Owner's Manual - Fimco IndustriesFM835...• 2.5 H.P. Recoil Start Engine • 4 Roller Pump - 6...

Transcript of Owner's Manual - Fimco IndustriesFM835...• 2.5 H.P. Recoil Start Engine • 4 Roller Pump - 6...

Form No. 835 [5004613 (02/14)] Printed in the U.S.A.

AssemblyThe sprayer is mostly assembled at the factory.

Thread the pressure gauge into the pressure relief valve •using a good grade of thread sealant, or teflon tape. You will find this pressure gauge in the parts bag.Bolt the axle assembly to the frame with the four (4) bolts •and whiz nuts shown in the exploded view drawing. Place each wheel over the hubs (valve stem outward) and tighten the lug nuts down securely.Bolt the boom mounting brackets to the frame (if not •done so already) with the hardware shown in the exploded view drawing.Bolt the boom assembly to these brackets with the two (2) •u-bolts and four (4) whiz nuts provided. Center the center boom member about the frame of the sprayer, then tighten the nuts/u-bolts securely. The boom 'wings' are intended to fold 'backwards', not upwards.Install the nozzle harness onto the boom. The nozzles •should end up being on the back side of the boom after being clamped to the tubular member(s). Slide a hose clamp onto the boom feeder hose, and slip the hose onto the 'cross' fitting on the center nozzle of the boom. Tighten the hose clamp down securely.

Note: Add proper oil to the engine crankcase and gasoline to the gas tank. Refer to the engine manual for the correct type and amount. It is important to test the sprayer with plain water before actual spraying is attempted. This will enable you to check the sprayer for leaks in the plumbing system.

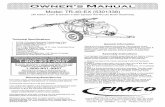

Model: ATVTS-60-4R (5301306)(60 Gallon Trailer Sprayer w/2.5 H.P. Engine, 4-Roller Pump, Deluxe Handgun)

Owner's Manual

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440

www.fimcoindustries.com

General InformationThank you for purchasing this product. The purpose of this manual is to assist you in operating and maintaining your trailer sprayer. Please read it carefully, as it furnishes information which will help you achieve years of trouble-free operation.

Warranty/Parts/ServiceFor home usage, products are warranted for one year from date of purchase against manufacturer or workmanship defects.

Commercial users have a 90 day warranty.

Your authorized dealer is the best source of replacement parts and service. To obtain prompt, efficient service, always remember to give the following information...

- Correct Part Description and/or part number. - Model number/Serial number of your sprayer.

Part descriptions and part numbers can be obtained from the illustrated parts list section(s) of this manual.

Whenever you need parts or repair service, contact your distributor/dealer first. For warranty work, always take your original sales slip, or other evidence of purchase date, to your distributor/dealer.

Technical Specifications• 2.5 H.P. Recoil Start Engine• 4 Roller Pump - 6 G.P.M.• Pressure Relief Valve• Pressure Gauge• Suction Line Filter• Pistol Grip Spray Gun w/25 Ft. of Handgun Hose• 7-Nozzle Boom Assembly - 140" Spray Coverage• Break-Away Outer Boom Members• Pneumatic Tires: 18 x 850 x 8 (10 MPH MAX)

(*) = Parts available only in spare parts kit #7771796.

4-Roller Pump#5275495 (4101C-07)

1/4"-20 x 3/8" Set ScrewCollar Set ScrewCollarBall Bearing (Sealed)Bearing CoverShaft Bearing CoverEnd PlateBody w/Seal

Description

Rotor & Shaft Assembly

End Plate ScrewHollow Shaft (Only)

Pump Model StickerSuper Roller (4-Roller Pump)Seal (Viton)O-Ring Gasket

DescriptionQtyPart NumberNoItem

2220-0018 0551-40000301-4101N

* 5112029* 5110052* 5072220

5

65.1

2

43

1

---1

41

42

1

1

QtyPart NumberNoItem

51170505117049505500750311135017481501748050172335002351

11

141312

8

109

7

2

111

1

11

1

64 10

6

8

1

112

5.15

14

3

13

2

7

119

12

Page 2

1. Open the tank lid and be sure the tank is clean and free of foreign material. Fill the tank about 1/2 full with plain water.

NOTE:It is VERY important for you to test your sprayer with plain water before actual spraying is attempted. This will enable you to check the sprayer for leaks, without the possibility of losing any expensive chemicals.

CAUTION: Always be sure that water has reached the roller pump before starting your sprayer. If the pump is run dry, serious damage to the pump will result. Do not run your sprayer with the boom/handgun line closed AND the bypass line closed. Doing this will damage the pump.

2. Open the brass valve in the suction line underneath the tank, and allow water to flow to the pump. The valve is located at this point to enable the strainer to be taken apart for cleaning, while solution remains in the tank.

3. It is always best to start the sprayer at little or no pressure. This sprayer is equipped with a spring loaded pressure relief/bypass valve. Turn the valve knob out (counter-clockwise) to decrease pressure and in (clockwise) for increased pressure.

The bypass valve is the "pressure control" for the entire plumbing system. The more that valve is open, the lower your line pressure. Fully closed provides maximum pressure to your boom and/or handgun.

4. You may now start the sprayer engine following the engine manufacturers instructions. Let the sprayer run at low pressure until water has reached the handgun and all air has been purged from the system.

CAUTION: Care must be taken, being sure the handgun is secured in the operators hand. If this is not done a recoiling action may occur causing damage or personal injury.

Information About The SprayerIn this pumping system, solution is drawn from the tank, and forced to a planned source, such as boom nozzles, or handgun. The pressure is controlled by opening/closing the valve which recirculates solution back into the tank..

Testing the Sprayer

Periodically close the suction line valve. Check the line strainer and clean the screen. Always flush the entire plumbing system with water or a neutralizing agent, such as FIMCO Tank Neutralizer and Cleaner, after completing the spraying operation.

Proper care and maintenance will prolong the life of your sprayer.

After use, fill the sprayer tank part way with water. Start the sprayer, and allow the clear water to be pumped through the plumbing system and out through the spray nozzles.Refill the tank about half full with plain water and use FIMCO Tank Neutralizer and Cleaner, and repeat cleaning instructions above.Flush the entire sprayer with the neutralizing/cleaning agent, then flush out one more time with plain water. Follow the chemical manufacturer's disposal instructions of all wash or rinsing water.For the boom, (if applicable) remove the tips and screens from the nozzle assemblies. Wash these items out thoroughly. Blow the orifice clean and dry. If the orifice remains clogged, clean it with a fine bristle (NOT WIRE) brush, or with a toothpick. Do not damage the orifice. Water rinse and dry the tips before storing.

WARNING: Some chemicals will damage the pump valves if allowed to soak untreated for a length of time! ALWAYS flush the pump as instructed after each use.

Maintenance During/After Spraying

Drain all water out of your sprayer, paying special attention to the pump, handgun, and valve(s). These items are especially prone to damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a solution of RV antifreeze through the entire plumbing system. This antifreeze solution should remain in the plumbing system during the winter months. When spring time comes and you are preparing your sprayer for the spray season, rinse the entire plumbing system out, clearing the lines of the antifreeze solution. Proper care and maintenance will prolong the life of your sprayer.

Winter Storage

A21

30

3315

11

14

14

26

35.8

135.2

35.6

35.435.3

35.135.6

35.5

35.7

8 20 20

31

40

26

126

17

63

3

16

12

12

37

36

31

28

4

13

32

23

39

9

6

710

29

39

253

27

2

23101818

2827

3

3834.734.6

34.534.1

34.434.3

34.2

5

71919

9 20 20

6 20 20

Plumbing Components Shown

DETAIL A

22

24 15

30

DETAIL B

26

1

35

40

26

Page 3

Exploded View(s):Model: ATVTS-60-4R (5301306)

Boom Clamp Assembly (7xs)

7-Nozzle Boom Assembly2.1

2.2

2.5

1.6

50161571.3.4

1.5.1

1.4.51.4.41.4.31.4.21.4.1

1.3.5

1.5

1.4

505611352776895018371501615750462195116019505611452776905018371

1.3.31.3.21.3.1

Item

1.3

1.11

1.2

NoPart

5046219511601950561155277691502051050511445277696Number

1.5.2

1.5.51.5.3

1.5.4

1.5.11.2

Single Hose Shank (3/8" Hose)"ELL" Nozzle Sub-Assembly (3/8")Air-Induction XR Flat Spray Tip (AIXR11002VP)Seat Washer (QJ Caps)Quick TeeJet Cap ONLY (Yellow)Nozzle Strainer, Red (50 Mesh)Double Hose Shank (3/8" Hose)"TEE" Nozzle Sub-Assembly (3/8")Air-Induction XR Flat Spray Tip (AIXR11002VP)Seat Washer (QJ Caps)Quick TeeJet Cap ONLY (Yellow)Nozzle Strainer, Red (50 Mesh)Triple Hose Shank (3/8" Hose)"Cross" Nozzle Sub-Assembly (3/8")Hose, 3/8"-1 Brd. x 19-3/8"

7-Nozzle Harness (3/8")

1

1

1

12

1

4

11

1

Hose Clamp, 3/8"

DescriptionQty

1

11

1

121

4

1.3.41.3.51.3.3

2.4

1.21.4.41.4.51.4.3

1.4.11.4.2

1.11.7

2.8

1.3.11.3.2

2.2

2.2

2.12.3

Outer Boom Weldment (LH) (1" Sq Tube)Outer Boom Weldment (RH) (1" Sq Tube)Center Boom Weldment 1" Sq. TubeSquare Cap, Black (1" Square Tube)

3/8"-16 Flange Locknut (Grade F)3/8"-16 Hex Whiz (Flange) Locknut

Boom Clamp Assembly (1in Sq.)Air-Induction XR Flat Spray Tip (AIXR11002VP)

Quick TeeJet Cap ONLY (Yellow)Nozzle Strainer, Red (50 Mesh)

1.7

250203471.7

527783752778365277838504610650341695019228500634550062595277780

2.82.72.62.52.42.32.22.12

1

2

11

2

64

2

1

5277923

Number

1.61.5.51.5.41.5.31.5.2No

Item

5018371501615750462195116019

Part

1

17

1

Qty1

Hose, 3/8"-1 Brd. x 21"

H.H.C.S., 3/8"-16 x 2 1/2"Extension Spring

7-Nozzle Boom Assembly

2.2

Seat Washer (QJ Caps)

Description

1.2

2.6 2.1

2.2 2.22.3 2.1

2.4

2.7

1.11.2

2.5

Gallons Per 1000 Sq. Ft. - Based on Water

MPH

Pressure

Pressure

AIXR11002VP

Number

AIXR11002VP

Number

Tip

Tip

18"

HeightSpray

18"

HeightSpray

.27.34.45.680.2040

Gallons Per Acre - Based on Water

(GPM)Capacity

(GPM)Capacity

0.2040

302015

(psi)

0.170.140.12

302015

(psi)

0.170.140.12

29.859.6

MPH

.58

.48

.41

2

50.441.635.6MPH

1MPH

25.220.817.8

2

.23

.19

.16MPH

5

11.910.18.37.1

MPH5

14.919.8

.29

.24

.20MPHMPH

.39

.32

.27

3 4

12.610.4

MPHMPH

16.813.811.8

3

8.9

4

7.49.98.46.95.9

MPH6

6.35.24.5

8

Spray Tip Rate Chart(20" Spacing)

110° wide, tapered flat spray angle with air induction technology for better drift management. Made of 2-piece UHMWPE polymer

construction which provides excellent chemical resistance, including acids, as well as exceptional wear life. Compact size to

prevent tip damage. Removable pre-orifice. Excellent for systemic products and drift management.

Page 4

Parts List, Model: ATVTS-60-4R (5301306)

Item No Part Number Qty Description1 5006259 12 3/8-16nc Hex Flanged Whiz Nut Gr. 52 5006306 4 1/4-20nc Hex Flanged Whiz Nut Gr. 53 5006307 10 5/16-18nc Hex Flanged Whiz Nut Gr. 54 5006337 2 1/2-13nc Hex Flanged Whiz Nut Gr. 55 5010202 1 Poly Elbow, 1/2" MNPT x 3/8" HB6 5020131 1 Hose, 3/8"-1 Brd. x 90"7 5020233 1 Hose, 3/4"-2 Brd. x 20"8 5020527 1 Hose, 3/8"-1 Brd. x 25 Ft.9 5020530 1 Hose, 3/8"-1 Brd. x 51"

10 5020540 1 Hose, 5/8"-1 Brd. x 7"11 5034101 4 H.H.C.S., 3/8"-16 x 1 3/4"12 5034159 2 Square U-Bolt, 5/16" x 1 5/16" x 1 7/8"13 5034700 2 H.H.C.S. Flanged 1/2"-13nc x 3 1/2" Long14 5038698 4 Plastic Tank Hold-Down Leg Clip15 5038775 1 Handgun Bracket16 5038833 1 Boom Mount R.H.17 5038834 1 Boom Mount L.H.

Item No Part Number Qty Description18 5051023 2 Hose Clamp, 5/8"19 5051024 2 Hose Clamp, 3/4"20 5051144 6 Hose Clamp, 3/8"21 5058188 1 Tank Lid w/Lanyard22 5075014 2 Rubber Grommet (Black)23 5095350 1 Manifold Mount (TR-40-GAS)24 5117234 2 #10-24 x 1/2" Phillips Truss Head Machine Screw25 5117301 4 H.H.C.S. Flanged 1/4"-20nc x 1" Long26 5117307 8 H.H.C.S. Flanged 3/8"-16nc x 1" Long27 5117323 6 H.H.C.S. Flanged 5/16"-18nc x 3/4" Long28 5152104 1 PowerPro 2.5 HP Engine (1/2" Shaft)29 5167004 1 Gauge, 0-200# (Dry)30 5169249 1 60 Gallon Elliptical Tank (White)31 5272464 2 Wheel, 18 x 9.5 x 8 - 4-Bolt32 5273204 1 Hitch Clevis Weldment33 5273959 1 Deluxe Pistol-Grip Handgun w/X-26 Tip34 5274939 1 Tank Valve Assembly

34.1 5005196 1 Poly Adapter, 3/4" MNPT x 3/4" MGHT34.2 5143190 1 3/4" "T-800" Brass Ball Valve34.3 5011147 1 Poly Reducing Nipple, 3/4" MNPT x 1/2" MNPT

34.4 5010243 1 Poly Street Elbow, (90 Deg) 1/2" MNPT x 1/2" FNPT

34.5 5016066 1 Garden Hose Washer34.6 5149037 1 Poly Swivel, 3/4" Flat Seat Hose Barb34.7 5006209 1 Poly Knurled Swivel Nut, 3/4" FGHT35 5274955 1 Axle & Hub Assembly

35.1 5006301 8 1/2"-20 Hex Cone Wheel Nut35.2 5274954 1 Axle Weldment (ATVTS-60)35.3 5085018 2 Hub Assembly (4-Stud)35.4 5072471 2 Grease Seal35.5 5046327 2 Grease Cap35.6 5031139 4 Cone Bearing35.7 5006300 2 Castle Nut, 1"35.8 5101081 2 Cotter Pin, 5/32" x 2-1/4"36 5277696 1 7-Nozzle Harness (3/8")37 5277780 1 7-Nozzle Boom Assembly38 5278023 1 Pump Assembly (TR-40-GAS)39 5278067 1 Valve Assembly (ATVTS-60-4R)40 5278078 1 Frame Weldment (ATVTS-60) (Red)

'DIRECTO VALVE' - MANUALLY OPERATED CONTROL VALVE

513207151172815101220508604350781785053091501923050162805002476Number

section spray control- Valves may be connected w/close nipples for multiple

- 3/4" NPT (F) Continuous By-Pass Connection

- 1/2" NPT (F) Spray Line Connection

- 3/4" NPT (F) Inlet Connection

- Large Capacity - 12.5 G.P.M. @ 5 p.s.i. Pressure Drop

- Maximum Pressure = 150 p.s.i.

Polypropylene, 316SS and Polyethylene- Corrosion Resistant Materials: Wetted Parts

5

7

12

9

6

112

10

2

9

1213

1110

****

****

6

87

543

3

ItemNo.1

Part

4

#10-24 x 5/16" Phillips Truss Head Mach. Screw

Repair Kit (Marked **)

Position

2CP36307-PPB

F14CP38726-VI

CP7717-2/209-VICP7717-2/108-VI

CP36304-SSCP38725-SSCP36308-SSCP36302-PPCP36301-NY

CP36309-302SSCP36306-302SS

1

11

11

111

11

1

CP36303-PP

Mfg Part Number

21

Qty

1Washer

Pipe Plug, 1/4" MNPTShut-Off Washer, Viton

Poly Body Insert, (Black)Handle (Gray)Retaining Clip

Stem

O-Ring, VitonO-Ring, Viton

Groove Pin

Spring

Poly Body (AA6B)

PK-AB6B-KIT

Mfg. Number

5168718

Description

5143316

NumberPart

AA6B

13 PositionClosed (Bypass)

8

Open

Control Valve

Description

PISTON TYPE PRESSURE RELIEF/REGULATING VALVES

How to order: Specify valve number (Example: 23120-1/2-PP Polypropylene)

Model 23120

Selected pressure setting firmly held in place by locknut. Extra large passages to handle large flows.Bypasses excess liquid. Adjustable to maintain control of line pressure at any pressure within the valve operating range.

5115078511026651080955046270

PK-AB23120-KIT

23120-1/2-PP

23120-3/4-PP

Mfg Part Number

- Choice of 1/2" or 3/4" NPT (M) inlet & (F) outlet connections- 1/4" port for pressure gauge- For pressure to 150 p.s.i.

- Excellent chemical resistance- Polypropylene with stainless steel spring

5143199

5168717

5143200

NumberFIMCO

13

- EPDM O-Rings

6

Repair Kit, Items Marked **

3/4" Poly Valve

1/2" Poly Valve

Description

28

**7

1098

------**

Item

74

PartNumber

3

56

4

12

No

****

Poly Body (1/2" NPT)Poly Body (3/4" NPT)O-Ring, EPDM Rubber

Retaining PinPipe Plug, 1/4" MNPT

Spring RetainerAdjusting Cap, Nylon (Gray)

5143199/Qty

1CP23127-302SS

CP23128-PPCP23121-PP

CP7717-15-EPR

-11

CP23126-302SS

CP23125-PPCP23123-PPCP23124-PPCP23122-NY

Mfg Part Number

F14

1

111

11

Spring1

1

1-

5143200/Qty

1

111

11

Description

Guide SeatLock Ring

9

5

(10)

Page 5

to Handgun

1

Inlet

2

4

to Boom

1

Return to Tank

3

57

6

Valve Assembly #5278067

Directo-Valve (AA6B)Pressure Relief Valve, (3/4" NPT)

Poly Reducing Nipple, 3/4" MNPT xPoly Tee, 1/2" FNPTPoly Elbow, 3/4" MNPT x 3/8" HBPoly Elbow, 1/2" MNPT x 5/8" HBPoly Elbow, 1/2" MNPT x 3/8" HB

150102304

51433165143199

5011147

76

5 1/2" MNPT11

1

501020650102045010202

Number

3

1

NoItem Part

2

DescriptionQty

11

2

Pump Assembly #5278023

8

2

5

9.1

9.310

6

4

6

9.2

9.4

3

Poly Fitting, 3/4" MNPT x 3/4" HBPoly Fitting, 3/4" MNPT x 5/8" HBRubber-Headed Machine Screw Bumper (#10-24)

5/16"-18 x 1/2" Hex Flanged Bolt (Grd. 5)Poly Close Nipple, 3/4" MNPT45 Degree Poly Street Elbow, 3/4" NPT#10-24 Hex Whiz (Flange) Locknut

7150671267

109.49.39.29.1

1

4

89

5275495504608851163235072229505812551163225067127

4-Roller PumpStrainer Cap40 Mesh ScreenEPDM GasketStrainer Bowl3/4" Black Poly Strainer

1

1

11

1

11

QtyNoItem

3

56

4

12

Part

504000450387305034604501114050102495006186Number

Torque Bracket

Description

1

12

2

21

Page 6