Plastomers Gradeslate ProductGuide

-

Upload

maheshgupte -

Category

Documents

-

view

214 -

download

5

Transcript of Plastomers Gradeslate ProductGuide

FDA Note FDA Statement

1a Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.2a, and may be usedas articles or components of articles intended for use in contact with food, including use in articles usedfor packing or holding food during cooking.

1b Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.2a, and may be usedas articles or components of articles intended for use in contact with food, including use in articles usedfor packing or holding food during cooking. Finished articles may contact all food types identified in Table1 of CFR 176.170(c) only under Conditions of Use B through H described in Table 2 of 21 CFR176.170(c), at temperatures not in excess of 212°F.

2 Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.1a, and may be usedas articles or components of articles intended for use in contact with food, except for articles used forpacking or holding food during cooking.

3 Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.6, provided that it isused only as a blend component with specific regulated FDA materials to make films no thicker than 4 mils.

4 Complies with FDA Regulation 21 CFR 175.105 “Adhesives” and may be used to prepare adhesives thatare used as components of articles intended for use in packaging, transporting or holding food, subjectto the restrictions provided in 21 CFR 175.105 (a) (2).

5 Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.2a, and may be usedas articles or components of articles intended for use in contact with food, including use in articles usedfor packing or holding food during cooking.

6 Complies with FDA regulation 21 CFR 177.1520 “Olefin polymers” paragraph (c)3.2c, and may be usedin materials or articles that contact food. Finished articles may contact all food types identified in Table 1of CFR 176.170(c) only under Conditions of Use C through H described in Table 2 of 21 CFR 176.170(c),at temperatures up to hot-filled or pasteurized above 150°F (less than 212°F).

©2006 Exxon Mobil Corporation. The user mayforward, distribute, and/or photocopy this copy-righted document only if unaltered and complete,including all of its headers, footers, disclaimers,and other information. ExxonMobil does not guar-antee the typical (or other) values. Typical valuesonly represent the values one would expect if theproperty were tested in our laboratories with ourtest methods on the specified date. Some productproperties are not frequently measured, andaccordingly typical values are not based upon astatistically relevant number of tests. The informa-tion in this document relates only to the namedproduct or materials when not in combination withany other product or materials. We based theinformation on data believed to be reliable on thedate compiled, but we do not represent, warrant,or otherwise guarantee, expressly or impliedly, themerchantability, fitness for a particular purpose,suitability, accuracy, reliability, or completeness ofthis information or the products, materials, orprocesses described. The user is solely responsi-ble for all determinations regarding any use andany process. We expressly disclaim liability for anyloss, damage, or injury directly or indirectly suf-fered or incurred as a result of or related to anyoneusing or relying on any of the information in thisdocument. There is no warranty against patentinfringement, nor any endorsement of any productor process, and we expressly disclaim any con-trary implication. The terms, “we,” “our,”“ExxonMobil Chemical,” or “ExxonMobil” are usedfor convenience, and may include any one or moreof ExxonMobil Chemical Company, Exxon MobilCorporation, or any affiliates they directly or indi-rectly steward. ExxonMobil, the “Interlocking X”Device, Exact, and Exxpol are trademarks ofExxon Mobil Corporation.

Products with densities ≥0.880 g/cc may not beavailable in all regions.

Worldwide Sales OfficesAmericasExxonMobil Chemical13501 Katy Frwy.Houston, Texas 77079Tel. 281.584.7614Fax 281.588.2577

EuropeExxonMobil ChemicalHermeslaan, 2B-1831 Machelen, BelgiumTel. 32.02.722.4363Fax 32.02.722.4369

Asia PacificExxonMobil Chemical1 HarbourFront Place#06-00 HarbourFront Tower OneSingapore 098633Tel. 65.6885.8473Fax 65.6885.8488

exactplastomers.comexxonmobilchemical.com P

rinte

d in

U.S

.A. •

Aug

ust 2

006

• 11

9-08

06-1

00 •

2,0

00

EXACT™ Plastomers

Grade Slate And Product Guide

A Well-Balanced Portfolio For Your Precise Needs.

FDA StatusTy

pe

of

Eth

ylen

e C

op

oly

mer

(CA

S#

2521

3-02

-9)

(CA

S#

2508

7-34

-7)

EXACT Plastomers Density Melt Index FDA NoteGrade (g/cc) (dg/min) 3024 0.905 4.5 1a

3035 0.900 3.5 1a

3128 0.900 1.2 1a

4006 0.880 10 4

4053 0.888 2.2 3

4049 0.873 4.5 4

3040 0.900 16.5 2

3131 0.900 3.5 1b

3132 0.900 1.2 1b

3139 0.900 7.5 1b

4056 0.883 2.2 4

4150 0.895 3.5 2

4151 0.895 2.2 1b

0201 0.902 1.1 5

0201FX 0.902 1.1 1b

0203 0.902 3.0 5

0210 0.902 10 6

0230 0.902 30 6

5061 0.868 0.5 6

5062 0.860 0.5 6

5101 0.902 1.1 5

5171 0.870 1.0 6

5181 0.882 1.1 6

5361 0.860 3.0 6

5371 0.870 5.0 6

8201 0.882 1.1 6

8203 0.882 3.0 6

8210 0.882 10 6

8230 0.882 30 6

(CA

S#

2622

1-73

-8)

BUTENE HEXENE OCTENE

EX

AC

T™

PLA

ST

OM

ER

S–

FOR

YO

UR

PR

EC

ISE

NE

ED

S

EXACTTM Plastomers are a family of ethylene alpha olefin copolymers produced using ExxonMobil Chemical’s ExxpolTM

metallocene catalyst technology. They offer a unique set of properties in which rubber-like properties and plastic process-

ability are realized in one material. Used neat or as polymer modifiers, EXACT Plastomers offer endless possibilities to

bring value to your products. They enhance the toughness, clarity and sealing performance of flexible packaging materials.

In molded and extruded products, they improve impact strength and flexibility. The combination of comonomer type and

process technology offered by ExxonMobil results in a wide range of products designed to serve customers’ unique needs:

Butene Good film properties, including high oxygen transmission rates for fresh produce packaging

Good property balance in PP-based TPOs

Hexene Outstanding toughness and puncture resistance for film applications

Excellent hot-tack strength and seal-through contamination in film heat-seal applications

Octene Excellent toughness and heat-seal properties for film applications

Easy processing for all applications due to shear thinning characteristics

Low density grades for outstanding low temperature impact resistance in PP-based TPOs

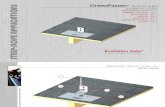

Typical Applications and Properties of EXACT™ Plastomers GradesPolymer Modification

Film/Flexible Packaging

1. EXACT 0201FX is EXACT 0201 with slip and anti-block

BLOWN FILM

CAST FILM

BUTENE HEXENE OCTENE

5061

5171

Ethylene Octene 8230

8210

8203

0230

0210

51818201

4056 4151

4150

3139

Ethylene Hexene

3040

4049

4006

4053

3035 3024

3128

Ethylene Butene

EXACT™ Plastomers Grade Slate

Density (g/cc)

0.86

100

10

1

00.87 0.88 0.89 0.90 0.91

Mel

t In

dex

(dg

/min

)

5361

5062

31310203

5371

51010201

0201FX

3132

BLOWN FILM

CAST FILM

3024 • 3024 0.905 4.5 100 16 90 97

3035 • 3035 0.900 3.5 70 16 94 88

4006 • • 4006 0.880 10 17 6 79 60

4053 • 4053 0.888 2.2 27 22 84 70

0201 • • • 0201 0.902 1.1 68 >21 90 97

0203 • • • 0203 0.902 3.0 76 >21 87 94

0210 • • 0210 0.902 10 76 14.8 85 96

0230 • • 0230 0.902 30 80 11 88 95

5061 • • 5061 0.868 0.5 12 >7 65 53

5062 • • 5062 0.860 0.5 6 >4 57 43

5101 • • • 5101 0.902 1.1 88 >21 90 98

5171 • • 5171 0.870 1.0 13 >8 70 55

5181 • • 5181 0.882 1.1 26 >14 84 73

5361 • • • 5361 0.860 3.0 4 1.4 52 36

5371 • • 5371 0.870 5.0 13 >5 70 64

8201 • • • 8201 0.882 1.1 26 >14 78 67

8203 • • • 8203 0.882 3.0 28 >10 80 73

8210 • • 8210 0.882 10 26 >8 79 74

8230 • • 8230 0.882 30 26 6 75 77

3128 • • 3128 0.900 1.3 73/77 60/52 670 924053 • • • 4053 0.888 2.2 34/38 57/50 140 693132 • • 3132 0.900 1.2 73/78 74/74 1330 964056 • 4056 0.883 2.2 30/34 78/72 1030 724151 • • • 4151 0.895 2.2 56/61 78/72 1215 880201/0201FX1 • • • 0201 0.902 1.1 68/75 56/61 610 965101 • • • 5101 0.902 1.1 73/83 66/63 600 995181 • • • 5181 0.882 1.1 29/35 56/54 225 718201 • • • 8201 0.882 1.1 28/33 66/52 270 71

3024 • 3024 0.905 4.5 85/97 48/32 140 97

4053 • • 4053 0.888 2.2 37/36 65/46 120 694049 • 4049 0.873 4.5 533040 • 3040 0.900 16.5 70/76 55/47 100 953131 • • • 3131 0.900 3.5 67/75 74/61 1050 943139 • 3139 0.900 7.5 68/76 66/56 240 954150 • • • 4150 0.895 3.5 56/59 78/70 540 894151 • • 4151 0.895 2.2 56/64 85/69 940 880203 • • • 0203 0.902 3.0 73/84 66/51 230 950210 • 0210 0.902 10 70/77 44/35 90 950230 • 0230 0.902 30 69/74 32/25 70 958203 • • • 8203 0.882 3.0 33/38 55/45 170 728210 • • 8210 0.882 10 30/32 35/29 70 738230 • • 8230 0.882 30

EXACT Blow- Injection EXACT Density Melt Index Flexural Ultimate Tensile Hardness DSC MeltingPlastomers Extrusion Molded Molding TPOs Foams Rotomolding Plastomers 190°C, 2.16 kg Modulus Strength Peak, 10°C/minGrade Packaging Grade (g/cc) (dg/min) 1% Sec (MPa) (MPa) (Shore A) (°C)

Test Method Based on: ExxonMobil ASTM D-1238 ASTM D-790 ASTM D-638 ASTM D-2240 ExxonMobil

EXACT Heat Fresh Cling Extrusion Batch Toughness EXACT Density Melt Index 1% Secant Modulus Tensile Strength Dart Drop DSC MeltingPlastomers Seal Produce Layer in Coating Inclusion Layer Plastomers 190°C, 2.16 kg MD/TD MD/TD Impact, Peak, 10°C/minGrade Layer Packaging Stretch Film Bag Film Grade (g/cc) (dg/min) (MPa) (MPa) F50 (g) (°C)

Test Method Based on: ExxonMobil ASTM D-1238 ASTM D-882 ASTM D-882 ASTM D-1709(A) ExxonMobil