Pfmea Preview

Transcript of Pfmea Preview

Process Failure Modes Effects Analysis

PFMEA BenefitsPFMEA Benefits

• You can effectively PreventPrevent– rework, retest, re-inspection, poor quality, higher costs, etc.

• It costs companies less to prevent problems than to react to them (Firefighting = Dollars Wasted)(Firefighting = Dollars Wasted)

• You can improve Cycle-times– Time, Labor, and money is more effectively spent on “preventing”

rather than “reacting” to errors

• PFMEAs make teams more effective!

By PreventingPreventing errors or problems…

You prevent waste, improve quality and You prevent waste, improve quality and cycle-times, and reduce costs !cycle-times, and reduce costs !

Process Failure Modes Effects Analysis

How do we perform a PFMEA?How do we perform a PFMEA?

#1: Identify the process or product that requires the PFMEA #1: Identify the process or product that requires the PFMEA Analysis …Analysis …

Recommended:Recommended:

• New processes being launched

• Business, transaction, service, or manufacturing process

• Current processes with poor yields, rework, errors, defects, poor cycle-times, high costs, high customer dissatisfaction, etc.

Process Failure Modes Effects Analysis

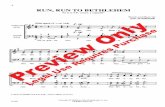

FMEA Number:Page: of

Process Responsibility: Prepared by:FMEA Date (Orig.)

Actions Taken

Se

veri

ty

Occ

urr

en

ce

De

tect

ion

RP

N

Action ResultsResponsibility

& Target Completion

Date

Recommended Action(s)

RP

N

De

tect

ion

Current Process Controls Detection

Current Process Controls

PreventionO

ccu

rre

ncePotential

Cause(s)/ Mechanism(s)

of Failure

Cla

ss

Se

veri

ty

Potential Effect(s) of

Failure

Potential Failure Mode

Process Function [Process

Step Name]

Drive to Work

Stuck inTraffic

Late forWork

Complete the next column in the PFMEA tool…Complete the next column in the PFMEA tool…• Column 3 – Brainstorm and list all the “effects” of the

failure mode(s )if it actually occurred. The “effects” of a failure, defect or error could be both the internal (e.g. at the next operation) effect and the external effect (e.g. at the customer)

In Column 3 – List all of the potential (internal and external) effects of the

Failure Modes, defects or errors : Example- Customer rejects, poor fit,

rework, cycle-time increase, test failure

This “effects” list will help you determine the “Severity” ranking to be

placed in column 4

How to perform a PFMEAHow to perform a PFMEA