PLASTERING - metaldata.pt · Corner and stop bead profiles for thin-coat plastering. ... Corner...

-

Upload

nguyenduong -

Category

Documents

-

view

258 -

download

5

Transcript of PLASTERING - metaldata.pt · Corner and stop bead profiles for thin-coat plastering. ... Corner...

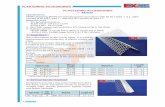

Cl/SfB (22.3)(35.1)(35.3)

Hh2Jh2

PLASTERING ACCESSORIES

DECEMBER 02

PLASTER BEADS FOR INTERNAL USE ONLY

PLASTER BEADS FOR THIN-COAT PLASTER

BEADS FOR DRY-LINING

BEADS FOR EXTERNAL USE

Corner and stop bead profiles for internal plastering.

Corner and stop bead profiles for thin-coat plastering.

Corner and edging bead profiles for dry-lining, eg. plasterboard.

Corner and stop bead profiles for external render work.

QUALITY IN ACTION

Expamet Beads & Laths are designedand manufactured by Expamet BuildingProducts – the name behind the marketleading BAT Fixings range and manyother high quality building productsincluding Lintels, Wall Starters, Arch Formers and Hy-Rib formwork for concrete and Metpost fence spikes.

Expamet products are manufactured toBS EN ISO 9002: 1994 and ISO 14001.

EXPAMET BEADS

Expamet are one of the world's largestproducers of expanded metal products.Bead manufacture began over 40 yearsago and today, if our total Beadproduction were laid end to end, itwould stretch to the moon and backwith miles to spare.

As the established market leader inthe UK, the Expamet Bead range iscomprehensive, from high performanceproducts through to easy-to-useeconomy beads. It's a choice backedby quality that today's tradesmen trustto deliver lasting, value for moneyperformance.

Galvanised Steel BeadsBS EN 10142: 1991. DX51D + Z275& DX51D + Z450.

Stainless Steel BeadsBS EN 10088-1 : 1995 X5CrNi18-10 / 1.4301

PlusSynthetically coated GalvanisedSteel Beads.

• Beads should be fixed using plaster or renderdabs or a suitable mechanical fixing ata maximum of 600mm centres.

• Beads may be wire tied to the face of metallathing backgrounds.

• Use tinsnips or shears to cut to size.

• When jointing angle beads use a dowel insertedin the nose to ensure continuity and alignment.

• Avoid damage to beads when trowelling plaster or render.

• Stainless steel beads are specifically designedfor cement based renders and should not be usedwith gypsum based plasters unless they arespecified with an approved protective finish.

• Epoxy/polyester coated galvanised steel beads,with PVC nosing, are designed for external useonly in sheltered or moderate environments.Similar usage restrictions also apply to theExpamet 570 Render Stop.

GENERAL INSTALLATION INFORMATION:

METHOD 1

• Fix one stop bead down the side of the buildingmovement joint, levelling with the timber grounds.

• When this bead is set, fix the second bead into positionusing timber inserts to control the required gap. Alsolevelling to the timber grounds.

• When both beads are set, remove timber inserts andcomplete the plastering. Fill the gap with flexible sealant.

METHOD 2

• Plaster stop beads used with insert to make a bead for building movement control joint. Use timber battenwired to beads to set up gap width. On removal of thetimber batten flexible sealant can be used as required.Width of gap determined by the flexible nature of sealantand expected masonry movement.

JOINTS IN PLASTER OVER BUILDING MOVEMENTCONTROL JOINTS:

EXPAMET BEADS

ANGLE BEADRef. 558 (Pre-Galvanised Steel)Provides a true, straight corner which protectsand reinforces plaster where it is most vulnerable.One size adjusts for thickness.

REF 562 563 565 566T x L (mm) 10 x 60 13 x 60 16 x 61 19 x 58Lengths per Carton 50 50 50 50Stock lengths 2400 / 3000 2400 / 3000 2400 / 3000 2400 / 3000

REF 558T x L (mm) 10 / 13 x 46Lengths per Carton 100Stock lengths 2400 / 2700 / 3000

REF 550T x L (mm) 10 / 13 x 55Lengths per Carton 100Stock lengths 2400 / 2700 / 3000

REF 588T x L (mm) 13 x 123Lengths per Carton 20Stock lengths 3000

REF 587T x L (mm) 13 x 60Lengths per Carton 20Stock lengths 3000

ANGLE BEADRef. 550 (Pre-Galvanised Steel)Provides a true, straight corner which protectsand reinforces plaster where it is most vulnerable.One size adjusts for thickness.

PLASTER STOP BEADRef. 562, 563, 565 & 566 (Pre-Galvanised Steel)Finishes and reinforces plaster edges.

5

(L)(T)

5(L)

(T)(T)

(L)

1

The bead consists of two lengthsof galvanised Stop Bead joined by a white pvc extrusion whichfeatures a special knockout foreasy installation. This knockoutstrip is removed at completion ofplastering providing up to ±3mmmovement in both planes.

CORNER MOVEMENT BEAD*Ref. 587 (Pre-Galvanised Steel)Provides up to 6mm movement in both planes.

MOVEMENT BEAD*Ref. 588 (Pre-Galvanised Steel)Forms movement joints in plasterand render, allows for +3mm, -1mm movement.

(T)

(L)

1

21

(L)

(T)13

3

1010

* Must not be used over building movement control joints. See General Installation Information inside front cover.

PLASTER BEADS FOR INTERNAL USE ONLY

2

PLASTER BEADS FOR THIN-COAT PLASTER

THIN-COAT ANGLE BEADRef. 553 & 554 (Pre-Galvanised Steel)For 3mm plaster finishes on plasterboardor any smooth background.

THIN-COAT STOP BEADRef. 560 & 561 (Pre-Galvanised Steel)Finishes and reinforces edges of thin-coat plaster.

THIN-COAT EXPANDED SMALL-MESH WING ANGLE BEADRef. 595 (Pre-Galvanised Steel)The expanded mesh wings provide an excellent key for thin-coat plaster corners.

ARCHITRAVE & FEATURE BEAD (ABUTTING)Ref. 585 & 579 (Pre-Galvanised Steel)Creates feature at plaster edges, abutting with frame.

ARCHITRAVE & FEATURE BEAD (ABUTTING)Ref. 581 (Pre-Galvanised Steel)Creates feature at plaster edges, abutting with frame togive a 22mm shadow gap.

(T)

(L)

(T)

(L) (T)

(L)

(T)

(L)

ARCHITRAVE & FEATURE BEAD (ENGAGING)Ref. 586 & 580 (Pre-Galvanised Steel)Creates feature at plaster edges, engaging with frame.

(T)

(L)

20

1522

REF 586 580T x L (mm) 10 x 52 13 x 52 Lengths per Carton 50 50Stock lengths 3000 3000

REF 560 561T x L (mm) 3 x 28 6 x 25Lengths per Carton 50 50Stock lengths 2400 / 3000 2400 / 3000

REF 553 554T x L (mm) 3 x 24 6 x 24Lengths per Carton 100 bundled in 10’s 100 bundled in 10’sStock lengths 2400 / 2700 / 3000 2400 / 2700 / 3000

EXTENDED LEG ANGLE BEADRef. 596 (Pre-Galvanised Steel)To provide enhanced cover at plasterboardjoints to minimise cracking.REF 596T x L x L1(mm) 3 x 24 x 30Lengths per Carton 50Stock lengths 2400 / 3000

135O THIN-COAT ANGLE BEADRef. 597 (Pre-Galvanised Steel)For 135o plasterboard corners.REF 597T x L (mm) 3 x 24Lengths per Carton 10Stock lengths 2400 / 3000

REF 595T x L (mm) 3 x 24Lengths per Carton 50Stock lengths 2400 / 3000

REF 585 579T x L (mm) 10 x 52 13 x 52 Lengths per Carton 50 50Stock lengths 3000 3000

REF 581T x L (mm) 13 x 52 Lengths per Carton 50Stock lengths 3000

(T)

(L)

(L1)

(T)

(L)

(T)

(L)135o

PLASTER BEADS FOR INTERNAL USE ONLY

3

REF PFB001Plaster Thickness 3mmT x L (mm) 3 x 28.3Lengths per Carton 25Stock lengths 3000

REF 548T x L (mm) 2 x 19Lengths per Carton 50Stock lengths 2400 / 3000

REF 513Plaster Board Thickness 9.5 / 12.5 / 15mmLengths per Carton 50Stock lengths 3000

REF 514Plaster Board Thickness 9.5 / 12.5 / 15mmLengths per Carton 50Stock lengths 3000

PLASTERBOARD EDGING BEADRef. 567, 568 & 576 (Pre-Galvanised Steel)A reversible, dual-purpose bead which reinforcesplasterboard edges by enclosing them in a protectivesteel section.

Reverse side of 567, 568 and 576.

DRY LINING ARCH BEADRef. PFB001 (Recycled pvc)For creating curved and arched forms in thin-coat and dry-lining applications.

(L1)

(L)

(T)

DRY WALL CORNER BEADRef. 548 (Pre-Galvanised Steel)For steel protection on plaster board corners.

(T)

(L)

DRY WALL FEATURE BEAD (ENGAGING)Ref. 513 (Pre-Galvanised Steel)Neat shadow lines and recesses can be formedaround door frames, abutments and the like.

2

9.5 9.520

25

DRY WALL FEATURE BEAD (ABUTTING)Ref. 514 (Pre-Galvanised Steel)Neat shadow lines and recesses can be formedaround door frames, abutments and the like.

2

9.5 9.515

25

3.428.3

28.3

REF 567 568 576Plaster Board Thickness 9.5mm 12.5mm 15mmT x L x L1 (mm) 2 x 24 x 12.5 2 x 24 x 9 2 x 25.5 x 10Lengths per Carton 50 50 50Stock lengths 3000 3000 3000

BEADS FOR DRY-LINING

4

ANGLE BEADRef. 571 (Pre-Galvanised and synthetically coated with pvc protective nosing)Protects render corners.

STOP BEADRef. 534, 533, 526 & 546 (Stainless Steel)Finishes and protects render edges.

ANGLE BEADRef. 545 (Stainless Steel)For external render work. One sizefor both thicknesses.

ANGLE BEAD (STANDARD WING)Ref. 506 (Stainless Steel)For external render work. One size for both thicknesses.

5

(L)(T) 5

(L) (T)

8

(L) (T)

(T)

(L)

REF 545T x L (mm) 16 / 20 x 64Lengths per Carton 25Stock lengths 3000

REF 571T x L (mm) 20 x 52Lengths per Carton 25Stock lengths 3000

REF 572T x L (mm) 19 / 20 x 55Lengths per Carton 25Stock lengths 3000

REF 506T x L (mm) 16 / 20 x 53Lengths per Carton 25Stock lengths 3000

REF 534 533 526 546T x L (mm) 10 x 60 13 x 60 16 x 61 19 x 58Lengths per Carton 25 25 25 25Stock lengths 3000 3000 3000 3000

REF 509 510 511 507T x L (mm) 10 x 57 13 x 54 16 x 55 19 x 52Lengths per Carton 25 25 25 25Stock lengths 3000 3000 3000 3000

EXTERNAL STOP BEADRef. 572 (Pre-Galvanised and synthetically coated with pvc protective nosing)Finishes and protects render edges.

STOP BEAD (STANDARD WING)Ref. 509, 510, 511 & 507 (Stainless Steel)Finishes and protects render edges.

(T)

(L)

(T)

(L)

BEADS FOR EXTERNAL USE

5

REF 542 543 544T x L (mm) 13 x 123 16 x 123 21 x 119Lengths per Carton 14 14 14Stock lengths 3000 3000 3000

REF 589 590T x L (mm) 18 / 19 x 125 21 x 119Lengths per Carton 14 12Stock lengths 3000 3000

REF 547T x L x L1 (mm) 16 / 20 x 65 x 25Lengths per Carton 25Stock lengths 3000

REF 508T x L x L1 (mm) 16 / 20 x 58 x 25Lengths per Carton 25Stock lengths 3000

REF 570T x L x L1 (mm) 16 / 20 x 25 x 65Lengths per Carton 50Stock lengths 3000

REF 573T x L x L1 (mm) 20 x 20 x 56Lengths per Carton 25Stock lengths 3000

* Must not be used overbuilding movement controljoints. See GeneralInstallation Informationinside front cover.

(L)

(T)

(L1)

(L)

(T)

(L1)

(T)

(L)

(L1)

(L)

(T)

(L1)

EXTERNAL RENDER STOPRef. 547 (Stainless Steel)Forms and protects lower edge of render.

EXTERNAL RENDER STOP (STANDARD WING)Ref. 508 (Stainless Steel)Forms and protects lower edge of render.

EXTERNAL RENDER STOPRef. 570 (Pre-Galvanised Steel)Forms and protects lower edge of render.

EXTERNAL STOP TYPE 2Ref. 573 (Pre-Galvanised and synthetically coated with pvc protective nosing)Forms and protects lower edge of render.

MOVEMENT BEAD*Ref. 589 &590 (Pre-Galvanised Steel with white pvc nosing)Forms movement joints in render, allows for +3mm, -1mm movement.

MOVEMENT BEAD*Ref. 542, 543 & 544 (Stainless Steel with white pvc nosing)Forms movement joints in render, allows for +3mm, -1mm movement.

(T)(L)

1

21

(T)(L)

21

1

Expamet have manufactured expanded

metal products for over 100 years. Our

current Lath range is No.1 in the UK and,

through international distributors, has

significant worldwide sales.

With a proven track record on all types

of contract from large commercial

projects through to home refurbishment,

Expamet Lathing provides an excellent

key for finishing materials on masonry,

ceilings, suspended ceilings and timber

frame buildings.

Suitable for internal or external applications

Expamet Lathing is easily formed, allowing

designers to create free forms such as

arches, domes and vaults in a trouble-free

effective manner. Expamet Lathing can also

be used as a carrier for fire protection

finishes to structural steelwork.

Simple to use and fix, and easy to work

with, the Expamet Lathing range is

designed to provide durable, effective

solutions whatever kind of plastering

or rendering work your job entails.

EXPAMET LATHING RANGEManufactured from pre-galvanised orstainless steel, Expamet Lathing is producedto BS 1369 in two main forms, each in arange of weights:

• Expanded metal lathing with diamond patterned mesh.

• Riblath expanded metal lathing with a herringbone pattern mesh of 3 hole design incorporating V-profiled solid ribs.

Galvanised Steel LathBS EN 10142 : 1991 DX51D + Z275Stainless Steel LathBS EN 10088-1 : 1995 X5CrNi18-10 / 1.4301

EXPANDED METAL LATHING

BB263 – Provides a key for lightweight plasters over small openings and chases.

BB264 – Carrier for lightweight plaster finishes on walls and ceilings.

BB265 – General plaster reinforcement.

EXPAMET LATHING

METAL LATHING FOR INTERNAL USE

Ref. Material Nominal Mesh Size Maximum fixing Sheet SizeThickness (mm) Weight kg/m2 SW (mm) Centres (mm) (mm)

263 0.500 1.11 9 300 2500 x 700264 0.725 1.61 9 350 2500 x 700265 0.400 0.90 9 300 2500 x 700

METAL LATHING FOR INTERNAL USE

METAL LATHING FOR EXTERNAL USE

Expanded metal lathing and Riblath for internal plasterwork.

Expanded metal lathing and Riblath for external rendering.

6

RIBLATH

269 – To carry lightweight plasters on a solid background.

271 – To carry sand/cement plaster and lightweight plaster on support systems or ceilings.

Ref. Material Nominal Rib Depth Maximum Centres Sheet SizeThickness (mm) Weight kg/m2 (mm) of support (mm) (mm)

269 0.3 1.16 8 600 2500 x 600271 0.5 1.80 8 600 2500 x 600

METAL LATHING FOR INTERNAL USE

7

Ref. Material Material Weight Sheet SizeThickness (mm) Type kg/m2 LW x SW (mm)

HD1 (2073F) 3 Flattened Mesh 8.59 2440 x 1220MD1 (2076F) 1.2 Flattened Mesh 1.85 2440 x 1220

1220 x 2440HDR (2089) 3 Standard profile mesh 6.52 2440 x 1220

with raised edge for rendering

SECURILATH SECURITY MESH

To prevent forced entry through walls, partitions, ceilings and roofs.

HD1 – Heavyweight option for security in walls, partitions and ceilings.

MD1 – Lightweight option for security in walls, partitions and ceilings.

HDR – For internal/external brick or block walls. An excellent key for plaster/render finishes.Has a raised edge for rendering.

Ref. Material Nominal Rib Depth Maximum Centres Sheet SizeThickness (mm) Weight kg/m2 (mm) of support (mm) (mm)

267 0.3 1.16 8 600 2500 x 600274 0.5 1.91 8 600 2500 x 600

RIBLATH267 – Stainlees steel carrier for all rendered finishes.

274 Red-Rib – Pre-galvanised carrier of render only to be used in sheltered/moderate exposure away from the coast.

Pre-galvanised steel DX51D + Z450 to BS EN 10142 : 1991.

METAL LATHING FOR EXTERNAL USE

EXPANDED METAL LATHING

95S – Carrier for render finishes.

Ref. Material Nominal Mesh Size Maximum fixing Sheet SizeThickness (mm) Weight kg/m2 SW x LW (mm) Centres (mm) (mm)

95S 0.460 1.15 9.2 x 28.6 350 2500 x 700

Supplied by/Order from: The Expanded Metal Co. Ltd. Tel: +44 (0) 1429 867388 Fax: +44 (0) 1429 866795Please see seperate brochure and website www.expandedmetalcompany.co.uk

Supplied by/Order from: The Expanded Metal Co. Ltd. Tel: +44 (0) 1429 867388 Fax: +44 (0) 1429 866795Please see seperate brochure and website www.expandedmetalcompany.co.uk

EXPANDED METAL LATHING

94G – For use with heavyweight plasters eg. Barium based.

Ref. Material Nominal Mesh Size Maximum fixing Sheet SizeThickness (mm) Weight kg/m2 SW x LW (mm) Centres (mm) (mm)

94G 0.95 2.50 9.5 x 28.6 450 2500 x 700

Supplied by/Order from: The Expanded Metal Co. Ltd. Tel: +44 (0) 1429 867388 Fax: +44 (0) 1429 866795Please see seperate brochure and website www.expandedmetalcompany.co.uk

8

GENERAL FIXING INFORMATION FOR FIXING TO METAL/TIMBER SUPPORTS.

1. FIXING EXPANDED METAL LATHING TO METAL ORTIMBER SUPPORTS

• Fix with the long way of mesh running from support to support, with all strands sloping downwards andinwards from the face of the coating.

• To connect to timber grounds use 38x2mm plasterersnails or galvanised staples. Start at the centre of thesheet and work out towards the edges, always fix at anangle (see fig 1 & 2) to allow lath to be pulled tight.

• To fix to steel channels, tie with 1.22mm tying wire at100mm centres. Tie as illustrated (see fig 3) by creating a 'hairpin' shape with the wire then pull tight and twist.Take care that cut wire ends are not close to plastersurface.

Fig. 1

Fig. 3

Fig. 4

Fig. 2Direction of fixing Direction of fixing

Steel channelrunner

End laps should be wired together at 150mm inter-vals and lap 50mm on supports

50mm Fixing to supports should be at 100mm centres

Side laps should be not less than 25mm andshould be wired together at 150mm intervals.

150mm

25mm

Expandedmetallath

100mm

INSTALLATION INSTRUCTIONS

9

1a FIXING EXPANDED METAL LATHING TO SOLIDBACKGROUNDS. See fig 5.

Fig. 6

Fig. 9

Fig. 7

Fig. 8

Fig. 5

• When joining Riblath sheets overlap the edge ribsand tie the edges with 1.22mm tying wire at 150mmcentres as illustrated (fig 7 & 8). If the end jointoccurs in front of a support overlap by 50mm, if itdoes not then overlap sheets by 100mm and providetwo 1.63mm wire ties per rib overlap.

• Always fix so that plaster or render is applied to thecorrect face, see fig 9.

2. FIXING RIBLATH TO METAL OR TIMBER SUPPORTS

• Riblath is fixed at each rib to timber grounds using the same fixings as Expanded Metal Lathing. Use 1.63mm or two strands of 1.22mmgalvanised mild steel wire or stainless steel tying wire to secure to steel supports - see fig 6. Ribs should run at right angles to supportswith the apex of the rib in contact with the support.

S U P P O R T I N G B A C K G R O U N D

Timber studs at max. 600mm centres Steel studs at max. 600mm centres

Proprietary fixingincluding 6mmmin. spacer

Max. 200mm

Max. 300mm

Max. 200mm

2500mm

Overlap 50mm

Overlap 25mm

Max. 350mm

Max. 150mm

Edge ribs overlapped (nested)

Edge ribs nested and wired at 150mm intervals

Section through plastered Rib-lath

Wire tie38mm Nail 32mm Staple

Typical fixing with integral spacer and largediameter headed nail.

Typical Fixing

• Where galvanised materials areused, the drying out period for theplaster or render must be kept to aminimum to prevent the possibilityof corrosion of the steel.

• The customer must ensure that theapplication environment and finishingmaterials are compatible with thebead and lath materials

• Ensure that all the metal componentsused in a given installation are of thesame material type.

• All materials should be storedunder cover in dry conditions, offthe ground, kept flat and protectedfrom accidental damage.

• Always wear gloves when cuttingor handling to prevent injury fromsharp edges.

• Proprietary fixings should be used. Ifin doubt contact the fixingsmanufacturer to ensure your fixingsare suitable for the background.

• National Building Specifications are:

M20 – Local plaster and render

reinforcement, metal angle beads,

screed beads and plaster stops.

M30 – Metal mesh lathing/anchored

reinforcement for plaster coatings.

Technical Information for specificExpamet bead and lath applicationsis available:

– Fixing EML/Riblath to solidbackgrounds and over insulation.

– Fixing EML/Riblath to timber framebackgrounds.

– Suspended Ceilings.

– Curved Suspended Ceilings.

– External Suspended Ceilings.

– Swimming Pool SuspendedCeilings.

• Specifiers must ensure that theresulting finish will be suitable for the intended application. For designand specification information refer to the British Standards listed andmanufacturers’ literature.

• Relevant British Standards are:

BS 6452: Part 1: 1984 –

Beads for Internal Plastering

& Dry Lining. Part 1. Specification

for galvanised steel beads.

BS 1369: Part 1: 1987 –

Steel Lathing for Internal Plastering

and External Rendering. Part 1.

Specification for expanded metal

and ribbed lathing.

BS 5492: 1990 – Code of Practice

for Internal Plastering.

BS 5262: 1991 – Code of Practice

for External Rendering.

BS 8212: 1995 – Code of Practice

for Dry Lining and Partitioning using

Gypsum Plaster.

BS 8000: Part 10: 1995 – Workmanship

on Site. Part 10, Code of Practice for

Plastering and Rendering.

2a FIXING RIBLATH TOVERTICAL SOLID BACKGROUNDS.

Proprietary fixings should be used tohold the ribs of the lath firmly againstthe background, see fig 10.

Where Riblath is fixed with the ribsrunning vertically, fixings should bemade through all ribs at 600mmcentres.

GENERAL NOTES FOR EXPAMET BEADS & LATHS:

Fig. 10 TYPICAL FIXING TO VERTICAL SOLID BACKGROUNDS.

• Fixing location1.2mm wire tie or screw location

600mm 600mm

150mm

STAINLESS STEEL FIXINGS FOR RIBLATH 267Ref. Material Application Material Size (mm)

HIS50 Hammer in Screws Combined stainless steel screw Stainless Steel 6 x 50and plug for brick, concrete

and dense aggregate blockworkTY1S Tying Wire For lapped joints and fixing Stainless Steel 1.22 dia x 1kg

to metal supports

10

Channels can be supplied for use with expandedmetal laths. BB expanded metal lath or Rib-lathis wired to the channels and then plastered.

Steel channels are:Manufactured from 1.500mm pre-galvanised steel.Used as furring and bearers for suspended ceilings.

STEEL CHANNELS

Galvanised mesh reinforcement for plasteringover wall chases.

EXPAMET EXMET

Ref CH27

Ref CH28

115mm

Ref. Material Size (mm) Length (mm)

CH27 Galvanised 38 x 11 5000 CH28 Galvanised 51 x 13 5000 CH27S Stainless Steel 38 x 11 5000 CH28S Stainless Steel 51 x 13 5000

Ref. Material Coil Width (mm) Length (m)

76320 Galvanised 65 2076420 Galvanised 115 2076520 Galvanised 175 20 76620 Galvanised 225 20 76720 Galvanised 305 20 76340 Galvanised 65 40 76440 Galvanised 115 40763100 Galvanised 65 100 764100 Galvanised 115 100 765100 Galvanised 175 100 766100 Galvanised 225 100 767100 Galvanised 305 100

11

Ref. Type Material Material Weight Mesh Size SizeThickness (mm) kg/m2 SW (mm) (mm)

521 Corner Mesh Stainless Steel 0.56 2.08 9 x 28.6 2500 x 50 x 50522 Strip Mesh Stainless Steel 0.56 2.08 9 x 28.6 2500 x 100583 Corner Mesh Galvanised 0.5 1.92 9 x 28.6 2500 x 50 x 50584 Strip Mesh Galvanised 0.5 1.92 9 x 28.6 2500 x 100

521 & 522 – Stainless steel carrier for all render finishes.

583 & 584 – Pre-galvanised carrier for render and plaster – only tobe used in sheltered/moderate exposure away from the coast.

Supplied by/Order from: The Expanded Metal Co. Ltd. Tel: +44 (0) 1429 867388 Fax: +44 (0) 1429 866795Please see seperate brochure and website www.expandedmetalcompany.co.uk

CORNER MESH & STRIP MESH

12

Expamet Arch Formers add elegance and style to any home, indoors or out. Suitable

for a wide range of openings, and available in an attractive range of shapes, they allow

housebuilders, designers, refurbishers and DIY enthusiasts to create distinctive,

decorative arches with ease and speed.

Manufactured from tough pre-galvanised steel, the strength and rigidity for a quality

finish is assured by the parallel strand mesh. The special downward and inward angling

of the horizontal strands ensures an excellent plaster key.

N.B. For external use the customer must get the Expamet Arch Formers coated with corrosion

resistant epoxy polyester.

Metal Arch Formers

ARCH CORNER SEMICIRCLE ELLIPTICAL

To suit wall widthsup to 230mm.For wall widthsover this usesoffit strips.

To suit wall widthsup to 230mm.For wall widthsover this usesoffit strips.

To suit wall widths up to 230mm.For wall widths over this use

soffit strips.

6 piece arch joints (4 piece arch hasjoint at centre only)

Overlap65mm

Overlap 65mm

Overlap 65mm

Rise

Opening width

Opening width

R

R

No other Arch Former range has Expamet’s

unique PVC nosing. It simply clips into

place to cover the metal and provide a

continuous edge – an edge that you can

follow to create a more accurate,

professional finish when plastering.

Unique PVC nosing

ARCH FORMERS

Ref. Structural Opening Finished Radius Number of Width (mm) (R) mm Parts

ESC30 760 372 4ESC32 810 397 4ESC33 840 412 4ESC36 920 452 4ESC48 1220 602 4ESC60 1520 752 4

Ref. Structural Opening Finished Rise Number of Width (mm) (mm) Parts

EEL48 1220 340 4EEL54 1370 360 4EEL60 1520 380 4EEL72 1830 410 6EEL84 2130 430 6EEL96 2440 440 6EEL120 3050 520 6

Ref. Finished Radius Number of (R) mm Parts

EAC15 372 2EAC18 452 2EAC24 602 2EAC30 752 2

13

SPANDREL MAKE-UP PIECE

LATH SOFFIT STRIP

Supplied as a coil

8 piece arch joints(4 piece arch hasjoint at centre only)

Rise

To suit wall widths up to 230mm.For wall widths over this use

soffit strips.

Overlap65mm

Opening width

R

R

INTERNAL LINERS FOR CIRCULAR WINDOWS

BULLSEYE

Overlap 65mm

To accommodate any opening widthmake-up pieces can be used with both

Arch corners and Semicircle Arch Formers.Supplied in two 600mm lengths. Ref MP24.

Lengths can be cut to make a former to span any width of opening.

65mm

Ref. Structural Opening Finished Radius Rise Number of Width (mm) (R) mm (mm) Parts

ESP30 760 180 220 4ESP36 910 180 240 4ESP48 1220 230 290 4ESP60 1520 230 330 4ESP72 1830 230 360 4ESP84 2130 230 370 4ESP96 2440 230 390 8ESP120 3050 230 440 8

Ref. Opening Finished Number of Width (mm) Diameter (mm) Parts

WBE24 610 594 8

Ref. Structural Opening Finished Radius Number of Width (mm) (R) mm Parts

BE18 460 222 4

Ref. Length(mm)

MP24 600

Ref. Length Width(mm) (mm)

LSS6 1830 155

14

The opening ready to receive an Expamet Arch Former. Where a previous-ly plastered wall is involved, the plaster surrounding the opening should becut back. This will result in a flush joint of new with existing plaster.

Arch Formers are not designed to carry structural loads. A Lintel mustalways be used when forming new openings.

Fixing the first part on an Arch Former with masonrynails or plug and screw. The Arch nosing should be13mm proud of the wall face to which it is being fixed.

Lightly pinching the nosing of the arch over a 40mm length of plasticdowel, supplied with the kit, which acts as a link between sections.

Arch Former sections in position on bothsides of an opening. A galvanised wire tiehas been inserted to securely unite theArch Former sections.

Start at the bottom junction, where the arch andangle bead should touch. Clip on the pvc nosingover the metal nose with guiding thumb pressureaction. Work completely round the arch.

Liquid soap can be used to aid application ifrequired.

a) Sufficient length pvc nosing is supplied tocover all the metal nosing.

b) The pvc nosing can be cut with heavy-dutyscissors, Stanley Knife or small hacksaw.

NOTE If you prefer, the Arch Former can still be used without the pvc nosing.

A render coat of Carlite Bonding or Thistle Hardwall plaster should be applied tothe Arch Former to a thickness of approx. 6mm from the surface of the lath. Thisshould be deeply cross-scratched to key a floating coat of the same plaster. Thefloating coat should be ruled evenly to the Arch Former nosing and lightlyscratched to key the finish plaster. Proprietary one-coat plasters now available canbe used. Follow suppliers instructions.

Finish plaster can then be applied.

Installation of Expamet Arch Formers in special situations.

a. Where the arch abuts a wall at right angles, the flanges can be removed, and thesides of the Arch Former unit can be nailed into suitably placed timber battens.

b. Alternatively the flanges can be bent at right angles along the wall/ceiling andfixed with masonry nails.

c. Concrete lintels. If direct fixing is difficult, timber battens should be fixed insidethe opening, to receive the Arch Former units.

d. For walls thicker than 230mm use lath soffit strip.

How to ensure best results

The nosing of the Arch Former should be 13mm proud of the wall face to which it isbeing fixed. Where the flange is to be bent, cut into the nosing bead as shown in Fig. b.Form the bend over a straight edge such as the edge of a bench or scaffold plank.

Tools needed:

1. Tin snips or heavy duty scissors and hacksaw.For cutting the nosing prior to bending and trimming away surplus material.

2. Hammer and suitable nails.

3. Pliers.

The component parts ready for installation.

If the pvc nosing is being used the Arch Formershould be set back approximately 1mm fromthe angle bead to allow for nosing thickness.

Twisting the wire tie to secure it. The endof the tie is then bent inwards between anaperture of the lath. Alternatively, self-tappingscrews may be used.

Fixing the pvc Nosing

Plaster lineall arches

Nails

a.

c.

b.

Cut line

MasonryNails

1

5

6

7

8

9

2

3

4

ARCH FORMERSINSTALLATION INSTRUCTIONS

PLASTERBOARD COMPOSITE& STUD PARTITIONS

DRY-LINED BLOCKWALLS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

1 Measure 403mm* from corner ‘C’ to springing point ‘S’ and head point ‘H’,complete plasterboarding to these points.

2 Fix arches in place with approved drywall adhesive, 10mm thickness. The arch soffitshould be positioned allowing for thickness of skim coat to the pasterboard.

3 Secondary fix arches using 4 No. 8 plated woodscrews into plugs with a minimumof 25mm screw penetration to background. Do not over-tighten screws.

4 Follow instructions 5, 6 and 7 above to complete installation.

*Note: 403mm = Arch + 10mm(ie. 393mm + 10mm adhesive).All dimensions are subject to

manufacturing tolerances.

Corner of stud partition readyto receive Plaster Arch.

Insert No. 8 plated woodscrews or plasterboard screwsinto the Plaster Arch (30mmlength).

Centre line of arch to align withcentre of stud.

Tape jointsbetween plas-terboard andPlaster Arch.

Apply plaster skim.

Install plasterboardcover strips. (9.5mm plasterboard).

Fix Expamet AngleBeads, ensuringthe nose matchesthe nose of thePlaster Arch.

403mm

PLASTERBOARD& SKIM

403mm

‘C’

‘S’ SPRINGING LINE

DRYWALL ADHESIVE

DABS

DRYWALLADHESIVE ‘H’ HEAD POINT

380mm RADIUS

1

5

6

7

2

Position the PlasterArch in the partitioncorner and screw to timber studding.Taking care to alignthe arch. Do not over-tighten screws.

3

4

Expamet Plaster Arch Formers allow simple internal arches to beformed even more easily. Simply fix in place with plasterboardscrews in the pre-formed holes, and then just plaster skim the flatsides for a guaranteed quality finish.

An accurate radius (380mm) ensures symmetry from arch to arch and the quality and simplicity of installation has made the range anestablished choice with major housebuilders and the trade. ExpametPlaster Arches are available in five sizes and are suitable for variouswidths of composite or stud partitions and dry lined blockwalls.

PLASTER ARCH

Ref Finished TypeThickness

PA63 63mm Composite partitions

PA75 75mm Metal stud and plasterboard partitions with a finished thickness of 75mm.

PA90 90mm Timber & Stud partitions. Use 65mm machined P.S.E. timber. 9.5mm plasterboard.

PA100 100mm Timber Stud partitions. Use 75mm sawn timber. 9.5mm plasterboard.

Alternative:Use 69mm machined P.S.E. timber. 12.5mm plasterboard.

PA145 145mm Dry-Lined Blockwalls

15

16

1. Hold arch firmly in place against the wall. Gently mark outline of the outer edge of the arch on to the wall with a pencil. Repeat procedure on both sides.

5. Fix arch piece firmly into position onto the wall.Repeat procedure on both sides.

2. Establish the centrepoint (see further details below).After finding the centrepoint cut each piece of arch to suit the arch opening width. You can leave up to a 7mm gap between the pieces. The keystone willcover this up.

6. Place corbel feature between both arches (one on each side of the wall) and mark. Cut corbel,glue and fit. The versatility of our design allows thecorbel to be cut to varying lengths, thus suiting anywall thickness.

3. Prepare the wall surface to take the adhesive.Cut along the outline marked in (fig1) with a sharpblade. Then strip the wallpaper off the wall. Nowapply suitable adhesive.

7. The final step before finishing is to add the keystone. Glue keystone on the grooved side thenplace keystone on the centrepoint, grooved sidedown to corresponding groves on arch.

4. Next lightly tack nails into the wall as shownabove to act as temporary supports for the archpieces whilst the adhesive sets.

8. Your decorative arch is now ready to finish.Remove nails, fill gaps between corbel and archwith filler then paint entire arch. You should nowbe able to enjoy the elegance your decorativearch will provide.

X centre section (17 x 56 TorusArchitrave not supplied) can be of any length, this gives you the possibility to make the archany width.

ARCH WIDTH VERSATILITYFINDING THE CENTRE POINT

To find the centre spotmarked “x” lightly mark thewall with a pencil at the endof each curve. This gives you2 points, the centre mark isbetween these 2 points.

x

Use timber architrave toextend to floor level

EXTENDING TO THE FLOOR

YOUR STEP-BY-STEP GUIDE TO A BEAUTIFUL DECORATIVE ARCH

DESIGNED TO COMPLIMENT EXPAMETPLASTER ARCHES (PA63, PA80, PA90, PA100, PA145) AND ARCHFORMERS (ESC15 & ESC30)

PATENT NO. 2275940 UK REG. DESIGN NO. 3004603

Kit comprises of:

4 Formed Arch Pieces2 Corbel Features

2 KeystonesRef. No. PADA380

NB. Torus Architrave not supplied

The Simple Way to Add Elegance to your Home

The Expamet Decorative Arch Kit is manufactured from pre-cast plasterwith an ingenious design to allow most openings to be turned into a feature.

The 380mm radius arch kit is adaptable to fit flat top arches up to 900mm wide.Extra wide flat top arches can be created using readily available 17 x 56mm Torus Architrave - see X oncentre illustration (bottom of page).

Quick, easy to fix

Arch width versatility

Create perfect, accurate finish every time

MULTI-SIZE DECORATIVE ARCH KIT

A company focused on customer needsAll Expamet products are designed to offer customers three key benefits:

Superior Design - to save you time and money

Proven Quality - for guaranteed performance

Ease of Use - for fast, accurate installation

Quality you can trustBecause we are a customer focused company, Expamet is also at the forefront of new product development. Our trackrecord of innovation includes quality too. We led the industry in achieving BS EN ISO 9002, and we were the first in oursector to be awarded BS EN ISO 14001 - the new Environmental Quality Standard. Where relevant Expamet products alsomeet or exceed current Building Regulations and have BBA and NHBC approval. Key products in our BAT Structural Fixingsrange also have BM TRADA Certification Q Mark.

Extensive Product RangeEvery Expamet product group has its own brochure, with full installation and product selection advice - use our WebsiteDownload facility to obtain a copy.

www.expamet.co.ukTechnical SupportDo you need assistance?

Free advice on the complete Expamet product range is available from our dedicated support team.

Our technical staff have a wealth of construction and engineering experience to help you solve the problems that arise in design and construction.

Contact the Expamet Technical Department direct on:

Telephone: 01429 866655 Fax: 01429 851873 Email: [email protected]

New Product IdeasHave you had a great product idea?

Contact the Technical Department (details above) for a confidential discussion on commecial potential, manufacture and distribution.

17

EMS 45225FM 36694

CERTIFICATE No. 89/2292

The company policy is one of continuous development, we therefore reserve the right to alterspecifications, etc. without notice. Stock material may be collected from company depots forcash or by prior arrangement. Customers are advised to check availability of material.

CERTIFICATE No. 89/2292

Quality Assurance BS EN ISO 9002:1994 and ISO 14001 Registered Firms Certificate No. FM36694, EMS 45225

COSHH We are not aware of any risk to the person arising from chemicals or other substancespresent on or in our products.

However, there exists the possibility of superficial injury from edges of relatively thin gaugemetals but this is obvious and arises largely from careless handling. It is akin to the risk fromtimber splinters or any sharp corner.

Expamet Building Products is a subsidiary of The Expanded Metal Company Limited.

Expamet International Limited

UK SALES & DISTRIBUTION CENTRE

PO Box 52, Greatham Street, Longhill Industrial Estate (North), Hartlepool

TS25 1PR England

TE L EPHONE

General: +44 (0)1429 866688 Sales: +44 (0)1429 866611

Fax: +44 (0)1429 866633 E-mail: [email protected]

Technical: +44 (0)1429 866655 Tech E-mail: [email protected]

Website: www.expamet.co.uk

EMS 45225FM 36694

IRELAND SALES & DISTRIBUTION CENTRE

DUBLIN: Westlink Industrial Estate, Kylemore Road, Ballyfermot, D10

Tel: 00-3531 626 5981 Fax: 00-3531 626 7802