Pigment Dyeing - T R I

Transcript of Pigment Dyeing - T R I

Tri-Tex co inc.

Tri-Tex co inc.

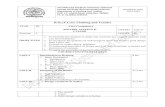

Cationic Pre-treatment• Setbathat80°F(L/R15:1)• Add0.3%Triscour jet conc.• Optional0.3%Bioprep PDE(BiopolishEnzymes)• Heatto140°Ffast• Add5%Texafix BR newdozingover15minutes• Circulatefor20minutes• Add0.5%Acetic Acid 56%dosing5minutes• Rinseoverflow,Drop,Rinsewarm

Pigment Dyeing• Setbathat80°F(L/R15:1)• MixX%Tripigmentwith4%(owg)of

Tribinder AC-M 2240N• AddTripigmentandTribinder AC-M 2240N

dosingover15minutes• Heatto140°Fover20minutes• Runfor20minutes• Add1%Acetic Acid 56%dosing5minutes• Runfor10minutes• Rinseoverflow,drop.

Softener Application • Setthebathat80°F(L/R15:1)• Add3%Tricosoft CWS liq.• Heatto120°F• Runfor15minutes• Drop,Extract,Dry.

MethodofDyeing

Dyeing with PigmentsExhaust dyeing

ECOrEspOnsIblE

Dy

eing &

ing Fl

uoresc

ent c

olor

cha

rt

Tri-Tex co inc.1001 boulevard IndustrielSaint-Eustache, Qc, Canada J7R 6C3

1-800-363-2660 450-974-1001

www.tritex.comP

ho

to ©

Ch

iliro

se

Printing Formulation X.0g/kg Tripigment 800.0g/kg Stockthickening(CLEAR) 0-120g/kg Tribinder HON-NF Y.0g/kg Stockthickening(tocompletefinalvolume)

Print,dryandcurefor3minutesat160°C.

Stock Thickening (CLEAR) Formulation 900.0g/kg Coldwater 15.0g/kg Triconc NF 1.0g/kg Kathon LX X.0g/kg Coldwater(toadjusttheviscosity)

Procedure to make stock thickening: (CLEAR) • Chargethewater.• AddtheTriconc NFandKathon LX.• Startthehighshearagitatorfor2-3minutesthenstopfor

2-3hoursforbestswelling.• Stirforatleast10minutesoruntilverysmoothand

homogenous.• AddtheTribinder HON-NFandpigment.

Notes A)Tocalculatetheamountofbindertoaddtotheprintpasteperkilo,usethefollowingformula:

Theamountofbinderrequired=(80+3a/2)gramofbinder.a=concentrationofpigments

Example:for20grampigmentweadd(80+3*20/2=110grambinder/kg).

Exhaust6% Printing80g/L Tota

lSol

id(%

)

Pigm

entS

olid

(%)

PH

Fastnessproperties

Ligh

tfas

tnes

s

Was

hCO

Was

hCH

Dry

Wet

Alk

alit

reat

men

t

Aci

dtr

eatm

ent

Tripigment FL Yellow G

50 40 7+1 4-5 3-4 4 2-3 2 3 2-3

Tripigment FL Golden Yellow RB

50 40 7+1 4-5 3 3-4 2-3 2-3 3 2-3

Tripigment FL Orange YR

50 40 7+1 4-5 3 3-4 2-3 3 3-4 3

Tripigment FL Orange RR

50 40 7+1 4-5 3 4 2-3 2-3 3-4 2-3

Tripigment FL Red Y

50 40 7+1 4-5 3 4 2-3 2-3 3-4 2-3

Tripigment FL Pink B

50 40 7+1 4-5 3 4 2-3 2 3 3

Tripigment FL Magenta

50 40 7+1 4-5 3-4 3-4 2-3 2 3-4 3

Tripigment FL Violet Y

50 40 7+1 4-5 3-4 4 2-3 2 3 3

Tripigment FL Violet B

50 40 7+1 4-5 3-4 4 2-3 2 3 3

Tripigment FL Turquoise

50 38 7+1 4-5 3-4 3 2-3 4 4 6-7

Tripigment FL Green

50 38 7+1 4-5 3-4 3-4 3 4 4 7

Typical procedurefor Pigment Printing