part 2

20

Grain crop drying, handling and storage By SAMIR ALBADRI

-

Upload

samir-albadri -

Category

Documents

-

view

7 -

download

1

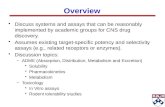

Transcript of part 2

- 1. Grain crop drying, handling and storage By SAMIR ALBADRI

- 2. S.L.A.M. Sanitation Loading Aeration Monitoring

- 3. Bin Sanitation Clean and sanitize aeration ducts, augers, floors Remove weeds, trash, moldy crop Spray insecticides while bin is empty Clean/inspect/replace aeration equipment and dryers

- 4. Loading Optimize handling & storage operations Operate augers at capacity, slow speed Use a spreader to fill bin Core the fines from center of grain Record grain moistures going into storage Screen for my cotoxins

- 5. Aeration Goals To cool dried grain uniformly to 30-35oF. Move cooling front completely through and out of grain mass Avoid condensation on inside walls/roof Maintain low grain temps as long as possible

- 6. Aeration Aeration rates depend upon 4 factors. Bin type Air distribution system Desired grain moisture content Management practices

- 7. Movement of Cooling Zones During Aeration Air flow either positive pressure (flow up) or negative (flow down)

- 8. Aeration Air flow either positive pressure (flow up) or negative (flow down) Ventilation required during fan operation Fan operation times depend upon airflow rate

- 9. Static pressure

- 10. Static pressure - Static pressure is the force required to overcome the resistance to air flow through grain and is usually expressed in inches of water column. - It is also the measure used to rate a fan's performance under load conditions such as drying, cooling and aerating grain - Static pressure is measured with a simple instrument known as a manometer (which is connected to the air plenum of a grain bin (air space below the false floor).

- 11. Monitoring Check for insects while grain temperature is above 50 F. If found then fumigate. Fumigation will not be effective below 50 F. Temperatures below 50 F will control insects Inspect grain surface at least every other week Walk on grain, poke into it, check for hot spots or insect infestations.

- 12. Bridged grain

- 13. 3D Level Scanner http://www.gulfatlanticequipment.com/manufacturer-binmaster.php

- 14. Drying Methods Equilibrium Natural air and fans Relative vapor pressure Charts Drying front moves through grain

- 15. Drying Methods .Non-equilibrium -Heated air in a bin or column dryer

- 16. Drying Calculations to get the amount of grain stored You can calculate the size of the job You can relate it all to the speed of harvest for bin management

- 17. Bin Safety Enter a bin only if you know its history and if you are not alone If grain has not been removed you should see a cone in the middle of the bin. If grain has been removed you should see a flat area or inverted cone, and a shiny surface on the side of the bin. If you do not see these signs, surface may be crusted and unsafe to enter.

- 18. Bin Safety Shut off and lock out power when entering Do not work alone in bins Do not enter while loading/unloading

- 19. Grain Bin Entry Procedures Saves Lives http://www.youtube.com/watch?v=FhIq87HPkT0

- 20. Thank you