Parameter Mesin Extrusion

-

Upload

hery-kurniawan -

Category

Documents

-

view

32 -

download

1

Transcript of Parameter Mesin Extrusion

Parameter Mesin Extrusion Rinso Anti Noda 25 gr, Mesin OH-Sung

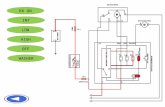

PARAMETER SATUANUNWINDER

Unwind Tension N 5.5Dencer Air Kgf/cm2 1

IN FEED PARTIn Feed Tension N 7M-Side Kgf/cm2 3G-Side Kgf/cm2 3Denser Air Kgf/cm2 3In Feed Current A 1

LAMINATING UNITSilicone Roll M-Side Kgf/cm2 4Silicone Roll G-Side Kgf/cm2 3Back-Up Roll Kgf/cm2 2Support Roll Kgf/cm2 1

OUT FEED PARTOut Feed Tension N 7M-Side Kgf/cm2 3G-Side Kgf/cm2 2Denser Air Kgf/cm2 2

POWDER SPRAYERPowder Volt 2

REWINDERRewind Tension N 12Web Touch Kgf/cm2 2Dancer Air Kgf/cm2 1Touch Roll Kgf/cm2 4Cutting Kgf/cm2 6Taper Kgf/cm2 2

PANEL CONTROLLine Speed Mtr/mnt 150Line Current AExtruder RPM RPM 87Extruder Current A 120Rein TIC CChiler Temperature C 22Resin Pressure CResin Temperature C

1 2 3 4 5 6 7 A S N 1 2 3 4 5 6 7Temp.Barrel 200 230 245 255 265 275 280Temp.Die 280 280 280 262 271 271 271 271 274 264