PIECENAMP Module 5 – Controllability Analysis 1 Tier II Worked Examples.

-

Upload

anissa-atkins -

Category

Documents

-

view

212 -

download

0

Transcript of PIECENAMP Module 5 – Controllability Analysis 1 Tier II Worked Examples.

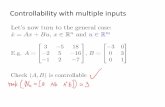

Module 5 – Controllability Analysis 11

PIECENAMP

Tier IIWorked Examples

Module 5 – Controllability Analysis 22

PIECENAMP

Tier II Statement of intentTier II Statement of intent

The goal of this tier is to demonstrate various The goal of this tier is to demonstrate various concepts and tools of concepts and tools of Controllability Analysis Controllability Analysis using using real examples. Some examples will be given, focusing real examples. Some examples will be given, focusing mainly on mainly on Controllability Analysis Controllability Analysis tools. At the end of tools. At the end of Tier II, the student should have a general idea of what Tier II, the student should have a general idea of what is:is:

Relative Gain ArrayRelative Gain ArrayNiederlinski IndexNiederlinski IndexController designController designDesign of multivariable controllersDesign of multivariable controllersSteady State Decoupling (Singular Value Steady State Decoupling (Singular Value Decomposition)Decomposition)

Module 5 – Controllability Analysis 33

PIECENAMP

2.0 Inverse of a matrix2.0 Inverse of a matrix2.0 Inverse of a matrix2.0 Inverse of a matrix

To obtain the To obtain the Relative Gain ArrayRelative Gain Array ( (RGARGA) of a transfer function ) of a transfer function matrix, first of all it is necessary to review how to obtain the matrix, first of all it is necessary to review how to obtain the inverse of a matrix.inverse of a matrix.

The inverse of a matrix does not exist for all matrices, it The inverse of a matrix does not exist for all matrices, it exists only if:exists only if:

The matrix is square, andThe matrix is square, and

Its determinant is not zero (non-singular Its determinant is not zero (non-singular matrix).matrix).

Now given the 3x3 matrix Now given the 3x3 matrix AA, it is desired to obtain the , it is desired to obtain the inverse of the matrix inverse of the matrix AA..

Module 5 – Controllability Analysis 44

PIECENAMP

32

412A

32

412A

1.1. Determinant of matrix Determinant of matrix AA..

The determinant of matrix The determinant of matrix AA is obtained using the is obtained using the cofactors based on any row. In this case the first row is cofactors based on any row. In this case the first row is selected.selected.

As it can be seen, the determinant is not equal to zero As it can be seen, the determinant is not equal to zero

35

401

35

401

25

103

25

103

5)50(3)200(1)83(2 5)50(3)200(1)83(2

325

410

312

A

Module 5 – Controllability Analysis 55

PIECENAMP

In a 3x3 matrix there is no problem to calculate the In a 3x3 matrix there is no problem to calculate the determinant. Nevertheless it is important to note that the determinant. Nevertheless it is important to note that the second cofactor is being multiplied by the factor of (-1). second cofactor is being multiplied by the factor of (-1).

This is because the cofactor of each matrix element must be This is because the cofactor of each matrix element must be multiplied by the following term:multiplied by the following term:

where where ii is the row number and is the row number and j j is the column number of the is the column number of the element for which the cofactor is calculated.element for which the cofactor is calculated.

It means that for matrix It means that for matrix AA, the cofactors which are multiplied , the cofactors which are multiplied by (-1) are:by (-1) are:

ji )1(

325

410

312

A

325

410

312

A

CC(12)(12), , CC(21)(21), , CC(23)(23) and Cand C(32)(32)

Module 5 – Controllability Analysis 66

PIECENAMP

325

410

312

A

532

4111 C 5

32

4111 C

332

3121 C 3

32

3121 C

2.2. Matrix of cofactors (Matrix of cofactors (CC).).

Now it is necessary to calculate the cofactors matrix (Now it is necessary to calculate the cofactors matrix (CC) ) for each element of matrix for each element of matrix A.A.

840

3232 C 8

40

3232 C

2035

4012 C 20

35

4012 C

935

3222 C 9

35

3222 C

141

3131 C 1

41

3131 C

525

1013 C 5

25

1013 C

125

1223 C 1

25

1223 C

210

1233 C 2

10

1233 C

281

193

5205

C

281

193

5205

CAnd this way the cofactor matrix has been And this way the cofactor matrix has been obtained:obtained:

Module 5 – Controllability Analysis 77

PIECENAMP

3.3. Adjoint of (Adjoint of (AA).).

The Adjoint of The Adjoint of AA is the transpose of matrix is the transpose of matrix C.C.

52

511

58

594

51

531

215

8920

135

5

1)(

11

Α

CA

ΑΑ

T

adj

52

511

58

594

51

531

215

8920

135

5

1)(

11

Α

CA

ΑΑ

T

adj

215

8920

135

)( Tadj CA

215

8920

135

)( Tadj CA

281

193

5205

C

281

193

5205

C

4.4. Now the inverse of Now the inverse of A A is obtained using the determinant is obtained using the determinant and the adjoint of and the adjoint of A.A.

5.5. Check now that by matrix multiplication that the identity Check now that by matrix multiplication that the identity matrix is obtained multiplying matrix is obtained multiplying A A andand A A-1-1. .

100

010

001

52

511

58

594

51

531

325

410

3121AA

100

010

001

52

511

58

594

51

531

325

410

3121AA

Module 5 – Controllability Analysis 88

PIECENAMP

As can be seen, the amount of work is extensive, just to As can be seen, the amount of work is extensive, just to calculate the inverse of a matrix!.calculate the inverse of a matrix!.

Therefore, it will now be shown how to obtain the same Therefore, it will now be shown how to obtain the same inverse matrix inverse matrix AA-1-1 of matrix of matrix A A now using Excel.now using Excel.

1.1. Determinant of matrix Determinant of matrix AA, using Excel., using Excel.

Fill the numbers of the matrix in an excel sheet, using a Fill the numbers of the matrix in an excel sheet, using a cell for each element of the matrix.cell for each element of the matrix.

Module 5 – Controllability Analysis 99

PIECENAMP

++--

2.2. Calculate the matrixCalculate the matrix determinant, this will be done using determinant, this will be done using cofactors of the first row.cofactors of the first row.

Elements Elements CC(11)(11), , CC(12)(12) and and CC(13)(13) are the cofactors of each element of are the cofactors of each element of the first row, which are elements athe first row, which are elements a1111, a, a1212 and a and a1313 according to according to matrix matrix AA::

333231

232221

131211

aaa

aaa

aaa

A

333231

232221

131211

aaa

aaa

aaa

A

Each cofactor must be calculated using the appropriate formula Each cofactor must be calculated using the appropriate formula as shown in the Excel formula bar. Pay attention on cofactor Cas shown in the Excel formula bar. Pay attention on cofactor C(12)(12) because it must be negative, as it has been shown previously.because it must be negative, as it has been shown previously.

Module 5 – Controllability Analysis 1010

PIECENAMP

3.3. Calculate the matrixCalculate the matrix determinant, using the formula shown determinant, using the formula shown on the excel sheet.on the excel sheet.

The determinant of this matrix is not equal to zero. For this The determinant of this matrix is not equal to zero. For this reason it is possible to obtain its inverse matrix.reason it is possible to obtain its inverse matrix.

Remember that the cofactor of element aRemember that the cofactor of element a1212 must must be negative!be negative!

Module 5 – Controllability Analysis 1111

PIECENAMP

4.4. Calculate the cofactors of matrix Calculate the cofactors of matrix AA for the second and third for the second and third rows.rows.

Now remember, the cofactors for the elements Now remember, the cofactors for the elements CC(21)(21),, CC(23)(23),, andand

CC(32)(32),, are:are:(select one)(select one)POSITIVE NEGATIVE

As you can see in the Excel sheet, it is necessary to As you can see in the Excel sheet, it is necessary to include the sign for each cofactor, and it arithmetically include the sign for each cofactor, and it arithmetically appears on the cell that calculates the matrix determinant appears on the cell that calculates the matrix determinant (red one). Do not confuse this sign with the one that has (red one). Do not confuse this sign with the one that has been written in front of the matrix in the excel sheet (blue been written in front of the matrix in the excel sheet (blue one). The latter one is just to show the sign of the cofactor.one). The latter one is just to show the sign of the cofactor.

Module 5 – Controllability Analysis 1212

PIECENAMP

5.5. Create the cofactors matrix Create the cofactors matrix C C placing each cofactor in placing each cofactor in the corresponding place of the element of which it has the corresponding place of the element of which it has been calculated, as the excel formula bar shows.been calculated, as the excel formula bar shows.

Do the same with the second and third rows of matrix Do the same with the second and third rows of matrix CC..

Module 5 – Controllability Analysis 1313

PIECENAMP

6.6. Calculate the adjoint of matrix Calculate the adjoint of matrix AA, this will be done just , this will be done just transposing the matrix C (matrix of cofactors).transposing the matrix C (matrix of cofactors).

Module 5 – Controllability Analysis 1414

PIECENAMP

6.6. Calculate the inverse of matrix Calculate the inverse of matrix A A ((AA-1-1). To do this, divide ). To do this, divide the Adjoint matrix by the determinant of matrix A, already the Adjoint matrix by the determinant of matrix A, already calculated.calculated.

And do the same for the remaining elements of matrix And do the same for the remaining elements of matrix AA-1-1

Module 5 – Controllability Analysis 1515

PIECENAMP

7.7. Check by matrix multiplication that matrix A multiplied by Check by matrix multiplication that matrix A multiplied by AA-1-1 gives the Identity Matrix. gives the Identity Matrix.

And do the same for the rest of elements of matrix And do the same for the rest of elements of matrix AA-1-1

Module 5 – Controllability Analysis 1616

PIECENAMP

As can be seen, even using excel to obtain the inverse of a As can be seen, even using excel to obtain the inverse of a matrix is still hard work.matrix is still hard work.

But there exist some functions in Excel that allow you to But there exist some functions in Excel that allow you to obtain the inverse of a matrix rapidly. This will be shown obtain the inverse of a matrix rapidly. This will be shown next.next.

Module 5 – Controllability Analysis 1717

PIECENAMP

1.1. Determinant of matrix Determinant of matrix AA, using an Excel functions., using an Excel functions.

Fill the numbers, as before, of the matrix in an Excel sheet, Fill the numbers, as before, of the matrix in an Excel sheet, using a cell for each element of the matrix. Select the cell using a cell for each element of the matrix. Select the cell where the determinant is to appear. Select where the determinant is to appear. Select function/insertfunction/insert and choose the function and choose the function mdetermmdeterm..

Now it will be shown how to use some Excel functions to Now it will be shown how to use some Excel functions to manipulate matrices. manipulate matrices.

Module 5 – Controllability Analysis 1818

PIECENAMP

2.2. Next, it is necessary to select the range of the matrix Next, it is necessary to select the range of the matrix data.data.

This way, the determinant of This way, the determinant of AA is easily calculated. is easily calculated.

Module 5 – Controllability Analysis 1919

PIECENAMP

3.3. Now the transpose matrix of Now the transpose matrix of A A will be calculated.will be calculated.Select the cell where the first element Select the cell where the first element aa1111

TT is to appear. is to appear.

Select Select function/insertfunction/insert and choose the function and choose the function transposetranspose..

Next, select the range of the matrix, as the next slide Next, select the range of the matrix, as the next slide shows.shows.

Module 5 – Controllability Analysis 2020

PIECENAMP

Once the range of the matrix has been selected press Once the range of the matrix has been selected press OK.OK.

4.4. Select the range of the matrix, as shown below.Select the range of the matrix, as shown below.

Module 5 – Controllability Analysis 2121

PIECENAMP

5.5. No values appear in the cell because it is necessary to No values appear in the cell because it is necessary to introduce the formula as an array. To do that, select the introduce the formula as an array. To do that, select the range that the transpose matrix will occupy and press range that the transpose matrix will occupy and press F2F2. Then, press . Then, press shift+ctrl+enter.shift+ctrl+enter. The Excel sheet should The Excel sheet should look like the one below.look like the one below.

Module 5 – Controllability Analysis 2222

PIECENAMP

6.6. It is possible to obtain directly the inverse of a matrix. It is possible to obtain directly the inverse of a matrix. Select the cell where the first element Select the cell where the first element aa1111

-1-1 is to appear. is to appear.

Select Select function/insertfunction/insert and choose the function and choose the function minverseminverse..

Then, select the range of the matrix, as shown on the next Then, select the range of the matrix, as shown on the next slide.slide.

Module 5 – Controllability Analysis 2323

PIECENAMP

Once the range of the matrix has been selected press Once the range of the matrix has been selected press OK.OK.

7.7. Select the range of the matrix, as shown below.Select the range of the matrix, as shown below.

Module 5 – Controllability Analysis 2424

PIECENAMP

8.8. Again no values appear in the cell because it is Again no values appear in the cell because it is necessary to introduce the formula as an array. To do necessary to introduce the formula as an array. To do that, select the range that the inverse matrix will occupy that, select the range that the inverse matrix will occupy and press and press F2. F2. Next, press Next, press shift+ctrl+enter.shift+ctrl+enter. The Excel The Excel sheet must look like the one below.sheet must look like the one below.

Module 5 – Controllability Analysis 2525

PIECENAMP

The determinant, transpose and inverse of matrix The determinant, transpose and inverse of matrix AA can easily be can easily be obtained. To verify if the Identity matrix is obtained, the function obtained. To verify if the Identity matrix is obtained, the function MMULTMMULT of excel is used. Matrix A can be multiplied by Matrix A of excel is used. Matrix A can be multiplied by Matrix A-1-1..

9.9. Multiplying matrices. Select the cell where the element Multiplying matrices. Select the cell where the element II1111 is to appear. Select is to appear. Select function/insertfunction/insert and select the and select the function function mmultmmult..

Module 5 – Controllability Analysis 2626

PIECENAMP

Once the ranges of the matrices have been selected, Once the ranges of the matrices have been selected, press press OK.OK.

10.10. Next, select the range of each matrix to be multiplied, as Next, select the range of each matrix to be multiplied, as shown below.shown below.

Module 5 – Controllability Analysis 2727

PIECENAMP

11.11. No values appear in the cell because it is necessary to No values appear in the cell because it is necessary to introduce the formula as an array. To do that, select the introduce the formula as an array. To do that, select the range that the identity matrix will occupy and press range that the identity matrix will occupy and press F2F2. . Next, press Next, press shift+ctrl+enter.shift+ctrl+enter. The Excel sheet should look The Excel sheet should look like the one below.like the one below.

Module 5 – Controllability Analysis 2828

PIECENAMP

As it was seen, Excel functions are very helpful to As it was seen, Excel functions are very helpful to obtain the determinant, the transpose and the inverse obtain the determinant, the transpose and the inverse of a matrix, even for matrix multiplication.of a matrix, even for matrix multiplication.

Of course there are several software packages with the Of course there are several software packages with the availability to work with matrices, but Excel has been availability to work with matrices, but Excel has been chosen because it is available in almost every chosen because it is available in almost every computer that students have access.computer that students have access.

These Excel functions are the main tools that will serve These Excel functions are the main tools that will serve to obtain the Relative Gain Array, as it will be shown to obtain the Relative Gain Array, as it will be shown shortly. shortly.

Few examples will be covered.Few examples will be covered.

Module 5 – Controllability Analysis 2929

PIECENAMP

Despite the great help that Excel can provide, some Despite the great help that Excel can provide, some limitations must be specified. These limitations are:limitations must be specified. These limitations are:

Determinant.Determinant.

The size of the array must not exceed 73 rows by The size of the array must not exceed 73 rows by 73 columns.73 columns.

Multiplication.Multiplication.

The size of the resulting array must not be equal or The size of the resulting array must not be equal or greater than a total of 5 461 cells.greater than a total of 5 461 cells.

Inverse.Inverse.

The size of the array must not exceed 52 columns The size of the array must not exceed 52 columns by 52 rowsby 52 rows

Module 5 – Controllability Analysis 3030

PIECENAMP

2.1 Relative Gain Array2.1 Relative Gain Array2.1 Relative Gain Array2.1 Relative Gain Array2.1.12.1.1 Obtain the Obtain the RGARGA for the linear model of a distillation for the linear model of a distillation

column used in separating methanol and water as column used in separating methanol and water as reported in [1] (see next slide). It is a system with two reported in [1] (see next slide). It is a system with two output variables, two input variables, and one disturbance output variables, two input variables, and one disturbance variable. All variables are defined in terms on deviation variable. All variables are defined in terms on deviation variables:variables:

14.14

4.19

19.10

6.610.21

9.18

17.16

8.12

)( 37

3

s

e

s

es

e

s

e

s ss

ss

G

14.14

4.19

19.10

6.610.21

9.18

17.16

8.12

)( 37

3

s

e

s

es

e

s

e

s ss

ss

G

The 2x2 transfer function matrix is:The 2x2 transfer function matrix is:

12.13

9.419.14

8.3

)( 4.3

1.8

s

es

e

s s

s

dG

12.13

9.419.14

8.3

)( 4.3

1.8

s

es

e

s s

s

dG

yy11= overhead mole fraction = overhead mole fraction methanolmethanolyy22= bottoms mole fraction = bottoms mole fraction methanolmethanol

uu11= overhead reflux = overhead reflux flowrateflowrateuu22= bottoms steam = bottoms steam flowrateflowrated d = column feed flowrate= column feed flowrate

Module 5 – Controllability Analysis 3131

PIECENAMP

Feed Feed flow flow

rate (d)rate (d)

Overhead mole Overhead mole fraction methanol fraction methanol (y1)

Bottoms mole Bottoms mole fraction methanol fraction methanol

(y2)

Overhead reflux Overhead reflux flow rate (uflow rate (u11))

Bottoms steam Bottoms steam flow rate (uflow rate (u22))

Distillation column used in separating Distillation column used in separating methanol and watermethanol and water

It is easy to identify both manipulated and controlled variables. It is easy to identify both manipulated and controlled variables.

Module 5 – Controllability Analysis 3232

PIECENAMP

The steady-state gain matrix is:The steady-state gain matrix is:

4.196.6

9.188.12)0(GK

4.196.6

9.188.12)0(GK

Based on this matrix, the Excel functions seen previously Based on this matrix, the Excel functions seen previously can be used to obtain the can be used to obtain the RGARGA as the next slide shows. as the next slide shows.

Problem description.Problem description.

From the transfer function matrix G(s), it is possible to From the transfer function matrix G(s), it is possible to obtain the steady-state gain matrix.obtain the steady-state gain matrix.

Module 5 – Controllability Analysis 3333

PIECENAMP

R=

Matrix K Matrix R

It is possible to use any Excel sheet shown before, or you It is possible to use any Excel sheet shown before, or you can start a new one as the next figure shows. can start a new one as the next figure shows.

Be careful, because the multiplication of matrices Be careful, because the multiplication of matrices KK and and RR is a multiplication term by term. is a multiplication term by term.

Module 5 – Controllability Analysis 3434

PIECENAMP

The The RGARGA has therefore been obtained very easily: has therefore been obtained very easily:

01.20.1

0.101.2

01.20.1

0.101.2

The pairing rules recommend pairing 1-1/2-2, which The pairing rules recommend pairing 1-1/2-2, which means to use the overhead reflux flowrate to control means to use the overhead reflux flowrate to control the overhead mole fraction of methanol, and the the overhead mole fraction of methanol, and the bottoms steam flowrate to control the bottoms mole bottoms steam flowrate to control the bottoms mole fraction of methanol.fraction of methanol.

The final coupling is shown in the next slide.The final coupling is shown in the next slide.

Module 5 – Controllability Analysis 3535

PIECENAMP

Next, the Next, the RGARGA for a 3x3 system will be calculated. for a 3x3 system will be calculated.

CC

CC

LC

Feed Feed flow flow

rate (d)rate (d)

LC

Overhead mole Overhead mole fraction methanol fraction methanol (y1)

Bottoms mole Bottoms mole fraction methanol fraction methanol

(y2)

Overhead reflux Overhead reflux flow rate (uflow rate (u11))

Bottoms steam Bottoms steam flow rate (uflow rate (u22))

Final coupling suggested for Final coupling suggested for RGARGA from a from a distillation column used to separate methanol distillation column used to separate methanol

and waterand water

Module 5 – Controllability Analysis 3636

PIECENAMP

2.1.22.1.2 Obtain the Obtain the RGARGA for pilot scale binary distillation column for pilot scale binary distillation column used to separate ethanol and water for which the transfer used to separate ethanol and water for which the transfer function matrix is given below [2]. The process variables function matrix is given below [2]. The process variables are (in terms of deviations from their respective steady are (in terms of deviations from their respective steady state values):state values):

-2.6s -3.5s -s

1 -6.5s -3s -1.2s

2

-s3 -9.2s -9.4s

0.66e -0.61e -0.0049e

6.7s+1 8.64s+1 9.06s+1y u1.11e -2.3e -0.012e

y =3.5s+1 5s+1 7.09s+1

y0.87 11.61s+1 e-33.68e 46.2e

8.15s+1 10.9s+1 3.89s+1 18.8s+

1

2

3

u

u

-2.6s -3.5s -s

1 -6.5s -3s -1.2s

2

-s3 -9.2s -9.4s

0.66e -0.61e -0.0049e

6.7s+1 8.64s+1 9.06s+1y u1.11e -2.3e -0.012e

y =3.5s+1 5s+1 7.09s+1

y0.87 11.61s+1 e-33.68e 46.2e

8.15s+1 10.9s+1 3.89s+1 18.8s+

1

2

3

u

u

1 1

2 2

3 3

= overhead mole fraction ethanol = overhead reflux flowrate

= side stream ethanol mole fraction = side stream draw-off rate

= Temperature on Tray #19

y u

y u

y u = reboiler steam pressure

Module 5 – Controllability Analysis 3737

PIECENAMP

Feed flow Feed flow rate (d)rate (d)

Overhead mole fraction ethanol Overhead mole fraction ethanol (y1)

Reboiler steam pressure Reboiler steam pressure (u3)

Overhead Overhead reflux reflux

flow rate flow rate (u(u11))

Side stream draw-off rate Side stream draw-off rate (u(u22))

Distillation column used in separating Distillation column used in separating ethanol and waterethanol and water

Mole fraction of ethanol in the side stream Mole fraction of ethanol in the side stream (y2)

Temperature Temperature on tray #19 on tray #19

(y3)

Module 5 – Controllability Analysis 3838

PIECENAMP

Matrix K Matrix R

R=

From the transfer function model, the steady-state gain matrix From the transfer function model, the steady-state gain matrix is:is:

0.66 -0.61 -0.0049

K = G(0) = 1.11 -2.3 -0.012

-33.68 46.2 0.87

0.66 -0.61 -0.0049

K = G(0) = 1.11 -2.3 -0.012

-33.68 46.2 0.87

Problem description.Problem description.

Module 5 – Controllability Analysis 3939

PIECENAMP

Again, remember that the multiplication of matrices K Again, remember that the multiplication of matrices K and R is a multiplication term by term. and R is a multiplication term by term.

The The RGARGA for the 3x3 system has been obtained easily: for the 3x3 system has been obtained easily:

1.95 -0.67 -0.27

= -0.66 1.90 -0.23

-0.28 -0.23 1.51

1.95 -0.67 -0.27

= -0.66 1.90 -0.23

-0.28 -0.23 1.51

The pairing rules recommend pairing 1-1/2-2/3-3, The pairing rules recommend pairing 1-1/2-2/3-3, which means that the overhead mole fraction of which means that the overhead mole fraction of ethanol can be controlled using the overhead reflux ethanol can be controlled using the overhead reflux flowrate. In the same way, the mole fraction of ethanol flowrate. In the same way, the mole fraction of ethanol in the side stream can be controlled using the side in the side stream can be controlled using the side stream draw-off rate and the temperature on tray #19 stream draw-off rate and the temperature on tray #19 can be controlled using the reboiler steam pressure. can be controlled using the reboiler steam pressure.

The next slide shows the final coupling.The next slide shows the final coupling.

Module 5 – Controllability Analysis 4040

PIECENAMP

CC

Feed Feed flow rate flow rate

(d)(d)

Overhead mole fraction ethanol Overhead mole fraction ethanol (y1)

Reboiler steam pressure Reboiler steam pressure (u3)

Overhead reflux flow rate (uOverhead reflux flow rate (u11))

Side stream draw-off rate Side stream draw-off rate (u(u22))

Mole fraction of ethanol in the side stream Mole fraction of ethanol in the side stream (y2)

TemperaturTemperature on tray e on tray #19 #19 (y3)

Final coupling suggested for Final coupling suggested for RGARGA from a from a distillation column used in separating ethanol distillation column used in separating ethanol

and waterand water

CC

TC

Module 5 – Controllability Analysis 4141

PIECENAMP

2.2 Niederlinski Index2.2 Niederlinski Index2.2 Niederlinski Index2.2 Niederlinski Index

Up to now the utility of the Up to now the utility of the RGARGA has been used to has been used to find the appropriate pairing for the process find the appropriate pairing for the process variables. Despite the utility of the variables. Despite the utility of the RGARGA, , sometimes it is necessary to use the sometimes it is necessary to use the RGARGA with with another important tool such as the another important tool such as the NIEDERLINSKI NIEDERLINSKI INDEXINDEX ( (NINI). ).

The The NINI is very useful because it allows to identify is very useful because it allows to identify structurally unstable pairings and as a result to structurally unstable pairings and as a result to avoid them.avoid them.

Next the use of Next the use of NINI is shown. is shown.

Module 5 – Controllability Analysis 4242

PIECENAMP

2.2.12.2.1 Determine the best pairing using the Determine the best pairing using the RGARGA and the and the NINI for for the system with three output variables and threethe system with three output variables and three input input variables, the variables, the steady state matrixsteady state matrix is: is:

121.0

132

1.011

K

121.0

132

1.011

K

First of all, since the steady sate matrix is know, the First of all, since the steady sate matrix is know, the RGARGA is is obtained as before and the next slide shows just the obtained as before and the next slide shows just the RGARGA....

Problem description.Problem description.

yy33

yy11

yy22

uu33uu

11

uu22

Module 5 – Controllability Analysis 4343

PIECENAMP

89.102.313.0

58.360.502.3

70.058.389.1

RGA

Then, the RGA obtained is:Then, the RGA obtained is:

According to the According to the RGARGA, the only feasible pairing has to involve a , the only feasible pairing has to involve a negative negative RGARGA element, so it is possible to element, so it is possible to interchange rows 2 interchange rows 2 and 3and 3. .

Click to Click to InterchangeInterchangeRow 2 and 3Row 2 and 3

Interchanging the rows was necessary to calculate the Interchanging the rows was necessary to calculate the NiederlinskiNiederlinski IndexIndex, because all the pairing elements must be , because all the pairing elements must be on the diagonal of the on the diagonal of the KK matrix, as next slide shows. matrix, as next slide shows.

Now the steady state matrix is:Now the steady state matrix is:

Rows 2 and 3 of RGA have been interchanged.Rows 2 and 3 of RGA have been interchanged.Rows 2 and 3 of RGA have been interchanged.Rows 2 and 3 of RGA have been interchanged.

132

121.0

1.011

K

132

121.0

1.011

K

yy22yy22

yy11yy11

yy33yy33

uu33uu33uu

11

uu

11

uu22uu22

Module 5 – Controllability Analysis 4444

PIECENAMP

Niederlinski IndexNiederlinski Index

Now the Now the NINI shows that the system is shows that the system is notnot structurally unstable structurally unstable even pairing a negative element.even pairing a negative element.

Niederlinski IndexNiederlinski Index

1. Obtain the 1. Obtain the steady state steady state matrix matrix llKKll and its and its determinant.determinant.

2. Obtain the 2. Obtain the diagonal matrix diagonal matrix of of llKKll and its and its determinant.determinant.

3. Obtain the NI 3. Obtain the NI ratio:ratio:

27.02

53.0

)()0(

)0(

1

K

K

Diagg

GNI

ii

n

i

27.02

53.0

)()0(

)0(

1

K

K

Diagg

GNI

ii

n

i

Module 5 – Controllability Analysis 4545

PIECENAMP

According to these calculations, for the pairing 1-1/2-3/3-2, the According to these calculations, for the pairing 1-1/2-3/3-2, the system is not unstable, despite the rules of system is not unstable, despite the rules of RGARGA. However if the . However if the first loop is openedfirst loop is opened (y (y11– u– u11) or not included in the process ) or not included in the process model, the resulting subsystem is unstable as will be shown.model, the resulting subsystem is unstable as will be shown.

First loop of matrix First loop of matrix KK open ( open (KK):):

13

12K

13

12K

yy22yy22

yy33yy33

uu33uu33uu22uu22

132

121.0

1.011

K

132

121.0

1.011

K

yy22yy22

yy11yy11

yy33yy33

uu33uu33uu

11

uu

11

uu22uu22

o

And the NI for matrix And the NI for matrix KK is: is:o

2

1

2

)3(2

KNI

2

1

2

)3(2

KNI

Reminder: A negative Reminder: A negative NINI indicates that the system is indicates that the system is structurally structurally UNSTABLEUNSTABLE..

Module 5 – Controllability Analysis 4646

PIECENAMP

-10-5

05

10

-10-5

05

10-0.5

0

0.5

1

2.3 Nonlinear Systems2.3 Nonlinear Systems2.3 Nonlinear Systems2.3 Nonlinear Systems

Despite that many chemical processes can be adequately Despite that many chemical processes can be adequately represented by linear systems, via linear transfer function represented by linear systems, via linear transfer function models, the majority of chemical processes are inherently models, the majority of chemical processes are inherently nonlinear and sometimes need to use nonlinear models in nonlinear and sometimes need to use nonlinear models in order to be valid in a wider range of operation. order to be valid in a wider range of operation.

It is therefore necessary to see how the pairing of input and It is therefore necessary to see how the pairing of input and output variables of nonlinear systems is performed.output variables of nonlinear systems is performed.

05

1015

2025

0

10

20

30-8

-6

-4

-2

0

2

4

6

8

Module 5 – Controllability Analysis 4747

PIECENAMP

The same information used for the The same information used for the RGARGA of steady state of steady state systems is used for nonlinear systems. This feature can systems is used for nonlinear systems. This feature can appear for someone a appear for someone a ""disadvantagedisadvantage"", but it is precisely , but it is precisely this this ""disadvantagedisadvantage"" involving only steady state values that involving only steady state values that can be used to handle nonlinear systems.can be used to handle nonlinear systems.

Next, an example shows that according to the steady state Next, an example shows that according to the steady state values, the pairing of both manipulated and controlled variables is values, the pairing of both manipulated and controlled variables is selected.selected.

PLEASE !!!PLEASE !!!!!!!

DisadvantageDisadvantageororadvantage???advantage???

Take a decisionTake a decision

Module 5 – Controllability Analysis 4848

PIECENAMP

2.3.12.3.1 Obtain the Obtain the RGARGA for the multivariable system, a stirred mixing for the multivariable system, a stirred mixing tank, consisting in a hot stream and a cold stream which are tank, consisting in a hot stream and a cold stream which are used to control the liquid level and the tank temperature, and used to control the liquid level and the tank temperature, and use it to recommend which of the manipulated variables use it to recommend which of the manipulated variables should be used to control the liquid level and the tank should be used to control the liquid level and the tank temperature. The transfer function matrix is shown below.temperature. The transfer function matrix is shown below.

C C

C s C s

H s C s

C s C s

s C s

1 1

k kA s+ A s+

2A h 2A hs =

T -T T -T

k kA h s+ A h s +

Ac h A h

G

C C

C s C s

H s C s

C s C s

s C s

1 1

k kA s+ A s+

2A h 2A hs =

T -T T -T

k kA h s+ A h s +

Ac h A h

G

yy11= Liquid = Liquid levellevelyy22= Tank = Tank

temperaturetemperature

uu11= Hot stream = Hot stream flowrateflowrate

uu22= Cold stream = Cold stream temperaturetemperature

C

C s

ds s ds

C s C s

C s C s

10

kA s+

2A hs =

T -T F

k kA h s + A h s+

A h A h

dG

C

C s

ds s ds

C s C s

C s C s

10

kA s+

2A hs =

T -T F

k kA h s + A h s+

A h A h

dG

Where Where kk is a constant (see next slide) and A is a constant (see next slide) and Acc is the cross- is the cross-section area for the tank.section area for the tank.

Module 5 – Controllability Analysis 4949

PIECENAMP

hh

HOT STREAM HOT STREAM FLOWRATE (uFLOWRATE (u11))

DISTURBANCE (TDISTURBANCE (Tdd, , FFdd))

Output Flow rate Output Flow rate ((FF, , T)T)

COLD STREAM COLD STREAM FLOWRATE FLOWRATE

(u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE (y(y22))

A diagram of the tank is shown below.A diagram of the tank is shown below.

Problem description.Problem description.

FF==kk(h)(h)½ ½

Next it is necessary to obtain the steady state gain matrix, Next it is necessary to obtain the steady state gain matrix, as next slide shows.as next slide shows.

Module 5 – Controllability Analysis 5050

PIECENAMP

s s

H s C s

s s

2 h 2 h

k k = 0 =

T -T T -T

k h k h

K G

s s

H s C s

s s

2 h 2 h

k k = 0 =

T -T T -T

k h k h

K G

s s

H s C s

s s

2 h 2 h1

= T -T T -Tk

h h

K

s s

H s C s

s s

2 h 2 h1

= T -T T -Tk

h h

K

Now with the steady-state gain matrix, it is possible Now with the steady-state gain matrix, it is possible to obtain the RGA, using the full matrix method or, to obtain the RGA, using the full matrix method or, since it is a 2x2 matrix, in a more direct way as seen since it is a 2x2 matrix, in a more direct way as seen before. before.

Module 5 – Controllability Analysis 5151

PIECENAMP

To calculate the RGA of this 2x2 system it is possible to obtain using the First Principles.First Principles.

In Tier 1 has seen that:

2211 1

1

2211 1

1

H ss

s H s

C sC ss

s

T -T2 h

k k h T -T = =

T -TT -T2 h

k k h

H ss

s H s

C sC ss

s

T -T2 h

k k h T -T = =

T -TT -T2 h

k k h

2211

2112

KK

KK

2211

2112

KK

KK

Substituting the values of the matrix KK:

and,

C s11

H s C H

C s

T -T1 = =

T -T T -T1-

T -T

C s11

H s C H

C s

T -T1 = =

T -T T -T1-

T -T

Module 5 – Controllability Analysis 5252

PIECENAMP

In a similar way it is possible to obtain 1212 using:

H s

C s H s12

H s C H

C s

T -T-

T -T - T -T = =

T -T T -T1-

T -T

H s

C s H s12

H s C H

C s

T -T-

T -T - T -T = =

T -T T -T1-

T -T

According to this the value of 1212 is:

2112 1

2112 1

And the RGA for this systems is:

Module 5 – Controllability Analysis 5353

PIECENAMP

Here, it is due to mention that the Here, it is due to mention that the RGARGA depends only of depends only of values of hot and cold streams, and also for the values of values of hot and cold streams, and also for the values of the steady state values involved in the steady-sate gain the steady state values involved in the steady-sate gain matrix.matrix.

H sC s

C H C H

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

Λ

H sC s

C H C H

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

Λ

The values given to hot and cold stream are:

TTHH = 65ºC= 65ºC TTCC = 15ºC= 15ºC

These values are fixed and just the value of Ts will be changed according to different scenarios.

Module 5 – Controllability Analysis 5454

PIECENAMP

Five different values will givenFive different values will given to Ts :to Ts :

TTss > (T> (THH+T+TCC)/2;)/2; TTss = 55ºC= 55ºC

TTss < (T< (THH+T+TCC)/2; )/2; TTss = 25ºC= 25ºC

TTss = (T= (THH+T+TCC)/2 ; )/2 ; TTss = 40ºC= 40ºC

TTss = = T TH:H: TTss = 65ºC= 65ºC

TTss = = T TCC;; TTss = 15ºC= 15ºC

hh

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE (TDISTURBANCE (Tdd, F, Fdd))

Output Flow rate Output Flow rate ((FF, , T)T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE (yTEMPERATURE (y22))

FF==kk(h)(h)½ ½

TTHH = 65ºC= 65ºC

TTCC = 15ºC= 15ºC

According to this values the system of the stirred mixing tank is:

Module 5 – Controllability Analysis 5555

PIECENAMP

The physical meaning of this pairing is: since the temperature of cold stream (TC) is farther away from the steady state operating tank temperature, small changes in the cold stream produce noticeable changes in the tank temperature, whereas the temperature of the hot stream (TH) is closer to the operating steady state temperature, it can be used to control the level without causing significant changes in the tank temperature.

Case 1Case 1.. Ts Ts > (T> (THH+T+TCC)/2;)/2; TTss = 55ºC= 55ºC

From the RGARGA, the suggested pairing is 1-1/2-2.

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE DISTURBANCE (T(Tdd,F,Fdd))

Output Flow rate Output Flow rate ((FF, T), T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE

(y(y22))

FF==kk(h)(h)½½

TTHH = 65ºC= 65ºC

TTCC= 15ºC= 15ºC

Click to Click to Pairing Pairing 1-1/2-21-1/2-2

hh

TC

LLC

Module 5 – Controllability Analysis 5656

PIECENAMP

Again, the physical meaning of this pairing is: since the temperature of the hot stream (TH) is farther away from the steady state operating tank temperature, small changes in the hot stream produce noticeable changes in the tank temperature, whereas the temperature of cold stream (TC) is closer to the operating steady state temperature, it can be used to control the level without causing significant changes in the tank temperature.

Case 2Case 2.. Ts Ts < (T< (THH+T+TCC)/2;)/2; TTss = 25ºC= 25ºC

From the RGARGA, the suggested pairing is 1-2/2-1.

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE DISTURBANCE (T(Tdd,F,Fdd))

Output Flow rate Output Flow rate ((FF, T), T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE

(y(y22))

FF==kk(h)(h)½½

TTHH = 65ºC= 65ºC

TTCC = 15ºC= 15ºC

Click to Click to Pairing Pairing 1-2/2-11-2/2-1

hhLLC

TC

Module 5 – Controllability Analysis 5757

PIECENAMP

Case 3Case 3.. Ts = Ts = (T(THH+T+TCC)/2;)/2; TTss = 40ºC= 40ºC

Here the values of the RGARGA are all equal to 0.5 For this reason it is equally bad to pair 1-1/2-2 than 1-2/2-1, because the operating temperature is exactly equidistant from both the cold stream temperature and the hot stream temperature.

A poor control of the process under this undesirable special condition is obtained.

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE DISTURBANCE (T(Tdd,F,Fdd))

Output Flow rate Output Flow rate ((FF, T), T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE

(y(y22))

FF==kk(h)(h)½½

TTHH = 65ºC= 65ºC

TTCC = 15ºC= 15ºC

hh

Module 5 – Controllability Analysis 5858

PIECENAMP

Case 4Case 4.. TTss = = TTHH;; TTss = 65ºC= 65ºC

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE DISTURBANCE (T(Tdd,F,Fdd))

Output Flow rate Output Flow rate ((FF, T), T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE

(y(y22))

FF==kk(h)(h)½½

TTHH = 65ºC= 65ºC

TTCC = 15ºC= 15ºC

hh

Here, the temperature of the hot stream (TH) is the same that the steady state operating tank temperature. For that reason this stream is used to control the level of the tank, whereas the temperature of the cold stream (TC) is used to control the temperature because a small change of cold stream cause significant changes in the tank temperature.

From the RGARGA, the suggested pairing is 1-1/2-2. It is possible to achieve a perfect control of the level tank, without interacting with the temperature, using the hot stream.

TC

LLC

Click to Click to Pairing Pairing 1-1/2-21-1/2-2

Module 5 – Controllability Analysis 5959

PIECENAMP

Case 5Case 5.. TTss = = TTCC;; TTss = 15ºC= 15ºC

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE DISTURBANCE (T(Tdd,F,Fdd))

Output Flow rate Output Flow rate ((FF, T), T)

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE TEMPERATURE

(y(y22))

FF==kk(h)(h)½½

TTHH = 65ºC= 65ºC

TTCC = 15ºC= 15ºC

hh

Here, the temperature of the hot stream (TC) is the same than the steady state operating tank temperature. For that reason this stream is used to control the level of the tank, whereas the temperature of hot stream (TH) is used to control the temperature because a small change of hot stream cause significant changes in the tank temperature.

Click to Click to Pairing Pairing 1-2/2-11-2/2-1

LLC

TC

From the RGARGA, the suggested pairing is 1-2/2-1. It is possible to achieve a perfect control of the tank level, without affecting the temperature, using the cold stream.

Module 5 – Controllability Analysis 6060

PIECENAMP

-2-1

01

2

-2

-1

0

1

2-2

-1

0

1

2

05

1015

2025

0

10

20

30-10

-5

0

5

10

These five different analyses have demonstrated that These five different analyses have demonstrated that the the RGARGA can indeed be used for nonlinear as well as can indeed be used for nonlinear as well as for linear systems.for linear systems.

These five different analyses have demonstrated that These five different analyses have demonstrated that the the RGARGA can indeed be used for nonlinear as well as can indeed be used for nonlinear as well as for linear systems.for linear systems.

It is as if the nonlinear system was analyzed on different sections, or slides around `fixed` points, or in this case around steady states.

STEADY STATESTEADY STATE

Pay attention to the fact that the RGARGA suggests different pairings at different operating conditions. This because even that the analysis has been based on approximate linearized models, this property characteristic of the nonlinear systems

is not lost.

Module 5 – Controllability Analysis 6161

PIECENAMP

2.4 Non Square Systems2.4 Non Square Systems2.4 Non Square Systems2.4 Non Square Systems

This section discusses another important point about This section discusses another important point about RGARGA, the selection of variables for , the selection of variables for UnderdefinedUnderdefined and and OverdefinedOverdefined systems. systems.

To do this task, it is first of all absolutely necessary to To do this task, it is first of all absolutely necessary to manipulate the non square system in order to obtain a manipulate the non square system in order to obtain a square system. This is done according to the type of non square system. This is done according to the type of non square systems.square systems.

The objective in non square systems is pairing, as before, The objective in non square systems is pairing, as before, the process variables to minimize the interaction between the process variables to minimize the interaction between them.them.

Next slides show how to obtain a square system from a Next slides show how to obtain a square system from a UNDERDEFINEDUNDERDEFINED (therefore non square) system. (therefore non square) system.

Module 5 – Controllability Analysis 6262

PIECENAMP

2.4.12.4.1 Obtain the Obtain the RGARGA of a pilot scale binary distillation column of a pilot scale binary distillation column used to separate ethanol and water for which the transfer used to separate ethanol and water for which the transfer function is given below [2]. In addition, consider the side function is given below [2]. In addition, consider the side stream draw-off rate set at a fixed amount and it cannot be stream draw-off rate set at a fixed amount and it cannot be changed. Use the same process variables, that in Ex. changed. Use the same process variables, that in Ex. 2.1.22.1.2..

-2.6s -s

1 -6.5s -1.2s1

22

-s3 -9.2s

0.66e -0.0049e

6.7s+1 9.06s+1yu1.11e -0.012e

y =u3.5s+1 7.09s+1

y0.87 11.61s+1 e-33.68e

8.15s+1 3.89s+1 18.8s+

-2.6s -s

1 -6.5s -1.2s1

22

-s3 -9.2s

0.66e -0.0049e

6.7s+1 9.06s+1yu1.11e -0.012e

y =u3.5s+1 7.09s+1

y0.87 11.61s+1 e-33.68e

8.15s+1 3.89s+1 18.8s+

yy11= overhead mole fraction = overhead mole fraction ethanolethanol yy22= ethanol mole fraction in side stream= ethanol mole fraction in side stream

uu11= overhead reflux = overhead reflux flowrateflowrate

d d = column feed flowrate= column feed flowrate uu22= reboiler steam pressure= reboiler steam pressure

yy33= Temperature on Tray #19= Temperature on Tray #19

Problem description.Problem description.

Now , the side stream draw off rate is not a controlled variable, because it is fixed. For this reason the process model is:

Module 5 – Controllability Analysis 6363

PIECENAMP

Feed flow rate Feed flow rate (d)(d)

Overhead mole Overhead mole fraction ethanol fraction ethanol

(y1)

Reboiler steam Reboiler steam pressure pressure (u2)

Overhead reflux Overhead reflux flow rate (uflow rate (u11))

Distillation column used inDistillation column used inseparating ethanol and waterseparating ethanol and water

Mole fraction of ethanol Mole fraction of ethanol in the side stream in the side stream (y2)

Temperature on tray #19 Temperature on tray #19 (y3)

Module 5 – Controllability Analysis 6464

PIECENAMP

It is impossible to control all three output (ys) variables with

only two input variables (us).

For that reason it is necessary to select the two most important variables to be controlled, in this case the variables selected have been y1 and y3, as next diagram shows.

Feed flow Feed flow rate (d)rate (d)

Overhead mole Overhead mole fraction ethanol fraction ethanol

(y1)

Reboiler Reboiler steam steam

pressure pressure (u2)

Overhead reflux Overhead reflux flow rate (uflow rate (u11))

Temperature Temperature on tray #19 on tray #19

(y3)

Here the side stream mole

fraction of ethanol is taken as the

less important of the output variables.

Mole fraction of Mole fraction of ethanol in the side ethanol in the side

stream stream (y2)

Module 5 – Controllability Analysis 6565

PIECENAMP

Once it has been decided to leave the control of the side stream composition out of control scheme, the control model is now:

-2.6s -s

1 1-s-9.2s

3 2

0.66e -0.0049e

6.7s+1 9.06s+1y u =

0.87 11.61s+1 ey u-33.68e

8.15s+1 3.89s+1 18.8s+

-2.6s -s

1 1-s-9.2s

3 2

0.66e -0.0049e

6.7s+1 9.06s+1y u =

0.87 11.61s+1 ey u-33.68e

8.15s+1 3.89s+1 18.8s+

yy11= overhead mole fraction = overhead mole fraction ethanolethanol

uu11= overhead reflux = overhead reflux flowrateflowrate uu22= reboiler steam pressure= reboiler steam pressureyy33= Temperature on Tray #19= Temperature on Tray #19

This is a square (modified) subsystem. Therefore, now it is possible to perform the RGARGA analysis and also to obtain the additional relation:

-6.5s -1.2s

2 1 2

1.11e -0.012ey = u + u

3.5s+1 7.09s+1

-6.5s -1.2s

2 1 2

1.11e -0.012ey = u + u

3.5s+1 7.09s+1

Module 5 – Controllability Analysis 6666

PIECENAMP

From the subsystem, the steady state gain matrix and the RGARGA obtained is:

According to these values of RGARGA, a 1-1/2-2 pairing is recommended.

It means to use the overhead reflux (u1) to control the

overhead composition (y1), and use the reboiler steam

pressure (u2) to control Tray #19 temperature (y2). This makes sense.

Module 5 – Controllability Analysis 6767

PIECENAMP

It must notice that according to the relation:

-6.5s -1.2s

2 1 2

1.11e -0.012ey = u + u

3.5s+1 7.09s+1

-6.5s -1.2s

2 1 2

1.11e -0.012ey = u + u

3.5s+1 7.09s+1

The side stream composition will drift according to the values of the overhead reflux (u1) and the reboiler steam pressure (u2).

This is the nature of UNDERDEFINEDUNDERDEFINED systems. The previous system showed that it is only possible to achieve arbitrarily good control of two [overhead mole fraction ethanoloverhead mole fraction ethanol ( (y1) ) and

temperature on Tray #19temperature on Tray #19 ( (yy33))]] of the three output variables and accept the drift of the third one (composition on the side stream).The strategy to work with an UNDERDEFINEDUNDERDEFINED system is to choose a square subsystem by dropping off the excess number of output variables on the basis of economic importance; the subsequent analysis is the same as for square systems.

Module 5 – Controllability Analysis 6868

PIECENAMP

Next will be show how to deal with Next will be show how to deal with OverdefinedOverdefined systems. systems.

Next will be show how to deal with Next will be show how to deal with OverdefinedOverdefined systems. systems.

And this is the real challenge of non

square systems, so you must put all your

attention…

And this is the real challenge of non

square systems, so you must put all your

attention……and follow

the instructions given in the

next example.

…and follow the

instructions given in the

next example.

Module 5 – Controllability Analysis 6969

PIECENAMP

2.4.22.4.2 According to a certain system with two outputs (According to a certain system with two outputs (yy11 and and yy22) )

to be controlled using two of three available inputs (to be controlled using two of three available inputs (uu11, ,

uu22, and , and uu33), which loop pairing is expected to give the ), which loop pairing is expected to give the best controlbest control?.?. Through pulse testing, the following Through pulse testing, the following transfer function model was obtained. transfer function model was obtained. -0.2s -0.3s -0.03s

11

2-0.5s -0.2s -0.4s2

3

0.5e 0.07e 0.04e uy 3s+1 2.5s+1 2.8s+1 = uy 0.004e -0.003e -0.001e

u1.5s+1 s+1 1.6s+1

-0.2s -0.3s -0.03s

11

2-0.5s -0.2s -0.4s2

3

0.5e 0.07e 0.04e uy 3s+1 2.5s+1 2.8s+1 = uy 0.004e -0.003e -0.001e

u1.5s+1 s+1 1.6s+1

Problem description.Problem description.

This is a 2x3 system, this implies that only two of the three candidate input variables will be used for control, while the third input variable will have to be set at a fixed value and will therefore be redundant.

To determine which variables should be active and which ones should be redundant, first of all possible 2x2 subsystems must be obtained.

Module 5 – Controllability Analysis 7070

PIECENAMP

u!

Number of subsystems = n! u - n !

u!Number of subsystems =

n! u - n !

3 2 13!

Number of subsystems = = = 32! 3 - 2 ! 2 1 1

3 2 13!

Number of subsystems = = = 32! 3 - 2 ! 2 1 1

According to the previous system: u=3 and n=2

Where: u are the number of input variables and n the number of output variables.

Subsystem 1Subsystem 1.. Utilizing uUtilizing u11 and and uu22 for control: for control:

-0.2s -0.3s

1 1

-0.5s -0.2s2 2

0.5e 0.07ey u3s+1 2.5s+1 = y u0.004e -0.003e

1.5s+1 s+1

-0.2s -0.3s

1 1

-0.5s -0.2s2 2

0.5e 0.07ey u3s+1 2.5s+1 = y u0.004e -0.003e

1.5s+1 s+1

Module 5 – Controllability Analysis 7171

PIECENAMP

From the subsystem 1, the steady state matrix and the RGARGA are:

Subsystem 2Subsystem 2.. Utilizing uUtilizing u11 and and uu22 for control: for control: -0.2s -0.03s

11

-0.5s -0.4s32

0.5e 0.04euy 3s+1 2.8s+1 = uy 0.004e -0.001e

1.5s+1 1.6s+1

-0.2s -0.03s

11

-0.5s -0.4s32

0.5e 0.04euy 3s+1 2.8s+1 = uy 0.004e -0.001e

1.5s+1 1.6s+1

Module 5 – Controllability Analysis 7272

PIECENAMP

From the subsystem 2, the steady state matrix and the RGARGA are:

Subsystem 3Subsystem 3.. Utilizing uUtilizing u22 and and uu33 for control: for control:

-0.3s -0.03s

11

-0.2s -0.4s32

0.07e 0.04euy 2.5s+1 2.8s+1 = uy -0.003e -0.001e

s+1 1.6s+1

-0.3s -0.03s

11

-0.2s -0.4s32

0.07e 0.04euy 2.5s+1 2.8s+1 = uy -0.003e -0.001e

s+1 1.6s+1

Module 5 – Controllability Analysis 7373

PIECENAMP

From the subsystem 3, the steady state matrix and the RGARGA are:

Next slide shows the three RGARGA values obtained for each subsystem.

Module 5 – Controllability Analysis 7474

PIECENAMP

According to these values of RGARGA for each subsystem, the best possible control is the subsystem 1, because

it is closest to the ideal situation; it is somewhat better than subsystem 2 and far superior than

subsystem 3.

0.758 0.242

0.242 0.758

2Λ

0.758 0.242

0.242 0.758

2Λ

0.843 0.157

0.157 0.843

1Λ

0.843 0.157

0.157 0.843

1Λ

1.4 2.4

2.4 1.4

3Λ1.4 2.4

2.4 1.4

3Λ

RGA for subsystems 1 to 3.RGA for subsystems 1 to 3.

This subsystem involves pairing uu11 with yy11 and and yy2 2 with with uu22, and this also implies that uu33 is to be redundant.

Module 5 – Controllability Analysis 7575

PIECENAMP

2.5 Factors Influencing the Loop Pairing2.5 Factors Influencing the Loop Pairing2.5 Factors Influencing the Loop Pairing2.5 Factors Influencing the Loop Pairing

As seen in TIER I, there are some factors that affect As seen in TIER I, there are some factors that affect how the variables are paired. Some of those are:how the variables are paired. Some of those are:

Next slides show how to pair the process variables Next slides show how to pair the process variables according to these factors.according to these factors.

Constraints in the input variable,Constraints in the input variable,

Time delay,Time delay,

Inverse response,Inverse response,

Slow dynamics in the best Slow dynamics in the best RGARGA paring,paring,

Timescale decoupling of loop Timescale decoupling of loop dynamicsdynamics

Constraints in the input variable,Constraints in the input variable,

Time delay,Time delay,

Inverse response,Inverse response,

Slow dynamics in the best Slow dynamics in the best RGARGA paring,paring,

Timescale decoupling of loop Timescale decoupling of loop dynamicsdynamics

Module 5 – Controllability Analysis 7676

PIECENAMP

2.5.12.5.1 Take again Take again Ex. 2.3.1Ex. 2.3.1, but now, an in-tank heater was added to , but now, an in-tank heater was added to the stirred mixing tank to control the temperature with the the stirred mixing tank to control the temperature with the heater power Q. Obtain the heater power Q. Obtain the RGARGA for this system if for this system if TTss=(T=(THH+T+TCC)/2)/2. The transfer function is:. The transfer function is:

c c

c s c s

pH s C s

c s c s c s

c s c s c s

1 10

k kA s+ A s+

2A h 2A hs = 1

ρCT -T T -T

k k kA h s+ A h s+ A h s+

A h A h A h

G

c c

c s c s

pH s C s

c s c s c s

c s c s c s

1 10

k kA s+ A s+

2A h 2A hs = 1

ρCT -T T -T

k k kA h s+ A h s+ A h s+

A h A h A h

G

Where Where kk is the same constant as in is the same constant as in Ex. 2.3.1Ex. 2.3.1 and A and Acc is the cross- is the cross-section area for the tank.section area for the tank.

yy11= Liquid = Liquid levellevelyy22= Tank = Tank

temperaturetemperature

uu11= Hot stream = Hot stream flowrateflowrate

uu22= Cold stream = Cold stream temperaturetemperatureuu33= Heater power= Heater power

Module 5 – Controllability Analysis 7777

PIECENAMP

hh

HOT STREAM HOT STREAM FLOWRATE (uFLOWRATE (u11))

DISTURBANCE (TDISTURBANCE (Tdd, F, Fdd))

Output Flow rate Output Flow rate ((FF, , T)T)

COLD STREAM COLD STREAM FLOWRATE (uFLOWRATE (u22))

TANK LIQUID LEVEL (yTANK LIQUID LEVEL (y11))

TANKTANK TEMPERATURE (yTEMPERATURE (y22))

A diagram of the tank with the Heater is show below.A diagram of the tank with the Heater is show below.

FF==kk(h)(h)½ ½

Now it is an overdetermined system with more than one Now it is an overdetermined system with more than one subsystem to pair. First the subsystem to pair. First the RGARGA for each subsystem will for each subsystem will be obtained.be obtained.

HEAT POWER (uHEAT POWER (u33))

Problem description.Problem description.

Module 5 – Controllability Analysis 7878

PIECENAMP

In a similar way as Ex. In a similar way as Ex. 2.4.22.4.2, there are three different , there are three different subsystems:subsystems:

Subsystem 1Subsystem 1.. Utilizing uUtilizing u11 (Hot Stream) and (Hot Stream) and uu22 (Cold (Cold stream) for control.stream) for control.The steady state gain for this subsystem is the same that ex. The steady state gain for this subsystem is the same that ex. 2.3.12.3.1::

s s

H s C s

s s

2 h 2 h

k k =

T -T T -T

k h k h

K

s s

H s C s

s s

2 h 2 h

k k =

T -T T -T

k h k h

K

H sC s

C H C H

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

1Λ

H sC s

C H C H

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

1Λ

And the RGA is the same as obtained in ex. 2.3.12.3.1:

Module 5 – Controllability Analysis 7979

PIECENAMP

Subsystem 2Subsystem 2.. Utilizing uUtilizing u11 (Hot Stream) and (Hot Stream) and uu33 (Heater) (Heater) for control.for control.The transfer function matrix for this subsystem is:The transfer function matrix for this subsystem is:

c

c s

pH s

c s c s

c s c s

10

kA s+

2A h(s) = 1

ρCT -T

k kA h s+ A h s+

A h A h

G

c

c s

pH s

c s c s

c s c s

10

kA s+

2A h(s) = 1

ρCT -T

k kA h s+ A h s+

A h A h

G

And the steady state gain matrix is:

s

pH s

s s

2 h0

k = 1

ρCT -T

k h k h

K

s

pH s

s s

2 h0

k = 1

ρCT -T

k h k h

K

Module 5 – Controllability Analysis 8080

PIECENAMP

To calculate the RGA of this 2x2 system it is possible to obtain using the First Principles.First Principles.

Again: 2211 1

1

2211 1

1

H s

s

ps

s

T -T(0)

k h= = 0

1ρC2 h

k k h

H s

s

ps

s

T -T(0)

k h= = 0

1ρC2 h

k k h

2211

2112

KK

KK

2211

2112

KK

KK

Substituting the values of the matrix K K of this subsystem:

and,

101

111

1

01

111

Therefore 11 is:

Module 5 – Controllability Analysis 8181

PIECENAMP

And since, 1212:

012 012 Finally the value of 1212 is:

2112 1

2112 1

And the RGARGA for subsystem 2 is :

Next the RGA for subsystem 3, will be obtained.

2

1 0=

0 1

Λ2

1 0=

0 1

Λ

Module 5 – Controllability Analysis 8282

PIECENAMP

Subsystem 3Subsystem 3.. Utilizing uUtilizing u22 (Cold Stream) y (Cold Stream) y uu33 (Heater) for (Heater) for control.control.The transfer function matrix for this subsystem is:The transfer function matrix for this subsystem is:

And the steady state gain matrix is:

s

pC s

s s

2 h0

k = 1

ρCT -T

k h k h

K

s

pC s

s s

2 h0

k = 1

ρCT -T

k h k h

K

c

c s

pC s

c s c s

c s c s

10

kA s+

2A h(s) = 1

ρCT -T

k kA h s+ A h s+

A h A h

G

c

c s

pC s

c s c s

c s c s

10

kA s+

2A h(s) = 1

ρCT -T

k kA h s+ A h s+

A h A h

G

Module 5 – Controllability Analysis 8383

PIECENAMP

To calculate the RGA of this 2x2 system it is possible to obtain using the First Principles.First Principles.

Again: 2211 1

1

2211 1

1

C s

s

ps

s

T -T(0)

k h = = 0

1ρC2 h

k k h

C s

s

ps

s

T -T(0)

k h = = 0

1ρC2 h

k k h

2211

2112

KK

KK

2211

2112

KK

KK

Substituting the values of the matrix K K of this subsystem:

and,

101

111

1

01

111

Therefore 11 is:

Module 5 – Controllability Analysis 8484

PIECENAMP

And since, 1212:

012 012 Finally the value of 1212 is:

2112 1

2112 1

And the RGARGA for subsystem 3 is :

You must noted that the RGA for subsystem 2 and 3 is the same and both are independent of TTss.

3

1 0 =

0 1

Λ 3

1 0 =

0 1

Λ

Module 5 – Controllability Analysis 8585

PIECENAMP

H sC s

C H C H1

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

Λ

H sC s

C H C H1

H s C s

C H C H

- T -TT -T

T -T T -T =

- T -T T -T

T -T T -T

Λ 2

1 0=

0 1

Λ 2

1 0=

0 1

Λ

1

0.5 0.5 =

0.5 0.5

Λ 1

0.5 0.5 =

0.5 0.5

Λ

RGA for subsystems 1 to 3.RGA for subsystems 1 to 3.

Taking the case where TTss=(T=(THH+T+TCC)/2)/2, the RGARGA for each subsystem is:

Subsystem 1Subsystem 1.. Subsystem 2Subsystem 2.. Subsystem 3Subsystem 3..

3

1 0 =

0 1

Λ 3

1 0 =

0 1

Λ

Again, note that the RGARGA for subsystem 1 was obtained in Ex.Ex. 2.3.1.2.3.1. Subsystems 2 and 3 are the same and both are independent of TTss.

2

1 0=

0 1

Λ 2

1 0=

0 1

Λ 3

1 0 =

0 1

Λ 3

1 0 =

0 1

Λ

Module 5 – Controllability Analysis 8686

PIECENAMP

According to this analysis, the pairing in According to this analysis, the pairing in subsystem 2subsystem 2 involves to use the Hot stream temperature (involves to use the Hot stream temperature (uu11) to control ) to control the liquid level (the liquid level (yy11) and use the in tank heater () and use the in tank heater (uu33) to control ) to control the tank temperature (the tank temperature (yy22):):Subsystem 2Subsystem 2..

hh

HOT STREAM FLOWRATE (uHOT STREAM FLOWRATE (u11)) DISTURBANCE (TDISTURBANCE (Tdd, F, Fdd))

COLD STREAM FLOWRATE (uCOLD STREAM FLOWRATE (u22))

TANK LIQUID LEVEL TANK LIQUID LEVEL (y(y11))

TANKTANK TEMPERATURE (yTEMPERATURE (y22))

FF==kk(h)(h)½ ½ HEAT POWER (uHEAT POWER (u33))

Output Flow rate Output Flow rate ((FF, T), T)

LLC

Subsystem 3Subsystem 3..

Click to Click to Pairing Pairing

Subsystem 2Subsystem 2

TC

Module 5 – Controllability Analysis 8787

PIECENAMP

For subsystem 3 the pairing involves to use the Cold stream For subsystem 3 the pairing involves to use the Cold stream temperature (temperature (uu22) to control the liquid level () to control the liquid level (yy11) and use the ) and use the in-tank heater (in-tank heater (uu33) to control the tank temperature () to control the tank temperature (yy22):):

Subsystem 3Subsystem 3..

hh

HOT STREAM FLOWRATE HOT STREAM FLOWRATE (u(u11))

DISTURBANCE (TDISTURBANCE (Tdd, F, Fdd))

COLD STREAM FLOWRATE COLD STREAM FLOWRATE (u(u22))

TANK LIQUID LEVEL (yTANK LIQUID LEVEL (y11))

TANKTANK TEMPERATURE TEMPERATURE (y(y22))

FF==kk(h)(h)½ ½ HEAT POWER (uHEAT POWER (u33))

Output Flow rate Output Flow rate ((FF, T), T)

LLC

Subsystem 3Subsystem 3..

Click to Click to Pairing Pairing

Subsystem 3Subsystem 3

TC

Module 5 – Controllability Analysis 8888

PIECENAMP

But both pairings of these subsystems can become an But both pairings of these subsystems can become an undesirable pairing control as it will be discussed next.undesirable pairing control as it will be discussed next.But both pairings of these subsystems can become an But both pairings of these subsystems can become an undesirable pairing control as it will be discussed next.undesirable pairing control as it will be discussed next.

If the in-tank heater can barely achieve the If the in-tank heater can barely achieve the steady state, steady state, Ts, at maximum power, there is a , at maximum power, there is a

major problem.major problem.

If the in-tank heater can barely achieve the If the in-tank heater can barely achieve the steady state, steady state, Ts, at maximum power, there is a , at maximum power, there is a

major problem.major problem.

Thus, this subsystem would not be desirable for the regulatory temperature control because, following variations of the other process variable (hot or cold

stream), the IN-TANK HEATERIN-TANK HEATER has no more power has no more power to supply (or extract) heat to keep the new to supply (or extract) heat to keep the new

steady state temperaturesteady state temperature.

Module 5 – Controllability Analysis 8989

PIECENAMP

Now to overcome the power limitation, a much Now to overcome the power limitation, a much larger heater is installed in the tank, but as a larger heater is installed in the tank, but as a consequence of this, there is a consequence of this, there is a , between the control signal and the actual , between the control signal and the actual power delivery.power delivery.

VERY LARGE TIME DELAYVERY LARGE TIME DELAYVERY LARGE TIME DELAYVERY LARGE TIME DELAY

Next will be show another factor to considerer in the Next will be show another factor to considerer in the loop pairing of process variables.loop pairing of process variables.

And because of this sluggish closed-loop And because of this sluggish closed-loop response in the heater, the best choice for response in the heater, the best choice for pairing the process variables could be the pairing the process variables could be the poor poor RGARGA of subsystem 1. of subsystem 1.

Module 5 – Controllability Analysis 9090

PIECENAMP

2 2

10s+1 s+1s =1 -4

s+1 10s+1

G

2 2

10s+1 s+1s =1 -4

s+1 10s+1

G

2.5.22.5.2 Now considering a system with a transfer function given as Now considering a system with a transfer function given as below, obtain the below, obtain the RGARGA for this system and analyze a unit set for this system and analyze a unit set point change in (point change in (yy11) and a diagonal PI controller () and a diagonal PI controller (KKc1c1= 4, = 4,

I1I1=0.5; K=0.5; Kcc22=-4, =-4, I2I2=0.3=0.3) using the resulting pairing.) using the resulting pairing.

Problem description.Problem description.

First of all it is necessary to obtain the steady state gain First of all it is necessary to obtain the steady state gain matrix, as it is shows below.matrix, as it is shows below.

2 20 = =

1 4G K

2 20 = =

1 4G K

Module 5 – Controllability Analysis 9191

PIECENAMP

Now, the RGARGA obtained as before is:

According to the RGA, the recommended pairing is yy11-uu11 and

yy22-uu22.

Next step is to analyze a change in the set point.

Module 5 – Controllability Analysis 9292

PIECENAMP

Since the dynamic simulation of the Since the dynamic simulation of the analyzed system is beyond the scope of analyzed system is beyond the scope of this module, this module, only the resultonly the result of the of the change in the set point change in the set point will be displaywill be display..

Since the dynamic simulation of the Since the dynamic simulation of the analyzed system is beyond the scope of analyzed system is beyond the scope of this module, this module, only the resultonly the result of the of the change in the set point change in the set point will be displaywill be display..

Module 5 – Controllability Analysis 9393

PIECENAMP

As mentioned in last slide, the next graphic shows the closed loop As mentioned in last slide, the next graphic shows the closed loop response for a unit set point change in response for a unit set point change in yy11 using the pairing using the pairing suggested for the suggested for the RGARGA and a diagonal PI controller. and a diagonal PI controller.

The performance of The performance of this pairing is not too this pairing is not too bad considering that bad considering that the open loop time the open loop time constants on the constants on the diagonal are 10 diagonal are 10 minutesminutes

yy11

yy22

Inverse loop pairing involves to take the value of Inverse loop pairing involves to take the value of =0.2 in =0.2 in the pairing, but it has been mentioned as a situation to the pairing, but it has been mentioned as a situation to avoid !!!!!!!!.avoid !!!!!!!!.

Inverse loop pairing involves to take the value of Inverse loop pairing involves to take the value of =0.2 in =0.2 in the pairing, but it has been mentioned as a situation to the pairing, but it has been mentioned as a situation to avoid !!!!!!!!.avoid !!!!!!!!.

Pairing 1-1/2-2Pairing 1-1/2-2Pairing 1-1/2-2Pairing 1-1/2-2

Set pointSet point yy11

Set point ySet point y22

Despite this “Despite this “not not too badtoo bad” ” performance, the performance, the inverse pairing will inverse pairing will be analyzed for be analyzed for the same set point the same set point change.change.

Despite this “Despite this “not not too badtoo bad” ” performance, the performance, the inverse pairing will inverse pairing will be analyzed for be analyzed for the same set point the same set point change.change.

Module 5 – Controllability Analysis 9494

PIECENAMP

Different pairing also implies to use a different PI controller, for Different pairing also implies to use a different PI controller, for that reason the inverse pairing analysis of a unit set point that reason the inverse pairing analysis of a unit set point change in (change in (yy11), the new diagonal PI controller is (), the new diagonal PI controller is (KKc1c1= 10, = 10,

I1I1=0.3; K=0.3; Kc2c2= 20, = 20, I2I2=0.3=0.3).).

Pairing 1-2/2-1Pairing 1-2/2-1Pairing 1-2/2-1Pairing 1-2/2-1

yy11

yy22

The performance in this case The performance in this case is dramatically better than is dramatically better than the recommended pairing by the recommended pairing by the RGA, because the open the RGA, because the open loop time constants on the loop time constants on the diagonal are only 1 minute.diagonal are only 1 minute.

Set point ySet point y11

Set point ySet point y22

The reason is that The reason is that the control loops the control loops are able to are able to respond so rapidly respond so rapidly that the that the interactions that interactions that appear more appear more slowly are easily slowly are easily dealt with.dealt with.