Performance Evaluation of Propeller-Aspirator-pump Aerator

-

Upload

mohammed-eljamma -

Category

Documents

-

view

97 -

download

5

Transcript of Performance Evaluation of Propeller-Aspirator-pump Aerator

Aquacultural Engineering 42 (2010) 70–74

Performance evaluation of propeller-aspirator-pump aerator

Avinash Kumar, S. Moulick *, B.C. Mal

Agricultural and Food Engineering Department, IIT Kharagpur, Kharagpur 721302, West Bengal, India

A R T I C L E I N F O

Article history:

Received 17 August 2009

Accepted 1 December 2009

Keywords:

Aerator

Propeller

Standard aeration efficiency

Non-dimensional numbers

A B S T R A C T

Aeration experiments were conducted in a brick masonry tank of dimension 5.25 m � 2.87 m � 1.57 m

to study the effects of positional angle of propeller shaft (a), submergence depth and rotational speed of

shaft on standard aeration efficiency (SAE) of a propeller-aspirator-pump aerator. Non-dimensional

numbers related to standard aeration efficiency (SAE) and wire power (P) termed as E and Ne,

respectively, were proposed. To evaluate the optimum geometric condition, i.e., positional angle of

propeller shaft (a), aeration experiments were conducted at different values of a: 308, 458, 608, 758 and

908, keeping the rotational speed N (2130 rpm) and submergence depth of propeller shaft d (300 mm) as

constants. The results showed that SAE becomes maximum at a = 758. In a similar way, keeping the

geometric condition constant (a = 758), aeration experiments were further conducted at different

rotational speeds of propeller shaft, N (1420, 1775, 2130, 2485 and 2840 rpm) and different values of

submergence depth, d (140, 220, 300, 380 and 460 mm) to evaluate the effect of dynamic conditions on

aeration characteristics. It was found that E as well as Ne could be well correlated with Froude number

(Fr) and Reynolds number (Re), respectively. Finally, maximum SAE of 0.42 kg O2/kWh was obtained at

positional angle of 758, rotational speed of 2840 rpm and submergence depth of 0.14 m of propeller shaft.

� 2009 Elsevier B.V. All rights reserved.

Contents lists available at ScienceDirect

Aquacultural Engineering

journa l homepage: www.e lsev ier .com/ locate /aqua-onl ine

1. Introduction

Aerators are an essential part of an intensive aquaculturesystem to fulfil the oxygen demand of the culture environment.Aerators increase the interfacial area between air and water, thusenhancing the oxygen transfer and simultaneously provide watercirculation which prevents the stratification in the water body(Boyd and Martinson, 1984). Various types of aerators have beendeveloped over the years to maintain desired level of DOconcentration in the pond water in an effort to improve theenergy efficiency of the oxygen mass transfer process. To meet theaeration requirements, two broad methods are commonly used:(1) splash aeration by vertical pump, pump-sprayer, cascade andpaddle wheel aerators and (2) bubbling aeration by diffused-airsystems and propeller-aspirator-pumps. Vertical pumps, pump-sprayers, propeller-aspirator-pumps, paddle wheels, and diffused-air systems are probably the most widely used aerators in the fieldof aquaculture (Boyd, 1998). Paddle wheel aerators were found tobe the most efficient aerator in terms of aeration efficiency andcirculation (Rappaport et al., 1976; Boyd and Ahmad, 1987).However, in small ponds, vertical pump aerators, propeller-aspirator-pump aerators, and diffused-air aerators are more

* Corresponding author. Tel.: +91 3222283102; fax: +91 3222255303.

E-mail address: [email protected] (S. Moulick).

0144-8609/$ – see front matter � 2009 Elsevier B.V. All rights reserved.

doi:10.1016/j.aquaeng.2009.12.001

commonly used than the paddle wheel aerators due to economicreason (Boyd, 1998). The propeller-aspirator-pumps (1–3 HP) arethe least-cost system for ponds less than 2 ha in size whencompared to other aeration systems (Engle, 1989).

The propeller-aspirator-pump aerator draws atmospheric airthrough a rotating hollow shaft which is connected to an electricmotor at one end and a propeller at the other end which issubmerged under water. Basically the propeller accelerates thewater to a velocity high enough to cause a drop in pressure over thediffusing surface. This forces air to pass through a diffuser in thehollow shaft and enter into the water as fine bubbles. The finebubbles thus formed are thoroughly mixed with the water due tothe turbulence created by the propeller (Boyd and Martinson,1984).

Propeller-diffusers are manufactured in a variety of sizes from0.37 to over 11 kW. In practice the float supports the motor and shaftat an angle with the water surface and the angle can be adjusted tooperate in either deep or shallow-water conditions. Boyd andMartinson (1984) conducted experiments on propeller-aspirator-pump aerators of 0.38, 1.5 and 2.24 kW capacities in a shallow basin(1.04 m of water depth) and found that the standard aerationefficiency (SAE) ranged between 1.73 and 1.91 kg O2/kWh. Thepositional angle of the hollow shaft at which maximum aerationefficiency occurs was found to be 308. It was also observed that thepropeller-aspirator-pump was effective in mixing pond water.Ruttanagosrigit et al. (1991) found that propeller-aspirator-pump

A. Kumar et al. / Aquacultural Engineering 42 (2010) 70–74 71

aerators transferred oxygen to water more efficiently at salinities of10–30 ppt than at lower salinities. With regard to diffuser aerationsystem, Wagner and Popel (1998) stated that volumetric oxygentransfer rate VOTR [g/m3 h] can be increased with increasing depthof submergence at the same air flow rate. Cancino et al. (2004) andCancino (2004a,b) designed and developed a high efficiencycentrifugal surface aerator for fishponds. A theoretical design ofthe rotor using the traditional mass transfer equations and themechanical approach using the superficial similarities of aerators toaxial flow pumps was presented. Based on dimensional analysis,aerator’s behavior was expressed as a general equation. It wasconcluded that the aeration efficiency improves with the Froudenumber, but is inversely related to the speed and diameter of thepropeller. A maximum SAE of 1.805 kg O2/kWh was obtained using‘‘Kinetic 3’’ propeller—with a diameter of 94 mm, an inlet angle of118 and an exit angle of 258 at 10 8C. Vinatea and Carvalho (2007)conducted aeration experiments on paddle wheel (PW) andpropeller-aspirator-pump (PAP) aerators at different salinities.These results revealed that the efficiency of the aerators decreasesbeyond 30 ppt of salinity.

The research work conducted on propeller-aspirator-pumpaerator mainly focussed on the following aspects: (i) positionalangle of propeller shaft of propeller-aspirator-pump at whichaeration efficiency approaches maximum (Boyd and Martinson,1984), (ii) comparative aeration performance of propeller-aspira-tor-pump aerator, spray type surface aerators and diffused-airaerator of different power ratings (Boyd and Martinson, 1984) and(iii) aeration performance of propeller-aspirator-pump aerator atdifferent salinities (Ruttanagosrigit et al., 1991; Vinatea andCarvalho, 2007). The aeration performance of a propeller-aspira-tor-pump aerator depends on the positional angle of propellershaft, submergence depth of the shaft, rotational speed of thepropeller and the design features of the propeller. However, nostudy has been reported with regard to the effects of submergenceof the propeller shaft and rotational speed of the propeller onaeration efficiency. Keeping in view the above points, the presentinvestigation was focussed on determining the effect of variousgeometric and dynamic conditions on aeration efficiency of apropeller-aspirator-pump aerator (Make: Nan Rong Hai Co. Ltd.,Taiwan).

2. Theoretical considerations

The standard oxygen transfer rate (SOTR) of an aerating deviceis defined as the mass of oxygen that the device can introduce intoa body of water per unit time at standard conditions (20 8C watertemperature, 0 mg/L initial DO concentration, one atmosphericpressure and clear tap water, APHA, 1980):

SOTR ¼ kLa20 � ðC� � C0Þ � V ¼ kLa20 � 9:07� V � 10�3 (1)

where SOTR = standard oxygen transfer rate (kg O2/h), kLa20 = o-verall oxygen transfer coefficient at 20 8C (h�1) = kLaT/uT�20,kLaT = overall oxygen transfer coefficient at T 8C (h�1), u = temper-ature correction factor = 1.024 for pure water, C* = saturation valueof DO at test conditions (mg/L), C0 = DO concentration at time t = 0(mg/L), 9.07 = saturation value of DO (mg/L) at 20 8C and oneatmospheric pressure and V = aeration tank volume (m3). It is animportant parameter used to compare aerators. A better compar-ative parameter is the standard aeration efficiency (SAE), which isdefined as the SOTR per unit of power (Lawson and Merry, 1993).

SAE ðkg O2=kWhÞ ¼ SOTR ðkg O2=hÞP

(2)

where P = wire power (kW).

2.1. Dimensional analysis

The basic dimensional analysis of aeration process has beenpresented by many investigators (Eckenfelder, 1956; Schmidtkeand Horvath, 1976; Zlokarnik, 1979; Banks et al., 1983; Horvath,1984; Simha, 1991; Ognean, 1993; Rao, 1999; Moulick et al., 2002,2005; Cancino et al., 2004; Cancino, 2004a,b; Moulick and Mal,2009). Zlokarnik (1979) stated that the main parameter of theabsorption process is the absorption rate coefficient kLa20 � V,expressed as

kLa20 � V ¼ SOTR

DC(3)

where DC = DO deficit = C* � C0.The functional relationship between SOTR/DC and the variables

may be expressed as:

SOTR

DC¼ f 1ða; d;V ;N; g;ra;rw;nw;swÞ (4)

where a = positional angle of propeller shaft; d = submergencedepth of propeller shaft, i.e., the distance between the watersurface and the water suction hole; V = volume of water in thetank; N = rotational speed of propeller; g = acceleration due togravity; ra = mass density of air; rw = mass density of water;nw = kinematic viscosity of water and sw = surface tension of water

Based on Buckingham P theorem, Eq. (4) may be expressed asfollows:

Y ¼ f 2 a;V

d3;N2d

g;ra

rw

;Nd2

nw;

sw

g rwd2

" #(5)

where Y = absorption number = SOTR � (n/g2)1/3/(DC � d3), Nd2/nw = Reynolds number (Re) and sw/(grwd2) = Weber number (W).As the aeration tests were performed on a practically identicalsystem (pure water–air), ra/rw and W remain constant in theaeration tank and subsequently can be omitted from Eq. (5).

Elliott (1969) suggested aerator power to water volume ratio tobe less than 0.1 kW/m3. Thus in the present study, based on thepower consumption of the propeller, water volume was chosen tosatisfy the above condition. Hence, the term V/d3 is also omittedfrom Eq. (5). Thus, simplification of Eq. (5) results in

Y ¼ f 3fa; Fr;Reg (6)

The power consumption P of a given propeller-aspirator-pumpaerator is, in general, dependent upon the same parameters as theterm SOTR/DC. In a similar way, with the help of dimensionalanalysis the following relationship for power consumption, P isobtained:

Ne ¼ f 4½a; Fr;Re� (7)

where

Ne ¼ Power no: ¼ P

rw � N3 � d5(8)

As standard aeration efficiency (SAE) is a better comparativeparameter for performance evaluation of aerators (Lawson andMerry, 1993) it was also expressed in a non-dimensional form (E)by dividing the absorption number (Y) with power number (Ne)(Moulick et al., 2002, 2005 and Moulick and Mal, 2009) as follows:

E ¼ Y

Ne¼ SOTR

P

� �� nw

g2

� �1=3

� ðDC � d3Þ�1� rw � N3 � d5

or

E ¼ SAE� nw

g2

� �1=3

� ðDCÞ�1 � rw � N3 � d2 (9)

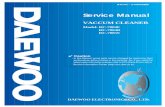

Fig. 1. Experimental set-up for testing of propeller-aspirator-pump aerator.

A. Kumar et al. / Aquacultural Engineering 42 (2010) 70–7472

or

E ¼ f 5½a; Fr;Re� (10)

2.1.1. Geometric similarity

Geometric similarity requires that all the linear ratios of themodel be related to corresponding ratios of the prototype at aparticular dynamic condition. Thus keeping Fr and Re as constant(i.e., maintaining rotational speed of the shaft, N and submergencedepth of the propeller, d as constant), the dynamic conditions canbe kept as constant and subsequently a particular relationshipbetween E and a can be found out by varying a at different levels.Thus, an optimum value of a can be determined at which E

becomes maximum. The volume of water to be aerated can bedecided following Elliott (1969).

2.1.2. Dynamic similarity

To obtain dynamic similarity between a model and a prototypein geometrically similar systems, all forces acting on the liquidmust bear same ratio in both the systems. The inertial, gravity andviscous forces acting in aeration process are expressed by two non-dimensional numbers: Froude (Fr) and Reynolds (Re). For dynamicsimilarity these two numbers should be same for the model andthe prototype. Once the value of a is fixed, the values of Ne and E

depend on the dynamic parameters: Fr and Re. Thus, Eqs. (7) and(10) can be represented as:

Ne ¼ f 6½Fr;Re� (11)

E ¼ f 7½Fr;Re� (12)

3. Materials and methods

The details of the experimental set-up and the experimentalprocedure are presented in this section.

3.1. Experimental set-up

The aeration experiments were conducted in a brick masonrytank of dimension 5.25 m � 2.87 m � 1.57 m. The test aeratorconsisted of a propeller-aspirator-pump aerator operated by a 2HP, 3 phase high speed induction motor (22 kg, 440 V and 3.3 A) of2840 rpm manufactured by Nan Rong Hai Co. Ltd., Taiwan. Thespecifications of the propeller are as follows: (i) material—highdensity polyethylene (HDP), (ii) number of paddles—4, (iii) totaldiameter—100 mm, (iv) inlet and exit angles—158 and 258, (v)inner and outer width of paddles—27 and 50 mm and (vi) length ofpaddles—30 mm. The propeller is attached with the motor througha 700 mm long shaft already fixed with the motor. Aerator wasmounted at the centre of the tank on supports fabricated by usingfour numbers of 40 mm diameter and 1.60 m long G.I. pipes (Fig. 1).

As the maximum speed of the motor is 2840 rpm and it wasdesired to evaluate its performance at different speeds, a frequencybased speed controller was connected to the motor by a 15 m, 3phase electric cable to control the speed to desired values.

The positional angle of propeller shaft a (inclination of the shaftwith the horizontal water surface) can be changed by changing theposition of an arm attached to the supporting structure. Theatmospheric air enters through the hole A of the propeller shaft dueto suction created by the aspirator. Water drawn through the holeB is thoroughly mixed with the air and is finally splashed into theatmosphere. Thus aeration of the water takes place. The depth ofsubmergence (d) can be changed by rotating the spindle of thestructure.

3.2. Aeration test

Oxygen transfer tests were conducted in a concrete tank usingclean tap water. Initially the tap water was deoxygenated using0.1 mg/L of cobalt chloride and 10 mg/L of sodium sulphite for each1 mg/L of dissolved oxygen present in water (Boyd, 1998).Thereafter the aerator was operated at the desired conditions asper the experimental design. The dissolved oxygen measurementswere taken using two YSI Professional Plus DO meters, positionedat mid-distances between the propeller and the opposite corners ofthe tank, both 0.20 m below the water surface (Baylar et al., 2007),at timed intervals till DO increased from zero to about 80%saturation. At least 20 DO measurements at equal time intervalswere taken. The DO deficit was computed for each time. The slopeof the best fit line obtained by plotting natural logarithms of DOdeficits on Y-axis against the time of aeration on X-axis gave theoxygen transfer coefficient at the test water temperature whichwas adjusted to 20 8C using temperature correction factor. Finallythe values of SOTR and SAE were calculated using Eqs. (1) and (2),respectively.

3.3. Experimental design

3.3.1. Effect of positional angle of propeller shaft on oxygen transfer

To obtain the optimum value of a, aeration tests wereconducted on propeller-aspirator-pump aerator positioned at fivedifferent positional angles (a): 908, 758, 608, 458 and 308 keepingthe dynamic conditions (rotational speed of the shaft, N andsubmergence depth of the propeller, d) constant (Section 2.1.1).The rotational speed of the shaft (N) and submergence depth of thepropeller (d) was fixed at 2130 rpm and 300 mm, respectively. Ineach case, the volume of water to be aerated (V) was maintained tosatisfy: P/V � 0.1 kW/m3 (Elliott, 1969).

3.3.2. Effect of dynamic conditions (Fr and Re) on oxygen transfer and

power consumption

Keeping the optimized value of a (obtained from previous set ofexperiments) constant, N and d were varied simultaneously to findout the effect of different dynamic conditions on E and Ne. Theranges of variation of N and d were from 1420 to 2840 rpm (at aninterval of 355 rpm) and 140 to 460 mm (at an interval of 80 mm),respectively amounting to 25 sets of experiments. The volume of

Fig. 2. Variation of E with positional angle of propeller shaft.

Fig. 3. Effects of Reynolds criterion on E.

Fig. 4. Effects of Froude criterion on E.

Fig. 5. Effects of Reynolds criterion on power number Ne.

A. Kumar et al. / Aquacultural Engineering 42 (2010) 70–74 73

water to be aerated was fixed in a similar fashion as stated inSection 3.3.1.

4. Results and discussion

4.1. Determination of optimum positional angle (a) of propeller shaft

Aeration tests were conducted at different values of a (Section3.3.1). A typical plot showing the variation of E with a is shown inFig. 2. It is seen from the figure that all the points could be wellfitted by a second order polynomial equation with the variation ofa in the range of 30–908.

E ¼ �4� 10�6 � a2 þ 0:0006� a� 0:0017; R2 ¼ 0:897 (13)

From the developed relationship, the value of a, at which E

reaches the peak value, is found to be 758. In this case, E is directlyproportional to SAE as N and d were kept as constants. Hence theoptimum positional angle corresponds to maximum SAE also.

4.2. Effect of dynamic conditions (Fr and Re) on oxygen transfer and

power consumption

The optimized value of a (758) was kept as a constant and N andd were varied to find out the effect of different dynamic conditionson E and Ne (Section 3.3.2).

4.2.1. Effect of Re and Fr on E

The relationship between E and Re and E and Fr is shown inFigs. 3 and 4, respectively. It can be seen from Fig. 3 that the datafrom different submergence depths followed different curves andindicated the scale effect of Re on E. All the curves show anexponential increase of E for the ranges of Re studied. However,Fig. 4 reveals that E could be well fitted with Fr by the followingequation suggesting a unique relationship between E and Fr.

E ¼ �0:0002� Fr2 þ 0:876� Fr

5:28þ 0:0068� Frþ ð3310=FrÞ ; R2 ¼ 0:976 (14)

The above equation is valid subject to 7.993 � Fr � 105.057.Therefore, it is seen that the scale effects are more pronounced ifthe Re criterion is used as compared to the Fr criterion on E. It ispossibly due to the fact that, gravity force plays a major role inoxygen transfer than the viscous forces as found out by earlierinvestigations on surface aerators (Zlokarnik, 1979; Horvath, 1984;Moulick et al., 2002, 2005; Moulick and Mal, 2009).

4.2.2. Effect of Re and Fr on Ne

The effect of Re and Fr on Ne is shown in Figs. 5 and 6,respectively. It can be seen from Fig. 5 that the data points fordifferent submergence depths are close to each other and could bewell fitted by the following equation:

Ne ¼ 11:139� ð10�5ReÞ�2:3213; R2 ¼ 0:944 (15)

However, no unique relationship could be established betweenFr and Ne (Fig. 6). No valid explanation could be offered for thisdiscrepancy.

Fig. 6. Effects of Froude criterion on power number Ne.

A. Kumar et al. / Aquacultural Engineering 42 (2010) 70–7474

4.3. Optimum dynamic condition for propeller-aspirator-pump

aerator

To arrive at a particular dynamic condition that yields themaximum SAE, E was expressed in terms of SAE (Eq. (9)) assumingthe water temperature to be 20 8C, value of g as 9.81 m/s2, DC as9.07 mg/L, rw as 1000 kg/m3, equated to Eq. (14) and the followingexpression is obtained:

SAE ¼ �0:0002� Fr2 þ 0:876� Fr=f5:28þ 0:0068� Frþ ð3310=FrÞg240:59� N3 � d2

(16)

The above equation is valid subject to 7.993 � Fr � 105.057.Substituting Fr = N2d/g in the above equation, an unconstrainednonlinear programming was followed using WinQSB (version 1.00)to determine the values of N and d at which SAE is maximum.

The maximum value of SAE was found to be 0.42 kg O2/kWh at asubmergence depth of propeller shaft, d = 0.14 m and rotationalspeed of N = 2837.59–2840 rpm. To calculate the power consump-tion, Eq. (15) can be rewritten by substituting Ne = P/(rwN3d5),Re = Nd2/nw (assuming water temperature = 20 8C), rw = 1000 kg/m3, N = 2840/60 = 47.33 rps, d = 0.14 m and nw = 1 � 10�6 m2/s asshown below.

P ¼11:139� rwN3d5 � 10�5 � Nd2

nw

!� 2:3213

¼11:139�1000�47:333�0:145� 10�5�47:33� 0:142

1�10�6

!�2:3213

¼360:8174 W ¼ 0:361 kW

Thus, SOTR = SAE � P = 0.42 � 0.361 = 0.15 kg O2/h.Therefore, a maximum SAE of 0.42 kg O2/kWh and correspond-

ing SOTR of 0.15 kg O2/h can be obtained by operating thepropeller-aspirator-pump aerator at a submergence depth,d = 0.14 m and rotational speed, N = 2840 rpm.

Boyd and Martinson (1984) conducted experiments onpropeller-aspirator-pump aerators (Aire-O2 aerators) and foundthat the SAE ranged between 1.73 and 1.91 kg O2/kWh. The resultsof the present study showed that a maximum SAE of only0.42 kg O2/kWh is achievable with propeller aerator of make NanRong Hai Co. Ltd., Taiwan. Therefore, it appears that the design ofthe particular propeller used for the study needs modification orreplacement to achieve higher efficiency. There is a need toconduct future studies with various designs of propeller.

5. Conclusions

A propeller-aspirator-pump aerator was tested with an aim toevaluate the optimum conditions that would result in maximumefficiency of the aerator. Based on dimensional analysis, non-dimensional numbers, E and Ne were proposed for standardaeration efficiency (SAE) and wire power (P), respectively. Keepingthe dynamic conditions constant, experiments were conducted atdifferent positional angles (a) of the propeller shaft. From thetesting optimum value of a was obtained as 758. Furtherexperiments were conducted at different dynamic conditionskeeping the geometric condition constant (a = 758). The resultsshowed that E and Ne are well correlated with Fr and Re,respectively. Maximum SOTR and SAE are found to be 0.15 kg O2/hand 0.42 kg O2/kWh, respectively at rotational speed (N) of2840 rpm, submergence depth (d) of 0.14 m and positional angleof 758 of the propeller shaft.

References

American Public Health Association (APHA), 1980. American Water Works Associ-ation, and Pollution Control Federal, 16th ed. APHA, Washington, DC.

Banks, R.B., Sally, L.R., Polprasert, C., 1983. Mechanical mixing and surface reaera-tion. J. Environ. Eng. 109 (1), 232–241.

Baylar, A., Bagatur, T., Emiroglu, M.E., 2007. Aeration efficiency with nappe flowover stepped cascades. Proc. Inst. Civ. Eng., Waters. Maritime Energ. 160 (WM1),43–50.

Boyd, C.E., 1998. Pond water aeration systems. Aquacult. Eng. 18 (1), 9–40.Boyd, C.E., Ahmad, T., 1987. Evaluation of Aerators for Channel Catfish Farming.

Alabama Agricultural Experiment Station, Auburn University, AL. Bulletin, p.584.

Boyd, C.E., Martinson, D.J., 1984. Evaluation of propeller-aspirator-pump aerators.Aquaculture 36 (3), 283–292.

Cancino, B., 2004a. Design of high efficiency surface aerators. Part 2. Rating ofsurface aerator rotors. Aquacult. Eng. 31 (1–2), 99–115.

Cancino, B., 2004b. Design of high efficiency surface aerators. Part 3. Dimensionalanalysis of rotor performance. Aquacult. Eng. 31 (1–2), 117–121.

Cancino, B., Roth, P., Reuß, M., 2004. Design of high efficiency surface aerators. Part1. Development of new rotors for surface aerators. Aquacult. Eng. 31 (1–2), 83–98.

Eckenfelder, W.W., 1956. Process design of aeration system for biological wastetreatment. Chem. Eng. Prog. 52 (7), 286–292.

Elliott, J.W., 1969. The oxygen requirements of chinook salmon. Prog. Fish Cult. 31,67.

Engle, C.R., 1989. An economic comparison of aeration devices for aquacultureponds. Aquacult. Eng. 8 (3), 193–207.

Horvath, I., 1984. Modelling in the Technology of Wastewater Treatment. Perga-mon, Tarrytown, NY.

Lawson, T.B., Merry, G.E., 1993. Procedures for evaluating low-power surfaceaerators under field conditions. Techniques for modern aquaculture. In: Wang,J.K. (Ed.), Proc. of an Aqua. Eng. Conf., ASAE, MI, USA, 21–23 June, p. 511.

Moulick, S., Mal, B.C., 2009. Performance evaluation of double-hub paddle wheelaerator. J. Environ. Eng. 135 (7), 562–566.

Moulick, S., Bandyopadhyay, S., Mal, B.C., 2005. Design characteristics of single hubpaddle wheel aerator. J. Environ. Eng. 131 (8), 1147–1154.

Moulick, S., Mal, B.C., Bandyopadhyay, S., 2002. Prediction of aeration performanceof paddle wheel aerators. Aquacult. Eng. 25 (4), 217–237.

Ognean, T., 1993. Aspects concerning scale-up criteria for surface aerators. WaterRes. 27 (3), 477–484.

Rao, A.R., 1999. Prediction of reaeration rates in square, stirred tanks. J. Environ. Eng.125 (3), 215–223.

Rappaport, U., Sarig, S., Marek, M., 1976. Results of tests of various aeration systemson the oxygen regime in the genosar experimental ponds and growth of fishthere in 1975. Bamidgeh 28, 35–49.

Ruttanagosrigit, W., Musig, Y., Boyd, C.E., Sukchareon, L., 1991. Effect of salinity onoxygen transfer by propeller-aspirator-pump and paddle wheel aerators usedin shrimp farming. Aquacult. Eng. 10 (2), 121–131.

Schmidtke, N.W., Horvath, T., 1976. Scale-up Methodology for Surface AeratedReactors. Progressive Water Technology, vol. 9. Pergamon Press, pp. 477–493.

Simha, L.U., 1991. Experimental studies on overall oxygen transfer coefficient. Ph.D.Thesis, Dept. of Civil Engineering, Indian Institute of Science, Bangalore, India, p.187.

Vinatea, L., Carvalho, J.W., 2007. Influence of water salinity on the SOTR of pad-dlewheel and propeller-aspirator-pump aerators, its relation to the number ofaerators per hectare and electricity costs. Aquacult. Eng. 31 (1), 73–78.

Wagner, M.R., Popel, H.J., 1998. Oxygen transfer and aeration efficiency—influenceof diffuser submergence, diffuser density, and blower type. Water Sci. Technol.38 (3), 1–6.

Zlokarnik, M., 1979. Scale-up of surface aerators for wastewater treatment. Adv.Biochem. Eng. 11 (2), 157–179.