Page 8 • January 17, 2021 • ...archive.constructionequipmentguide.com/web_edit...The W 220 Fi...

Transcript of Page 8 • January 17, 2021 • ...archive.constructionequipmentguide.com/web_edit...The W 220 Fi...

Page 8 • January 17, 2021 • www.constructionequipmentguide.com • CONSTRUCTION EQUIPMENT GUIDE

Contractor Completes Full-Depth Milling Project With WirtgenWhen it comes to cold milling machines,

it is always to the contractor’s advantage tohave options. From taking a little off the topto full-depth removal, Wirtgen’s new W 220Fi offers the ability to perform the task in themost effective and economical way.

Full-service road construction and asphaltproducer Atlas Paving Company recentlyused a W 220 Fi to remove a residential two-lane road in Canadian County, Okla., as partof a full-depth reclamation project. The jobcalled for milling 6-in. of existing asphalt, alittle more than half of the 14-in. capabilityof the 801-hp.mill. The W 220 Fi has a drumwidth of 7 ft., 3 in., so Atlas PavingCompany removed each 20-ft. lane in threepasses throughout the entire 3.5 mi.

“With the new W 220 Fi we were takingup 30 to 40 feet per minute, which is aboutdouble what we would normally get on aproject like this,” said Atlas Paving’s MillingLead Man Randy Stafford. “There are a lotof great features that increase production.For instance, with the push of a couple ofbuttons you can easily switch between theski, shoe, slope or GPS.”

Mill Assist for Optimal Performance

With the W 220 Fi, operators have multi-ple modes to choose from, including Power,which runs the milling drum at 1,700 to1,800 rpm and increases drum-speed effi-ciency, as it chews its way through hardasphalt. It is one of five modes available onthe W 220 Fi, including Auto, which, whenused with Wirtgen’s exclusive Mill Assiststandard assistance system, provides theoptimal balance between performance andoperating costs, according to GregoryGatewood, technology specialist of WirtgenAmerica.

“Auto mode with Mill Assist not onlyimproves performance, it also reduces

diesel, water and pick consumption, as wellas CO2 emissions,” Gatewood said. “MillAssist lets users set the milling index, includ-ing the drum and cutting tools, to get the bestpattern possible, along with excellent per-formance. The mill also has Eco, Manualand Pattern modes, so there is a lot of versa-tility, and operators can easily match themode to the task for optimal efficiency.Pattern is great for profile jobs.”Two-Speed Transmission Extends

Drum Speed RangeThe W 220 Fi has various drive concepts

that ensure maximum performance in allapplications and modes. For example, it isequipped with a two-speed dual shift trans-mission that switches from low to high dur-ing operation and offers a broad range ofapplications. Its intelligent control extendsboth the upper and lower ranges of possiblemilling drum speeds. At lower speed, fueland pick wear can be significantly reduced.At higher speeds, milling pattern quality isensured.

Operators also can preselect a workingstrategy from “Cost-optimized,”“Performance-optimized” or “Milling tex-ture quality.” For example, it is possible to

define the required milling texture quality ona scale of 1 (coarse) to 10 (very fine) inadvance with the touch of a button.

Further expanding the technologicalofferings on the W 220 Fi is the new WirtgenPerformance Tracker (WPT), which calcu-lates the precise milling surface perform-ance, volume and consumption values. WPTcollects and displays the data during opera-tion in real time on the machine’s operatorplatform. It also gathers the operational dataand automatically generates a report imme-diately upon completion of a project.

“The advanced features on the Wirtgen W220 Fi make it an ideal milling machine fora variety of applications,” said Kirby-SmithMachinery Territory Manager DonJacobson, who helped Atlas Paving add themill to a fleet that already included WirtgenW 210 and W 220 models. “We are planningto connect additional technology to the W220 Fi and make it compatible with aTopcon 3D system. This will allow intelli-gent machine control with GPS and a basestation.”

(Reprinted with permission from theKirby-Smith Connection January 2021 mag-azine.)

Randy Stafford, milling lead man ofAtlas Paving.

Don Jacobson, territory manager ofKirby-Smith Machinery.

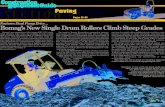

Wirtgen’s W 220 Fi cold milling machine features the exclusive Mill Assist standardassistance system that provides the optimal balance between performance andoperating costs.

Atlas Paving Company recently used a W 220 Fi to remove a residential two-laneroad in Canadian County, Okla., as part of a full-depth reclamation project. The jobcalled for milling 6 in. of existing asphalt, a little more than half of the 14-in. capa-bility of the 801-hp. mill.

Gregory Gatewood, technology special-ist of Wirtgen America.