pcgip.urbanunit.gov.pkpcgip.urbanunit.gov.pk/docs/energy/Final Report Ravi Road.pdf · The project...

Transcript of pcgip.urbanunit.gov.pkpcgip.urbanunit.gov.pk/docs/energy/Final Report Ravi Road.pdf · The project...

1

Punjab Cities Governance Improvement Project

Energy Audit & Energy Efficiency Improvement Program for WASAs in Punjab

REPORT Ravi Road Subdivision, Lahore

September 2015

NEC Consultants (Pvt.) Ltd.

2

Energy Audit & Energy Efficiency Improvement Program for WASAs in Punjab

September 2015 NEC Consultants Pvt. Ltd Perfect SITE, 22 KM Ferozepur Road, Near Gujju Matta Metro Bus Station, Lahore +92-42-35273741-46, www.nec.com.pk [email protected] This study was assigned by The Urban Unit, Punjab

3

DISCLAIMER No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or information storage and retrieval system, without prior written permission of the USPMSU. A publication of the Urban Sector Planning and Management Services Unit (Private) Limited, the opinion expressed in the document are solely those of the authors and publishing them does not in any way constitute an endorsement of the opinion by the USPMSU.

ACKNOWLEDGEMENTS This report has been prepared by The Urban Unit (Urban Sector Policy & Management Unit), P&D Department, Government of Punjab. The Urban Unit, under the Punjab Cities Governance Improvement Project (PCGIP)-DLI-4 is supporting WASA Lahore for implementing Energy Audit Management Opportunities. Energy management opportunities have been extracted from the energy audits of WASA pumps. The Team Dr. Nasir Javed Engr. Abid Hussainy Engr. Ali Raza Shafqat Ullah Muhammad Rizwan Kashif Shaukat Adnan Khan Editing & Layout By: Ms. Madiha Qamar Printed in Pakistan Copyright: Urban Sector Planning and Management Services Unit (Private) Limited.

4

CONTENTS Contents 4 List of Annexure 4 List of Figures 4 List of Tables 4 List of Acronyms and Abbreviations 5 Glossary 5 1.0 Introduction 7

1.1 Background 7 1.2 Methodology 7 1.3 Scope 8

2.0 Energy Audit Findings 9 2.1 Pumping system efficiency 10 2.2 Electricity consumption trend 11 2.3 Pumping system efficiency improvement potential 13 2.4 Interventions for the improvement of WASA stations 14

LIST OF ANNEXURE

I Energy Audit Reports 2 Selected Pictures

LIST OF FIGURES

I Pumping system efficiency category 11 2 Unit electricity consumption trend 13

LIST OF TABLES

1 Detail of WASAs pumps 8 2 Detail of Ravi Road subdivision 9 3 Typical overall pumping system efficiency classification 10 4 Detail of motor loading and pumping system efficiency 10 5 Detail of water discharge and electricity consumption 12 6 System energy efficiency potential of pumps 13

7A Interventions & investment required in WASA stations-Ravi Road Subdivision 15

7B Interventions & investment required in WASA stations-Ravi Road Subdivision 17

5

LIST OF ACRONYMS AND ABBREVIATIONS

Bhp Brake Horsepower Cusec Cubic Feet per Second Ehp Electrical Horsepower Gpm Gallon Per Minute Hp Horsepower kVA Kilo Volt Ampere kW Kilo Watt kWh Kilo Watt Hour LESCO Lahore Electric Supply Company m/s Meter Per Second m3/hr Cubic Meter Per Hour MCB Fuses or Miniature Circuit Breaker Mm Millimeter MS Mild Steel Psig Pound Per Square Inch (Gauge) RPM Revolution Per Minute TDH Total Dynamic Head VFD Variable Frequency Drive WASA Water and Sanitation Agency Whp Water Horsepower

GLOSSARY

Discharge Pressure

The pressure obtained at center line of pump discharge pipe using a calibrated gauge (psig). Discharge pressure is converted to feet and expressed as “Discharge Head”.

Brake Horsepower

The output horsepower of a motor to a pump; may also be used to refer to the required input horsepower to the pump itself.

Deep Well Turbine Pump

A turbine pump installed inside a well casing below the pumping water level in the well.

Discharge Head Head measured above center line of pump discharge pipe.

Drawdown The measured distance that a well’s water level changes from standing/static level to operating pumping level during observed test conditions.

Dynamic Head The sum of the pressure and the pumping head developed by a pump

Friction Head The head required to overcome the fluid friction in a pipe or water system

Friction Losses

Energy losses associated with moving water against rough surfaces. In water pumping applications, it is the water pressure lost as a result of contact between moving water and a pipeline or open channel.

GPM per Foot Drawdown

The ratio of capacity (GPM) to drawdown feet is useful in determining the well’s performance.

Head Alternate term for pressure. One pound per square inch (psi) = 2.31 feet of water head

Overall Plant The ratio of the water horsepower (the overall output of the plant)

6

or Pumping System Efficiency

to input horsepower (the power input). The overall output can also be defined as the amount of horsepower required to deliver the measured capacity (water gallons per minute) and the measured total head.

Pumping Water Level

The well’s operating water level below center line of discharge pipe as observed during test condition

Static Water Level The well’s water level obtained when pumping plant is at rest.

Suction Head Head measured above center line of pump suction intake. Most often obtained with calibrated bourdon tube pressure gauge (suction pressure) and converted to feet by conversion factor 2.31 ft. water/psi

Suction Lift The distance between pump discharge head and water level.

Total Head

The sum of the water head above and below the center line of the pump discharge pipe. For well applications, the Total Head is the sum of the Discharge Head and the Pumping Water Level. Total head is used in determination of water horsepower and pump performance.

Water Horsepower

The output horsepower of a water pump. It is the combination of flow rate and pressure.

7

1.0 Introduction 1.1 Background Energy Audit & Energy Efficiency Improvement gram Government of the Punjab, Pakistan with financial assistance from the World Bank, is implementing “Punjab Cities Governance Improvement Project (PCGIP)” for strengthening systems for improved planning, resource management, and accountability in five large cities of Punjab i.e. Lahore, Faisalabad, Multan, Gujranwala and Rawalpindi. The project utilizes a result-based approach and, consistent with this focus, the disbursement decisions to the city and its entities are based on achievement of pre-specified results, referred to as Disbursement linked Indicators (DLIs) which reflect priority elements in furthering the Government’s urban agenda, critical at the provincial level, within the existing legislative, regulative and policy framework of the Government. DLIs includes intermediate outcomes, incremental steps and results contributing to improved efficiency, effectiveness, accountability and service delivery during and beyond the project life by building capacities , system and processes . Disbursement Linked Indicator 4 (DLI -4) aims for improvements in own source revenue collection system that encourages the City Local Government (CDGs), Development Authorities (DAs) and Service providers (WASAs) to bring improved systems for revenue enhancement. This DLI is linked with the initiative of WASAs to carry out the Energy Audit for resources conservation and efficiency to improved service delivery, accountability and own source revenue. One of the proposed actions & initiatives to enhance revenue was to conduct energy audit of WASAs to reduce the power cost by various systematic analysis of the energy use and finding out the energy management opportunities. WASAs each year incur significant cost. It was Rs. 4,697 million in 2014 year for energy/Electricity bills, with an installed capacity of approximately 131 MW for 5,663 Million Gallons per Day (water management), which can be reduced through detailed energy audit and implementing its findings. In the context of existing scenario energy audit of WASAs is a technical and efficient way to obtain energy analysis and savings through improvements that optimize pumping systems of tube well stations and disposal stations to operate efficiently with significant cost saving. The Urban Planning and Management Services Unit, Pvt. Ltd. has assigned NEC Consultants Pvt. Ltd to conduct energy audits of WASAs in Punjab in five major cities of Lahore, Rawalpindi, Faisalabad, Multan and Gujranwala. This is the energy audit report of Ravi Road Subdivision of Lahore city. 1.2 Methodology The primary and secondary sources were used to collect data for different WASAs and pumps installed there. The Urban Unit provided information and contact detail of all the WASAs. An energy audit report template was developed to collect field data from each WASA subdivision. Prior to start the on field measurements of each subdivision, meetings were conducted with the respective WASA management and briefed them about the activity. The technical team then collected data by on field measurements of each pump and recorded in their energy audit report template. On the basis of this energy audit report template, The Urban Unit also developed Android based software to record data of each pump online. This data was also recorded on line in this Android based application. On the basis of field measurements, efficiency of the pumping system was calculated and

8

energy efficiency opportunities were identified. 1.3 Scope The scope of the this assignment is to conduct energy audits of about 1,600 fresh water supply and wastewater disposal pumps installed at different WASA stations in five major cities of Lahore, Rawalpindi, Multan, Faisalabad and Gujranwala. The detail of these pumps is given in Table-1.

Table-1: Detail of WASAs Pumps

WASA Population

Served (Million)

Total Water Connections

Total Sewerage

Connections

Total Supply

Stations

Total Disposal Stations

Total No. of Pump

Sets WASA Lahore 5.48 587,595 583,532 491 99 776

WASA Gujranwala 0.54 29,375 97,236 66 23 112

WASA Faisalabad 1.55 110,452 217,002 87 43 222

WASA Multan 1.2 43,996 175,615 102 21 161

WASA Rawalpindi 1.17 92,468 38,437 362 - 362

Total 9.94 863,886 1,111,822 1,108 186 1,633 The efficiency of each pumping system was evaluated and energy efficiency improvement opportunities were identified for those pumping systems whose efficiencies were not at required level. The detail of reports prepared is as under:

- The energy audit report of each pump was prepared. - On the basis of each pump report, summary report of findings of each WASA

subdivision was prepared. - On the basis of each subdivision summary report, one consolidated report of each city

for energy efficiency improvement opportunities of the WASAs was prepared.

9

2.0 Energy Audit Findings There are 20 WASA water supply stations and 09 wastewater disposal pumps in Ravi Road Subdivision. The detail of these stations along with pumps installed capacity and actual discharge is given in Table-2:

Table-2: Detail of Ravi Road Subdivision

# WASA Station

No. of Water Supply Pumps

Installed

Installed Capacity (Cusec)

Actual Discharge (Cusec)

1 Gulshan Riaz Colony 01 2.0 3.12 2 Shafiq Abad 01 2.0 0.68 3 Karim Park Old 01 4.0 5.04 4 Karim Park Block-03 01 4.0 4.10 5 Allah Wali Masjid 01 4.0 3.38 6 Rehmat Flour Mill 01 4.0 3.48 7 Yaseen Road 01 2.0 1.71 8 Ameen Park 01 2.0 2.20 9 Bagh Munshi Ladha 01 4.0 4.41 10 Shesh Mahal Road 01 3.0 4.62 11 Umer Park Old 01 2.0 0.15 12 Umer Park New 01 2.0 2.74 13 Adda Bajri Wala 01 4.0 2.94 14 Ravi Park-01 01 4.0 4.50 15 Munshi Hospital 01 4.0 4.73 16 Ibrahim Road 01 2.0 1.37 17 Salamat Mohallah 01 4.0 1.00 18 Sardar Chappal 01 4.0 0.26 19 Main Outfall New 01 5.0 4.65 20 Main Outfall Old 01 4.0 4.88 Total 20 66.0 59.96 Wastewater Disposal Pumps

21 Bagh Munshi Disposal-01 01 10.0 2.59 22 Bagh Munshi Disposal-02 01 20.0 7.49 23 Bagh Munshi Disposal-03 01 10.0 4.05 24 Bagh Munshi Disposal-04 01 20.0 7.95 25 Bagh Munshi Disposal-06 01 15.0 11.55 26 Marzi Pura disposal-01 01 5.0 1.66 27 Outfall Disposal-01 01 25.0 18.48 28 Outfall Disposal-02 01 25.0 19.85 29 Outfall Disposal-03 01 25.0 19.98 Total 09 155.0 93.60

The installed capacity of WASA tube wells of Ravi Road Subdivision is 39.31 million m3 per annum whereas actual discharge is 35.71 million m3 per annum, for average 16 hours per day operation and 365 days per year. This actual discharge is about 9% lesser than the installed capacity. The installed capacity of WASA disposal pumps of Ravi Road Subdivision is 69.24 million m3 per annum whereas actual discharge is 41.81 million m3 per annum, for average 12 hours per

10

day operation and 365 days per year. This actual discharge is about 40% lesser than the installed capacity. 2.1 Pumping System Efficiency Pumping plant performance can be classified as “Low”, “Fair”, “Good”, or “Excellent” by referring to the following table, which is based upon the results of thousands of pump tests conducted by Pacific Gas & Electric Company, USA. This classification is used to categorize WASA pumps.

Table-3: Typical Overall Pumping System Efficiency Classification

Motor HP Low Fair Good Excellent 3-7.5 <44.0 44-49.9 50-54.9 >54.9

10 <46.0 46-52.9 53-57.9 >57.9 15 <47.1 48-53.9 54-59.9 >59.9

20-25 <48.0 50-56.9 57-60.9 >60.9 30-50 <52.1 52.1-58.9 59-61.9 >61.9 60-75 <56.0 56-60.9 61-65.9 >65.9 100 <57.3 57.3-62.9 63-66.9 >66.9 150 <58.1 58.1-63.4 63.5-68.9 >68.9 200 <59.1 59.1-63.8 63.9-69.4 >69.4 250 <59.1 59.1-63.8 63.9-69.4 >69.4 300 <60 60-64.0 64.1-69.9 >69.9

Source: Pacific Gas & Electric Company, USA The detail of pumping system efficiency and motor loading of each WASA station is given in Table-4. The calculations for the efficiency determination are given in the energy audit report of each pump in Annexure-1.

Table-4: Detail of Motor Loading and Pumping System Efficiency

WASA Station Motor Load (%)

Pumping System Efficiency (%)

Pumping System Efficiency Rating

Gulshan Riaz Colony 81 84 EXCELLENT Karim Park Old 90 79 EXCELLENT Karim Park Block-03 74 72 EXCELLENT Ameen Park 80 68 EXCELLENT Bagh Munshi Ladha 88 81 EXCELLENT Umer Park New 97 83 EXCELLENT Ravi Park-01 89 69 EXCELLENT Main Outfall New 84 84 EXCELLENT Main Outfall Old 91 74 EXCELLENT Munshi Hospital 90 77 GOOD Shafiq Abad 30 58 FAIR Rehmat Flour Mill 85 59 FAIR Shesh Mahal Road 98 63 FAIR Sardar Chappal 22 13 LOW Allah Wali Masjid 93 48 LOW Yaseen Road 85 49 LOW Umer Park Old 25 13 LOW Adda Bajri Wala 87 44 LOW Ibrahim Road 91 33 LOW Salamat Mohallah 60 21 LOW

11

Disposal Pumps Bagh Munshi Disposal-02 44 33 LOW Bagh Munshi Disposal-01 31 26 LOW Bagh Munshi Disposal-03 48 31 LOW Bagh Munshi Disposal-04 47 27 LOW Bagh Munshi Disposal-06 91 50 LOW Marzi Pura disposal-01 39 37 LOW Outfall Disposal-01 86 30 LOW Outfall Disposal-02 93 31 LOW Outfall Disposal-03 94 31 LOW About 50% of the tube wells are under excellent and good category of pumping system efficiency whereas remaining 50% are under fair and low category as illustrated in Fig-1.

Figure-1: Pumping System Efficiency Category

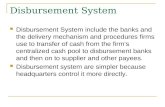

All the operational disposal pumps are under low category of pumping system efficiency. 2.2 Electricity Consumption Trend The detail of annual water discharge and correspondingly electricity consumption and unit electricity consumption of each WASA station is given in Table-5.

Excellent 45%

Good 5%

Fair 15%

Low 35%

12

Table-5: Detail of Water Discharge and Electricity Consumption

# WASA Station Annual Water

Discharge (m3)

Annual Electricity Consumption

(kWh)

Unit Electricity Consumption

(kWh/m3) 1 Gulshan Riaz Colony 1,862,960 285,346 0.15 2 Shafiq Abad 357,700 90,932 0.25 3 Karim Park Old 2,631,650 513,740 0.19 4 Karim Park Block-03 2,141,090 417,671 0.19 5 Allah Wali Masjid 1,762,950 522,474 0.29 6 Rehmat Flour Mill 1,814,050 484,303 0.26 7 Yaseen Road 894,250 262,007 0.29 8 Ameen Park 1,396,125 302,119 0.21 9 Bagh Munshi Ladha 2,299,500 497,300 0.21

10 Shesh Mahal Road 3,101,040 707,420 0.22 11 Umer Park Old 87,600 83,336 0.95 12 Umer Park New 1,533,000 313,033 0.20 13 Adda Bajri Wala 1,314,000 422,735 0.32 14 Ravi Park-01 2,014,800 431,542 0.21 15 Munshi Hospital 2,820,720 578,912 0.20 16 Ibrahim Road 868,700 340,610 0.39 17 Salamat Mohallah 483,990 314,849 0.65 18 Sardar Chappal 157,680 142,849 0.90 19 Main Outfall New 3,294,125 650,505 0.19 20 Main Outfall Old 3,453,630 701,402 0.20 Total 34,289,560 8,063,085 0.23 Disposal Pumps

21 Bagh Munshi Disposal-01 1,450,875 94,290 0.06 22 Bagh Munshi Disposal-02 4,182,900 218,303 0.05 23 Bagh Munshi Disposal-03 2,266,650 147,517 0.06 24 Bagh Munshi Disposal-04 4,440,225 288,593 0.06 25 Bagh Munshi Disposal-06 6,455,025 299,987 0.04 26 Marzi Pura disposal-01 931,298 97,207 0.10 27 Outfall Disposal-01 1,376,050 84,400 0.06 28 Outfall Disposal-02 1,478,250 91,886 0.06 29 Outfall Disposal-03 1,487,740 92,473 0.06 Total 24,069,013 1,414,656 0.05 Total annual energy cost of Ravi Road subdivision is about Rs. 123 million. The unit electricity consumption trend for each WASA station tube wells is illustrated in Fig-2. From figure, it is clear that 0.20 kWh/m3 is considered to be optimum figure for water supply pumps. This figure is based on NEC experience of conducting water turbine audits of different industries. WASA audits also reflect the similar figure.

13

Figure-2: Unit Electricity Consumption Trend

About 65% of the tube wells consume electricity more than the 0.20 kWh/m3. In case if all the 20 tube wells consume optimum electricity, then annually Rs. 16 million (15%) can be saved. 2.3 Pumping System Efficiency Improvement Potential The 10 tube wells and 09 disposal pumps having system efficiency in the category of FAIR to LOW, as given in Table-4, have the potential of efficiency improvement into the GOOD category. Table-6 gives detail of this efficiency improvement potential.

Table-6: System Energy Efficiency Potential of Pumps

WASA Station Existing Pumping Efficiency

(%)

Improved Pumping Efficiency

(%)

Annual

(kWh)

Saving

(Rs)

Impeller

Adjustment /Repair &

Maintenance

Intervention

Motor Replace

Pump Replace

Shafiq Abad 58 65 9,298 120,880 × Allah Wali Masjid

47 65 138,096 1,795,252 ×

Rehmat Flour Mill

59 65 44,597 579,759 ×

Yaseen Road 49 65 65,114 846,479 × Shesh Mahal Road

63 65 23,031 299,408 ×

Umer Park Old 13 68 67,251 874,260 × × Adda Bajri Wala 44 68 152,272 1,979,538 × Ibrahim Road 32 65 169,650 2,205,453 × Salamat Mohallah

21 65 211,381 2,747,954 ×

Sardar Chappal 13 68 115,682 1,503,860 × × Bagh Munshi Disposal-01

26 61 53,567 696,369 ×

Bagh Munshi 33 64 105,734 1,374,542 ×

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

kWh/m3

Optimum

14

Disposal-02 Bagh Munshi Disposal-03

31 61 72,669 944,697 ×

Bagh Munshi Disposal-04

27 64 166,201 2,160,616 ×

Bagh Munshi Disposal-06

50 61 56,064 728,830 ×

Marzi Pura disposal-01

37 61 38,790 504,275 ×

Outfall Disposal-01

30 63 44,078 573,013 ×

Outfall Disposal-02

31 63 47,324 615,206 ×

Outfall Disposal-03

31 63 47,504 617,547 ×

Total 1,628,303 21,167,938

2.4 Interventions for the Improvement of WASA Stations Energy audit activity of Ravi Road subdivision revealed that there are certain areas of electrical, mechanical and housekeeping which needs improvement. Table-7 presents detail of interventions and investment requirement in each WASA station for better, efficient and safe operation of WASA station. About Rs. 34.83 million are required to improve WASA stations of Ravi Road subdivision, Lahore.

15

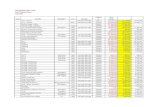

Table-7A: Interventions & Investment Required in WASA Stations- Ravi Road Subdivision

Intervention WASA Stations Gulshan

Riaz Shafiq Karim

Old Karim New

Allah Wali

Outfall New

Rehmat Flour

Yaseen Road

Ameen Park

Bagh Munshi

Shesh Mahel

Umer Old

Umer New

Adda Bajri

Ravi Park01

Electrical Install VFD × × × × × × × × × × × × × × × Install hour meter × × × × × × × × × × × × × × × Replace ampere meter × × × × × × × × × × Replace volt meter × × × × × × × Replace over current relays Replace over voltage relay Install/maintain PFI plant × × × × × × × × × × × × Install/connect capacitors at PFI plant

Install PFI control/relay × Install/replace motor terminal box /Improve open and loose motor connection

Improve panel condition × × × × × × Improve wiring condition × × × × × × Replace de-rated capacitors Relocate panel away from bore hole

Replace electrical motor Install fan in the panel Replace PFI HRC fuses Replace PFI display meter Correct date & time of electrical meter

Replace/correct electrical meter × Replace change over Replace main circuit breaker Mechanical Replace damaged/install new flow meter

× × × × × × × × × × × × × × ×

16

Intervention WASA Stations Gulshan

Riaz Shafiq Karim

Old Karim New

Allah Wali

Outfall New

Rehmat Flour

Yaseen Road

Ameen Park

Bagh Munshi

Shesh Mahel

Umer Old

Umer New

Adda Bajri

Ravi Park01

Replace damaged/install new digital pressure gauge

× × × × × × × × × × × × × × ×

Control gland leakage × × × × × × × × × × × × × × × Make operational/install new chlorinator

× × × × × × × × × × × ×

Maintain ratchet plate × × × Adjust impeller × × × × × × Repair & maintenance of pump × × × Replace existing pumping system × Maintain/install new non return valve

× ×

Housekeeping Improve general housekeeping × × × × Install shades on motor & pump Rain protection of motor & pump Fix panel properly Proper support of discharge pipeline

Maintain monthly record of fuel consumption

Station Wise Investment (M. Rs)

0.78 0.80 0.71 0.89 0.76 0.83 0.78 0.55 0.44 0.94 0.84 3.2 0.45 0.77 0.80

Annual Saving (M. Rs) 0.12 1.8 0.58 0.85 0.29 0.87 1.9 Payback (Year) 6.66 0.42 1.34 0.64 2.89 3.6 0.4

17

Table-7B: Interventions & Investment Required in WASA Stations- Ravi Road Subdivision Intervention WASA Stations Munshi Ibrahim Salamat Sardar Outfall

Old Bagh Disp-

01

Bagh Disp-02

Bagh Disp-03

Bagh Disp-

04

Bagh Disp-

06

Marzipur Disp-01

Outfal. Disp-

01

Outfal Disp-

02

Outfal. Disp-

03 Electrical Install VFD × × × × × Install hour meter × × × × × × × × × × × × × × Replace ampere meter × × × × Replace volt meter × × × × × × Replace over current relays Replace over voltage relay Install/maintain PFI plant × × × × × × × × × × × × Install/connect capacitors at PFI plant

Install PFI control/relay Install/replace motor terminal box /Improve open and loose motor connection

Improve panel condition × × × × Improve wiring condition × × × Replace de-rated capacitors Relocate panel away from bore hole Replace electrical motor Install fan in the panel Replace PFI HRC fuses Replace PFI display meter Correct date & time of electrical meter

Replace/correct electrical meter × Replace change over Replace main circuit breaker Mechanical Replace damaged/install new flow meter

× × × × × × × × × × × × × ×

18

Intervention WASA Stations Munshi Ibrahim Salamat Sardar Outfall

Old Bagh Disp-

01

Bagh Disp-02

Bagh Disp-03

Bagh Disp-

04

Bagh Disp-

06

Marzipur Disp-01

Outfal. Disp-

01

Outfal Disp-

02

Outfal. Disp-

03 Replace damaged/install new digital pressure gauge

× × × × × × × × × × × × × ×

Control gland leakage × × × × × Make operational/install new chlorinator

× ×

Maintain ratchet plate × × × Adjust impeller × × × × × × × Repair & maintenance of pump × × × Replace existing pumping system × × × × × Maintain/install new non return valve

× × ×

Housekeeping Improve general housekeeping × × × Install shades on motor & pump Rain protection of motor & pump Fix panel properly Proper support of discharge pipeline Maintain monthly record of fuel consumption

Station Wise Investment (M. Rs)

0.72 2.5 3.7 4.9 0.71 3.2 0.18 0.18 4.0 0.08 0.28 0.48 0.18 0.18

Annual Saving (M. Rs) 2.2 2.7 1.5 0.69 1.3 0.94 2.1 0.73 0.50 0.57 0.61 0.61 Payback (Year) 1.13 1.37 3.26 4.63 0.13 0.19 1.9 0.10 0.56 0.84 0.29 0.29 Total Investment of Subdivision (M.Rs) = 34.83

19

ANNEXURE-1

Energy Audit Reports

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Gulshan Riaz Colony

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact Mr. Ameer M Khan

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 16 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information (Pump Ref # CITY_FWPS/WWDS_Pump #)

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 5

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand KSB Country Pakistan

ii) Model B12 B/5 Serial 21-8-10-10312

iii) Certification Mark

iv) Year of Manufacture 2009

v) Flowrate (Q) 2 Cusec 204 m3/hr

vi) Head (H) 210 ft

vii) Discharge Pressure (P) 2.3 Psig

viii) Power / HP / BHP 59.5 BHP

ix) Speed (n) 1,450 RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 8 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data

i) Manufacturer Siemens

ii) Rated kW / hp 80 hp 60 kW

iii) Voltage Range (Volts) 380 Volts

iv) Current (Ampere) 115

v) Power Factor (Cos ɸ) 0.85

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,488 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 315 S

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading 31467.7

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 100 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant 25 KVAR

Panel Condition/Issues

Gland Leakage Normal

Non Return Valve ok

Chlorinator NA

Flow Meter NA

Pressure Gauge NA

Bore Hole in Front of Panel No

Wiring Poor

Housekeeping fair

Motor Terminal Fair

Foundation/Civil work ok

Ratchet Plate ok

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 8 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 319 m3/hr (Through Transit Time Ultrasonic Flowmeter)

Velocity in Pipe 2.73 m/sec

Pressure

i) Pressure at Discharge Side of Pump 2.3 Psig

ii) Pressure at Suction Side of Pump (Not Valid incase of Tubewells)

Levels

i) Static Water Level 35 meter

ii) Pumping Water Level 40 meter

Electric Measurements

i) Voltage 381 382.8 383.5

ii) Ampere 93 86 91

iii) Power Factor 0.79 0.78 0.83

iv) Appearant Power (kVA) 61 58 60.3

v) Running Power (kW) 48.6

vi) Reactive Power (kVAr) 37 35.5 33.5

vi) Motor Working on Loading Basis 81 %

Oversize Undersize Properly Sized

Poor/ Faulty A meter

Speed

i) Speed of Motor 1,495 RPM

ii) Speed of Pump Impeller 1,450 RPM

Noise Level

Noise Level (db(A)) Avg. Max: 88.2

Thermal Imaging

i) Motor Motor Pump Coupling

Pump Volute Casing Pump Bearings

Electric Panels

8 Calculations

i) Drawdown of Pump (Pumping water level - Static Water Level) 16.4 ft

ii) Static Suction Head (Only for WW Pump) ft

iii) Suction Side Frictional Head (Only for WW Pump) ft

iv) Dynamic Suction Head (ii+iii) (Only for WW Pump) ft

v) Discharge Head (Pressure Gauge) 5.313 ft

vi) Discharge Side Frictional Head 18.85 ft

vii) Dynamic Discharge Head (v+vi) 24.16 ft

viii) Total Dynamic Head of Pump (TDH) (vii + Pumping Water Level) 155.36 ft

ix) Specific Capacity of Pump (Water Turbine) gpm/ft of drawdown 85.64

x) Specific Speed of Pump

Ns = RPM x GPM0.5 / H0.75

impeller rpm necessary to produce 1gpm/ft head 1,235

500-10,000, standard, 2,000-3,000 high efficiency

xi) Difference of Pump Curve flow and Measured Flow at the TDH m3/hr

xii) Deviation of actual flow from the pump curve flow %

xiii) Water Horsepower (whp) (TDH x Actual Measured Flow) 55.10 hp

xiv) Brake Horsepower (bhp) (OEM Data) 59.5 hp

xv) Electrical Horsepower(ehp) (Electrical Measurement at Motor input) 65.15 hp

xvi) Efficiency of Individual Pump (ηpump) (whp/bhp) x 100 92.61 %

xvii) Efficiency of Pumping System (ηsystem)Existing (whp/ehp) x 100 84.58 %

xviii) Existing Specific Pumping Energy (En(pumping01)) 0.15 kWh/m3

xix) Avg. Cost of Energy (Based on Grid and Backup) 13 PKR/kWh

xx) Daily Operational Time of Pump 16 hrs

xxi) Daily Pump flow 5,104 m3/day

xxii) Annual working days 365 days

xxiii) Annual Pump flow 1,862,960 m3/yr

xxiv) Annual Energy Consumption of Pump (En(pumping01) x Annual Pump Flow) 285,346 kWh/yr

xxv) Annual Energy Expenditure on Pumping 3,709,496 PKR/Yr

xxvi) Pumping System Efficiency after Improvement 68 %

xxvii) Water Flow after Efficiency Improvement 256 m3/hr

xxviii) Specific Energy Consumption at New Efficiency 0.19 kWh/m3

9 Summary of Findings

Pumping system efficiency is 84%. For 80 HP motor efficiency >62% is considered to be excellent. This pumping system is efficient and requires no intervention.

10 Issues & Recommendations

ISSUES RECOMMENDATIONS

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

xiii)

xiv)

xv)

xvi)

xvii)

xviii)

Financial Analysis / Indicators

12 Estimated Investment for Improvement Plan 783,500 PKR

Replace A meter Defective A meter

Pressure gauge is not installed Install digital pressure gauge at discahrge pipeline

Install flowmeter No flowmeter

Replace PFI control unitPFI control is defective

No VFD installed Install VFD

There is moderate leakage at pump gland Remove leakage

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Shafiq Abad

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 14 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details 250

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information (Pump Ref # CITY_FWPS/WWDS_Pump #)

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 5

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand KSB Country Pakistan

ii) Model B12/B5 Serial 21-06-10-48/3

iii) Certification Mark

iv) Year of Manufacture 2006

v) Flowrate (Q) 2 Cusec 204 m3/hr

vi) Head (H) 220 ft

vii) Discharge Pressure (P) 19.8 Psig

viii) Power / HP / BHP 62.93 BHP

ix) Speed (n) 1,475 RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 8 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data NA

i) Manufacturer

ii) Rated kW / hp 80 hp 60 kW

iii) Voltage Range (Volts) Volts

iv) Current (Ampere)

v) Power Factor (Cos ɸ)

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,480 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 250 M

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading 33391.4

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 100 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant Not installed

Panel Condition/Issues

Gland Leakage Normal

Non Return Valve ok

Chlorinator NA

Flow Meter NA

Pressure Gauge NA

Bore Hole in Front of Panel No

Wiring POOR

Housekeeping Poor

Motor Terminal No terminal box

Foundation/Civil work ok

Ratchet Plate ok

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 8 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 70 m3/hr (Through Transit Time Ultrasonic Flowmeter)

Velocity in Pipe 0.60 m/sec

Pressure

i) Pressure at Discharge Side of Pump 19.8 Psig

ii) Pressure at Suction Side of Pump (Not Valid incase of Tubewells)

Levels

i) Static Water Level 35 meter

ii) Pumping Water Level 40 meter

Electric Measurements

i) Voltage 359.4 361.2 362.4

ii) Ampere 101 102 101

iii) Power Factor 0.49 0.46 0.47

iv) Appearant Power (kVA) 37 37 36.5

v) Running Power (kW) 17.7

vi) Reactive Power (kVAr) 32.63

vi) Motor Working on Loading Basis 29.6 %

Oversize Undersize Properly Sized

Poor

Speed

i) Speed of Motor 1,495 RPM

ii) Speed of Pump Impeller 1,475 RPM

Noise Level

Noise Level (db(A)) Avg. Max: 92.5

Thermal Imaging

i) Motor Motor Pump Coupling

Pump Volute Casing Pump Bearings

Electric Panels

8 Calculations

i) Drawdown of Pump (Pumping water level - Static Water Level) 16.4 ft

ii) Static Suction Head (Only for WW Pump) ft

iii) Suction Side Frictional Head (Only for WW Pump) ft

iv) Dynamic Suction Head (ii+iii) (Only for WW Pump) ft

v) Discharge Head (Pressure Gauge) 45.738 ft

vi) Discharge Side Frictional Head 0.95 ft

vii) Dynamic Discharge Head (v+vi) 46.69 ft

viii) Total Dynamic Head of Pump (TDH) (vii + Pumping Water Level) 177.89 ft

ix) Specific Capacity of Pump (Water Turbine) gpm/ft of drawdown 18.79

x) Specific Speed of Pump

Ns = RPM x GPM0.5 / H0.75

impeller rpm necessary to produce 1gpm/ft head 532

500-10,000, standard, 2,000-3,000 high efficiency

xi) Difference of Pump Curve flow and Measured Flow at the TDH m3/hr

xii) Deviation of actual flow from the pump curve flow %

xiii) Water Horsepower (whp) (TDH x Actual Measured Flow) 13.85 hp

xiv) Brake Horsepower (bhp) (OEM Data) 62.93 hp

xv) Electrical Horsepower(ehp) (Electrical Measurement at Motor input) 23.73 hp

xvi) Efficiency of Individual Pump (ηpump) (whp/bhp) x 100 22.00 %

xvii) Efficiency of Pumping System (ηsystem)Existing (whp/ehp) x 100 58.35 %

xviii) Existing Specific Pumping Energy (En(pumping01)) 0.25 kWh/m3

xix) Avg. Cost of Energy (Based on Grid and Backup) 13 PKR/kWh

xx) Daily Operational Time of Pump 14 hrs

xxi) Daily Pump flow 980 m3/day

xxii) Annual working days 365 days

xxiii) Annual Pump flow 357,700 m3/yr

xxiv) Annual Energy Consumption of Pump (En(pumping01) x Annual Pump Flow) 90,932 kWh/yr

xxv) Annual Energy Expenditure on Pumping 1,182,116 PKR/Yr

xxvi) Pumping System Efficiency after Improvement 65 %

xxvii) Water Flow after Efficiency Improvement 78 m3/hr

xxviii) Specific Energy Consumption at New Efficiency 0.23 kWh/m3

xxix) Potential of Energy Reduction 10.23 %

xxx) Reduced Annual Energy Consumption at Improved Efficiency 9,298 kWh/yr

xxxi) Annual Financial Saving on Pumping 120,880 PKR/Yr

9 Summary of Findings

Pumping system efficiency is 58%. For pump attached with 150 HP motor, efficiency <58% is LOW. This pumping system requires ampeller adjustment to increase the efficiency upto 65% which is GOOD. This intervention will save 120,880 Rs annually.

10 Issues & Recommendations

ISSUES RECOMMENDATIONS

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

xiii)

xiv)

xv)

xvi)

xvii)

xviii)

Financial Analysis / Indicators

12 Estimated Investment for Improvement Plan 803,000 PKR

Pressure gauge is not installed Install digital pressure gauge at discahrge pipeline

Install flowmeter Flow meter is not available

Install PFIPFI is not installed

No VFD installed Install VFD

There is moderate leakage at pump gland Remove leakage

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Karim Park new

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact Mr. Aamir Iqbal 0300-4688433

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 14 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Picture

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information (Pump Ref # CITY_FWPS/WWDS_Pump #)

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 4

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand KSB Country Pakistan

ii) Model B14/B4 Serial 9972688500/300

iii) Certification Mark

iv) Year of Manufacture 2014

v) Flowrate (Q) 4 Cusec 408 m3/hr

vi) Head (H) 210 15

vii) Discharge Pressure (P) Psig

viii) Power / HP / BHP 118.2 BHP

ix) Speed (n) 1,450 RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 10 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data

i) Manufacturer Siemens

ii) Rated kW / hp 150 hp 112.5 kW

iii) Voltage Range (Volts) 380 Volts

iv) Current (Ampere)

v) Power Factor (Cos ɸ) 0.84

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,488 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 315 S

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading 3368

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 200 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant 50 KVAR

Panel Condition/Issues

Gland Leakage Normal

Non Return Valve ok

Chlorinator ok

Flow Meter NA

Pressure Gauge NA

Bore Hole in Front of Panel No

Wiring Excellent

Housekeeping Good

Motor Terminal

Foundation/Civil work ok

Ratchet Plate ok

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 10 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 515 m3/hr (Through Transit Time Ultrasonic Flowmeter)

Velocity in Pipe 2.82 m/sec

Pressure

i) Pressure at Discharge Side of Pump 15 Psig

ii) Pressure at Suction Side of Pump (Not Valid incase of Tubewells)

Levels

i) Static Water Level 35 meter

ii) Pumping Water Level 40 meter

Electric Measurements

i) Voltage 388 388 389

ii) Ampere 166 173 163

iii) Power Factor 0.91 0.88 0.89

iv) Appearant Power (kVA) 111 116 110

v) Running Power (kW) 100

vi) Reactive Power (kVAr) 46 58 51

vi) Motor Working on Loading Basis 90 %

Oversize Undersize Properly Sized

Excellent

Speed

i) Speed of Motor 1,495 RPM

ii) Speed of Pump Impeller 1,475 RPM

Noise Level

Noise Level (db(A)) Avg. Max: 93.9

Thermal Imaging

i) Motor Motor Pump Coupling

Pump Volute Casing Pump Bearings

Electric Panels

8 Calculations

i) Drawdown of Pump (Pumping water level - Static Water Level) 16.4 ft

ii) Static Suction Head (Only for WW Pump) ft

iii) Suction Side Frictional Head (Only for WW Pump) ft

iv) Dynamic Suction Head (ii+iii) (Only for WW Pump) ft

v) Discharge Head (Pressure Gauge) 34.65 ft

vi) Discharge Side Frictional Head 19.25 ft

vii) Dynamic Discharge Head (v+vi) 53.90 ft

viii) Total Dynamic Head of Pump (TDH) (vii + Pumping Water Level) 185.10 ft

ix) Specific Capacity of Pump (Water Turbine) gpm/ft of drawdown 138.26

x) Specific Speed of Pump

Ns = RPM x GPM0.5 / H0.75

impeller rpm necessary to produce 1gpm/ft head 1,400

500-10,000, standard, 2,000-3,000 high efficiency

xi) Difference of Pump Curve flow and Measured Flow at the TDH m3/hr

xii) Deviation of actual flow from the pump curve flow %

xiii) Water Horsepower (whp) (TDH x Actual Measured Flow) 105.99 hp

xiv) Brake Horsepower (bhp) (OEM Data) 118.2 hp

xv) Electrical Horsepower(ehp) (Electrical Measurement at Motor input) 134 hp

xvi) Efficiency of Individual Pump (ηpump) (whp/bhp) x 100 89.67 %

xvii) Efficiency of Pumping System (ηsystem)Existing (whp/ehp) x 100 79.07 %

xviii) Existing Specific Pumping Energy (En(pumping01)) 0.20 kWh/m3

xix) Avg. Cost of Energy (Based on Grid and Backup) 13 PKR/kWh

xx) Daily Operational Time of Pump 14 hrs

xxi) Daily Pump flow 7,210 m3/day

xxii) Annual working days 365 days

xxiii) Annual Pump flow 2,631,650 m3/yr

xxiv) Annual Energy Consumption of Pump (En(pumping01) x Annual Pump Flow) 513,740 kWh/yr

xxv) Annual Energy Expenditure on Pumping 6,678,619 PKR/Yr

xxvi) Pumping System Efficiency after Improvement 68 %

xxvii) Water Flow after Efficiency Improvement 443 m3/hr

xxviii) Specific Energy Consumption at New Efficiency 0.23 kWh/m3

9 Summary of Findings

Pumping system efficiency is 80%. For pump attached with 150 HP motor, efficiency >69% is considered to be excellent. This pumping system does not require any energy efficiency measure.

10 Issues & Recommendations

ISSUES RECOMMENDATIONS

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

xiii)

xiv)

xv)

xvi)

xvii)

xviii)

Financial Analysis / Indicators

12 Estimated Investment for Improvement Plan 710,000 PKR

No flowmeter Install Flowmeter

Pressure gauge is not installed Install digital pressure gauge at discahrge pipeline

Install pressure guageNo pressure guage

No VFD installed Install VFD

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Karim Park Blk #3

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 14 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 4

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand Flow Pak Country

ii) Model 14 FMC/4SI Serial 14-1988

iii) Certification Mark

iv) Year of Manufacture 2014

v) Flowrate (Q) 4 Cusec 408 m3/hr

vi) Head (H) 210 ft

vii) Discharge Pressure (P) Psig

viii) Power / HP / 18.5 118.2 BHP

ix) Speed (n) 1,450 RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 10 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data

i) Manufacturer Siemens

ii) Rated kW / hp 150 hp 112.5 kW

iii) Voltage Range (Volts) 380 Volts

iv) Current (Ampere) 214

v) Power Factor (Cos ɸ) 0.86

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,488 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 315 S

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading Out of order

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 200 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant Not installed

Panel Condition/Issues

Gland Leakage Normal

Non Return Valve ok

Chlorinator Defected

Flow Meter NA

Pressure Gauge NA

Bore Hole in Front of Panel No

Wiring Good

Housekeeping fair

Motor Terminal

Foundation/Civil work ok

Ratchet Plate ok

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 10 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 419 m3/hr (Through Transit Time Ultrasonic Flowmeter)

Velocity in Pipe 2.30 m/sec

Pressure

i) Pressure at Discharge Side of Pump 10.5 Psig

ii) Pressure at Suction Side of Pump (Not Valid incase of Tubewells)

Levels

i) Static Water Level 35 meter

ii) Pumping Water Level 40 meter

Electric Measurements

i) Voltage 423 414 428

ii) Ampere 131 184 154

iii) Power Factor 0.63 0.67 0.86

iv) Appearant Power (kVA) 96 132 112

v) Running Power (kW) 81.3

vi) Reactive Power (kVAr) 74.6 98.4 55

vi) Motor Working on Loading Basis 73.9 %

Oversize Undersize Properly Sized

Good/Defective A meter

Speed

i) Speed of Motor 1,495 RPM

ii) Speed of Pump Impeller 1,475 RPM

Noise Level

Noise Level (db(A)) Avg. Max: 87.8

Thermal Imaging

i) Motor Motor Pump Coupling

Pump Volute Casing Pump Bearings

Electric Panels

8 Calculations

i) Drawdown of Pump (Pumping water level - Static Water Level) 16.4 ft

ii) Static Suction Head (Only for WW Pump) ft

iii) Suction Side Frictional Head (Only for WW Pump) ft

iv) Dynamic Suction Head (ii+iii) (Only for WW Pump) ft

v) Discharge Head (Pressure Gauge) 24.255 ft

vi) Discharge Side Frictional Head 12.80 ft

vii) Dynamic Discharge Head (v+vi) 37.06 ft

viii) Total Dynamic Head of Pump (TDH) (vii + Pumping Water Level) 168.26 ft

ix) Specific Capacity of Pump (Water Turbine) gpm/ft of drawdown 112.49

x) Specific Speed of Pump

Ns = RPM x GPM0.5 / H0.75

impeller rpm necessary to produce 1gpm/ft head 1,356

500-10,000, standard, 2,000-3,000 high efficiency

xi) Difference of Pump Curve flow and Measured Flow at the TDH m3/hr

xii) Deviation of actual flow from the pump curve flow %

xiii) Water Horsepower (whp) (TDH x Actual Measured Flow) 78.39 hp

xiv) Brake Horsepower (bhp) (OEM Data) 118.2 hp

xv) Electrical Horsepower(ehp) (Electrical Measurement at Motor input) 109 hp

xvi) Efficiency of Individual Pump (ηpump) (whp/bhp) x 100 66.32 %

xvii) Efficiency of Pumping System (ηsystem)Existing (whp/ehp) x 100 71.93 %

xviii) Existing Specific Pumping Energy (En(pumping01)) 0.20 kWh/m3

xix) Avg. Cost of Energy (Based on Grid and Backup) 13 PKR/kWh

xx) Daily Operational Time of Pump 14 hrs

xxi) Daily Pump flow 5,866 m3/day

xxii) Annual working days 365 days

xxiii) Annual Pump flow 2,141,090 m3/yr

xxiv) Annual Energy Consumption of Pump (En(pumping01) x Annual Pump Flow) 417,671 kWh/yr

xxv) Annual Energy Expenditure on Pumping 5,429,717 PKR/Yr

9 Summary of Findings

Pumping system efficiency is 71%. For pumping system with motor 150 HP efficiency >69% is excellent. This pumping system doest not require any energy efficiency measure

10 Issues & Recommendations

ISSUES RECOMMENDATIONS

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

xiii)

xiv)

xv)

xvi)

xvii)

xviii)

Financial Analysis / Indicators

12 Estimated Investment for Improvement Plan 893,500 PKR

Pressure gauge is not installed Install digital pressure gauge at discahrge pipeline

Install chlorinatorFaulty chlorinator

PFI plant of 50 KVAR is recommendedPFI plant is not installed

No VFD installed Install VFD

Defective A meter Install A meter

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Allah Wali Masjid

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact Mr. Ameer Afzal

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 14 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information (Pump Ref # CITY_FWPS/WWDS_Pump #)

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 4

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand KSB Country Pakistan

ii) Model B1/B4 Serial 21-05-10-4631

iii) Certification Mark

iv) Year of Manufacture 2005

v) Flowrate (Q) 4 Cusec 408 m3/hr

vi) Head (H) 220 ft

vii) Discharge Pressure (P) Psig

viii) Power / HP / BHP 122.63 BHP

ix) Speed (n) 1,485 RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 10 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data

i) Manufacturer Siemens

ii) Rated kW / hp 150 hp 112.5 kW

iii) Voltage Range (Volts) 380 Volts

iv) Current (Ampere)

v) Power Factor (Cos ɸ) 0.84

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,488 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 315 S

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading 48456.61

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 200 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant 25 kvar

Panel Condition/Issues

Gland Leakage Normal

Non Return Valve ok

Chlorinator Faulty

Flow Meter NA

Pressure Gauge NA

Bore Hole in Front of Panel No

Wiring Fair

Housekeeping Fair

Motor Terminal

Foundation/Civil work ok

Ratchet Plate Faulty

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 10 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 345 m3/hr (Through Transit Time Ultrasonic Flowmeter)

Velocity in Pipe 1.89 m/sec

Pressure

i) Pressure at Discharge Side of Pump 13 Psig

ii) Pressure at Suction Side of Pump (Not Valid incase of Tubewells)

Levels

i) Static Water Level 35 meter

ii) Pumping Water Level 40 meter

Electric Measurements

i) Voltage 381 380 381

ii) Ampere 175 183 173

iii) Power Factor 0.9 0.8 0.87

iv) Appearant Power (kVA) 115 120 114

v) Running Power (kW) 101.7

vi) Reactive Power (kVAr) 50 62.9 55

vi) Motor Working on Loading Basis 92.8 %

Oversize Undersize Properly Sized

Good/ Defective A and V meter

Speed

i) Speed of Motor 1,495 RPM

ii) Speed of Pump Impeller 1,475 RPM

Noise Level

Noise Level (db(A)) Avg. Max: 92.3

Thermal Imaging

i) Motor Motor Pump Coupling

Pump Volute Casing Pump Bearings

Electric Panels

8 Calculations

i) Drawdown of Pump (Pumping water level - Static Water Level) 16.4 ft

ii) Static Suction Head (Only for WW Pump) ft

iii) Suction Side Frictional Head (Only for WW Pump) ft

iv) Dynamic Suction Head (ii+iii) (Only for WW Pump) ft

v) Discharge Head (Pressure Gauge) 30.03 ft

vi) Discharge Side Frictional Head 8.72 ft

vii) Dynamic Discharge Head (v+vi) 38.75 ft

viii) Total Dynamic Head of Pump (TDH) (vii + Pumping Water Level) 169.95 ft

ix) Specific Capacity of Pump (Water Turbine) gpm/ft of drawdown 92.62

x) Specific Speed of Pump

Ns = RPM x GPM0.5 / H0.75

impeller rpm necessary to produce 1gpm/ft head 1,221

500-10,000, standard, 2,000-3,000 high efficiency

xi) Difference of Pump Curve flow and Measured Flow at the TDH m3/hr

xii) Deviation of actual flow from the pump curve flow %

xiii) Water Horsepower (whp) (TDH x Actual Measured Flow) 65.19 hp

xiv) Brake Horsepower (bhp) (OEM Data) 122.63 hp

xv) Electrical Horsepower(ehp) (Electrical Measurement at Motor input) 136 hp

xvi) Efficiency of Individual Pump (ηpump) (whp/bhp) x 100 53.16 %

xvii) Efficiency of Pumping System (ηsystem)Existing (whp/ehp) x 100 47.82 %

xviii) Existing Specific Pumping Energy (En(pumping01)) 0.30 kWh/m3

xix) Avg. Cost of Energy (Based on Grid and Backup) 13 PKR/kWh

xx) Daily Operational Time of Pump 14 hrs

xxi) Daily Pump flow 4,830 m3/day

xxii) Annual working days 365 days

xxiii) Annual Pump flow 1,762,950 m3/yr

xxiv) Annual Energy Consumption of Pump (En(pumping01) x Annual Pump Flow) 522,474 kWh/yr

xxv) Annual Energy Expenditure on Pumping 6,792,156 PKR/Yr

xxvi) Pumping System Efficiency after Improvement 65 %

xxvii) Water Flow after Efficiency Improvement 469 m3/hr

xxviii) Specific Energy Consumption at New Efficiency 0.22 kWh/m3

xxix) Potential of Energy Reduction 26.43 %

xxx) Reduced Annual Energy Consumption at Improved Efficiency 138,096 kWh/yr

xxxi) Annual Financial Saving on Pumping 1,795,252 PKR/Yr

9 Summary of Findings

Pumping system efficiency is 47%. For pump attached with 150 HP motor, efficiency below <58% is considered to be LOW (>68.9 is excellent). This pumping system requires impeler adjustment, repair and maintenance. This intervention will save 1,795,252 Rs annually

10 Issues & Recommendations

ISSUES RECOMMENDATIONS

i)

ii)

iii)

iv)

v)

vi)

vii)

viii)

ix)

x)

xi)

xii)

xiii)

xiv)

xv)

xvi)

xvii)

xviii)

Financial Analysis / Indicators

12 Estimated Investment for Improvement Plan 759,000 PKR

Install flow meter No flow meter

Replace PFI control unitDefective PFI control

No VFD installed Install VFD

There is moderate leakage at pump gland Remove leakage

Pressure gauge is not installed Install digital pressure gauge at discahrge pipeline

Install A and V meter Defective A and V meter

Defective chlorinator Install chlorinator

1 Pumping Station Information

1 Fresh Water Supply

2 Wastewater Disposal

3 Waste Water Treatment Plant

4 Water Treatment Plant

Name of Engineer

WASA Staff Name

i) Name of Pumping Station Main Outfall NEW

ii) Name of Subdivision Ravi Road , Lahore

iii) Operator Name & Contact Shaukat Ali 0300 4266838

iv) Total Number of Pumps Installed 1

v) Total Number of Pumps in Operation 1

vi) Year of Starting Operation

vii) Types of Pumps

Standard Deep Well Water Turbine Pumps Qty 1

Submersible Deep Well Water Turbine Pumps Qty

Centrifugal Pump Qty

vi) Operational Scheme of Pumps Qty

Independent 1

Series

Parallel

vii) Any Header / Tank / Reservoir

Yes No

viii) Any Record Keeping

Time Flow Pressure

Level Quality of Water Power Consumption

Maintenance Record Electricity Bill Fuel Consumption Data

viii) Daily Operational Time 19 hrs/day

ix) Annual Working Days 365 days

x) Source of Power

Energy Report of WASA Pumps

Primary LESCO Secondary

xi) In Case of Secondary Power Source Fuel Data Details

xii) Operational Hours of Secondary Power Source hrs/day

2 Pump Basic Information

i) Type of Pump Deep Well

Submersible

Overhung

Between Bearing

ii) Mounting / Erection

Horizontal Vertical

Foundation

iii) Concrete Bolted Bolted

iv) Lubrication Type

Oil Water

v) Cooling Type

Water Cooled Air Cooled

vi) Number of Stages

Single Multi 4

vii) Pump and Motor Assembly

Direct Coupled Belt / Gear

viii) Source of Suction

Ground Water Aquafier Overhead Tank Underground Tank

Pressurized Source

ix) Pump Discharge Destination

Overhead Tank Drain On Ground Reservoir

Fresh Water Supply Network

Pump Operational Scheme

On / OFF Proportional

x) Pump Flow Control

Throttle VFD Controlled

xi) Any Retrofits ?

Impeller Detail

Casing / Volute Detail

Line Shaft (DW) Detail

Column Sett. (DW) Detail

Motor Replacement Detail

Motor Rewinding Detail

xii) Self Priming

Yes No NA (not applicable)

xiii) Non Clogging (In case of wastewater)

Yes No

3 Pump Nameplate Data

i) Make / Brand KSB Country

ii) Model B14 D/2 Serial 6102

iii) Certification Mark

iv) Year of Manufacture

v) Flowrate (Q) 5 Cusec 510 m3/hr

vi) Head (H) ft

vii) Discharge Pressure (P) Psig

viii) Power / HP / BHP 153.2 BHP

ix) Speed (n) RPM

x) Maximum Pressure (Pmax)

xi) Maxiumum Allowable Temperature

4 Piping System

Suction Side

Select Pipe Material of Construction MS Pipe

i) Enter Diameter of Suction Pipe (In) 10 (Not Valid incase of Tubewells)

ii) Enter Length of Suction Pipe (ft) (Not Valid incase of Tubewells)

iii) Enter Fittings on Suction Pipe (Not Valid incase of Tubewells)

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Foot Valve 1

Bends

Strainer 1

iv) Storage Capacity of Suction Source (Aquafier)

v) Working Volume of Source

vi) Suction Lift (from Datum Line)

ix) Suction Pressure (Not Valid incase of Tubewells)

Discharge Side

Pipe Material of Construction MS Pipe

i) Diameter of Discharge Pipe 10 inch

ii) Length of Discharge Pipe (Not known as directly connected to network underground)

iii) Fittings on Discharge Pipe

Fitting Type 1 Qty Type 2 Qty Type 3 Qty

Valves Control 1 Check 1

Bends Elbow 1

Strainer

iv) Storage Capacity of Discharge Destination (Not known as directly connected to network underground))

v) Working Volume of Discharge Destination (Not known as directly connected to network underground))

vi) Discharge Elevation (from Datum Line) (In case of no gauge)

5 Motor Nameplate Data

i) Manufacturer Siemens

ii) Rated kW / hp 150 hp 112.5 kW

iii) Voltage Range (Volts) 380 Volts

iv) Current (Ampere)

v) Power Factor (Cos ɸ) 0.86

Efficiency Class

IE3 Eff 1

IE2 Eff 2

IE1 Eff 3

Standard Efficiency

vi) Motor Speed 1,485 RPM

vii) Reference Frequency 50 C/S

viii) Insulation Class F

ix) Motor Frame Size 350 S

6 Electrical & Mechanical System Observations

i) Electrical Meter Reference Number

ii) Meter Reading

iii) Meter Time and Date

Correct FALSE

Lag by Lead by

iv) Transformer Rating (kVA) 200 Condition OK

Pump O & M Cost

v) Motor Starting Method

Direct Online Star (Wye) - Delta

Autotransformer Starter Soft Starter

Variable Frequency Drives

v) Electrical Protections Available

Earthing / Grounding Fuses or Miniature Circuit Breaker (MCB)

Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB)

PFI Plant 50 KVAR

Panel Condition/Issues

Gland Leakage Significant

Non Return Valve Faulty

Chlorinator Faulty

Flow Meter NA'

Pressure Gauge NA'

Bore Hole in Front of Panel No

Wiring Fair

Housekeeping Fair

Motor Terminal

Foundation/Civil work ok

Ratchet Plate ok'

7 Field Measurements

Flow Measurement

i) Flow Measurement Location

Discharge Pipe Suction Pipe

ii) Pipe Material of Construction MS Pipe

iii) Paint on Pipe Yes No

iv) Pipe Diameter 10 inches (on which flowmeter is clamped)

v) Pipe Perimeter mm (on which flowmeter is clamped)

vi) Type of Clamping (V/N/Z) V

viii) Flow Measurement 475 m3/hr (Through Transit Time Ultrasonic Flowmeter)