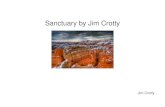

Fine Art Nature And Landscape Photography By Jim Crotty 012208

Plant Engineering / Corporate Metrology © 3M 2007. All Rights Reserved. Laboratory/ Process Safety...

-

Upload

karlee-reek -

Category

Documents

-

view

213 -

download

0

Transcript of Plant Engineering / Corporate Metrology © 3M 2007. All Rights Reserved. Laboratory/ Process Safety...

Plant Engineering / Corporate Metrology

© 3M 2007. All Rights Reserved.

Laboratory/ Process Safety Ventilation Program By Tom Crotty

Metrology With Results Bringing process safety, energy conservation

and data collection together.

2

Plant Engineering / Corporate Metrology

Learning Objectives Ventilation Program

1. To convey best practices of a ventilation program and the method used for testing.

2. Provide a platform for developing a value added testing program using Metrology.

3. The participants will be able to replicate a similar program using the reference tools provided in this lecture

© 3M 2007. All Rights Reserved.

3

Plant Engineering / Corporate Metrology

3M Corporate Headquarters Campus Campus = 425 acres, 41 buildings, 8.2 million square feet

Office space Research and development Full scale product testing Pilot process lines Manufacturing

© 3M 2007. All Rights Reserved.

4

Plant Engineering / Corporate Metrology

Process to review and make changes

© 3M 2007. All Rights Reserved.

5

Plant Engineering / Corporate Metrology

Types of systems and how many on site

© 3M 2007. All Rights Reserved.

6

Plant Engineering / Corporate Metrology

Ventilation Systems Covered Laboratory Ventilation hoods

Vertical sash, Horizontal sash, Walk in style

Flexible Flanged trunks Slot Exhaust Oven Exhaust Out of Scope

Biological Safety cabinets HEPA Rooms, Tables, Cabinets, Filter Systems Environmental Chambers, Rooms Re-circulating Air Systems

© 3M 2007. All Rights Reserved.

7

Plant Engineering / Corporate Metrology

Laboratory Ventilation Fume Hood Vertical Sash

© 3M 2007. All Rights Reserved.

8

Plant Engineering / Corporate Metrology

Laboratory Ventilation Fume Hood Horizontal Sash

© 3M 2007. All Rights Reserved.

9

Plant Engineering / Corporate Metrology

Walk In Laboratory Ventilation Fume Hood

© 3M 2007. All Rights Reserved.

10

Plant Engineering / Corporate Metrology

Flanged, Moveable Fume Extractors Some manufactured systems types: Nederman,

Plymovent, Torit, and Micro-Air.

non-flanged ventilation, “elephant trunks”

11

Plant Engineering / Corporate Metrology

Taking the Face Velocity Reading

Use a calibrated anemometer to take the velocity measurement at the face of the ventilation opening.

Slowly move the probe around the face of the opening until the highest face velocity is reached

Document the highest consistent face velocity.

© 3M 2007. All Rights Reserved.

12

Plant Engineering / Corporate Metrology

Flanged, Moveable Fume Extractors Labels

Minimum requirement is 200 fpm face velocity. ~ 600 of these systems at 3M Center Pass: active hoods must be certified annually with yellow sticker Interim (low): orange sticker for systems between 50-200 fpm, can still use

during repair Fail: red sticker stating “Do Not Use”

13

Plant Engineering / Corporate Metrology

Oven - Indirect Side Ventilation

© 3M 2007. All Rights Reserved.

14

Plant Engineering / Corporate Metrology

Oven Standard - Smoke Tube Test

For oven exhaust on the top of the oven: hold the smoke tube parallel to the oven surface in the center of the opening. Discharge a stream of smoke.

For oven exhaust on the side of the oven: hold the smoke tube parallel to the exhaust opening in the center of the opening. Discharge a stream of smoke.

Smoke tube test results descriptions: Good: No reverse flow observed. Smooth flow into & around the boundaries of

the exhaust opening. Fair: Some reverse flow, not necessarily at the opening. No visible escape of

smoke. Poor: Reverse flow of smoke near openings or lazy flow into the openings along

boundaries. Poor performance shows potential for escape of smoke. Fail: Smoke observed escaping from the duct or box

15

Plant Engineering / Corporate Metrology

Slot Exhausts

Yellow label shows the effective capture distance. The blue and white Caution label remind the user to conduct a Hazard Review before start-up.Guidance for safety survey: finding = no sticker or more than 1 year since last

certification (need to call *3 to get certified),

finding = using ventilation with red failure label or with Caution label

16

Plant Engineering / Corporate Metrology

Setting Specifications - Base line FPM

© 3M 2007. All Rights Reserved.

ANSI/ASHRAE 110 (1995)

For 3MHoods with average face velocities between 80-120 fpm:

Place a sash height indication label on the hood to the right of the sash indicating the sash position that the hood has been certified at (for vertical sashes only).

17

Plant Engineering / Corporate Metrology

Ventilation testing kit

© 3M 2007. All Rights Reserved.

•TSI Air Velocity Meter Model 8345•Label Stickers pass/fail•Pens•Do not use ribbon •Tape•Razorblade (in holder)•Replacement blades•Calibration procedure•TSI monitor procedure (for fume hood controls)•Tape measure•Caution Do Not Use Tape

18

Plant Engineering / Corporate Metrology

TSI 8345 Velocity Meter calibration

© 3M 2007. All Rights Reserved.

19

Plant Engineering / Corporate Metrology

TSI 8345 Traceability

© 3M 2007. All Rights Reserved.

20

Plant Engineering / Corporate Metrology

TSI 8345 Uncertainty

© 3M 2007. All Rights Reserved.

21

Plant Engineering / Corporate Metrology

Decommissioning of Systems

© 3M 2007. All Rights Reserved.

22

Plant Engineering / Corporate Metrology

Online information for employees

© 3M 2007. All Rights Reserved.

23

Plant Engineering / Corporate Metrology

General Employee Training -COMBO

© 3M 2007. All Rights Reserved.

24

Plant Engineering / Corporate Metrology

General Employee Training -COMBO

© 3M 2007. All Rights Reserved.

25

Plant Engineering / Corporate Metrology

General Employee Training -COMBO

© 3M 2007. All Rights Reserved.

Plant Engineering / Corporate Metrology

Thank You!Any Questions?

© 3M 2007. All Rights Reserved.

27

Plant Engineering / Corporate Metrology

References ACGIH (February 17, 2004) 25th Edition of Industrial Ventilation: A Manual of

Recommended Practice. ISBN# 1-882417-52-6, Publication #2094 Cincinnati, Ohio

NSF/ANSI 49 (2008) Bio-safety Cabinetry: Design, Construction, Performance, and Field Certification Tracking Number 49i35r1 Retrieved from website, http://standards.nsf.org/apps/group_public/download.php/3617/49i35%20w.g.%20UL%20and%20annex%20F.pdf

U.S. Department of Labor, OSHA 1910 Occupational Safety and Health Standards

1910.94 (c) (6)(i) Retrieved from web site, http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_id=9734&p_table=standards

ASHRAE Standard 62 (2011) retrieved from website,

http://www.ashrae.org/technology/page/132

© 3M 2007. All Rights Reserved.