlocking due to atomic bonding or Vander Waals

forces.d. Deagglomeration - Breaking of agglomerates.

Powder Production Methods

Milling Equipment's1. Crushers - ceramic materials such as oxides of metals.

a. Jaw Crushersb. Gyratory Crushersc. Roll Crushers

2. Grinders - reactive metals such as titanium, zirconium, niobium, tantalum.

Milling Equipment's - Grinders1. Ball Mill

• Cylindrical vessel rotating horizontally along the axis.• The grinding media may be made of hardened steel, or tungsten

carbide, ceramics like agate, porcelain, alumina, zirconia.• Process grinds the powder materials by impact/collision & attrition.• Dry Milling - 25 vol% of powder is added along with about 1 wt% of a

lubricant such as stearic or oleic acid.• Wet Milling - 30-40 vol% of powder with 1 wt% of dispersing agent such

as water, alcohol or hexane is employed.• Diameter – 250 mm

Milling Equipment's - Grinders2. Vibratory Ball Mill

• Longer period – Fine Powder.• High amount of energy is imparted to the particles and milling is

accelerated by vibrating the container.• Electric motor connected to the shaft of the drum by an elastic

coupling.• Drum is lined with wear resistant material.• 80% of container is filled at starting with grinding and starting material.• Vibratory motion is obtained by an eccentric shaft that is mounted on a

frame inside the mill. The rotation of eccentric shaft causes the drum of the vibrating mill to oscillate.

• Frequency – 1500 to 3000 oscillation/min.• Amplitude of oscillation – 2 to 3 mm.• Grinding Bodies – Steel / Carbide Balls – 10 to 20mm.• Fined Particle size – 5 to 100 microns.

Milling Equipment's - Grinders3. Attrition Mill• The charge is ground to fine size by the action of a vertical shaft

with side arms attached to it. The ball to charge ratio may be 5:1, 10:1, 15:1.

• This method is more efficient in achieving fine particle size.

Milling Equipment's - Grinders4. Rod Mill• Horizontal rods are used instead of balls to grind. • Granularity of the discharge material is 40-10 mm. • The mill speed varies from 12 to 30 rpm.

Milling Equipment's - Grinders5. Planetary Mill• High energy mill widely used for producing metal, alloy, and

composite powders.

Milling Equipment's - Grinders6. Fluid Energy Grinding or Jet Mill

• The basic principle of fluid energy mill is to induce particles to collide against each other at high velocity, causing them to fracture into fine particles.

• The pressurized fluid is introduced into the grinding zone through specially designed nozzles which convert the applied pressure to kinetic energy. Also materials to be powdered are introduced simultaneously into the turbulent zone.

• Can create powders of average particle size less than 5 μm.• The fluid used is either air about 0.7 MPa or stream at 2 MPa.

Powder Production Methods

Other Mechanical Processes are:• Machining – Chips from turning are crushed into powder – Mg, Be, Ag,

Solder and Dental Alloys.

• Shotting - Fine stream of molten metal is poured through a vibratory screen into air or protective gas medium. When the molten metals falls through screen, it disintegrates and solidifies as spherical particles. These particles get oxidized. The particles thus obtained depends on pore size of screen, temperature, gas used, frequency of vibration. Metal produced by the method are Cu, Brass, Al, Zn, Sn, Pb, Ni.

• Graining - Same as shotting except that the falling material through sieve is collected in water; Powders of cadmium, Bismuth, antimony are produced.

Powder Production Method2. Physical Methods : a. Electrolytic Deposition:

• Used for producing copper ,iron , zinc, tin, nickel, cadmium, antimony, silver, lead, beryllium powders.

• Metals of high purity are precipitated from aqueous solution on the cathode of an electrolytic cell.

• Copper Powder => Solution containing copper sulphate and sulphuric acid and crude copper as anode.at anode: Cu -> Cu+ + e-; at cathode: Cu+ + e- ->Cu

• Iron powder => anode is low carbon steel; cathode is stainless steel.

• Mg powder => electrode position from a purified magnesium sulphate electrolyte using insoluble lead anodes and stainless steel cathodes.

Final deposition occurs in three ways:1. A hard brittle layer of pure metal which is subsequently milled to obtain powder (eg. iron powder)2. A soft, spongy substance which is loosely adherent and easily removed by scrubbing.3. A direct powder deposit from the electrolyte that collects at the bottom of the cell.

Powder Production Method b. Atomization:• This uses high pressure fluid jets to break up a molten metal stream

into very fine droplets, which then solidify into fine particles.• High quality powders of Al, brass, iron, stainless steel, tool steel,

superalloys.• Mechanism for atomization:

In conventional (gas or water) atomization, a liquid metal is produced by pouring molten metal through a tundish with a nozzle at its base. The stream of liquid is then broken into droplets by the impingement of high pressure gas or water. This disintegration of liquid stream is shown in fig. This has five stages-

i) Formation of wavy surface of the liquid due to small disturbances

ii) Wave fragmentation and ligament formationiii) Disintegration of ligament into fine dropletsiv) Further breakdown of fragments into fine particlesv) Collision and coalescence of particles

Atomization• Lower surface tension of molten metal, high cooling rate =>

formation of irregular surface => like in water atomization• High surface tension, low cooling rates => spherical shape formation

=> like in inert gas atomization

Atomization1. Water Atomization

• High pressure water jets.

• Water is used because of high viscosity and quenching ability.

• Small scale purpose.

2. Gas Atomization

• Use of Argon, Nitrogen, Helium

Atomization3. Centrifugal Atomization / rotating consumable electrode atomization.• Titanium powder can be produced

Atomization Unit• Melting and Superheating Facility - Air melting, inert gas or vacuum

induction melting. Metal is transferred to Tundish, which serves as reservoir for molten metal.

• Atomization Chamber - Atomization nozzle system is necessary, to avoid oxidation of powders, the tank is purged with inert gas like nitrogen.-> Twin Jet Nozzle-> Annular Jet Nozzle

• Powder Collection Chamber – Dry or wet collection, needs to be cooled for long run operations.

Powder Production• Other Methodsa. Reduction – Hydrogen/Carbon monoxide (spongy and

porous having uniform sized spherical or angular shapes).

b. Carbonyls – Metal carbonyls such as Fe(CO)5 and Ni(CO)4 (uniform spherical particles with high purity).

c. Precipitation from a chemical solution.

d. Vapour condensation.

Compacting• Blended Powders are pressed into shapes in dies.• In general- without application of heat.• Pressed powder is known as GREEN COMPACT.• Hydraulic or Mechanical presses.• High Density – High Strength – High Resistance to External

Forces.• Compacting Pressure.• Particle Size – Introduction of Small particles.• Tungsten carbide dies are mostly used – punches are of

same material.

Compacting Process

Compacting Cycle

Compacting

Greencompact

Core Rod

Punches

Compacting Methods• Isostatic Pressing - Hot and Cold

• Rolling• Extrusion – Encased in metal container

P=400MPa

Neoprene RubberUrethanePolyvinyl chlorideOther elastomers

Sintering• Green compacts are heated – controlled atmosphere – below the

melting point – high enough for fusion/bonding of individual particles.

• Green compact – green strength is low.• Sintering time – 10 min.(Fe & Cu alloys) to 8 Hrs.'(Tungsten &

Tantalum)• Mechanical bonds to stronger metal bonds.

Sintering• Carried out in three stages:

a. Melting of minor constituents in powder particles.

b. Diffusion between the powder particles.

c. Mechanical Bonding.

Sintering Methods1. Solid State Sintering• Neck formation at contact points b/w particles - diffusion.• Neck Growth – Skeleton of solid particle is formed.• Pore size is reduced – shrinkage – fully sintered part.

Sintering Methods2. Liquid Phase sintering• One particle is having low M.P. than other – surface tension.• Neck formation by liquid phase material transport – particle

rearrangement at liquid phase.• Solution and precipitation state – small particles dissolve from

contact• Final sintered product is obtained.

Sintering Environment• Prevent undesirable reactions• Reduction of surface oxides• Composition control• Managing the impurity levels.• Ex – Pure hydrogen, Ammonia, inert gases, vacuum, nitrogen

based mixtures with carburizing agents.

The process

Advantages of PM• Virtually unlimited choice of alloys,

composites, and associated properties • Refractory materials are popular by this

process• Controlled porosity for self lubrication

or filtration uses • Can be very economical at large run

sizes (100,000 parts)• Long term reliability through close

control of dimensions and physical properties

• Wide latitude of shape and design • Very good material utilization• 500 parts per hour not uncommon for

average size part• 60,000 parts per hour achievable for small,

low complexity parts in a rolling press

Disadvantages of PM• Limited in size capability due to large forces • Specialty machines• Need to control the environment – corrosion concern• Will not typically produce part as strong as wrought

product. (Can repress items to overcome that)• Cost of die – typical to that of forging, except that design

can be more – specialty• Less well known process

Application of PM• Cutting tools and dies – Tungsten Carbide• Machinery Parts – Gears for garden tractors• Bearing and bushes• Magnets• Electrical Parts