Piston and Ring Failures 1

-

Upload

sushant-patil -

Category

Documents

-

view

223 -

download

0

Transcript of Piston and Ring Failures 1

-

8/13/2019 Piston and Ring Failures 1

1/27

-

8/13/2019 Piston and Ring Failures 1

2/27

Tribology plays a key role inautomotive vehicle design andperformance

Most significant role will beplayed in Engine design drivetrain, brakes, clutches, wheelbearings and axles

-

8/13/2019 Piston and Ring Failures 1

3/27

-

8/13/2019 Piston and Ring Failures 1

4/27

-

8/13/2019 Piston and Ring Failures 1

5/27

-

8/13/2019 Piston and Ring Failures 1

6/27

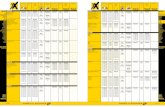

Characteristics

The piston skirt shows axial scoring marks predominantly on the thrust side

Causes

Abrasive particles entering the space between the pistonand cylinder. This can be due to operation in a dustyenvironment with poor air filtration.

Similar damage can arise in piston ring scuffing hasoccurred since this can generate hard particulate debris

More rarely the problem can arise from an excessivelyrough cylinder surface finish

-

8/13/2019 Piston and Ring Failures 1

7/27

-

8/13/2019 Piston and Ring Failures 1

8/27

Characteristics

Severe scuffing damage, particularly on the piston skirtbut often extending to the crown and ring lands. Thedamage is often worse on the thrust side.

Causes Operation with an inadequate clearance between the

piston and cylinder

This can be associated with inadequate cooling or a

poor piston profile Similar damage could also arise if there was an inadequate

rate of lubricant feed up the bore from crankshaft bearingsplash

-

8/13/2019 Piston and Ring Failures 1

9/27

-

8/13/2019 Piston and Ring Failures 1

10/27

Characteristics

The crown may show crack and the crown land andlands between the rings may show major distortion,often with the ring ends digging in to the

landsCauses

Major overheating caused by poor cooling and indiesel engines defective injectors and combustion

The problem may arise from inadequate cylindercoolant flow or from the failure of piston coolingarising from blocked oil cooling jets

-

8/13/2019 Piston and Ring Failures 1

11/27

Characteristics

The bedding on the skirt is not purely axial but showsdiagonal bedding.

Causes Crankshaft deflections or connecting rod bending.

Misalignment of rod or gudgeon pin bores.

-

8/13/2019 Piston and Ring Failures 1

12/27

Characteristics

Cracks near the gudgeon pin bosses and behind thering grooves.

Causes Inadequate gudgeon pin stiffness can cause cracking in

adjacent parts of the piston, or parts of the piston crosssection may be of inadequate area.

-

8/13/2019 Piston and Ring Failures 1

13/27

The most common problem with piston rings isscuffing of their running surfaces. Slight localscuffing is not uncommon in the first 20 to 50hours of running from new when the rings arebedding in to an appropriate operating profile.However the condition of the ring surfaces shouldprogressively improve and scuffing damage should notspread all round the rings.

-

8/13/2019 Piston and Ring Failures 1

14/27

Characteristics Local zones around the ring surface where there are axial

dragging marks and associated surface roughening.Detailed examination often shows thin surface layers of

material with a hardness exceeding 1000 Hv and composedof non-etching fine grained martensite (white layer).

Causes

Can arise from an unsuitable initial finish on the cylindersurface

It can also arise if the rings tend to bed at the top of theirrunning surface due to unsuitable profiling or fromthermal distortion of the piston

-

8/13/2019 Piston and Ring Failures 1

15/27

Characteristics The presence of dark bands running across the width of the

ring surface usually associated with transversecircumferential cracks. In severe cases portions of thechromium plating may be dragged from the surface.

Causes Unsuitable cylinder surface finish or poor profiling of the

piston rings Chromium plated top rings need to have a barelled

profile as installed to avoid hard bedding at the edges In some cases the problem can also arise from poor

quality plating in which the plated surface isexcessively rough or globular and can give local sharpareas on the ring edges after machining

-

8/13/2019 Piston and Ring Failures 1

16/27

Characteristics

The rings are found to be fixed in their grooves or very sluggish in motion. There may be excessive blowby or oil consumption.

Causes

The ring groove temperatures are too high due toconditions of operation or poor cooling

The use of a lubricating oil of inadequate qualitycan also aggravate the problem

-

8/13/2019 Piston and Ring Failures 1

17/27

Problems with cylinders tend to be of three types:

Running in problems such as bore polishing or insome cases scuffing

Rates of wear in service which are high and givereduced life

Other problems such as bore distortion arising from the engine design or cavitation erosion

damage of the water side of a cylinder liner, whichcan penetrate through to the bore

-

8/13/2019 Piston and Ring Failures 1

18/27

Characteristics

Local areas of the bore surface become polishedand oil consumption and blow by tend to increasebecause the piston rings do not then bed evenlyaround the bore. The polished areas can be very hardthin, wear-resistant 'white' layers.

-

8/13/2019 Piston and Ring Failures 1

19/27

Causes

The build up of hard carbon deposits on the top landof the piston can rub away local areas of the boresurface and remove the controlled surface roughnessrequired to bed in the piston rings

If there is noticeable bore distortion from structuraldeflections or thermal effects, the resulting high spots

will be preferentially smoothed by the piston rings The chemical nature of the lubricating oil can be a

significant factor in both the hard carbon build-up andin the polishing action

-

8/13/2019 Piston and Ring Failures 1

20/27

Characteristics

Cylinder liners wear in normal service due to theaction of fine abrasive particles drawn in by the intakeair. The greatest wear occurs near to the TDC positionof the top ring.

Corrosion of a cast iron bore surface can howeverrelease hard flake-like particles of iron carbide from

the pearlite in the iron. These give a greatly increasedrate of abrasive wear.

-

8/13/2019 Piston and Ring Failures 1

21/27

Causes

Inadequate air filtration when engines are operated industy environments

Engines operating at too low a coolant temperature,i.e. below about 80°C, since this allows the internalcondensation of water vapour from the combustionprocess, and the formation of corrosion pits in the

cylinder surface

-

8/13/2019 Piston and Ring Failures 1

22/27

Characteristics

An increasing rate of wear with operating time associated withthe loss of the surface profiling which provides a dispersed lubricantsupply. The surface becomes smooth initially and then scuffs becauseof the unsatisfactory surface profile. This then results in a major

increase in wear rate.

Causes

High rates of abrasive particle ingestion from the environment cancause this problem

A more likely cause may be inadequate quality of chromiumplating and its finishing process aimed at providing surface porosity

Some finishing processes can leave relatively loose particles ofchromium in the surface which become loose in service and acceleratethe wear process

-

8/13/2019 Piston and Ring Failures 1

23/27

Characteristics

Occurs in conjunction with piston ring scuffing. The surface of the cylindershows areas where the metal has been dragged in an axial direction withassociated surface roughening.

Causes

The same as for piston ring scuffing but in addition the problem can beaccentuated if the metallurgical structure of the cylinder surface isunsatisfactory.

In the case of cast iron the material must be pearlitic and should containdispersed hard constituents derived from phosphorous, chromium or

vanadium constituents. The surface finish must also be of the correct roughness to give

satisfactory bedding in of the piston rings.

In the case of chromium plated cylinder liners it is essential that the surface asan undulating or grooved profile to provide dispersed lubricant feeding tothe surface.

-

8/13/2019 Piston and Ring Failures 1

24/27

Characteristics

If separate cylinder liners are used with coolant incontact with their outside surface, areas of cavitationattack can occur on the outside. The materialremoval by cavitation continues and eventually theliner is perforated and allows the coolant to enter theinside of the engine.

Causes Vibration of the cylinder liner under the influence of

piston impact forces is the main cause of this problembut it is accentuated by crevice corrosion effects if the

outside of the liner has dead areas away from the

-

8/13/2019 Piston and Ring Failures 1

25/27

-

8/13/2019 Piston and Ring Failures 1

26/27

Lubrication in the valve train differs from that in the bearings and thepiston assembly, since it is generally accepted that the valve train is inthe mixed or boundary regime for most of its operating conditions

This is certainly true as far as conventional engines are concerned

Measurements of valve train friction torque frequently show that,under normal operating conditions, the valve train friction torqueincreases as the viscosity of the oil decreases

It is also in the valve train that friction modifier additives are thought tohave the largest effect

In a valve train lubrication model, the kinematics of the cam-followersystem need to described, and from knowing the cam and followerprofiles, the oil film thickness may be calculated fromelastohydrodynamic lubrication theory

Friction losses may then also be calculated

Ttotal = TB + Cµω

-

8/13/2019 Piston and Ring Failures 1

27/27

where TB is the friction torque due to boundary friction, and thesecond term represents hydrodynamic friction in the valve train system(both from the cam-follower contact and from the camshaft bearings).In the term for hydrodynamic friction, C is a constant, µ is thelubricant viscosity (at the appropriate temperature) and ω is thecamshaft angular speed

The boundary friction torque may be calculated by estimating the oilfilm thickness using elastohydrodynamic theory, and then comparingthis value to the combined surface roughness of cam and follower, and

assigning an effective friction coefficient

This approach has been used successfully by researchers from Shell39,Ford40 and Nissan41, and is found to give good agreement withexperimental measurements

A lower viscosity lubricant will give a higher boundary friction torque, whereas the hydrodynamic friction torque will be lower. Frictionmodifier additives can be added to the lubricant, and these are effectiveat reducing the boundary friction torque

![PISTON TECH - materion.com · material, piston material [or ring groove] and the piston liner and its surface treatment.” 1. A 3D illustration of a piston ring motion 2. With a](https://static.fdocuments.us/doc/165x107/5fcadda8a379fe5ba73c99c0/piston-tech-material-piston-material-or-ring-groove-and-the-piston-liner-and.jpg)