Part 4 MECHANICAL PROPERTIES - Yazd Composite Materials M. S. Ahmadi 192 Part 4 MECHANICAL...

Transcript of Part 4 MECHANICAL PROPERTIES - Yazd Composite Materials M. S. Ahmadi 192 Part 4 MECHANICAL...

4/17/2015

1

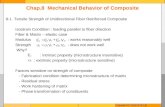

Fiber Composite Materials M. S. Ahmadi 192

Part 4

MECHANICALPROPERTIES

Fiber Composite Materials M. S. Ahmadi 193

TENSILE PROPERTIES

Tensile properties, such as tensile strength, tensile modulus, and Poisson’s ratio of flat composite laminates, are determined by static tension tests in accordance with ASTM D3039.

4/17/2015

2

Fiber Composite Materials M. S. Ahmadi 194

As end tab materials, balanced [0=90] cross-ply tabs of nonwoven E-glass–epoxy have shown satisfactory results. Any high-elongation (tough) adhesive system can be used for mounting the end tabs to the test specimen.

Recommended cross-head speed: 2 mm/min

Fiber Composite Materials M. S. Ahmadi 195

COMPRESSIVE PROPERTIES

Compressive properties of thin composite laminates are difficult to measure owing to sidewise buckling of specimens. A number of test methods and specimen designs have been developed to overcome the buckling problem

ASTM D3410

4/17/2015

3

Fiber Composite Materials M. S. Ahmadi 196

FLEXURAL PROPERTIES

Flexural properties, such as flexural strength and modulus, are determined by ASTM test method D790. In this test, a composite beam specimen of rectangular cross section is loaded in either a three-point bending mode or a four-point bending mode.

Fiber Composite Materials M. S. Ahmadi 197

Using a homogeneous beam theory, the flexural strength in a three-point flexural test is given by

Flexural modulus is calculated from the initial slope of the load–deflectioncurve:

where m is the initial slope of the load–deflect ion curve.

4/17/2015

4

Fiber Composite Materials M. S. Ahmadi 198

IMPACT PROPERTIES

A variety of standard impact test methods are available for metals (ASTME23) and unreinforced polymers (ASTM D256). Some of these tests have alsobeen adopted for fiber-reinforced composite materials.

CHARPY, IZOD, AND DROP-WEIGHT IMPACT TEST

Charpy and Izod impact tests are performed on commercially availablemachines in which a pendulum hammer is released from a standard height to contact a beam specimen (either notched or unnotched) with a specified kinetic energy. A horizontal simply supported beam specimen is used in the Charpy test, whereas a vertical cantilever beam specimen is used in the Izodtest.

Fiber Composite Materials M. S. Ahmadi 199

Charpy impact tests Izod impact tests

The dimensions of a standard specimen for ASTM D256 are 63.5 × 12.7× 3.2 mm (2.5 × 0.5 × 0.125 in). The most common specimen thickness is 3.2 mm (0.125 in), but the width can vary between 3.0 and 12.7 mm(0.118 in and 0.500 in).

ASTM D6110For a typical fiber reinforced polymer Charpy specimen, L = 126 ± 1 mm,D = 12.7 ± 0.15 mm, and 3.00 mm < w < 12.7 mm

4/17/2015

5

Fiber Composite Materials M. S. Ahmadi 200

Fiber Composite Materials M. S. Ahmadi 201

ASTM D 5628

4/17/2015

6

Fiber Composite Materials M. S. Ahmadi 202

The drop -weight impact test uses the free fall of a known weight to supplythe energy to break a beam or a plate specimen. The specimen can be either simply sup ported or fixed . The kinetic energy of the falling weight is adjusted by varying its drop height . The impact load on the specimen ismeasured by instrumenting either the striking head or the specimen supports.Energy absorbed by the specimen is calculated as

Fiber Composite Materials M. S. Ahmadi 203

Composite Material Stiffness Predictions

–Rule of Mixtures (ROM) –ROM with Efficiency Factor –Hart Smith 10% rule –Classical Laminate Analysis

4/17/2015

7

Fiber Composite Materials M. S. Ahmadi 204

Lamina Axis Notation

Fiber Composite Materials M. S. Ahmadi 205

Example Material for Analysis

4/17/2015

9

Fiber Composite Materials M. S. Ahmadi 208

Rule of Mixtures: Efficiency Factor

• The Efficiency Factor or Krenchel factorcan be used to predict the effect of fibreorientation on stiffness• This is a term that is used to factor theRule of Mixtures formula according to thefibre angle

Fiber Composite Materials M. S. Ahmadi 209

![Mechanical Properties of Reinforced Epoxy Composite Using ... · sisal epoxy composite. [10]. Study Akindapo, mechanical behavior of rice husks carbon fiber and groundnut shell carbon](https://static.fdocuments.us/doc/165x107/5e7390b8a23510133c749c77/mechanical-properties-of-reinforced-epoxy-composite-using-sisal-epoxy-composite.jpg)