Pipelines - M. Amerini

-

Upload

henry-ardiyanto -

Category

Documents

-

view

219 -

download

0

Transcript of Pipelines - M. Amerini

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 1/150

PIPELINEStefano TARCHIAlberto TESEI

Maurizio Amerini

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 2/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today10. Environmental Impact

NOTE : Most slides in sections 3-6are courtesy of SRG

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 3/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today10. Environmental Impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 4/150

4

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Bcm/y

-155

-22-67

'05 ' 15 '30North America

-516

-292

-375

'05 '15 '3 0Europe

-61

-6-13

'05 '15 '30India

-127

0

-28

'05 ' 15 '3 0China

70

1624

'0 5 '1 5 ' 30

Latin America

290

101

143

'05 '15 '30

Africa

301

43

195

'0 5 '15 ' 30

ME

237

208 186

'05 ' 15 '3 0

Russia

Pacific

-37-38-66

'05 '15 '30

Production - Consumption

Source: WorldEnergy Outlook 2007 (EIA), BP Statistical Review 08.

NA Gas Cons.

2005

3% 20%

2020

97% 80%

Gas importedIndigenous Production

Natural GasReserves (% of total

World)

5%

3%

8%

4%

31%

41%

8%

Gas Market… Regional Unbalance

EU Gas Cons.

2005

50%75%

2020

50%25%

Gas importedIndigenous Production China Gas Cons.

2005

35%

2020

100% 65%

Gas importedIndigenous Production

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 5/150

5

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

PIPELINE vs LNG1. PIP & LNG factors (Qualitative)

- Same factors affect the two markets in a different way…i.e. geographical; geopolitical;

execution risk; technical complexity; selling gas alternatives; chain bottlenecks (I.e.pipe, vessels etc…)

2. PIP & LNG Value Chain (Quantitative)

- CAPEX: Engineering, Constructions etc..

- OPEX: Maintenance, Fuel, Operations etc..

- ROI and Payback period; sensitivity depending on variables(i.e. distance; plant size/flow; gas price)

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 6/150

6

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

LNG vs Pip: in the Mediterranean

Source: C-Engineering

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 7/150

7

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Economies of scale – 1000 km

Source: C-Engineering

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 8/150

8

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Economies of scale – 4000 km

Source: C-Engineering

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 9/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today10. Environmental Impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 10/150

10

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pipeline Design – Main Steps

1. Route selection

2. Pipe selection

3. Pipeline Hydraulic modeling

4. Compression stations

5. Model validation

6. Off design

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 11/150

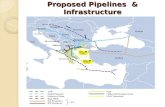

1. Route Selection

Geopolitical factor is oftenkey to project success

Decisive criteria to ensure optimum route

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 12/150

12

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

2. Pipe Selection

Larger pipes => reduced losses (Opex) but higher Capex...need the right compromise

Gas flow in a pipe...pressure..velocity.. losses

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 13/150

13

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

2. Pipe Selection

Not necessarily only #1 pipe...looping,construction and emergency issues may lead to different solutions

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 14/150

14

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Kilometrs

SOIL THERMAL PROFILE

0

0.0001

0.0002

0.0003

0.0004

0.0005

0.0006

0.0007

0.0008

0 500 1000 1500 2000 2500

S o i l T h e

r m a l C o n d u c t i v i t y , w / m * k

Soil Thermal Conduct.

Roughness Profile

0

0.005

0.01

0.015

0.02

0.025

0 500 1000 1500 2000 2500

Kilometers

P i p e R o u g h n e s s , m m

roughness mm

PIPELINE ELEVATION PROFILE

-200

0

200

400

600

800

1000

1200

1400

0 500 1000 1500 2000 2500

Kilometers

E l e v a t i o n , M

elev m

Inputs Needed:

• Pipe characteristics (i.e. Lenght,

roughness, size, thermal exch.

coefficient etc..)

• Soil temperature

• Ambient temperature

• Elevation profile

• Gas Composition and flow

• Establish treshold limits

PIPELINE ROUTE

3. Pipeline Hydraulic Modeling

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 15/150

15

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

4. Compression Stations

• Need to find the right balance between reducing pipe losses (whichmaximizes # stations) and relevant stations costs

• Optimum balance depending on several factors (i.e pipe rating, routeslosses etc...); typical order of magnitude is 150 km average distance

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 16/150

16

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

•Once Station power is established, need to move to

compression units selection within the station• Units selection shall based on flow profile forecasts,

available units size in the market andsparing philosophy

•CC and GT curves are then includedin the hydraulic model

•Several simulation are run to check properfunctioning of the system at different ambienttemperatures, flow profiles and operating

conditions (iterative process)

4. Model validation

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 17/150

17

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Off design may be due to:

1. Units/Stations in shutdown due

to (un)scheduled maintenance

2. Pipe Unavailability (SeaLine)

Units off-design: Sparing Philosophy

A. Parallel (N+1)

B. Series Operation (extra installed

power)

C. Dynamic (recovery during cold

period, if possible)

Disch. Pressure 1740 Psig (120 bara)

GT power and CC pressureratio are maximized during

one station outage

No Compressionrequired / available

5. Off Design - Units

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 18/150

18

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Cape Bon Head Station

910 Km OnshorePipeline

Algeria-Tunisia

1430 Km OnshorePipeline

Italian Peninsula

160 Km 20’’Three Lines 20” and Two Lines

26”Pipeline Under Sicilian Channel

CAPE BON SEA LINE HEAD STATION

N°10 FR52 + BCL404/A Compressor

5. Off Design - Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 19/150

19

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Initial Normal Conditions (1983)4 Units working in parallel to maximize Gas Flow

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

Discharge Header (150 Bar)

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

Suction Header

Middle Pressure Header (Not Used)

Cape Bon Plant Operating Scheme

Stand-By

Unit

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 20/150

20

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

Suction Header

BCL404/a

BCL404/a

MS5002BMS5002B

BCL404/a

BCL404/a

MS5002BMS5002B

Initial Emergency Conditions (1983)3 Units Middle Pressure and 2 Unites to Discharge Header

Unit InOperation

Discharge Header (205 Bar)

Middle Pressure Header (In Operation)

Cape Bon Plant Operating Scheme

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 21/150

21

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Large PIP evolution: design trends

(*) Price indicated refers to market price ( HenryHub) at time of installation, not to price ofgas delivered trough that pipeline.

100200N/AEmissions(NOx ppm)

NoSparing

N+12+1SparingPhilosophy

6.74.21.7Gas Price

($/MMBTU)*

200620001992Year

#900#600#600Pipe #

Yes(St.1)

NONOWaste Heatrecovery

160150120Aver.dist(Km)

41.1%37.7%36% incl.

regen cycleDriver ISOEfficiency

PGT25+PGT25FR5B/CDriver type

987555-75Pd (bara)

Russia Algeria IndiaProject

WHR becominga must

DischargePressure

Environmentalconstraints

LCC approach

Gas price up...focus on

efficiency (>43%)

Trends

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 22/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 23/150

23

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Onshore Pipeline Design Key Issues

• During the feasibility study, several pipeline routes areanalysed to minimize the impact to the environment

• The geology and the hydrological context of the pipelineroutes is analysed

• When the route is defined, the Company contacts the

landowners to explain the project

• Several studies and surveys are required for the detail

design and for the local and national permit procedures

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 24/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 25/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 26/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 27/150

27

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

2 - Clearing and gradingthe working strip

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 28/150

28

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

3 - Handling and stringing

Pipe transport

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 29/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 30/150

30

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

3 - Handling and stringing

Stringing phases

Trailers

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 31/150

31

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

3 - Handling and stringing

Stringing of pipesalong the pipelinework strip

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 32/150

32

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

4 - Bending

Pipes can be bent in the field to fit the

moderate changes in pipeline route andthe morfology

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 33/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 34/150

34

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

5 – Welding & Examination

Automatic welding

Manual welding

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 35/150

35

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

5 – Welding & examination

Ultra-sound examination of welds

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 36/150

36

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

6 - Digging the trench

The trenching crew uses specialised

escavators to dig the pipe trench

0.9 mBackfill

(subsoil)

Humus(topsoil)

Italian law requires for

the cover of the pipe a

minimum of 0,9m under

the ground level pipe

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 37/150

37

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

6 - Digging the trench

Trench

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 38/150

38

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

7 - Lowering into the trench

Using a number of side-booms,operators simultaneously liftand lower the pipe into thetrench

Such operation needs closecoordination and skilledoperators

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 39/150

39

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

7 - Lowering into the trench

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 40/150

40

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

7 - Lowering into the trench

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 41/150

41

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

7 - Lowering into the trench

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 42/150

42

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

7 – Lowering & Backfilling

Backfilling top soil

Backfilling

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 43/150

43

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

8 - Installing plants

Construction includes design and installation of:

Pig TrapsPig Traps

Pressure Reduction StationsPressure Reduction Stations

Gas Compressor StationsGas Compressor Stations Section valvesSection valves

Etc…Etc…

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 44/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 45/150

45

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

8 - Installing plantsPig trap

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 46/150

46

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

8 - Installing plants

Interconnection node

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 47/150

47

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

8 - Installing plants

High Pressure Reduction Station

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 48/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 49/150

49

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

8 - Installing plants

Gas Compressor Station

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 50/150

50

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

9 - Special Crossing

* Several techniques are available for crossing railways,

roads, waterways or special natural areaswithout digging open trenches

* Depending on soil conditions and geo-hydrology, the

appropriate trenchless technique can be selected from thefollowing:

a.a. Raise borerRaise borer

b.b. Horizontal Directional DrillingHorizontal Directional Drilling

c.c. MicroMicro--tunnelingtunneling

d.d. Tunnel Boring MachineTunnel Boring Machine

e.e. ……

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 51/150

51

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

9a - Raise Borer

well

Horizontalgallery

Drilling machine

Raise boring is an inclined drilling. The pipe is lowered in the borehole.

The benefit of this technique is that it allows installation of the pipeline withoutany vegetal and morphologic impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 52/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 53/150

53

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

9b - Horizontal Directional Drilling

* Based on techniques developed fordrilling deviated oil wellsFrom the point of departure where the drilling unit isplaced, a small diameter pilot bore is drilled along theplanned path.The hole is successively reamed out by a boring machine

until it achieves the proper diameter for the pipe.At this point, the pipeline is pulled and laid in the hole

* Is the most commonly used trenchless technology,with a reliable directional control system

* In Italy it was used for the first time by Snam in 1982 tocross the Po River

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 54/150

54

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

9b - Horizontal Directional Drilling

Jet drill D e s

i g na x i

s

Directional

control

Conductor pipe

Pilot borehole

Tubo dilinea

Trivellazione orizzontale controllata (TOC)Trivellazione orizzontale controllata (TOC)

Pulling pipe

Conductor pipe Borer

Boring

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 55/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 56/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 57/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 58/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 59/150

59

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Vegetation andmorphology is preserved

9c - Microtunnel

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 60/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 61/150

61

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Tunne l i =

6.35%

L = 2,343 m

328 m

Section

T u n n e l

9d - Tunnel boring machine

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 62/150

62

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

9d - Tunnel boring machine

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 63/150

63

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Demolishing the last brattice

9d - Tunnel boring machine

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 64/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 65/150

65

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

End of works: tunnel entrance

9d - Tunnel boring machine

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 66/150

66

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

10 - Testing

After backfilling, the pipeline is hydraulically tested:

In the Strength test, the pipeline stays for at least 1

hour at a pressure not less than 1.3 times the Design

Pressure

In the Hydraulic test, the pipeline stay for at least 48

hour at a pressure not less than 1.2 times the Design

Pressure

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 67/150

67

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

11 - Restoration

* Since the design phase, foresty agronomists andgeologists perform all the operations to protect theecosystems, water courses and landscapes

* The final step in the construction process is restoringthe land as closely as possible to its original condition

* Restoration works includes:

- Morphologic restoration

- Vegetation restoration

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 68/150

68

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

During works… …After 1 year… …After 2 years…

11 - Restoration

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 69/150

69

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

After construction, the only evidence of thepipe presence, are the pipeline markings

11 - Restoration

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 70/150

70

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

orchard

vineyard

fields

11 - Restoration

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 71/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 72/150

Source: Nordstream website

Offshore pipelines – Proven Technology

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 73/150

73

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

MECHANICAL ASSEMBLYMECHANICAL ASSEMBLY

WORK ON THE SEA FLOORWORK ON THE SEA FLOOR

TESTING AND START UPTESTING AND START UP

Offshore Construction

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 74/150

74

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Offshore Construction:Mechanical Assembly

Laying Methods

• ‘S-lay’ and the ‘J-lay’

• Coiled Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 75/150

75

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Laying

J-Lay S-Lay

Offshore Construction:Mechanical Assembly

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 76/150

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 77/150

Offshore Construction:Mechanical Assembly

Source: Nordstream website

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 78/150

78

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

J - Lay ProcessThis system is used to lay pipelines at depths of between 400 and 3500

m. Here the pipe is welded in a vertical position and lowered onto the

sea floor without the use of a support structure, thus forming a “J”

shape

Offshore Construction:Mechanical Assembly

http://www.medgaz.com/medgaz/pages/archivos_multimedia-eng.htm

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 79/150

79

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Coiled Pipeline

Pipes which have already welded together an onshore worksite.

For pipelines of a modest diameter, up to 14-16 inches

(35.6-40.6 cm)

Requires pipes with thick walls

Offshore Construction:Mechanical Assembly

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 80/150

80

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

MECHANICAL ASSEMBLY

WORK ON THE SEA FLOOR

TESTING AND START UP

Offshore Construction

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 81/150

81

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Offshore ConstructionWork on the Sea bed

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 82/150

82

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

MECHANICAL ASSEMBLYMECHANICAL ASSEMBLY

WORK ON THE SEA FLOOR

TESTING AND START UP

Offshore Construction

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 83/150

83

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Testing and preparation for Start up

1. Fill with water /cleaning by pigs

2. Hydraulic Test (1.15/1.25 times the project pressure)

3. Dewater by air through a train of pigs4. Air-dry

5. Nitrogen fill or air purging

6. Gas or oil fill

Offshore Construction

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 84/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 85/150

85

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Gas transmission is ensured through network pressure controlusing the following plants installed along the pipelines:

Compressor stations

Manifolds

Pressure reduction and regulation plants

Check valves.

The control is managed through:

Continuous monitoring of the process parametersof the network

Use of simulation SW to predict gas demand and balance

of the network

Gas transmission control

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 86/150

86

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Supervisory Control & Data AcquisitionComposed by SW, telecommunication and control systems designed toensure remote and centralized control of network operation.

Transmissionsystems

HMI

Server

RTU

Cable

Radio/Satellte transmission

Control Room

Transmissionsystems

RTU

RTU

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 87/150

87

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Dispatching Centre

Integrated control system capable of making gas readily available

anywhere at any time

Evaluating the total volume

of gas available

Regulating the gas flowsaccording to the demand

Monitoring thetransportation systemthrough data acquisitionstations

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 88/150

88

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Physical compressor station...

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 89/150

89

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

...SCADA compressor station

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 90/150

90

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Station Control System (SCS)

Operating modes

Local manual

Local automatic

Remote automatic

HMI

Measurement and regulation system

Supervision system (operation logic)

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 91/150

91

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Compressor Stations remote control

To ensure the remote control of the stations, a local automated controlsystem is installed in the station interfaced with the Dispatching Centre

that operates the plant directly from Headquarters.The operation is optimised according to operating needs defined in termsof the overall transportation flows and the global operational conditions.

Transport optimization consists of finding a steady condition of network

operation which minimizes total fuel gas consumption of compressor stations,ensuring gas transmission satisfying gas demand.

Dispatching Centre Station Control Room

i l i

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 92/150

92

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Compressor Station regulation

To ensure compressor station regulation,

Dispatching Centre define setpoints for:• suction pressure• discharge pressure• flow• discharge temperature (local set point)

and starts a number of units according to simulation results.

The station control system (SCS), through UCP, automatically regulates theunits speed match the required setpoint

l l d d l

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 93/150

93

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Annual Supply – Demand Modulation

Sum of:•Importation•Domestic Production•Storage withdrawal

Demand

Storage withdrawal

Storage injection

I d

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 94/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance

7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

E G Pi li I id

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 95/150

95

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

European Gas Pipeline IncidentData Group 1970-2004

E G Pi li I id t

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 96/150

96

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

European Gas Pipeline IncidentData Group 1970-2004

E G Pi li I id t

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 97/150

97

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

European Gas Pipeline IncidentData Group 1970-2004

E G Pi li I id t

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 98/150

98

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

European Gas Pipeline IncidentData Group 1970-2004

Thi d ti i t f i

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 99/150

99

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Third parties interferencies

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 100/150

Floodings

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 101/150

101

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Floodings

Mill / Construction defects

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 102/150

102

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Mill / Construction defects

Welding defects

Base material

defects

Misallignment

Porosity

Slag

Lack of fusion

Lack of penetration

UndercutCracking

Delamination

InclusionCracking

Ground movements

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 103/150

103

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Ground movements

Landslide monitoring

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 104/150

104

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Landslide monitoring

MAIN PIPELINES

GEOLOGICALLY UNSTABLE AREAS

* For the gas pipeline network in

Italy over 1,800 geologicallyunstable areas have been

identified.

* Over 320 critical areas are

currently monitored using a

combination of inclinometers,

piezometers and strain gauges.

* Periodical geological surveys are

performed to visually monitor

morphological evolutions

Landslide monitoring

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 105/150

105

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Landslide monitoring

STRAIN GAUGES

Landslide control

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 106/150

106

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Landslide control

SOIL CONSOLIDATION STRESS RELEASE

Corrosion

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 107/150

107

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Corrosion

Cathodic protection

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 108/150

108

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Installation of electrical (cathodic) protection

Impressed Currents Cathodic Protection Rectifier

Cathodic protection

Cathodic protection

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 109/150

109

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Cathodic protection

Pig inspections

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 110/150

110

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pig inspections

Inspection/Maintenance:

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 111/150

111

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Inspection/Maintenance:Pigging Operations

Pig Before Cleaning

Inspection/Maintenance:

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 112/150

112

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Inspection/Maintenance:Pigging Operations

Pig After Cleaning

Inspection/Maintenance:

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 113/150

113

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Traps for Launching and Receiving Pigs

.PIPI1

2

32

4

Pipeline

3 Pig transit signaller

4 Receiving Trap

3

1 Launching Trap

2 Special T

Inspection/Maintenance:Pigging Operations

Inspection/Maintenance:

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 114/150

114

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Traps for Launching and Receiving Pigs:

Normal Production Condition

PIPI12

3

24

Pipeline start Pipeline arrival

Pipeline

3

Inspection/Maintenance:Pigging Operations

Inspection/Maintenance:

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 115/150

115

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Traps for Launching and Receiving Pigs

Cleaning Condition

PIPI12

3

24

Pipeline start Pipelinearrival

Pipeline

3

Inspection/Maintenance:Pigging Operations

Pipeline repair

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 116/150

116

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pipeline repair

Pipeline repair

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 117/150

117

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pipeline repair

Index

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 118/150

Index

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

Components of a Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 119/150

119

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Components of a Pipeline

INITIAL INJECTION STATIONThis is the beginning of the system, where the product is injected

into the line.

Storage facilities, pumps or compressors are usually located at

these locations.

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 120/150

Components of a Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 121/150

121

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

COMPRESSOR/PUMP STATIONSCOMPRESSOR/PUMP STATIONS

Pumps for liquid pipelines and compressors for gas pipelines are

located along the line to move the product through the pipeline.

The location of these stations is defined by the topography of the

terrain, the type of product being transported, or operational

conditions of the network.

Components of a Pipeline

Components of a Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 122/150

122

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

BLOCK VALVESBLOCK VALVESThese are the first line of protection for pipelines. With these valves

the operator can isolate any segment of the line for maintenance

work or isolate a rupture or leak. Block valves are usually located at

regular intervals along the line, depending on the type of pipeline.

Components of a Pipeline

Components of a Pipeline

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 123/150

123

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

FINAL DELIVERY STATIONFINAL DELIVERY STATION

Known also as Outlet stations or Terminals, this is where the

product will be distributed to the consumer..

Components of a Pipeline

Compressor Stations

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 124/150

124

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

gas coolers

gas filters

compressor unit control room

p

Typical CS Process Flow Diagram

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 125/150

125

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

yp g

Design Philosophy for Gas Pipeline CS

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 126/150

126

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

g p y p

• Referenced High efficiency tri-dimensional impellers

• Wide operating range with flat efficiency curve• Robust Design for Availability/Reliability

• Very stiff casing providing excellent internal alignment at full pressureand capability to withstand extremely high nozzle loads

Centrifugal Compressor

• Aero derivative high efficiency• High reliability / Availability

• Reduced maintenance with Extended Life Parts

Gas Turbine

• Security of Supply

• Maximum efficiency• Maximum availability/reliability

• Maximum Service Intervals

Unit design to

Why is efficiency so important in PIP?

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 127/150

127

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

y y p

Incl. In capexSpares

100% 82 Total

9%7

Maintenance

18%15CAPEX (Unit)

55%45Fuel

18%15CAPEX (Station)

MM$ %Order of Magnitude

Assumptions

- 20 Y Cycle- WACC: 12%

Fuel

- 8600 FH/Y

- 30 MW unit: 85% GT Load

- 37.5% eff. (6800 BTU/Hp-hr)

- Gas price: 3$/MMBTU

Maintenance

- BI; (every 6m)

- HGPI (25kFH)

- MI (50kFH)

Gas Pipeline Compressors

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 128/150

128

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Cover

Head

Cover

Head

Typical Design used when:• Optimized stages efficiency (>88%)

• Short time assembly and maintenance time

• Cylindrical Barrel casing permits shortermanufacturing cycles (no weldings) andmaximum optimization of the dischargevolute (here not limited by the casing)

p p

BEAM TYPE with Two Cover Head fixed with “shear rings” method

Centrifugal Compressor Skid

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 129/150

129

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

g p

Reduction Station: Typical scheme

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 130/150

130

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

yp

inlet

outlet

by-pass

meter run

relief valve

pressure regulation streamsfilters heating

Filters

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 131/150

131

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

inlet

outlet

by-pass

meter run

relief valve

pressure regulation streamsfiltersheating

Heaters

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 132/150

132

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

inlet

outlet

by-pass

meter run

relief valve

pressure regulation streamsfiltersheating

Pressure regulators

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 133/150

133

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

g

inlet

outlet

by-pass

meter run

relief valve

pressure regulation streamsfiltersheating

Index

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 134/150

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

The Gas Storage Market

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 135/150

135

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Source: www.gie.com (updated at Feb 09)

CAGR ~4%’08-’20

UGS

WGV(Bcm)

200

250

300

350

400

450

500

550

600

650700

2008 2010 2012 2015 2020

high

base

min

Installed UGS+

under construction

UGS market is growing worldwide... ...because its role is also evolving

• Existing capacity insufficient… needed +15 BCMY

• Higher demand for flexibility & peak gas rates

• Growth driven by security of supply & arbitrage

2 main operating modes in Gas Storage

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 136/150

136

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

I.Filling the

Reservoir

From grid Pressure to the MaxPressure of the Reservoir

From cavern Pressure to grid Pr

II. Exporting

the Gas

• Flexibility in pressure ratio & flows necessary

to manage both the operating modes• Pgrid high variance range enhance the need for flexibility

P max

P grid

P max

P grid

Compressorstart up

Note: curve profiles are qualitative

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 137/150

Main Types of Storage

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 138/150

138

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Porous Rocks

Caverns

Aquifer Reservoir

Depleted Oil/Gas Reservoirs

Salty Caverns

Abandoned Mines

Lined Rock Caverns

Max P 170 bar

Max P 250 bar

Max P 250 bar … exceptionally

up to 450 bar

Index

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 139/150

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

Pipeline Capex (By Cost Component)

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 140/150

140

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pipeline Capex (By Product)

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 141/150

141

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Pipeline Capex (By Region)

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 142/150

142

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

EU Pipeline Infrastructure

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 143/150

143

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

China Pipeline Infrastructure

K l di d bHeihe

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 144/150

144

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

29/GE Oil & Gas ECLP/

10/28/2008

Alashankou

Kelamayi

Cainan

Dushanzi

Tazhong

Lunnan

Kuerle

Shanshan

花土沟

Geermu

Jingbian

Qingyang

Saihantala

阿尔善

Fangshan

Dezhou

Daqing

Tieling

Anshan

Dalian

Jilin

Fushun

Bo’ai

Qingdao

Cangzhou

Puyang

Dongying

NingboAnqing

Jiujiang

Maoming

Dali

Huaihua

Hengyang

Linyi

Zibo

Jining

Liuzhou

Huai’an

Xiangfan

Xiaogan

Yancheng

Shangrao

Rui’anZhangshu

Ruijin

Guilin

Hetian

Tahe

Luntai

Baotou

Handan

Baoji

Sebei

Dunhuang

Jiangyou

Dujiangyan

Nanchong

Anyang

Yilan

Kaladierdaban

Gas from Turkmenistan andKazahkstan

Manzhouli

Legend

Existing

New

Hongliu

Longgang

Northeast Pipelines

967km

1016mm

10MPa

2010

Shaanxi-BJ 3

1400km

1016mm

10MPa

2011

WEPP 2

8000-9000km

1219mm

10MPa

2011

China - Burma

2748km

1016mm

10MPa

2011

Northeast Pipelines

390km

1016mm

10MPa

2011

Tangshan Pipelines

450km

1016mm

10MPa

N/A

Lhasa Pipeline1200km

508mm

10MPa

N/A

LonggangPipeline

670km

1016mm

10MPa

2013

Sebei-Xining-LanzhouDuplicate

930km

660mm

2012

Urumuqi

Yinchuan

Lanzhou

Xining

HohhotBeijing

Tianjin

Shijiazhuang

Taiyuan

Harbin

Changchun

Shenyang

Zhengzhou

NanjingHefeiShanghai

Fuzhou

Hangzhou

Nanchang

Wuhan

Changsha

Guangzhou

Hong Kong

Macao

Haikou

Nanning

Kunming

Guiyang

Chengdu

Chongqing

Lhasa

Taipei

Huoerguosi

Zhongning

Xi’an

Zhuaji

Yingkou

Qinhuangdao

Jinan

Zhumadian

Pingxiang

Shaoguan

Xiangtan

North America Pipeline Infrastructure

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 145/150

145

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

India Pipeline Infrastructure

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 146/150

146

GE Confidential and Proprietary InformationGE2006 All Rights Reserved

Author: S.Tarchi

2/22/2010 Rev. 0

Index

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 147/150

1. Need for Gas Transportation: Pipeline vs LNG

2. Pipeline Design

3. Construction (Onshore)

4. Construction (Offshore)

5. Operation

6. Maintenance7. Main Pipeline Components

8. Gas Storage

9. The Pipelines Market Today

10. Environmental Impact

Environmental Impact - Example

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 148/150

Source: Nordstream website

Environmental Impact - Example

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 149/150

Source: Nordstream website

7/31/2019 Pipelines - M. Amerini

http://slidepdf.com/reader/full/pipelines-m-amerini 150/150

BACK-UP