Overheads 4554

-

Upload

sampathgsk -

Category

Documents

-

view

225 -

download

0

Transcript of Overheads 4554

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 1/67

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 2/67

Agenda

Basics of SCM

Drivers of SCM

Elements of SCM E-Commerce Impact on SCM

Performance Measurement

Collaboration in SCM Purchasing

How to Choose and Evaluate Suppliers

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 3/67

Basic Concepts ofSupply Chain Management

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 4/67

Supply Chain Management

Supply Chain:

The sequence of organizations - their

facilities, functions, and activities - that areinvolved in producing and delivering a product

or service.

Sometimes referred to as value chains

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 5/67

The Value Chain internal to a

company

PurchasingReceiving Storage Operations Storage

Production Distribution

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 6/67

Typical Supply Chain

activities for a Manufacturer

Supplier

Supplier

Supplier

Storage} Mfg. Storage Dist. Retailer Customer

supply

chain

demandchain

internal

value

chain

supply chain management (SCM) concerns supplier activities,internal value chain activities, and demand chain activities

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 7/67

Supplier

Supplier}Storage Service Customer

Typical Supply Chain for a

Service

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 8/67

Goal of SCM

Goal of SCM

To link all components of the supply chain so

that market demand will be met as efficiently

as possible across the entire chain

Match supply to demand at each stage of the

supply chain

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 9/67

Supply network encompasses a

number of facilities

Warehouses

Factories

Processing centers Distribution centers

Retail outlets

Offices

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 10/67

Supply network performs various

functions and activities

Forecasting

Purchasing

Inventory management Information management

Quality assurance

Scheduling

Production and delivery

Customer service

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 11/67

Supply Chain Management

Issues

Quality control

Production planning and

control

Inventory policies

Purchasing policies

Production policiesTransportation

policies

Quality policies

Design of the

supply chain,

partnering

Operating Issues Tactical Issues StrategicIssues

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 12/67

Drivers of Supply ChainManagement

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 13/67

History of SCM

Why attempt to manage supply chains?

In the not too distant past (i.e. pre-1990s),

many companies didn’t manage their supplychains

Some advanced companies realized that

huge inefficiency resulted from no/poor SCM

In particular, identified the “Bullwhip Effect”

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 14/67

Bullwhip Effect

Tier 2

Suppliers

Tier 1

SuppliersProducer Distributor Retailer

Final

Customer

Amount of

inventory=

“I’ll buy 2” “I’ll order 2 more.”

“Hmm. Last period they

ordered 1.

Maybe demand

is up. I had

better order 8.”

“Wow! 8! I better

build 30!”

“@%*$! We are

really

behind.

Build 100!”

“The sky

is falling!

Build 250!”

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 15/67

Bullwhip Effect

Tier 2

Suppliers

Tier 1

SuppliersProducer Distributor Retailer

Final

Customer

Amount of

inventory=

“I’ll buy 0” “I’ll order 0 more. I

have 2

in stock.”

“0?. But I’ve got 6 left.

Don’t buyany more.”

“0? But I’ve

got 22 in

stock! Stop

the line.”

“0? @%*$! What are

we gonna

do with the

70 we have?”

“0? But we’ve got 150 in stock!”

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 16/67

Result of the Bullwhip Effect

Inventory

Backorder At each stage of the supply chain, a pattern like the above

develops, of huge inventory buildups (and costs), followed

by periods of huge stockouts and backordering (and mad

customers + backordering costs)

Time

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 17/67

Benefits of Supply Chain

Management

Counteract the Bullwhip Effect

Lower inventories

Higher productivity Greater agility

Shorter lead times

Higher profits

Greater customer loyalty

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 18/67

Today, many other problems can also

drive Supply Chain Management

1. Improve operations

2. Increasing levels of outsourcing

3. Increasing transportation costs4. Competitive pressures

5. Increasing globalization

6. Increasing importance of e-commerce

7. Complexity of supply chains

8. Manage inventories

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 19/67

Supply Chain Benefits and

Drawbacks

Operational

Problem

Potential

Improvement

Benefits Possible

Drawbacks

Large

inventories

Smaller, more

frequent deliveries

Reduced holding

costs

Traffic congestion

Increased costs

Long lead

times

Delayed

differentiation

Disintermediation

Quick response May not be

feasible

May need absorb

functions

Large number

of parts

Modular Fewer parts

Simpler ordering

Less variety

Cost

Quality

Outsourcing Reduced cost,

higher quality

Loss of control

Variability Shorter lead times,

better forecasts

Able to match

supply and

demand

Less variety

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 20/67

Examples of SCM Benefits at

Various Companies

Organization Benefit

Campbell Soup Doubled inventory turnover rate

Hewlett-Packard Cut supply costs 75%

Sport Obermeyer Doubled profits and increased sales 60%

National Bicycle Increased market share from 5% to 29%

Wal-Mart Largest and most profitable retailer in the world

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 21/67

As a result of competitors working on

SCM, SCM has become strategic

Strategic importance

Cost

Quality Agility

Customer service

Competitive advantage

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 22/67

But, SCM projects can be very

risky to undertake

Technology management drives SCM Adoption/Success/Failure

Benefits SCM packages, when adopted well, can transform

an organization’s operations

Risks Poorly planned for/implemented SCM packages

can wreck a company’s operations Very expensive to install these pages – many

millions of dollars

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 23/67

Elements of SCM

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 24/67

SCM involves coordinating

activities across supply chain

Deciding how to best move and store materialsLogistics

Determining location of facilitiesLocation

Monitoring supplier quality, delivery, and relationsSuppliers

Evaluating suppliers and supporting operationsPurchasing

Meeting demand while managing inventory costsInventory

Controlling quality, scheduling workProcessing

Incorporating customer wants, mfg., and timeDesignPredicting quantity and timing of demandForecasting

Determining what customers wantCustomers

Typical IssuesElement

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 25/67

Logistics

Logistics

Refers to the movement of materials and

information within a facility and to incoming

and outgoing shipments of goods and

materials in a supply chain

Raw materials

Work in process Finished goods

Support items – fuel, equipment, parts, tools, etc.

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 26/67

Logistics

• Movement within the facility

• Traffic planning for incoming and

outgoing shipments

• Bar coding

• EDI• Distribution

• JIT Deliveries

0

214800 232087768

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 27/67

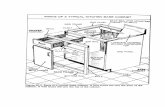

Materials Movement

R E C E I V I N G

Storage

Work

center

Work centerWork center

Storage

Work

center

Storage

Shipping

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 28/67

Distribution Requirements

Planning (DRP)

Distribution requirements planning (DRP)

is a system for inventory management and

distribution planning

Extends the concepts of MRPII to

multiechelon warehouse inventories

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 29/67

Uses of DRP

Management uses DRP to plan and

coordinate:

Transportation Warehousing

Workers

Equipment

Financial flows

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 30/67

Electronic Data Interchange

(EDI)

EDI

The direct transmission of inter-organizational

transactions, computer-to-computer, including

purchase orders, shipping notices, and debit

or credit memos.

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 31/67

Electronic Data Interchange

Increased productivity

Reduction of paperwork

Lead time and inventory reduction Facilitation of just-in-time systems

Electronic transfer of funds

Improved control of operations

Reduction in clerical labor

Increased accuracy

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 32/67

Third Party Logistics (3PL)

3PL

The outsourcing of logistics management

Companies turn over their warehouse anddistribution to companies that specialize in

these areas

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 33/67

E-Commerce Impact on SCM

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 34/67

E-Commerce

E-Commerce: The use of electronic technology (e.g., WWW, Web

Services, mobile devices) to facilitate businesstransactions

Applications include Internet buying and selling

Order and shipment tracking

Electronic data interchange

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 35/67

SCM Benefits of E-Commerce

Companies can:

Have a global presence

Improve competitiveness and quality

Analyze customer interests

Collect detailed information

Shorten supply chain response times

Realize substantial cost savings Create virtual companies

Level the playing field for small companies

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 36/67

SCM Challenges of E-Commerce

Customer expectations

Order quickly -> fast delivery

Order fulfillment

Order rate often exceeds ability to fulfill it

Inventory holding

Outsourcing loss of control

Internal holding costs

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 37/67

How to Measure SCM

Performance?

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 38/67

Successful SCM has certain

characteristics

Trust among trading partners

Effective communications

Supply chain visibility

Access to real-time data on inventory levels, shipping

status, related information

Requires data sharing between trading partners

Event-management capability The ability to detect and respond to unplanned events

Performance metrics

Measure the system to make sure you are doing well

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 39/67

Overall Objectives for Supply

Chain Performance

Cost

Quality

Flexibility

Velocity

Customer service

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 40/67

Velocity

Inventory velocity

The rate at which inventory (material) goes

through the supply chain

Information velocity

The rate at which information is

communicated in a supply chain

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 41/67

Trade-offs Between Performance

Measures

Lot-size vs. inventory

Ordering economies vs. inventory held

Risks the Bullwhip effect

Inventory vs. transportation costs

Shippers prefer to ship full truckloads, which increases inventorycarrying costs

Solutions: combine orders, smaller trucks, cross-docking

Lead time vs. transportation costs

Waiting for a full truck increases production lead times

Product variety vs. inventory Higher variety leads to smaller lot sizes, more setups, other costs

Solution: Delayed differentiation

Cost vs. customer service

Large volumes reduce cost, but can hurt customer service

Solution: Disintermediation

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 42/67

Cross-Docking

Cross-docking

Goods arriving at a warehouse from a supplier are

unloaded from the supplier’s truck and loaded onto

outbound trucks

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 43/67

Delayed Differentiation

Delayed differentiation

Production of standard components and

subassemblies, which are held until late in the

process to add differentiating features

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 44/67

Disintermediation

Disintermediation

Reducing one or more steps in a supply chain

by cutting out one or more intermediaries

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 45/67

SCM Performance Measures

SCOR (Supply Chain Operations

Reference) Model

Plan, Source, Make Deliver, Return

SCOR addresses …

Product from supplier’s to customer’s

SCOR does not address …

Sales, Marketing, R&D, Support

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 46/67

SCOR Metrics provide a

standard way to measure SCM

Perspective Metrics

Reliability On-time delivery

Order fulfillment lead time

Fill rate (fraction of demand met from stock)

Perfect order fulfillmentFlexibility Supply chain response time

Upside production flexibility

Expenses Supply chain management costs

Warranty cost as a percent of revenueValue added per employee

Assets/utilization Total inventory days of supply

Cash-to-cash cycle time

Net asset turns

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 47/67

SCOR’s SCM PerformanceMetrics

Reliability – delivery performance, fill rate,

perfect fulfillment

Responsiveness – order fill lead time

Flexibility – SC response time, ops flexibility

Cost – warranty cost, productivity, CGS, SCM

cost

Assets – turns, inventory days, cash cycle

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 48/67

Collaborative Approaches to

SCM

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 49/67

Creating an Effective Supply

Chain Involves Partnerships

Develop strategic objectives and tactics

Integrate and coordinate activities in the

internal supply chain Coordinate activities with suppliers with

customers

Coordinate planning and execution acrossthe supply chain

Form strategic partnerships

C

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 50/67

Collaboration Assumes Your

Supplier can be a Partner

Aspect Adversary PartnerNumber of suppliers Many One or a few

Length of relationship May be brief Long-term

Low price Major consideration Moderately important

Reliability May not be high High

Openness Low High

Quality May be unreliable;buyer inspects At the source; vendorcertified

Volume of business May be low High

Flexibility Relatively low Relatively high

Location Widely dispersed Nearness is important

P hi i h li

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 51/67

Partnerships with suppliers can

improve your own operations

Ideas from suppliers could lead to improved

competitiveness

Reduce cost of making the purchase

Reduce transportation costs

Reduce production costs

Improve product quality

Improve product design

Reduce time to market

Improve customer satisfaction

Reduce inventory costs

Introduce new products or services

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 52/67

Efficient Consumer Response

Efficient Consumer Response (ECR)

A supply chain management initiative specific

to the food industry

Reflects companies’ efforts to achievequick response using EDI and bar codes

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 53/67

CPFR

Collaborative Planning, Forecasting, and

Replenishment (CPFR)

Focuses on information sharing among

trading partners

Forecasts can be frozen and then converted

into a shipping plan

Eliminates typical order processing

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 54/67

CPFR Process

Step 1 – Front-end agreement on structureof CPFR collaboration

Step 2 – Develop joint business plan for

collaborators

Steps 3-5 – Sales forecast collaboration

Steps 6-8 – Order forecast collaboration

Step 9 – Order generation/deliveryexecution

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 55/67

CPFR Results

Nabisco and Wegmans

50% increase in category sales

Wal-mart and Sara Lee 14% reduction in store-level inventory

32% increase in sales

Kimberly-Clark and Kmart Increased category sales that exceeded

market growth

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 56/67

Challenges to Collaboration

Barriers to integration of organizations

Getting top management on board

Dealing with trade-offs

Small businesses – no money to invest, no time,no slack resources, insufficient technology

Actions that create more variability anduncertainty

Long lead times hinder the ability of a supplychain to respond to changing customerdemands

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 57/67

Purchasing

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 58/67

Purchasing

Purchasing is responsible for obtaining the

materials, parts, and supplies and services

needed to produce a product or provide a

service.

Goal of Purchasing

Develop and implement purchasing plans for productsand services that support operations strategies

Quality of materials purchased is sufficient for operations

Timing of deliveries supports operations

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 59/67

Fun Facts About Purchasing

Institute for Supply

Management

> 60% cost of finished

manufactured goods is

purchased

>90% cost of retail &

wholesale goods ispurchased

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 60/67

Duties of Purchasing

Identifying sources of supply

Negotiating contracts

Maintaining a database of suppliers

Obtaining goods and services

Managing supplies

P h i i t f ith th

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 61/67

Purchasing interfaces with other

functions and with external suppliers

Purchasing

Legal

AccountingOperations

Data

processing

Design &

Engineering

ReceivingSuppliers

Uses

materials

Negotiates contracts

Pays for

materials

Specifies quality of

materials

Inspects incoming shipments

Purchasing follows a cycle of

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 62/67

Purchasing follows a cycle of

activities

1. Requisition received

2. Supplier selected3. Order is placed with supplier

4. Monitor orders

5. Receive orders

Purchasing

Legal

AccountingOperations

Data

process-

ing

Design

Receiving

Suppliers

Centralized vs Decentralized

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 63/67

Centralized vs. Decentralized

Purchasing

Centralized purchasing

Purchasing is handled by one special

department

Decentralized purchasing

Individual departments or separate locations

handle their own purchasing requirements

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 64/67

How to Choose and Evaluate

Suppliers?

Management of Supplier Network

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 65/67

Management of Supplier Network

Involves Several Activities

Choosing suppliers

Evaluating sources of supply

Supplier audits Supplier certification

Supplier relationships

Supplier partnerships

Factors in Choosing a

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 66/67

Factors in Choosing a

Supplier

Quality and quality assurance

Flexibility

Location

Price

Product or service changes

Reputation and financial stability

Lead times and on-time delivery

Other accounts

8/11/2019 Overheads 4554

http://slidepdf.com/reader/full/overheads-4554 67/67

Evaluating Sources of Supply

Vendor Analysis - evaluating the sources

of supply in terms of …

Price

Quality

Services

Location

Inventory policy

Flexibility