POWDER METALLURGY

description

Transcript of POWDER METALLURGY

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 11

POWDER METALLURGYPOWDER METALLURGY

Lecture 8Lecture 8

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 22

ATOMISATION TECHNIQUESATOMISATION TECHNIQUES

In this process, molten metal is separated In this process, molten metal is separated into small droplets and frozen rapidly into small droplets and frozen rapidly before the drops come into contact with before the drops come into contact with each other or with a solid surface. each other or with a solid surface. Typically, a thin stream of molten metal is Typically, a thin stream of molten metal is disintegrated by subjecting it to the impact disintegrated by subjecting it to the impact of high-energy jets of gas or liquid.of high-energy jets of gas or liquid.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 33

Atomisation TechniqueAtomisation TechniqueIn principle, the technique is applicable to all In principle, the technique is applicable to all metals that can be melted and is used metals that can be melted and is used commercially for the production of iron; commercially for the production of iron; copper; alloy steels; brass; bronze; low-copper; alloy steels; brass; bronze; low-melting-point metals such as aluminum, tin, melting-point metals such as aluminum, tin, lead, zinc, and cadmium; and, in selected lead, zinc, and cadmium; and, in selected instances, tungsten, titanium, rhenium, and instances, tungsten, titanium, rhenium, and other high-melting-point materials.other high-melting-point materials.Production rate of commercial atomisation Production rate of commercial atomisation units are 400 kg/min. units are 400 kg/min.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 44

Atomisation TechniqueAtomisation Technique

Gas atomisationGas atomisation

Water AtomisationWater Atomisation

Centrifugal AtomisationCentrifugal Atomisation

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 55

GAS ATOMISATIONGAS ATOMISATION

The liquid metal stream is disintegrated by rapid The liquid metal stream is disintegrated by rapid gas expansion out of a nozzle.gas expansion out of a nozzle.Gas used are air, NGas used are air, N22, He or Ar., He or Ar.Application: nickel-base superalloys and many Application: nickel-base superalloys and many other highly alloyed materials.other highly alloyed materials.There are horisontal and vertical gas atomiser.There are horisontal and vertical gas atomiser.The particle shape is spherical with a fairly wide The particle shape is spherical with a fairly wide distribution.distribution.The product is homogeneous and has good The product is homogeneous and has good packing properties.packing properties.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 66

Horisontal Gas AtomisationHorisontal Gas AtomisationLow temperature atomisers. High velocity gas emerging Low temperature atomisers. High velocity gas emerging from the nozzle creates a siphon, pulling molten metal into from the nozzle creates a siphon, pulling molten metal into the gas expansion zone. A high gas velocity aids breakup the gas expansion zone. A high gas velocity aids breakup of the metal. During flight through collection chamber, the of the metal. During flight through collection chamber, the droplets lose heat and solidify. droplets lose heat and solidify.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 77

VERTICAL GAS ATOMISATIONVERTICAL GAS ATOMISATION

The melt is prepared by The melt is prepared by induction melting and is induction melting and is poured into the nozzle. poured into the nozzle. The melt must be The melt must be superheated over Tsuperheated over Tmm. . The gas jets can be The gas jets can be formed by multiple formed by multiple nozzles arranged in a nozzles arranged in a circle around the melt circle around the melt stream.stream.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 88

Operating Variables in Operating Variables in the Gas Atomisation Processthe Gas Atomisation Process

The MeltThe Melt Melt temperatureMelt temperature Melt viscosity as it Melt viscosity as it

enters the nozzle.enters the nozzle. Alloy type,Alloy type, Metal feed rateMetal feed rate

Nozzle geometryNozzle geometry The nozzle-to-melt The nozzle-to-melt

distancedistance

The GasThe Gas Gas typeGas type Residual atmosphereResidual atmosphere Gas pressureGas pressure Gas feed rate and Gas feed rate and

velocityvelocity Gas temperatureGas temperature

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 99

The Production Parameters for The Production Parameters for Ni-based Superalloy PowderNi-based Superalloy Powder

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1010

The Formation of Metal Powder by The Formation of Metal Powder by Gas AtomisationGas Atomisation

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1111

Changes of the Droplet ShapeChanges of the Droplet Shape

The droplet shape sequence, with distance from The droplet shape sequence, with distance from the nozzle, occurs as cylinder – cone – sheet – the nozzle, occurs as cylinder – cone – sheet – ligament – sphere. Depending on the amount of ligament – sphere. Depending on the amount of superheat and other variables, solidification can superheat and other variables, solidification can produce one of these shapes.produce one of these shapes.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1212

The satellites present The satellites present (Fig. 3.19 left) are due to (Fig. 3.19 left) are due to turbulence and smooth turbulence and smooth particles (Fig. 3.19 right) particles (Fig. 3.19 right) formed by control of the formed by control of the flow near the nozzle. flow near the nozzle. The elimination of The elimination of satellites is importand for satellites is importand for good packing and flow good packing and flow attributes.attributes.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1313

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1414

WATER ATOMISATIONWATER ATOMISATIONThe most common The most common technique for producing technique for producing elemental and alloy elemental and alloy powders from metals powders from metals which melt < 1600which melt < 1600ooC.C.High pressure water jets High pressure water jets (single jet, multiple jets (single jet, multiple jets or an annular ring) are or an annular ring) are directed against the melt directed against the melt stream, forcing stream, forcing disintegration and rapid disintegration and rapid solidification.solidification.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1515

WATER ATOMISATIONWATER ATOMISATION

The process is similar to gas atomisation, The process is similar to gas atomisation, except for the rapid quenching and except for the rapid quenching and differing fluid properties.differing fluid properties.Because of rapid cooling, the powder Because of rapid cooling, the powder shape is irregular and rough, with some shape is irregular and rough, with some oxidation. Chemical segregation within an oxidation. Chemical segregation within an alloy particle tends to be quite limited.alloy particle tends to be quite limited.Milling may be required after atomisation Milling may be required after atomisation to eliminate particle bonding.to eliminate particle bonding.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1616

Four Possible Particle Generation Four Possible Particle Generation MechanismsMechanisms

Particles are Particles are generated by generated by cratering, splashing, cratering, splashing, stripping, and bursting stripping, and bursting mechanism.mechanism.Bursting mechanism Bursting mechanism results in the smallest results in the smallest powders.powders.Typical mass flow Typical mass flow rate: 5 kg water/kg rate: 5 kg water/kg metal powder.metal powder.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1717

Process Control VariableProcess Control Variable

Water pressureWater pressureThe nozzle-to-melt The nozzle-to-melt distancedistance

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1818

A 3.5% carbon steel is water atomised, oxidised, A 3.5% carbon steel is water atomised, oxidised, milled, decarburised, and annealed to form a milled, decarburised, and annealed to form a sponge which is ground to form an iron powder.sponge which is ground to form an iron powder.

Other materials produced by water atomisation Other materials produced by water atomisation include stainless steel, copper, brass, bronze, include stainless steel, copper, brass, bronze, tool steel, cobalt, nickel alloys, precious metals, tool steel, cobalt, nickel alloys, precious metals, and low melting temperature metals (Pb, Sn, and low melting temperature metals (Pb, Sn, and Zn alloys). and Zn alloys).

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 1919

A Comparison Between Gas and Water A Comparison Between Gas and Water AtomisationAtomisation

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2020

Water vs Gas AtomisationWater vs Gas Atomisation

The powder shapeThe powder shapeThe surface contaminationThe surface contamination

Oxide coating can be removed by heating in Oxide coating can be removed by heating in hydrogen after atomisation.hydrogen after atomisation.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2121

CENTRIFUGAL ATOMISATIONCENTRIFUGAL ATOMISATION

Reason for development of centrifugal Reason for development of centrifugal atomisation is the desire to control particle atomisation is the desire to control particle size and the difficulties in fabricating size and the difficulties in fabricating powders from reactive metals.powders from reactive metals.Combination of a fusion process and a Combination of a fusion process and a centrifugal force. The centrifugal force centrifugal force. The centrifugal force throws off the molten metal as a fine spray throws off the molten metal as a fine spray which solidifies into a powder.which solidifies into a powder.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2222

A consumable electrode (anode) made from the A consumable electrode (anode) made from the desired material and rotates at velocities up to desired material and rotates at velocities up to 50,000 rpm. The electrode is melted at its end 50,000 rpm. The electrode is melted at its end by either plasma arc or stationary tungsten by either plasma arc or stationary tungsten electrode.electrode.

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2323

Spherical Steel Powder Formed by Spherical Steel Powder Formed by Centrifugal AtomisationCentrifugal Atomisation

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2424

The Droplet Formation EventsThe Droplet Formation Events

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2525

Some Examples of Some Examples of Centrifugal AtomisersCentrifugal Atomisers

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2626

Atomisation LimitationsAtomisation Limitations

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2727

Forming Specific Metal PowdersForming Specific Metal Powders

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2828

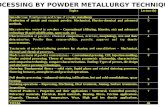

PRESS-AND-SINTER PROCESSPRESS-AND-SINTER PROCESSIn this process, custom-blended metal powders are fed into a die, compacted into the desired In this process, custom-blended metal powders are fed into a die, compacted into the desired shape, ejected from the die, and then sintered (solid-state diffused) at a temperature below the shape, ejected from the die, and then sintered (solid-state diffused) at a temperature below the melting point of the base material in a controlled atmosphere furnace. melting point of the base material in a controlled atmosphere furnace. The compaction step requires the part to be removable from the die in the vertical direction with The compaction step requires the part to be removable from the die in the vertical direction with no cross movements of the tool members. The sintering step creates metallurgical bonds no cross movements of the tool members. The sintering step creates metallurgical bonds between the powder particles, imparting the necessary mechanical and physical properties to the between the powder particles, imparting the necessary mechanical and physical properties to the part.part.Conventional PM offers many advantages over the other consolidation methods. It offers the Conventional PM offers many advantages over the other consolidation methods. It offers the lowest manufacturing cost, including modest tooling costs. It also produces the closest tolerances lowest manufacturing cost, including modest tooling costs. It also produces the closest tolerances in the finished parts. Since it is a net-shape processing technology, it yields parts requiring little in the finished parts. Since it is a net-shape processing technology, it yields parts requiring little or no secondary machining operations. Lastly, it makes available to designers and fabricators a or no secondary machining operations. Lastly, it makes available to designers and fabricators a wide variety of material systems from which to choose. wide variety of material systems from which to choose. Parts produced through the press-and-sinter process are subject to certain limitations as well. Parts produced through the press-and-sinter process are subject to certain limitations as well. Tooling and the maximum press tonnage capabilities impose size and shape constraints on parts Tooling and the maximum press tonnage capabilities impose size and shape constraints on parts that can be fabricated. Annual production quantities dictate how quickly the costs of tool set-ups that can be fabricated. Annual production quantities dictate how quickly the costs of tool set-ups and maintenance can be amortized. Finally, the presence of residual porosity in the parts will and maintenance can be amortized. Finally, the presence of residual porosity in the parts will cause certain physical and mechanical properties to be lower than those of the wrought material.cause certain physical and mechanical properties to be lower than those of the wrought material.Typical Press-and-Sinter ProductsTypical Press-and-Sinter Products—gears, sprockets, cams, ratchets, levers, clutch plates, —gears, sprockets, cams, ratchets, levers, clutch plates, pressure plates, housings, pole pieces, bearings, bushingspressure plates, housings, pole pieces, bearings, bushings

Typical Markets Using Press-and-Sinter PartsTypical Markets Using Press-and-Sinter Parts—automotive, appliances, power tools, —automotive, appliances, power tools, hydraulics, lawn and garden, agriculture, off-road equipment, motors, firearms, recreational hydraulics, lawn and garden, agriculture, off-road equipment, motors, firearms, recreational equipment, hardware, business equipmentequipment, hardware, business equipment

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 2929

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 3030

04/22/2304/22/23 Petra Christian UniversityPetra Christian University 3131