p11

-

Upload

maghfoor-ahmed-mughal -

Category

Documents

-

view

48 -

download

5

Transcript of p11

Drive Electronics pQ 11 Plug-in type amplifier for proportional valves

Output current for solenoids:0 ... 1000 mA or 0 ... 2400 mA Catalog Register

A17, P17, H17

Publication 7502961.06.11.96

Description

DesignThe electronic plug-in type amplifier pQ 11 is used tocontrol proportional pressure and directional controlvalves. It is mounted directly on the proportional solenoidand secured by means of a screw.

FunctionThe amplifier supplies a direct current for the control of theproportional solenoid. This current is proportional to the setpoint at the amplifier input. In conjunction with a propor-tional valve, this allows a pressure or a flow to be set toany desired value.Accessories include set point adjusters.

Features lControl of one solenoidlMounts directly on valve bodylStandard voltage and current signals for set point inputslControl from computer also possiblelImpressed solenoid current, thus no change in the

controlled variable due to environmental influences(e.g. temperatures and mains fluctuations)

lPlug-in type connection for proportional solenoid withcontact arrangement to DIN 43650, Type A or B.Infinitely adjustable between 0 ... 270°

lSupply via connector to DIN 43651 or cable, 2 m long

ParametersGeneral parametersDesignation Drive electronics pQ11Symbol

Design Plug-in type amplifier with constant-current regulatorDegree of protection IP 65 (plugged in and mounted)Mounting position OptionalAmbienttemperature range ϑU [°C] –20 ... +50

Weight [kg] 0.18Connection Cable 6 x 0.5mm2 + PE 2 m long, screened

Alternatively:6-pin + PE connector to DIN 43651

IMI Norgren-Herion Fluidtronic GmbH & Co. KG, D-70731 FellbachStuttgarter Straße 120, D-70736 Fellbach ⋅ Tel.: +49 (0)7 11 / 52 09-0 ⋅ Fax: +49 (0)7 11 / 52 09-6 14

Drive Electronics pQ 11 0660689.00005980081.00005980082.0000

ParametersElectrical parametersSupply with residual ripple ≤ 10%(UB) [VDC] 18 ... 32

Version (see Type survey, Page 3)0 ... 1000 mA 0 ... 2400 mA

Output current for solenoid1) [mA] 0 .. 400 0 ... 800 0 ... 1000 0 ... 1600 0 ... 2400Current consumptionPlug-in type amplifier [mA] 400 700 800 1400 2200Solenoid resistance R20 [Ω] 2.5 ... 28 2.5 ... 14 2.5 ... 11 2.5 ... 7 2.5 ... 4,5

Output for supply ofset point adjusters 15V, 3mAZero point adjustment(selectable via jumper)Zero point shift (offset)at set point w = 0or:

[% IAmax.] 0 ... 30

Zero point jumpwith set point w ≥ 2% [% IAmax.] 0 ... 30

Drive limitation [% IAmax.] 10 ... 100Superimposed dither (amplitude) [% IAmax.] 0 ... 30Dither frequency(internally selectable) [Hz] 40/80Ramp shaperAdjustment time(selectable via jumper)Valid for rising or falling rampRamp off:Ramp on:

[ms]approx. [s]

< 22)

0.18 ... 182)

Set point w (selectable via jumper)Voltage inputSet point UE

Input resistance Ri

Current input:Set point IESet point IEInput resistance Ri

[V][Ω]

[mA][mA][Ω]

0 ... 10> 330k

0 ... 204 ... 20< 135

Elektromagnetische VerträglichkeitStörfestigkeit Einstrahlung nach EN 50140 und 50141

Burst nach DIN 50082 Teil 2 IEC 801-4

1) selectable via jumper2) with jump-like change of set point ∆ w = 100%

2 7502961.06.11.96

Block diagram / Amplifier pQ 11

Dimensional drawings [mm]

01Version with cable

02Version with connector to DIN 43651

Solenoid current selection0 ... 1000 mA 0 ... 2400 mA

IA max. IA max.

A 400 mA A 1600 mAB 800 mA C 2400 mAC 1000 mA

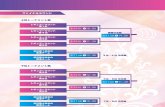

Type survey (standard units)Design Output currents1)

[mA]Solenoid connection Contact arrangement toDIN 43650

Type of connection Connectiondiagram

Dimensionaldrawing

Cat. No.

Form A(wide)

Form B(narrow)

Cable, 2 m long Connector toDIN 43651 No. No.

0 ... 2400 mA 0 ... 1600 / 2400 02 02 59800812)

01 01 59800850 ... 1000 mA 0 ... 400 / 800 /

1000 02 02 59800822)

01 01 5980086 02 02 59800832)

01 01 59800870 ... 2400 mA 0 ... 1600 / 2400 02 02 5980118

01 01 5980119

1) internally switchable2) Cable plug to be ordered separately (Cat. No. 0660689)

7502961.06.11.96 3

Connection diagram01

Version with cable

02

Version with connector to DIN 43651

1) Recommended fuse: M 1.0 A for amplifier 5980082, 5980083, 5980086 and 5980087 M 2.5 A for amplifier 5980081 and 59800852) For allocation, see table on Page 8, Item 3.4. Measurement at connection 23) Screen connection: Setpoint of 0 V.

4 7502961.06.11.96

Definitions

Drive limitation

Trimming potentiometer E "A B" (p/Q)If the customer-specific working range represents only partof the valve adjustment range, the trimming potentiometer"A B" can be used to match the working range to the fullset point signal from 0 to 100%. This provides the possi-bility of assigning a defined pressure or a defined flowvolume to the end point in order to obtain greater resolu-tion.

Zero point Adjustment: Trimming potentiometer D1 "NUL"Preselection: Jumper D2(for instructions to this see Page 7)

Zero-shift (Fig. 1) (Jumper D2 to position "OFS" = offset)Via the trimming potentiometer "NUL“ the solenoid currentcan be increased. This provides the possibility of assigninga defined pressure or defined flow volume to the start point(set point = 0)

Zero-step function (Fig. 2) (Jumper D2 to position "SPR" = jump)By means of the zero-step function, valve overlapping canbe eliminated.As soon as the setpoint adjustment is exceeded by morethan 2% the solenoid current is raised corresponding to theadjustment of the trimming potentiometer "NUL". This wayit is assured that with set point = 0 the solenoid current is0 mA.

Ramp shaper (Fig. 3)Trimming potentiometer F2 "RMP"The ramp module provides a ramp-like change of thesolenoid current if the set point changes abruptly. The finalvalue of the solenoid current thereby corresponds to theset point. The adjustment time between two working pointscan be adjusted, measured with a set point change of100%. By means of jumper F1 the ramp shaper can bedisconnected.

Dither amplitudeTrimming potentiometer C2 "OSZ"In order to improve the hysteresis characteristics in a valve,static friction on the valve piston must be avoided. This isachieved by superimposing a dither signal on the valvecurrent. Via the trimming potentiometer "OSZ" the ampli-tude of the superimposed current can be adjusted withinthe range of 0 to 30% of the rated current. Optimum settingis achieved when small changes in the set point areregistered on the final control element. The minimum ditheramplitude possible should be used at all times.

Fig. 1

Fig. 2

Fig. 3

7502961.06.11.96 5

Adjusters, jumpers and check points

Trimming potentiometerDesignation Range adjustment

Direction of rotationon trimming potentiometercounterclockwise clockwise

Basic setting,factory adjusted

E Modulation limitation "A B" [mA] 10 ... 100% 100%D1 Zero-point "NUL" [%IA max.] 0 ... 30 0

F2 Ramp "RMP" approx. [s] 0.18 ... 18 18

C2 Superimposed dither "OSZ" [%IA max.] 0 ... 30 15

Switches and jumpers

A Set point preselection

Set point 0 ... 10 V 1) 0 ... 20 mA 4 ... 20 mA

Switch positions

B Selection of solenoid currentType 0 ... 1000 mA 0 ... 2400 mAOutput current range [mA]

0 ... 400 0 ... 800 0 ... 1000 0 ... 1600 0 ... 2400

Jumpers A B C A C

1) 1)

1) Factory adjusted

6 7502961.06.11.96

C1 Superimposed dither

Frequency [Hz] 40 1) 80

Switch positions

D2 Zero-point adjustment Jumper

Zero-point shift Position "OFS" 1)

Zero jump Position "SPR"

F1 Ramp shaper Jumper

Ramp OFF Position "OFF" 1)

Ramp ON Position "ON"

1) Factory adjusted

Check pointsG Check points

Mp1 = 0 V (reference potential)Mp2 = Set pointMp3 = Solenoid current

7502961.06.11.96 7

1. Installation and connecting instructions1.1 Supply: 18 ... 32 VDC, excess voltage leads to

amplifier defects.

1.2 The plug-in type amplifier should not be installed too close to a power relay.

1.3 The conductors to the external set point adjusters (drive) must be screened. The screening must be connected on one side to terminal 2.

2. Adjusting instructions(below order must be strictly adhered to).

2.1 Preselection of set pointOn switch A "UE/IE"Select switch position according to the given setpoint.

2.2 Selection of solenoid current On jumpers B "IA" Select jumper according to the required current value.

2.3 Dither

2.3.1 Dither frequency On switch C1 "f" / Select 40 or 80 Hz frequency via switch

2.3.2 Imposed dither (amplitude) On trimming potentiometer C2 "OSZ" For adjustment of the dither a setpoint ≤ 20% must be selected. Turn trimming potentiometer clockwise until the manipulated variable changes due to small changes on the setpoint adjuster. Make sure, however, always to select the smallest possible value.

2.4 Zero-point adjustment

2.4.1 Zero-point shift ("OFS") a) Switch jumper D2 to position "OFS" b) Adjust setpoint to zero c) Turn trimming potentiometer D1 "NUL" clockwise until the desired value of the flow volume or pres- sure has been reached with the setpoint adjusted to zero.

2.4.2 Zero-point jump a) Switch jumper D2 to position "OFS" b) Adjust setpoint to zero c) Turn trimming potentiometer D1 "NUL" clockwise

until the valve opens. Then turn it anticlockwiseuntil the valve has closed again.

d) Switch jumper D2 to position "SPR"

2.5 Drive limitation

Trimming potentiometer E "AB" a) Turn trimming potentiometer E "AB" approx. 12

counterclockwise b) Adjust set point to max. value c) Turn trimming potentiometer E "AB" clockwise until the desired value of the flow volume or pressure has been reached.

2.6 Ramp shaper

2.6.1 Ramp off Switch jumper F1 to position "OFF"

2.6.2 Ramp on a) Switch jumper F1 to position "ON" b) Set trimming potentiometer F2 "RMP" to the longest adjusting time by turning it clockwise. c) By turning the trimming potentiometer F2 anticlockwise set the adjusting time so that the desired transient response is achieved when the set point is changed.

3. Trouble shooting3.1 Measure the amplifier supply voltage

(+18 ... 32 V) between terminals 5 and 1, if necessary, check the supply cable and the fuse in this.

3.2 Measure the internal amplifier operating voltage (+15 V) between terminals 4 and 1.

3.3 Measure the set point input signal between check points Mp2 and Mp1 Measuring values according to table.

Check point Check point Mp1 = 0 V (reference potential) Check point Mp2 = Set point

DefinitionSet point Measured value

(measured against Mp1)

0 ... 10 V 0 ... 10 V0 ... 20 mA 0 ... 2 V4 ... 20 mA 0.4 ... 2 V

Definition U = f (ISolenoid)Type Assignment Measured value

(measured againstMp1)

0 ... 1000 mA 1 mV corresp. to 3 mA 0 ... 325 mV0 ... 2400 mA 1 mV corresp. to 10 mA 0 ... 240 mV

Measure between check points Mp3 and Mp1 and, in the case of a plug-in type amplifier, also between plug pins 2 and 6. With setpoint = 0, the solenoid current must be 0 mA (measurement 0 mV). The trimming potentiometer for zero-point lift "NUL" must be set to zero (left-hand stop).

Important: The solenoid current can be measured onlywhen the amplifier on the solenoid is plugged in.

3.4 Measuring the solenoid current The solenoid current can be measured by means of a voltmeter.

Check point Mp3 (solenoid current). Measure UMp3 = f (I solenoid) for measurement of sole- noid current by means of a voltmeter with Ri ≥ 1 MΩ. For assignment, see table.

8 7502961.06.11.96

Accessories for amplifier pQ 11Designation Specification Cat. No. Publication

Set point adjusterSE 01Angle of rotation 270°

For pressure andflow volume

5998534 7501675

Set point adjusterSE 02Angle of rotation 360°

For pressure andflow volume

5998536 7501782

Set point adjusterSE 03Digital

For pressure andflow volume

5998647 7501783

Set point adjusterSE 13

For pressure and flow volumeOutput 0 ... 20 mAOutput 4 ... 20 mA

59987745998775

7502504

TransformerTR 21

115/230 VAC24 VDC, 3.0 A

5998609 7501789

TransformerTR 22

380 VAC24 VDC, 6.0 A

5998611

Plug connector foramplifiers 5980081, 5980082, 5980083 and5980114

6-pin + PEDIN 43651

0660689 –

Set point switch 1)

SU 012 internalset points

5998737 7502595

1) Possible only with plug-in type version

7502961.06.11.96 9