PB0001 - Kimray · PDF filePB0001 Dec. 2017. High Pressure Control Valves ... Kimray conform...

Transcript of PB0001 - Kimray · PDF filePB0001 Dec. 2017. High Pressure Control Valves ... Kimray conform...

High Pressure Control Valves Model PB

Product Bulletin

1Kimray Inc.- 52 NW 42nd Street Oklahoma City, Ok 73118 USA - Ph: (405) 525-6601, Fax: (405) 525-7520 - Kimray.com

Summary:Valve Description Cage Guided globe valveNormal Service Liquid or GasConnection Size: 2 in. - 10 in.

(50 mm - 250 mm) DN 25 - DN 225

Body Style: ThroughConnection Type: Threaded (NPT), Flanged or

Socket WeldActuation: Fail Open or Fail Closed

Single Acting Spring ReturnControl: Upstream or DownstreamTemperature: -20°F to 500°F

-29°C to 260°CCold Working Maximum Pressure:

6000 psig413 bar

Options: Reduced trim capacityTrim materialElastomer materialQuick exhaust slam-shutActuator spring rangesAdjustable actuatorCoatings

IntroductionThe Kimray High Pressure Control Valve is designed for controlling a variety of fluids at pressures up to 6000 psig (413 bar) and can be used for the discharge of liquid or gas from vessels, separators, treaters, knockouts, similar liquid accumulators and other areas of natural gas production. The Kimray High Pressure Control Valve comes with a variety of connection types from 2 inches to 10 inches (50 mm to 250 mm).

NOTE

This information is presented in good faith. Kimray assumes no liability for advice or recommendations made concerning results to be obtained from the user of any Kimray product or service. Responsibility for the selection, use and maintenance of any Kimray products remain with the purchaser and end-user.

Kimray reserves the right to modify or improve the designs or specifications of such products at any time without prior notice.

Contents Page

Body Styles 3,4

Valve Dimensions 5

Specifications 6,7

Elastomers 8

Valve Trim 9,10,11

Packing Box 12

Actuators 13

Model Code 14, 15

High Pressure Control Valve

PB0001Dec. 2017

High Pressure Control Valves Model PB

Product Bulletin

2

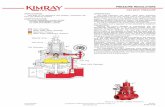

Adjusting Screw

Coupling Block

Actuator Base

Packing Box

Bonnet

Piston/Cage Assembly

Ratio Plug

Rugged Actuator Design

● Standard actuator is made from Ductile Iron (ASTM-A395) ● Capable of 45 psig (3.1 bar) diaphragm pressure for actuation ● Multiple spring options make it ideal for operation with I/P or electro-pneumatic positioners ● An optional “65 Topworks” actuator is available with an adjustable spring from 10 psig to 30 psig (0.68 bar to 2 bar) and is made from 1018CW ASTM 108 steel. ● Reversible Actuator allows simple change from “fail close” to “fail open” with no extra parts required.

Open Yoke Design

● Allows for position indicator to be easily seen from any direction. ● Open or closed scale on all models. ● Prevents process fluids from energizing the diaphragm if packing box leaks.● Four bolts hold actuator to the valve body for easy access to trim com-ponents.

Balanced Piston Design

● Upstream balanced piston assembly for bubble tight shut off (Class VI, ANSI/FCI 70.2) against upstream pressure. ● Smooth control when used as a pressure regulator. ● Pressure drop does not effect activation pressure.

Optional Trim Sizes

● Standard trim available with full line size port to offer maximum flow. ● Easy to change reduced ratio plug. ● Reduce port size while maintaining equal percentage trim characteris-tics. ● One bolt holds the ratio plug to the piston for a quick and easy change.

Soft Seat Seal

● Soft seat placed in the valve body and out of the flow path for longer life against abrasive conditions.

Upper Piston Seat

● Several materials available to accommodate abrasive and corrosive services (Table 10 - Upper Piston Seat Material). ● Replace upper piston seat without replacing the piston.

Steel Body

● Standard globe valve body is made from cast steel A216-WCB with optional CF8M material available.

NACE Compliance

● Special materials available for sour service application in accordance with the requirements of NACE specification MR0175.

Features

Figure 1

Upper Piston Seat

Yoke

Body

High Pressure Control Valves Model PB

Product Bulletin

3

* Standard body is A216-WCB* KIMCOAT coating available for any body material

Kimray body materials conform to ASME B16.5-1996 for external dimensions, working pressure class rating per ASME B16.34 and face to face per ANSI 75.08.01-2002.

Table 1 - Body Materials and End ConnectionsMain ValveBody Size Material Group ASTM Group Available Connections

2 inch (50 mm)

WCB A216-WCB 1500 psig, 4000 psig, or 6000 psig NPT (103 bar, 275 bar, 413 bar)

LCC A352-LCC 1500 psig, 4000 psig, or 6000 psig NPT (103 bar, 275 bar, 413 bar)

CF8M A351-CF8M 1500 psig, 4000 psig, or 6000 psig NPT (103 bar, 275 bar, 413 bar)

WCB A216-WCB 150RF, 300RF, 600RF, 1500RF

LCC A352-LCC 150RF, 300RF, 600RF, 1500RF

CF8M A351-CF8M 150RF, 300RF, 600RF, 1500RF

WCB A216-WCB 300RTJ, 600RTJ, 1500RTJ

LCC A352-LCC 300RTJ, 600RTJ, 1500RTJ

CF8M A351-CF8M 300RTJ, 600RTJ, 1500RTJ

2 in with 3 in RF (50 mm with 80 mm RF)

WCB A216-WCB 300RF, 600RF

2 in with 3 in RTJ(50 mm with 80 mm RTJ)

WCB A216-WCB 300RTJ, 1500RTJ

2 in with 4 in RF(2 mm with 100 mm RF

WCB A216-WCB 300RF, 600RF

3 in (80 mm)

WCB A216-WCB 150RF, 300RF, 600RF

LCC A352-LCC 150RF, 300RF, 600RF

CF8M A351-CF8M 150RF, 300RF, 600RF

WCB A216-WCB 300RTJ, 600RTJ

LCC A352-LCC 300RTJ, 600RTJ

CF8M A351-CF8M 300RTJ, 600RTJ

3 in with 4 in RF(80 mm with 100 mm RF)

WCB A216-WCB 300RF

4”, 6”, 8”, 10”

WCB A216-WCB 150RF, 300RF, 600RF

LCC A352-LCC 150RF, 300RF, 600RF

CF8M A351-CF8M 150RF, 300RF, 600RF

WCB A216-WCB 150RTJ, 300RTJ, 600RTJ

LCC A352-LCC 150RTJ, 300RTJ, 600RTJ

CF8M A351-CF8M 150RTJ, 300RTJ, 600RTJ

High Pressure Control Valves Model PB

Product Bulletin

4

Table 2 - Temperature vs. Pressure Rating

Temperature°F (°C)

Flange Class

150 300 600 900 1500 2500

Hydrostatic Test Pressure (psig)450 (31 bar) 1125 (77.5 bar) 2250 (153.4 bar) 3375 (230.9 bar) 5625 (384.3 bar) 9375 (639.4 bar)

*Maximum Allowable Non-Shock Pressure (psig)

WCB - A216-WCB-20 to 100 (-28 to 37) 285 (19.7 bar) 740 (51.0 bar) 1480 (102 bar) 2220 (153.1 bar) 3705 (255.5 bar) 6170 (425.4 bar)

200 (93) 260 (17.9 bar) 680 (46.9 bar) 1360 (93.8 bar) 2035 (140.3 bar) 3395 (234.1 bar) 5655 (389.9 bar)

300 (148) 230 (15.9 bar) 655 (45.2 bar) 1310 (90.3 bar) 1965 (135.5 bar) 3270 (225.5 bar) 5450 (375.8 bar)

400 (204) 200 (13.8 bar) 635 (43.8 bar) 1265 (87.2 bar) 1900 (131.0 bar) 3170 (218.6 bar) 5280 (364.0 bar)

500 (260) 170 (11.7 bar) 605 (41.7 bar) 1205 (83.1 bar) 1810 (124.8 bar) 3015 (207.9 bar) 5025 (346.5 bar)

600 (315) 140 (9.7 bar) 570 (39.3 bar) 1135 (78.3 bar) 1705 (117.6 bar) 2840 (195.8 bar) 4730 (326.1 bar)

650 (343) 125 (8.6 bar) 550 (37.9 bar) 1100 (75.8 bar) 1650 (113.8 bar) 2745 (189.3 bar) 4575 (315.4 bar)

700 (371) 110 (7.6 bar) 530 (36.5 bar) 1060 (73.1 bar) 1590 (109.6 bar) 2665 (183.7 bar) 4425 (305.1 bar)

LCC - A352-LCCFlange Class

150 300 600 900 1500 2500

-20 to 100 (-28 to 37) 290 (20.0 bar) 750 (51.7 bar) 1500 (103.4 bar) 2250 (155.1 bar) 3750 (258.6 bar) 6250 (430.9 bar)

200 (93) 260 (17.9 bar) 750 (51.7 bar) 1500 (103.4 bar) 2250 (155.1 bar) 3750 (258.6 bar) 6250 (430.9 bar)

300 (148) 230 (15.9 bar) 730 (50.3 bar) 1455 (100.3 bar) 2185 (150.7 bar) 3640 (251.0 bar) 6070 (418.5 bar)

400 (204) 200 (13.8 bar) 705 (48.6 bar) 1405 (96.9 bar) 2110 (145.5 bar) 3520 (242.7 bar) 5865 (404.4 bar)

500 (260) 170 (11.7 bar) 665 (45.9 bar) 1330 (91.7 bar) 1995 (137.6 bar) 3325 (229.3 bar) 5540 (382.0 bar)

600 (315) 140 (9.7 bar) 605 (41.7 bar) 1210 (83.4 bar) 1815 (125.1 bar) 3025 (208.6 bar) 5040 (347.5 bar)

650 (343) 125 (8.6 bar) 590 (40.7 bar) 1175 (81.0 bar) 1765 (121.7 bar) 2940 (202.7 bar) 4905 (338.2 bar)

700 (371) 110 (7.6 bar) 555 (38.3 bar) 1110 (76.5 bar) 1665 (114.8 bar) 2775 (191.3 bar) 4630 (319.2 bar)

CF8M - A351-CF8MFlange Class

150 300 600 900 1500 2500

-20 to 100 (-28 to 37) 275 (19.0 bar) 720 (49.6 bar) 1440 (99.3 bar) 2160 (148.9 bar) 3600 (248.2 bar) 6000 (413.7 bar)

200 (93) 235 (16.2 bar) 620 (42.7 bar) 1240 (85.5 bar) 1860 (128.2 bar) 3095 (213.4 bar) 5160 (355.8 bar)

300 (148) 215 (14.8 bar) 560 (38.6 bar) 1120 (77.2 bar) 1680 (115.8 bar) 2795 (192.7 bar) 4660 (321.3 bar)

400 (204) 195 (13.4 bar) 515 (35.5 bar) 1025 (70.7 bar) 1540 (106.2 bar) 2570 (177.2 bar) 4280 (295.1 bar)

500 (260) 170 (11.7 bar) 480 (33.1 bar) 955 (65.8 bar) 1435 (98.9 bar) 2390 (164.8 bar) 3980 (274.4 bar)

600 (315) 140 (9.7 bar) 450 (31.0 bar) 900 (62.1 bar) 1355 (93.4 bar) 2255 (155.5 bar) 3760 (259.2 bar)

650 (343) 125 (8.6 bar) 440 (30.3 bar) 885 (61.0 bar) 1325 (91.4 bar) 2210 (152.4 bar) 3680 (253.7 bar)

700 (371) 110 (7.6 bar) 435 (30 bar) 870 (60.0 bar) 1305 (90.0 bar) 2170 (149.6 bar) 3620 (249.6 bar)

Kimray conform to ASME B16.34-2009 for working pressure vs working temperature and ASME B16.5-1996 for flanges and flanged fittings.

*Kimray HPCV PB valve is capable of full rated pressure drop.

High Pressure Control Valves Model PB

Product Bulletin

5

Figure 2

�

�

�

�

Kimray valve dimensions conform to ANSI/ISA 75 series.

Table 3 - Valve Dimensions

Piston Balanced

End Connection

A B C D Weight

2”

150RF 10.00 in. (254 mm) 5.62 in. (142 mm) 17.0 in. (431 mm) 12.87 in. (327 mm) 100 lb (45.3 kg)

300RF 10.50 in. (266 mm) 5.62 in. (142 mm) 17.0 in. (431 mm) 12.87 in. (327 mm) 121 lb (54.8 kg)

600RF 11.25 in. (285 mm) 5.62 in. (142 mm) 17.0 in. (431 mm) 12.87 in. (327 mm) 121 lb (54.8 kg)

1500RF 13.37 in. (339 mm) 5.62 in. (142 mm) 17.0 in. (431 mm) 12.87 in. (327 mm) 150 lb (68.0 kg)

1500RTJ 13.50 in. (342 mm) 5.62 in. (142 mm) 17.0 in. (431 mm) 12.87 in. (327 mm) 170 lb (77.1 kg)

3”

150RF 11.75 in. (298 mm) 7.25 in. (184 mm) 27.0 in. (685 mm) 15.75 in. (400 mm) 263 lb (119.3 kg)

300RF 12.50 in. (317 mm) 7.25 in. (184 mm) 27.0 in. (685 mm) 15.75 in. (400 mm) 263 lb (119.3 kg)

600RF 13.25 in. (336 mm) 7.25 in. (184 mm) 27.0 in. (685 mm) 15.75 in. (400 mm) 263 lb (119.3 kg)

600RTJ 13.37 in. (339 mm) 7.25 in. (184 mm) 27.0 in. (685 mm) 15.75 in. (400 mm) 263 lb (119.3 kg)

4”150RF 13.87 in. (352 mm) 11.00 in. (279 mm) 30.0 in. (762 mm) 15.75 in. (400 mm) 365 lb (165.6 kg)

300RF 14.50 in. (368 mm) 11.00 in. (279 mm) 30.0 in. (762 mm) 15.75 in. (400 mm) 365 lb (165.6 kg)

600RF 15.50 in. (393 mm) 11.00 in. (279 mm) 30.0 in. (762 mm) 15.75 in. (400 mm) 365 lb (165.6 kg)

6”150RF 17.75 in. (450 mm) 11.18 in. (284 mm) 34.5 in. (876 mm) 20.43 in. (519 mm) 700 lb (317.5 kg)

300RF 18.62 in. (473 mm) 11.18 in. (284 mm) 34.5 in. (876 mm) 20.43 in. (519 mm) 740 lb (335.6 kg)

600RF 20.06 in. (509 mm) 11.18 in. (284 mm) 34.5 in. (876 mm) 20.43 in. (519 mm) 840 lb (381.0 kg)

8”150RF 21.37 in. (568 mm) 21.37 in. (542 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) 830 lb (376.5 kg)

300RF 22.37 in. (569 mm) 22.37 in. (568 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) 1040 lb (471.7 kg)

600RF 24.00 in. (609 mm) 24.00 in. (609 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) 1040 lb (471.7 kg)

10”

150RF 26.50 in. (752 mm) 11.28 in. (286 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) lb ( kg)

300RF 27.87 in. (708 mm) 11.31 in. (287 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) 1200 lb (544.3 kg)

600RF 29.56 in. (750 mm) 11.93 in. (303 mm) 34.5 in. (876 mm) 20.50 in. (520 mm) 1400 lb (635.0 kg)

High Pressure Control Valves Model PB

Product Bulletin

6

Table 5 - Materials of ConstructionValve Components Standard NACE *Compliant Optional

Body ASTM A216 WCB ASTM A216 WCB A352 LCC A351 CF8M

Actuator ASTM A395 ASTM A395 ASTM A395

Cover Bonnet (Upper Housing) ASTM A216 WCB A351 CF8M A352 LCC

Packing Box ASTM A105 316SS6 (ASTM A351 CF8M)

Stem 303SS (ASTM A582) 316SS6 (ASTM A479) 17-4PH (ASTM A564)

Cage 316SS6 316SS6 (ASTM A351 CF8M) 17-4PH (ASTM A747)

Piston ASTM A681 D-2 316SS6 (ASTM A479)

Hard Seat ASTM A681 D-2 316SS6 (ASTM A479) 17-4PH (ASTM A564)440C

Upper Piston Seat ASTM A681 D-2 316SS6 (ASTM A479)17-4PH (ASTM A564)

440C Zirconia

Ratio Plug ASTM A681 D-2 316SS6 (ASTM A479) 17-4PH (ASTM A564)440C

Springs Chrome Silicon 316SS6 (ASTM A479) Inconel

Diaphragm Nitrile Viton

Packing Nitrile Viton Aflas Low Temp Nitrile

O-rings Nitrile Viton Aflas

Packing Sleeve Teflon Teflon

Seal Ring Polyurethane AflasGeothermal EPDM

Peek PPDI

* NACE MR0-175 certification upon request.

High Pressure Control Valves Model PB

Product Bulletin

7

Table 6 - Material SpecificationBody Inner Parts

CAST STEEL

CAST STEEL

CAST 316 STAINLESS STEEL

316 STAIN-LESS STEEL

17-4 PH STAINLESS STEEL

D-2 TOOL STEEL 440C STAIN-LESS STEEL

KIMRAY SUFFIX CS LCC C6 SS6 PH -

ASTM GROUP ASTM A216 ASTM A352 ASTM A351 ASTM A276 ASTM A564 ASTM A681 ASTM A276

GRADE WCB LCC CF8M 316 630 D-2

UNS J03002 J02505 J92900 S31600 S17400 T30402 S44004

NACE Compliant Yes Yes Yes Yes Yes No

Mechanical Properties

Allowable Stress (ksi) 20 20 20 N/A N/A N/A

Tensile min (ksi) 70 70 70 80 130 HT Dependability 110

Yield min (ksi) 36 40 30 35 105 HT Dependability 65

Hardness HB 170 310 209-217 230

Physical Properties

Density (lbs/in3) 0.29 0.28 0.283 0.275

Electrical Resistivity @ 68°F (microhn-in)

29.4 38.6 23.6

Specific Heat @ 32-212°F (BTU/lb/°F) 0.12 0.11 0.11

Thermal Conductivity BTU/hr/ft2/ft/°F @ 212°F

9.4 14

Coeff. of Thermal Expansion (in/in/°F) 32-212°F

8.9x10-6 6.0x10-6 5.83x10-6 5.6x10-6

Coeff. of Thermal Expansion (in/in/°F) 32-600°F

9.0x10-6 6.2x10-6 6.56x10-6

Modulus of Elasticity (ksi) Tension 28.0 x 103 29.0 x 103

Modulus of Elasticity (ksi) Torsion 11.2 x 103 9.68 x 103

Magnetic Permeability, H Oersteds 200 200

Chemical Composition

Al 0.03-.06 .03-.06 .03-.09 - - - -

C 0.30 max 0.25 max 0.08 max 0.08 max 0.07 max 1.40-1.60 0.95-1.20

Cb - - - - 0.15-0.45 - -

Co - - - - - 1.00 max -

Cr 0.50 max 0.05 max 18.0-21.0 16.00-18.00 15.50-17.50 11.00-13.00 16.00-18.00

Cu 0.30 max 0.30 max - - 3.00-5.00 - -

Mg - - - - - - -

Mn 1.00 max 1.20 max 1.20 max 2.00 max 1.00 max 0.60 max 1.00 max

Mo 0.20 max 0.20 max 2.0-3.0 2.00-3.00 - 0.70-1.20 0.75 max

Ni 0.50 max 0.50 max 9.0-12.0 10.00-14.00 3.00-5.00 - -

P 0.04 max 0.04 max 0.04 max 0.045 max 0.040 max 0.030 max 0.040 max

Pb - - - - - - -

S 0.045 max 0.045 max 0.04 max 0.030 max 0.030 max 0.030 max 0.030 max

Si 0.60 max 0.60 max 1.5 max 1.00 max 1.00 max 0.60 max 1.00 max

V 0.03 max .03 max - - - 1.10 max -

Zn - - - - - - -

Temp. Range (°F) -20 to 800 -50 to 700 -20 to 1000 -20 to 850 -20 to 650 -20 to 800

Temp. Range (°C) -28 to 426 -45 to 371 -28 to 537 -28 to 454 -28 to 343 -28 to 426

Kimray reserves the right to modify or improve the designs or specifications of such products at any time without notice.

High Pressure Control Valves Model PB

Product Bulletin

8

Table 7 - Elastomer OptionsPart Standard Material Optional Material

Actuator Diaphragm Buna-N Viton

Bonnet seal rings Buna-N Viton, Aflas

Packing Box Buna-N Aflas, Low Temp Nitrile, Viton

Packing Box / Body Buna-N Aflas, Low Temp Nitrile, Viton, Vee Packing

Piston Assembly Buna-N Viton, Aflas

Seat Polyeurathane (PPDI) Aflas, GEP, PK

Table 8 - Elastomer SpecificationsELASTOMERS PLASTICS

AFLAS ETHYLENE PROPYLENE

VITON HIGHLY SATURATED NITRILE

BUNA-N LOW TEMP. BUNA-N

POLY- ACRY-LATE

GEO- THERMAL EPDM

POLY- URETHANE

GYLON PEEK PPDI TEFLON

Kimray Suffix AF EP V HSN - LTN H GEP P GY PK PPDI T

Res

ista

nce

Abrasion GE GE G G G G G GE E E E E E

Acid E G E E F F P G P E G P E

Chemical E E E FG FG FG P E FG E G FG E

Cold P GE PF G G E P GE G E P G E

Flame E P E P P P P P P P P P P

Heat E G E E G G E E F E G G E

Oil E P E E E E E F G E G G E

Ozone E E E G P P E E E E G E E

Set PF GE E GE GE GE F GE F P P F P

Tear PF GE F FG FG FG FG GE GE E E GE E

Water/Steam GE E P E FG FG P E P E E P E

Weather E E E G F F E E E E G E E

CO2 GE GE PG GE FG FG P GE G E G G E

H2S E P P FG P P P F G E G G E

Methanol PF G PF P P P P G P E G G E

Prop

ertie

s

Dynamic GE GE GE GE GE GE F GE E P G G P

Electrical E E F F F F F E FG E E FG E

Impermeability G G G G G G E G G E E G E

Tensile Strength FG GE GE E GE GE F GE E E E E E

Temp. Range (°F) 25 to 450

-65 to 300 -15 to 350

-20 to 300 -30 to 250

-65 to 225 0 to 300 0 to 500 -40 to 180 -350 to 500

-30 to 400

-65 to 275

-40 to 400

Temp. Range (°C) -3 to 232

-53 to 148 -26 to 176

-28 to 148 -34 to 121

-53 to 107 -17 to 148 -17 to 260 -40 to 82 -212 to 260

-34 to 204

-53 to 135

-40 to 204

Form O,S,D O,S,D O,S,D O,S,D O,S,D O,D O,S,D O, S S,D S,D S S O, S

RATINGS: P - POOR; F - FAIR; G - GOOD; E - EXCELLENT

Responsibility for the selection, use and maintenance of any Kimray products remain with the purchaser and end-user.

High Pressure Control Valves Model PB

Product Bulletin

9

Table 9 - Port Size and Seat MaterialSize Valve

in.(mm)Standard Port

in.(mm)Reduced Port

in.(mm)Standard Material

in.(mm)Optional Material

2 (50) 2 (50) 1.5 (38) Tool Steel (D2) 316SS6, 17-4PH, 440C

3 (80) 3 (80) 2 (50) Tool Steel (D2) 316SS6, 17-4PH, 440C

4 (100) 4.325 (110) 3 (80) Tool Steel (D2) 316SS6, 17-4PH, 440C

6 (150) 6.75 (170) 4 (100) Tool Steel (D2) 316SS6, 17-4PH, 440C

8 (200) 8 (200) 6 (150) Tool Steel (D2) 316SS6, 17-4PH, 440C

10 (250) 8 (200) 6 (150) Tool Steel (D2) 316SS6, 17-4PH, 440C

Reduced Trim

An optional reduced trim can be installed to reduce the flow area. The valve will maintain the line size connection, but keep the flow conditions inside the rangability of the valve. The reduced trim follows the equal percentage trim flow characteristics.

Equal Percentage Trim

The closure member is designed with a ratio plug shaped to produce an equal percentage of increased flow when the closure member is moved in equal increments of distance. With equal percentage trim, an equal increment of change in stem position will produce an equal percent of change in Cv. For every 10% increase in valve position, the flow coefficient changes 154%, see Figure 3.

Figure 3

Modified Percentage Trim

Modified percentage trim is designed to achieve maximum flow at full open and precise control at the lower end. This type of characteristic is particularly useful in suction controller applications, see Figure 4.

Figure 4

Typical Equal Percentage Characteristic

Modified Percentage Characteristic

Percentage Stem Travel

Percentage Stem Travel

Per

cent

age

of F

low

Per

cent

age

of F

low

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

Kimray inherent flow characteristics conform to ANSI/ISA 75.11.01 -1985

High Pressure Control Valves Model PBProduct Bulletin

10

Table 10 - Flow Coefficient(Cv) at Valve Position2” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Sizein.(mm) CF

Valve Opening Percentage10 20 30 40 50 60 70 80 90 100

Equal Percentage1.5 (38) 0.75 0.6 1.3 2.2 3.4 5 8.6 14 21 26 28.6

2 (50) 0.76 2 4 6 8 11 20 33 45 51 57

3” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Size CFValve Opening Percentage

10 20 30 40 50 60 70 80 90 100

Equal Percentage2 (50) 0.75 2.9 4.9 7.4 9.5 12 17.4 28.9 40.8 48.1 52.6

3 (80) 0.76 4 6 10 13 16 26 54 83 97 107

4” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Size CFValve Opening Percentage

10 20 30 40 50 60 70 80 90 100Equal Percentage 3 (80) 0.75 4 6 9 12 16 25 52 81 95 115

4.325 (110) 0.75 9 13 18 26 36 64 104 148 197 222

6” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Size CFValve Opening Percentage

10 20 30 40 50 60 70 80 90 100

Equal Percentage4 (100) 0.75 9 13 18 26 36 64 104 148 197 222

6.75 (170) 0.75 7 20 45 78 108 140 222 318 399 431

8” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Size CFValve Opening Percentage

10 20 30 40 50 60 70 80 90 100

Equal Percentage6 (150) 0.75 47 60 90 106 119 139 173 243 294 453

8.5 (215) 0.75 51 55 64 134 162 330 452 527 571 630

Modified Percentage 8.5 (215) 0.75 51 53 235 362 485 584 665 699 745 810

10” Piston Balanced High Pressure Control Valve

Flow Characteristic Trim Size CFValve Opening Percentage

10 20 30 40 50 60 70 80 90 100

Equal Percentage6 (150) 0.75 26 37 46 53 56 58 104 146 655 655

8.5 (215) 0.75 21 22 27 103 209 429 596 663 695 884

Modified Percentage 8.5 (215) 0.75 28 72 420 509 632 678 769 814 832 1091

Kimray flow equations conform to ANSI/ISA - 75.01.01-2002

High Pressure Control Valves Model PB

Product Bulletin

11

Table 11 - Upper Piston Seat MaterialMaterial Service Do not use in

D-2 Tool Steel Abrasive service, Standard ratio plug Sour service, CO2, Steam

316SS6 Corrosive service, Nace, Steam Abrasive, erosive service

17-4PH Corrosive service, Nace, minor abrasive, erosive service. High Abrasive, CO2, Steam

440C Corrosive service, Nace, abrasive, erosive service High Abrasive

Zirconia Corrosive, Abrasive, Nace service. Ceramic material hardest available.

Upper Piston Seat

Where the piston seals against the valve body seat and where the flow stream impacts the piston greatest is called the upper piston seat (Figure 6). To compensate for certain abrasive and corrosive services, the upper piston seat is replaceable and available in several mate-rials (Table 10). This allows the upper piston seat to be replaced without the whole piston.

Balanced Piston

The balanced piston design applies upstream pressure above and below the closure member. This is accom-plished with four holes machined into the piston and ratio plug. The area of the balancing piston providing the bal-ancing force is slightly greater than the seal area of the seat providing upstream force. This ensures that the valve will remain sealed at high differential pressure. (Figure 5)

Flow

Upstream force

Balancing force

Communicating holes

Figure 5

Figure 6

Piston/Cage Assembly

Ratio Plug

Upper Piston Seat

High Pressure Control Valves Model PB

Product Bulletin

12

Live Load Packing Box

A spring is used to apply constant pressure against packing rings that squeeze a Teflon seal around the stem. When the Teflon sleeve begins to wear, the spring pressure provides leak proof service. Optional packing rings are available to match the service conditions (Table 11 - Packing Box Materials).

Table 12 - Stuffing Box Materials

Part Material Optional Materials

Packing Box D-2 Tool Steel 316SS6

Packing Rings Buna-N Aflas, Viton, Low Temp Nitrile, Vee Packing

Packing Sleeve Teflon None

Spring 316SS6 Hastelloy C

Follower 316SS6 None

Figure 7

Packing Sleeve

Follower

Spring

Packing Rings

Stuffing Box

High Pressure Control Valves Model PB

Product Bulletin

13

Table 13 - Actuator Diaphragm Area and Valve Stem TravelValve Size Diaphragm Area Stem Travel

2150 Topworks 65 in.2 (419 cm2) 0.75 in. (1.875 cm)

3150 Topworks 100 in.2 (645 cm2) 1.375 in. (3.4375 cm)

4150 Topworks 100 in.2 (645 cm2) 1.75 in. (4.375 cm)

6150, 8150, 10150 Topworks 120 in.2 (774 cm2) 2.5 in. (6.25cm)

Actuator

The pneumatic diaphragm actuator with single acting spring return, supplies the force and motion to position the closure member. Optional springs are available for a maximum travel diaphragm pressure of 15 psi, 20 psi, and 30 psi for the 2150 valve, and 30 psi in the 3”, 4”, 6”, 8” and 10 inch. “Table 13 - Actuator Crack to Full Open Pressure” lists the diaphragm pressure required to initially unseat and fully travel the closure member. The actuator can be in either fail open or fail closed configuration without the need for additional parts.

Figure 8

Table 14 - Actuator Crack to Full Open Pressure

Valve Description Spring 0 psig (0 bar) 100 psig (6.8 bar) 500 psig (34.4 bar) 1000 psig (68.9 bar) 1500 psig (103.4 bar)

Crack Full Crack Full Crack Full Crack Full Crack Full

2150 SMT PB 2 IN IV

15 lbs. 3 psig (0.21bar)

16 psig (1.1bar)

3.5 psig (0.24bar)

16 psig (1.1bar)

5.5 psig (0.38bar)

15 psig (1.03bar)

7.5 psig (0.52bar)

14 psig (0.97bar)

9.5 psig (0.66bar)

12 psig (0.83bar)

20 lbs. 3 psig (0.21bar)

19 psig (1.31bar)

3 psig (0.21bar)

18 psig (1.24bar)

5.5 psig (0.38bar)

17 psig (1.17bar)

8 psig (0.55bar)

16 psig (1.1bar)

8.5 psig (0.59bar)

15 psig (1.03bar)

30 lbs. 6 psig (0.41bar)

32 psig (2.21bar)

7 psig (0.48bar)

31 psig (2.14bar)

8 psig (0.55bar)

30 psig (2.07bar)

10.5 psig (0.72bar)

29 psig (2bar)

12.5 psig (0.86bar)

28 psig (1.93bar)

3150 FMT PB 3" IV 30 lbs. 6 psig (0.41bar)

30 psig (2.07bar)

6.5 psig (0.45bar)

27.5 psig (1.9bar)

10.5 psig (0.72bar)

27 psig (1.86bar)

13.5 psig (0.93bar)

25 psig (1.72bar)

17 psig (1.17bar)

22 psig (1.52bar)

3150 FMT PB 3" IV- PC 30 lbs. Shut 27 psig (1.86bar) Shut 28 psig

(1.93bar) Shut 30.5 psig (2.1bar) Shut 33 psig

(2.28bar) Shut 36.5 psig (2.52bar)

4150 FMT PB 30 lbs. 8.5 psig (0.59bar)

32 psig (2.21bar)

8.5 psig (0.59bar)

32 psig (2.21bar)

8 psig (0.55bar)

29.5 psig (2.03bar)

7.5 psig (0.52bar)

27 psig (1.86bar)

6 psig (0.41bar)

24.5 psig (1.69bar)

4150 FMT PB 4 IN IV PC 30 lbs. Shut 31 psig (2.14bar) Shut 32.5 psig

(2.24bar) Shut 34.5 psig (2.38bar) Shut 37 psig

(2.55bar) Shut 39.5 psig (2.72bar)

6150 FMT PB 6 IN IV 30 lbs. 8 psig (0.55bar)

29 psig (2bar)

9.5 psig (0.66bar)

28 psig (1.93bar)

10.5 psig (0.72bar)

27 psig (1.86bar)

11 psig (0.76bar)

25 psig (1.72bar)

11.5 psig (0.79bar)

22 psig (1.52bar)

8150 FMT PB 8 IN IV 30 lbs. 8 psig (0.55bar)

29 psig (2bar)

8.5 psig (0.59bar)

27.5 psig (1.9bar)

10 psig (0.69bar)

26.5 psig (1.83bar)

10.5 psig (0.72bar)

24 psig (1.65bar)

10.5 psig (0.72bar)

21.5 psig (1.48bar)

10150 FMT PB 8 IN IV 30 lbs. 7.5 psig (0.52bar)

28.5 psig (1.97bar)

8.5 psig (0.59bar)

27.5 psig (1.9bar)

9.5 psig (0.66bar)

26 psig (1.79bar)

10 psig (0.69bar)

24 psig (1.65bar)

10.5 psig (0.72bar)

21.5 psig (1.48bar)

Hig

h P

ress

ure

Con

trol V

alve

s Mo

dels

PB

Prod

uct B

ulle

tin 14

Spe

cial

Pro

cess

*

Cod

eD

escr

iptio

n

PU

Sta

ndar

d

PC

Pre

ssur

e C

lose

(i.

e. E

CP

PC

= 22

00 S

MT

PC

1"

IV)

ITI/P

Indi

rect

tra

nsdu

cer

DT

I/P D

irect

tra

nsdu

cer

PS

2PP

S2

4-20

HA

RT

PO

SIT

ION

P

LAS

TIC

STD

.

PS

2XP

PS

2 4-

20H

AR

T P

OS

ITIO

NE

R

EX

PLO

SIO

N

PR

OO

F

PS

2S6

PS

2 4-

20H

AR

T P

OS

ITIO

NE

R S

6

Trim

Mat

eria

l

Cod

eD

escr

iptio

n

-S

tand

ard

PH

17- 4

Trim

ZRZi

rcon

ia T

rim

440C

440C

Trim

S6

316S

S6

Trim

S6B

316S

S T

rim

& 3

16S

S6

Bod

y

QO

Qui

ck

Ope

ning

Elas

tom

er

Cod

eD

escr

iptio

n

-S

tand

ard

(Bun

a-N

)

AF

Afla

s

FGFa

wn

Gyl

on

GG

ylon

HS

NH

igh

Sat

urat

ed

Nitr

ile

LTN

Low

Tem

p N

itrile

TTe

flon

Sea

t

VVi

ton

Hig

h Pr

essu

re

Con

trol

Val

ve O

nly

VP

KVe

e P

acki

ng

GF

Gra

foil

Pac

king

VD

Vito

n D

iaph

ragm

(Use

d on

H

PM

VS

for

diap

hrag

m in

bo

nnet

)

PE

KP

EE

K

Pilo

t (H

PCV

only

)

Cod

eD

escr

iptio

nC

ontr

ol

Ran

ge

(psi

g)

-S

tand

ard

(no

pilo

t)n/

a

3B30

HP

CV

B

ack

Pre

ssur

e10

to 3

00

3P30

HP

CV

P

ress

ure

Red

ucin

g

10 to

300

7B75

HP

CV

B

ack

Pre

ssur

e75

to 7

50

7P75

HP

CV

P

ress

ure

Red

ucin

g

75 to

750

15B

150

HP

CV

B

ack

Pre

ssur

e12

5 to

15

00

15P

150

HP

CV

P

ress

ure

Red

ucin

g

125

to

1500

25B

250

HP

CV

B

ack

Pre

ssur

e20

0 to

25

00

25P

250

HP

CV

P

ress

ure

Red

ucin

g

200

to

2500

5PO

ZH

PC

V O

unce

s P

ress

ure

Red

ucin

g

1 oz

to

5 ps

i

2.5P

OZ

HP

CV

Oun

ces

Pre

ssur

e R

educ

ing

1 oz

to

5 ps

i

5BO

ZH

PC

V O

unce

s B

ack

Pre

ssur

e.5

oz

to

2.5

psi

2.5B

OZ

HP

CV

Oun

ces

Bac

k P

ress

ure

.5 o

z to

2.

5 ps

i

20P

OZ

HP

CV

Oun

ces

Pre

ssur

e R

educ

ing

1 ps

i to

20

psi

20B

OZ

HP

CV

Oun

ces

Bac

k P

ress

ure

1 ps

i to

20

psi

Sprin

g

Cod

eD

escr

iptio

n

-S

tand

ard

Hig

h Pr

essu

re C

ontr

ol

Valv

es

1515

# S

prin

g

2020

# S

prin

g

3030

# S

prin

g

Low

Pre

ssur

e C

ontr

ol

Valv

e

125

Use

d w

hen

chan

ging

from

300

#

sprin

g to

125

# sp

ring

Cer

tifica

tion

Cod

eD

escr

iptio

n

-N

o C

ertifi

catio

ns

CR

NC

anad

ian

Reg

istra

tion

CE

RTS

Mat

eria

l C

ertifi

catio

ns

on W

eld

neck

s, B

lind

Pla

tes,

&

Ham

mer

U

nion

s

NC

Nac

e

MTR

Mat

eria

l Te

st R

epor

ts

(i.e.

Ste

el

Cas

ting)

SP

TS

tatic

P

ress

ure

Test

s

Coa

ting

Cod

eD

escr

iptio

n

-N

o C

oatin

g

KC

Kim

Coa

ted

PR

Prim

er C

olor

P

aint

ed

Exp

ort C

rate

Cod

eD

escr

iptio

n

-N

o cr

ate

Onc

e al

l spa

ces

are

fille

d, re

mov

e al

l das

hes

and

cond

ense

with

out s

pace

s.

Bas

e C

ode

Cod

e

Thre

e ch

arac

ter

base

cod

e fro

m

page

ii

Kim

ray

rese

rve

the

right

to m

odify

or c

hang

e, w

ithou

t prio

r not

ice,

any

sta

tem

ent o

r inf

orm

atio

n co

ntai

ned

here

in.

Hig

h P

ress

ure

Con

trol V

alve

s Mo

dels

PB

Prod

uct B

ulle

tin 15K

imra

y re

serv

e th

e rig

ht to

mod

ify o

r cha

nge,

with

out p

rior n

otic

e, a

ny s

tate

men

t or i

nfor

mat

ion

cont

aine

d he

rein

.

Cod

eD

escr

iptio

nE

QA

4” F

MT

300R

F P

BP

C 4

” IV

EQ

C4”

FM

T 30

0RF

PB

PC

4” I

V

EQ

G4"

FM

T 60

0RTJ

PB

3" I

V

EIG

6" F

MT

150R

F P

B 6

" IV

EIA

6" F

MT

300R

F P

B 6

" IV

EIB

6" F

MT

600R

F P

B 6

” IV

EIK

6" F

MT

600R

TJ P

B 6

" IV

EIH

6" F

MT

150R

F P

B 4

" IV

EII

6" F

MT

300R

F P

B 4

" IV

Cod

eD

escr

iptio

nE

OQ

2" F

MT

150R

F P

B 2

" IV

EO

R2”

FM

T 15

0RF

PB

1 1

/2” I

V

EO

S2"

FM

T 30

0RF

PB

2" I

V

EO

U2"

FM

T 30

0RTJ

PB

2" I

V

EO

S2"

FM

T 30

0RF

PB

2" I

V

EO

U2"

FM

T 30

0RTJ

PB

2" I

V

EFI

2" F

MT

600R

F

PB

2" I

V

EFJ

2" F

MT

600R

TJ P

B 2

" IV

EFK

2" F

MT

1500

RF

PB

2" I

V

EFL

2" F

MT

1500

RTJ

PB

2" I

V

EO

T2"

FM

T 30

0RF

PB

1 1

/2” I

V

EO

V2"

FM

T 30

0RTJ

PB

1 1

/2” I

V

EQ

J2"

FM

T 60

0RF

PB

1 1

/2” I

V

EO

X2"

FM

T 60

0RTJ

PB

1 1

/2” I

V

EO

Y2"

FM

T 15

00R

F P

B 1

1/2

” IV

EO

Z2"

FM

T 15

00R

TJ P

B 1

1/2

” IV

ER

I2"

FM

T W

/3"3

00R

F P

B 1

1/2

” IV

ER

J2"

FM

T W

/3"3

00R

F P

B 2

" IV

EV

O2"

FM

T W

/3"1

500R

TJ P

B 2

" IV

EFG

2150

SM

T P

B 2

" IV

EFH

2400

SM

T P

B 2

" IV

EQ

I24

00 S

MT

PB

1.5

" IV

EIY

2600

SM

T P

B P

O 1

1/2

" IV

Cod

eD

escr

iptio

nE

ZO3"

FM

T 15

0RF

P

B 3

" IV

EZQ

3" F

MT

300R

F

PB

3" I

V

EZS

3" F

MT

300R

TJ

PB

3" I

V

EFU

3" F

MT

600R

F

PB

3" I

V

EFV

3" F

MT

600R

TJ P

B 3

” IV

EZP

3" F

MT

150R

F

PB

2"IV

EZR

3" F

MT

300R

F

PB

2"IV

EZT

3" F

MT

300R

TJ P

B 2

"IV

EZU

3" F

MT

600R

F

PB

2"IV

EZV

3" F

MT

600R

TJ P

B 2

"IV

Bas

e C

odes

for K

imra

y H

igh

Pres

sure

Con

trol

Val

ves

Cod

eD

escr

iptio

nE

IJ6"

FM

T 60

0RF

PB

4" I

V

EIM

8" F

MT

600R

F P

B 8

" IV

Cod

eD

escr

iptio

nE

IN8"

FM

T 30

0RF

PB

8" I

V

MFT

8” F

MT

150R

F P

BP

C 8

” IV

EIT

10" F

MT

600R

F P

B 8

" IV

EIZ

10" F

MT

600R

F P

B 6

" IV

High Pressure Control Valves Model PB

Product Bulletin

16

High Pressure Control Valves

Kimray is an ISO 9001- certified manufacturer.Kimray quality assurance process maintains strict controls

of materials and the certification of parts used in kimray control valves.

All contents of this publication including illustrations are believed to be reliable. And while efforts have been made to ensure their accuracy, they are not to be construed as warranties for guarantees, express or implied, regarding Kimray products or services described herein or their use or application. All sales are governed by our terms and conditions, which are available on request. Kimray reserves the right to modify or improve the designs or specifications of such products at any time without prior notice.

Related Publications:See Installation and Maintenance - IM0008See Catalog Page E1:i