P1M Series Swing Clamp - SeekPartfile.seekpart.com/keywordpdf/2011/3/30/2011330105215208.pdf · 3...

Transcript of P1M Series Swing Clamp - SeekPartfile.seekpart.com/keywordpdf/2011/3/30/2011330105215208.pdf · 3...

1 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

P1M SeriesSwing ClampExtra Low Profile Pneumatic Cylinders zc03

ContentsFeatures and Benefits ......................................................... 2How to Order ....................................................................... 3Cylinder Specifications ....................................................... 4Flexible Porting Options ...................................................... 5

Performance Data ............................................................... 6Custom Arm Sizing ............................................................. 7Dimensional Data ............................................................... 8Mechanical Accessories ................................................... 15

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

2

C086

Parker is pleased to announce the addition of theP1M Swing Clamp Cylinder to the P1M Series productline. The P1M Swing Clamp Cylinder incorporatesseveral innovative features including: 3-piece boltedconstruction, internal transfer tube, long bearing headoption standard, bumpers standard, outboard rotating

guide mechanism, and recessed sensor grooves.The combination of these features, in addition tomaintaining the smallest dimensional envelopepossible, make the P1M Swing Clamp Cylinder idealfor applications that require a compact design andsuperior clamping capability.

Catalog AU03-0900P-2/NA

Features and Benefits

3 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

How to Order P1M Series Swing Clamp Cylinders

* Cylinder with mounting fitted** Designator # 3 should be selected for special rod ends only. When selecting this option, please provide

rod style (male or female), thread pitch, thread depth, and wrench flat dimension.*** Both Ports Head NPT is the standard porting arrangement for this cylinder. Alternate porting

arrangements are available at an additional cost.+ Bumpers for this option are polyurethane. Piston, rod and body end seals are fluorocarbon.

Please review the following specification page for additional information.! Designator J should be selected for cylinders that require a special option not covered in catalog.!! See specification table for stroke lengths available per a given bore size.

Note: For sensor specifications and part numbers, please refer to the electronic sensors section.

PneumaticActuators

P 1 M 0 3 2 C H F M C 6 M 0 2 0

Series

Bore Size

CylinderStyle

C Basic, no mountingH Rear Flange*K Clamp Arm*

L Rear Flange &Clamp Arm*

CylinderOption

H Swing Clamp

J Swing Clamp Special(MTO) !

Function

F Right Hand RotationL Left Hand Rotation

Strokein mm !!

Port Type& Location

BSPP “G” ThreadsG Head & Cap RadialH Both in HeadJ Both in Cap RadialK Both in Cap Axial

NPT ThreadsN Head & Cap RadialM Both in Head***L Both in Cap RadialP Both in Cap Axial

BSPT “R” ThreadsQ Head & Cap RadialR Both in HeadS Both in Cap RadialT Both in Cap Axial

6 Metric Female3 Special**

RodThreads

Piston Rod& Bearings

C Chrome PlatedCarbon SteelB No Magnet, Bumpers,

Standard Seals

F No Magnet, Bumpers,Fluorocarbon Seals +

M Magnetic Piston,Bumpers, Std. SealsMagnetic Piston,

V Bumpers,Fluorocarbon Seals +

Bumpers,Magnet& Seals

032 32mm040 40mm050 50mm

Catalog AU03-0900P-2/NA

How to Order

Bore Class 132 L07866003240 L07866004050 L078660050

Seal Kit Part NumbersClass 5

L078670032L078670040L078670050

Service kits of expendable parts for fluid power cylinders arestocked in principal industrial locations across the U.S.A.and other countries. For prompt delivery and completeinformation, contact your nearest distributor.

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

4

C086

Catalog AU03-0900P-2/NA

Cylinder Specifications

Cylinder Specifications• Bore Sizes: 32, 40 and 50mm• Maximum Operating Pressure: 10 Bar or 145 PSI• Standard Operating Temperature: -20°C to +80°C or -4°F to +176°F• Optional High Temperature: -10°C to +121°C or +14°F to +250°F

Material Specifications• Piston Rod: Hard Chrome Plated Steel, 100,000 PSI Yield• Piston Rod Bearing: Multilayer PTFE with Steel Backing• Outboard Rotating Mechanism Cover: 2011 T3 Aluminum• End Covers: Black Anodized Aluminum• End Cover Fasteners: Zinc Plated Carbon Steel• Cylinder Body: Clear Anodized Aluminum• O-Rings: Nitrile Rubber, NBR• Piston: Aluminum Alloy• Piston Seal: Nitrile Rubber, NBR• Magnet: Plastic Coated Magnetic Material• Bumpers: Polyurethane

High Temperature Seal Option Material*• End Cover O-Rings: Fluorocarbon, FPM• Piston Rod Seal: Fluorocarbon, FPM• Piston Seal: Fluorocarbon, FPM

*Option intended for limited exposure to temperatures over 80°C, or 176°F. Option isprimarily for applications which subject the cylinder to fluids and or chemicals that have anadverse effect on external seals. If continued exposure to elevated temperatures isrequired, please consult the Cylinder Division for alternative options.

Cylinder Weights, g (lbs)Bore, Clamp Stroke,mm mm

10 600 (1.32) 691 (1.52) 664 (1.46) 755 (1.66)

20 673 (1.48) 764 (1.68) 736 (1.62) 827 (1.82)

10 700 (1.54) 791 (1.74) 782 (1.72) 873 (1.92)

20 800 (1.76) 891 (1.96) 882 (1.94) 973 (2.14)

20 1355 (2.98) 1527 (3.36) 1500 (3.30) 1673 (3.68)

50 1736 (3.82) 1909 (4.20) 1882 (4.14) 2055 (4.52)

Arm & FlangeMount

32

40

Rear FlangeMount

50

BasicMount

Clamp ArmMount

Clamp Forces, N (lbs)Bore, Rod Dia, Net Area,mm mm cm2 0.2 (29) 0.4 (58) 0.6 (87) 0.8 (116) 1.0 (145)

32 16 6.03 121 (27) 241 (54) 362 (81) 483 (108) 603 (136)

40 16 10.56 211 (47) 422 (95) 633 (142) 844 (190) 1056 (237)

50 20 16.49 330 (74) 660 (148) 990 (222) 1319 (297) 1649 (371)

Operating Pressure, MPa (psi)

Specifications32 40 50

Rotary Stroke, mm 19

Clamp Stroke, mm 20 / 50Allowable Moment, N-m (ft-lbs) 27 (20) 47 (35) 107 (79)

Degree of Non-Rotation +/- 1.0o +/- 1.0o +/- 0.8o

15

10 / 20

Bore, mmSpecifications

5 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Flexible Porting Options

P1M Series Swing Clamp Flexible Porting Options

Both Ports Head* Both Ports Cap

Head and Cap PortedBoth Ports Cap Face

2

4

2

4

42

2

4

To retract cylinder, apply air to port #2.To extend cylinder, apply air to port #4.

* Both Ports Head (NPT) is the standard porting configuration for theP1M Swing Clamp Cylinder. Alternate porting options are available atan additional cost.

Right Hand (Clockwise)Clamping Rotation

Left Hand (Counter-Clockwise)Clamping Rotation

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

6

C086

Catalog AU03-0900P-2/NA

Performance Data

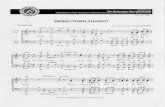

The following graph represents maximum clamp arm lengths per a given bore and operatingpressure. Care should be taken not to exceed maximum operating limits outlined in this graph.

Guidelines for Custom Clamp Arms

0

25

50

75

100

125

150

175

200

225

250

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Arm

Len

gth

(m

m)

32mm & 40mm Bores

50mm Bore

Pressure (MPa)

0.000

0.005

0.010

0.015

0.020

0.025

0.030

20 40 60 80 100 120 140 160 180 200

32mm & 40mm Bores

50mm Bore

Cylinder Speed (mm/s)

Mo

men

t o

f In

erti

a (k

g-m

2 )

The following graph represents maximum operating speeds per a given inertia moment whenincorporating a custom clamp arm. Exceeding the parameters outlined in the graph will lead tointernal cylinder component damage. Please refer to the following page for examples andformulas when designing the clamp arm to be applied.

7 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Custom Arm Sizing

Please use the following formulas and sizing examples when determiningwhat style of clamp arm will best suit your application requirements.

1) Round Bar (Asymmetric)Clamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at or near theend of the arm.

2) Round Bar (Symmetric)Clamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at the centerof the arm.

3) Rectangular Bar (Asymmetric)Clamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at or near theend of the arm.

4) Rectangular Bar (Symmetric)Clamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at the centerof the arm.

5) Rectangular Bar with BoltClamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at or near theend of the arm.

6) Round Bar with SphereClamping arm is positioned 90° degrees to thepiston rod assembly, and is fixed at or near theend of the arm.

ØDL

+=

163

22 DLmI

+=

1612

22 DLmI

L

ØD

L

W

+=

123

22 WLmI

L

W

+=12

22 WLmI

W

L2L1

ØD

L1

L2R

M2M1

ØD

++

+= 2

2

2

2

221

1 5

2

163L

rm

DLmI

++

+=

123163

222

2

221

1

WLm

DLmI

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

8

C086

Catalog AU03-0900P-2/NA

Dimensions – Head Ported

Head Ported Dimensions

*Both Ports Head (NPT) is the standard porting configuration for the P1M Swing Clamp Cylinder.Alternate porting options are available at an additional cost.

BSPP NPTF

32 18 46.5 17 48 56 24 G 1/8 1/8 1.1 9 5.5 13.5 4 M10x1.5

40 18 39 17.5 56 62.5 28 G 1/8 1/8 1.5 9 5.5 10 4 M10x1.5

50 25 47.5 23.5 67 74.5 33.5 G 1/8 1/8 2 12 5.5 12 5 M12x1.75

-0.1-0.2 I79 ZH9 I78 ZH8

32 25 16 9.5 30.5 34 10.5 M6x1 3 6.5 30 h9 67 92.5 76 101.5

40 20 16 11.5 22 40 10.5 M6x1 3 6.5 30 h9 60 92.5 70 102.5

50 20 20 14.5 28 50 13.5 M8x1.25 3.5 7.5 37 h9 72.5 113 81.5 122

14

L Y

BG1 E E1 E2BG2

SWRT

I12

MM NB PM R R1

Rc 1/8

Rc 1/8

EE1AFBSPT

Rc 1/8

Bore

BoreEE

I91

14

17

MagneticNon-MagneticVD WH

I92 KFHL

R

E2

E1

ØMM

R

E

L˚ L˚

NB NB

SW

ØY

I12

WH

VD

PM

I79 (I78) + CLAMP STROKE

ZH9 (ZH8) + 2X CLAMP STROKE

KF AF

I91

BG1BG2

I92

RT HLØR1 I91

MTG. HOLES @180˚2 PLACES EACH SIDE

HLHL

ØR1

ØR1

MOUNTING HOLE CONFIGURATION(2 PLACES)

2X ØEE PORT, ØEE1 ORIFICE

9 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Dimensions – Head and Cap Ported

Head and Cap Ported Dimensions

BSPP BSPT

32 18 46.5 25 48 56 24 G 1/8 Rc 1/8 1.1 2.7 9 5.5 13.5 11.5 M10x1.5

40 18 39 25.5 56 62.5 28 G 1/8 Rc 1/8 1.5 3.4 9 5.5 10 12 M10x1.5

50 25 47.5 29.5 67 74.5 33.5 G 1/8 Rc 1/8 2 4 12 5.5 12 11 M12x1.75

-0.1-0.2 I79 ZH9 I78 ZH8

32 25 16 9.5 8 30.5 34 10.5 M6x1 3 6.5 30 h9 75 100.5 84 109.5

40 20 16 11.5 7.5 22 40 10.5 M6x1 3 6.5 30 h9 68 100.5 78 110.5

50 20 20 14.5 8 28 50 13.5 M8x1.25 3.5 7.5 37 h9 78.5 119 87.5 128

I91

17

MagneticNon-MagneticVD WH

I92 KFEE1 HLEE2

14

I12

R R1 SWRT

1/8

14

Bore

Bore AF

Y

BG1 E1 E2BG2EE

NPTF

L

E

1/8

1/8

PMMM NB PL

E2

E1

ØMM

R

E

R

NB NB

L˚ L˚

SW

I12

VD

I79 (I78) + CLAMP STROKE

ZH9 (ZH8) + 2X CLAMP STROKE

WH ØY

PM PL

KF AF

ØEE PORTØEE1 ORIFICE

ØEE PORTØEE2 ORIFICE

I91

BG1

ØR1

I92

BG2

ØR1HL

HL

MOUNTING HOLE CONFIGURATION(2 PLACES)

RT HLØR1 I91

MTG. HOLES @180˚2 PLACES EACH SIDE

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

10

C086

Catalog AU03-0900P-2/NA

Dimensions – Cap Ported Radial

Cap Radial Ported Dimensions

BSPP NPTF

32 18 46.5 25 48 56 24 G 1/8 1/8 1.1 9 5.5 13.5 11.5 M10x1.5

40 18 39 25.5 56 62.5 28 G 1/8 1/8 1.5 9 5.5 10 12 M10x1.5

50 25 47.5 29.5 67 74.5 33.5 G 1/8 1/8 2 12 5.5 12 11 M12x1.75

-0.1-0.2 I79 ZH9 I78 ZH8

32 25 16 9.5 8 34 10.5 M6x1 3 6.5 30 h9 75 100.5 84 109.5

40 20 16 11.5 7.5 40 10.5 M6x1 3 6.5 30 h9 68 100.5 78 110.5

50 20 20 14.5 8 50 13.5 M8x1.25 3.5 7.5 37 h9 78.5 119 87.5 128

I91

14

L Y

BG1 E E1 E2BG2BSPT

I12

MM NB PL R

Rc 1/8

SWRTR1

Rc 1/8

AFEE

Bore

Bore

Rc 1/8

I92 KF

14

17

MagneticNon-MagneticVD WH

EE1 HL

R

ØMM

R

E

NB NB

L˚ L˚

E2

E1

SW

I12

VD

I79 (I78) + CLAMP STROKE

ZH9 (ZH8) + 2X CLAMP STROKE

KF AF

WH ØY

PLØEE PORTØEE1 ORIFICE

I91

BG1

ØR1

I92

BG2

ØR1HL

HL

MOUNTING HOLE CONFIGURATION(2 PLACES)

RT HLØR1 I91

MTG. HOLES @180˚2 PLACES EACH SIDE

11 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Dimensions – Cap Rear Face Porting

Cap Rear Face Ported Dimensions

BSPP BSPT

32 18 46.5 25 48 56 24 G 1/8 Rc 1/8 1.1 9 5.5 13.5 11.5 M10x1.5

40 18 39 25.5 56 62.5 28 G 1/8 Rc 1/8 1.5 9 5.5 10 12 M10x1.5

50 25 47.5 29.5 67 74.5 33.5 G 1/8 Rc 1/8 2 12 5.5 12 11 M12x1.75

-0.1-0.2 I79 ZH9 I78 ZH8

32 16 45.5 16.5 32 28.5 34 10.5 M6x1 3 6.5 30 h9 75 100.5 84 109.5

40 16 51 12 23 33 40 10.5 M6x1 3 6.5 30 h9 68 100.5 78 110.5

50 20 63 54.5 25 41.5 50 13.5 M8x1.25 3.5 7.5 37 h9 78.5 119 87.5 128

I92 KF

17

MagneticNon-MagneticVD WHSW

14

YBore

Bore I91

14

EE1 HL I12

MM P1 P4 R

AF

P2 P3

BG1 E E1 E2BG2EE

NPTF

1/8

RTR1

1/8

1/8

R

E2

E1

SW

P2

P3

P4

P1

ØMM

R

E

I12VD

I79 (I78) + CLAMP STROKE

ZH9 (ZH8) + 2X CLAMP STROKE

WH

ØY

2X ØEE PORT,ØEE1 ORIFICE

I91

BG1 I92

BG2

ØR1

HLHLØR1

MOUNTING HOLE CONFIGURATION(2 PLACES)

KF AF

RT HLØR1 I91

MTG. HOLES @180˚2 PLACES EACH SIDE

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

12

C086

Catalog AU03-0900P-2/NA

Dimensions – Clamp Arm Mount

C

D

10

B

F

G

A

H + Clamp Stroke

T9 (T8) + 2X CLAMP STROKE

Z9 (Z8) + 2X CLAMP STROKE

Clamp Arm Mount Dimensions

T9 Z9 T8 Z8

32 18 67 20 45 25 M8x1.25 39 106 63 115 72

40 18 67 20 45 25 M8x1.25 46 106 63 116 73

50 22 88 22 63 40 M10x1.5 58 130.5 68.5 139.5 77.5

T9 Z9 T8 Z8 T9 Z9 T8 Z8 T9 Z9 T8 Z8

32 114 71 123 80 114 71 123 80 114 71 123 80

40 114 71 124 81 114 71 124 81 114 71 124 81

50 136.5 74.5 145.5 83.5 136.5 74.5 145.5 83.5 136.5 74.5 145.5 83.5

Non-Magnetic Magnetic

Head Ported Only

Cap Rear Face Ported

Non-Magnetic MagneticBore

Head and Cap Ported

Non-Magnetic Magnetic

Cap Radial Ported

Non-Magnetic Magnetic

Bore CA B D F G H

13 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Dimensions – Rear Flange Mount

RE

R

TF

UF

MF

4X ØFB

ZF2 (ZF3) + 2X CLAMP STROKE

Rear Flange Mount Dimensions

Bore E

ZF2

Head Ported Only

79

FB MF R

32

ZF3 ZF2

Bore

5.5

Head and Cap Ported

ZF3

Non-Magnetic

67 6.6

Cap Radial Ported

40

50

8 40 66 76

9

108.5

TF UF

48

54

5.5 8 34 58 68

128

90

32

40

117.5

Magnetic Non-Magnetic Magnetic

50

Rear Flange Mounting Kits can be ordered assembled to the cylinder or separately as needed. Please refer to Page #?? for proper rear flange mounting kits associated with a given bore size.

118.5

50

100.5 109.5 108.5

100.5 110.5 108.5

122 131

Non-Magnetic

137 128 137

Magnetic

108.5

118.5

ZF2 ZF3

117.5

Rear Flange Mounting Kits can beordered assembled to the cylinder orseparately as needed. Please referto page 15 for proper rear flangemounting kits associated with a givenbore size.

Swing Clamp CylindersP1M Series

Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

14

C086

Catalog AU03-0900P-2/NA

Dimensions – Rear Flange/Clamp Arm Mount

Rear Flange and Clamp Arm Mount Dimensions

C

G

DB

10

A

H + CLAMP STROKE

F Z2 (Z3) + 2X CLAMP STROKE

T2 (T3) + 2X CLAMP STROKE

MF

RE

4X ØFB

R

TF

UF

154.5 92.5

6.5 9

122

122

58

45 48

5.5

80

54

63 67

Z3

25

40

40 18 67 4520

M10x1.5

58

40 66

FB MF R

85.520

C UF

39

H TFD E F

34

Bore A B

8

G

M8x1.25

M8x1.25

32 18 67

76

50 22 88 22 50 79 90

4625

68

Bore Non-Magnetic Magnetic Non-Magnetic

T2 Z2 T3 T2 Z2

Magnetic

Head Ported Only Head and Cap Ported Cap Radial Ported

Magnetic Non-Magnetic

Z3

114 71 123 122 79 131 88

T3 Z3 Z2 T3T2

83.5 154.5145.5

88

114 71 124 122 79 132 8981

77.5 148.5 145.5 83.586.5 92.5

32

40

50

79 132 89

139.5

79 131

SPANNER WRENCHPART # 0116760000

GLAND WRENCHPART # 0883060000

32mm Bore Assembly

To disassemble the front end cover, therod cover must first be removed. To dothis the ring nut must be unscrewed(right-hand thread) using the spannerand gland wrench shown to the left.Order each component separately.

15 Parker Hannifin CorporationActuator DivisionWadsworth, Ohio USA

Swing Clamp CylindersP1M Series

C086

Catalog AU03-0900P-2/NA

Mechanical Accessories

Clamp Arm Mounting Kit 32, 40, and 50mm Bore

Clamp Arm Mounting Kit Component Identification

Rear Flange Mount Kit 32, 40, and 50mm Bore

Rear Flange Mounting Kit Component Identification

1

5

4

2

3

Bore, Partmm Number N-m Inch-lbs32 L078550000 8 - 10 70 - 88

40 L078550000 8 - 10 70 - 88

50 L078560000 14 - 16 124 - 142

Fastener Torque Item PartNumber Description Material

1 Clamp Arm Aluminum

2 Clamp Bolt Steel

3 Hex Jam Nut Steel

4 Socket Head Cap Screw Steel

5 Lock Washer Steel

Note: To remove or install the arm on the piston rod, use a wrench to secure the arm while looseningor tightening the socket head cap screw. Do not secure any other part of the cylinder.

1

2

2

Bore, Partmm Number N-m Inch-lbs32 P1M-4KMB 3.6 - 4.0 32 - 36

40 P1M-4LMB 3.6 - 4.0 32 - 36

50 P1M-4MMB 8.0 - 9.0 72 - 80

Fastener Torque Item PartNumber Description Material

1 Flange Aluminum

2 Socket Head Cap Screw Steel