Our Boosting Fabrication Services - Swagelok

Transcript of Our Boosting Fabrication Services - Swagelok

BEFO

RE

BEFO

RE

Productivity-Boosting

Truths about...

AFTE

RAF

TER

OurFabrication

ServicesDesign-through-Delivery Excellence

CONTACT & FOLLOW US

Swagelok Pittsburgh | Tri-State Area412.761.3212

pittsburgh.swagelok.com@SwagelokPGH

SwagelokPittsburghSwagelok Pittsburgh | Tri State Area

Gas Panel

Large Instrument Panel

High-Volume Assembly

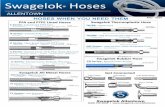

Hose Assembly

Simple Assembly Specialty Panel(with Orbital Welds)

Specialty Panel(with Orbital Welds)

Tube Bending

Manifold

Peop

le Place

Promise

Process Proven

Presenting Swagelok Pittsburgh I Tri-State Area’s Fabrication Technologies:

If a warrantied, premium-quality, turnkey fabricated solution – delivered as one part number – makes total fi nancial and functional sense for you, we can help.

If scrap, rework, and other operational ine� ciencies continually hamper your overall performance and profi tability, we can help.

If you lack the necessary equipment/machinery, specialized skills sets, or simply have too little available labor for your current workload, we can help.

If your instrumentation panel, enclosure, or general fl uid-system skid or assembly projects are taking too long, costing too much, or putting you at too great a risk, we can help.

OUR FABRICATION STAFF

GARY OSMAN, Applications EngineerA Penn State University Engineering graduate, Gary specializes in helping you take your idea to a design stage. He oversees all of our Fabrication projects, concept through delivery. Gary holds Swagelok certifi cations in Tube Fitting Installation, Threaded Fitting Assembly, Basic Electrical, Hose Assembly, Tube Bending, and Orbital Welding. He’s also one of our Hose Advisors.

OUR FABRICATION FACILITY• state-of-the-art 5,000-square-foot area• 5-ton overhead crane, with 18-foot clearance• climate-controlled environment• dedicated swaging, bending, coiling, orbital welding, and kitting stations• complete testing, inspection, cleaning, and packaging stations

OUR FABRICATION WORK COMMITMENT AND PROMISE• Mission: To convert every customer challenge, large or small, into an opportunity to deliver a reliable, repeatable, premium-quality solution that will signifi cantly enhance customer’s safety, productivity, e� ciency, and, ultimately, profi tability.• Whether a sub-assembly, simple assembly, or large, complex panel, we will provide superior consultation, design, and/or build assistance to enable you to dedicate your workers to more critical tasks…so that you can get more work out the door, on plan, on time, and within budget.• We will help substantially lower your engineering, scrap, rework, receiving, inspection, inventory handling, tracking, and administration costs.

Our Fabrication work is 100%-backed by the Swagelok Limited Lifetime Warranty: Swagelok and its authorized distributors hereby warrant to the purchaser of their products that the non-electrical components shall be free from defects in material and workmanship for the life of the products.

In addition, all Swagelok Fabrication o� erings are developed in accordance within the guidelines of Swagelok’s ISO-based quality system to ensure ultimate quality, safety, and reliability…thus enabling us to fabricate and install piping systems in accordance with ASME B31.1 and B31.3.

• receiving initial inquiry • conducting a site visit • taking critical measurements • providing conceptual and formal CAD drawings • adhering to an existing (or creating a new) P&ID • issuing job quote

• recommending/selecting/sourcing genuine Swagelok and/or, if necessary, other top- quality fl uid-system components • building a bill of materials • establishing a single part number • securing your approval to begin

OUR PROUD HISTORY OF FABRICATION SUCCESS• Gas Purge Panels and Cabinets• Distribution Manifolds• Ultra-High Purity Welded Manifolds• Custom Pre-Bent Compressor Lube Lines• Pump Seal Cooling Lines• Hose Assembly• Tube Assembly• Regulator Panels and Changeover Manifolds• Safety Grab Sample Panels• Standard Instrumentation Mounting Kits• Process Control Loops• High-Volume Tube Bending and Assembly• Test Stands• Medium-Pressure and High-Pressure Assemblies• Enclosures• Instrument Sub-Assemblies• Cylinder Assemblies• OEM Sub-Assemblies

MIKE GAGEL, Technical Trainer and Fabrication TechnicianA 20-year Swagelok Company veteran, Mike authored a majority of the Swagelok Installation, Inspection, Hose, and Tube Bending training content used globally. Like Gary and Mike Koster, Mike holds multiple Swagelok certifi cations and remains Swagelok’s primary Advanced Tube Bending worldwide go-to resource. Mike is also a Swagelok Hose Advisor.

MIKE KOSTER, Fabrication Center ManagerWith almost 40 years of applied practical Fabrication knowledge and experience, and fully certifi ed in multiple Swagelok disciplines – Swagelok Level 1 Weld Examiner, Activated Ball Valve Assembly, Relief Valve Setting, Fitting Installation, Tube Bending, Tube Coiling, and Orbital Welding, Mike brings an unparalleled and proven “build” expertise to our Fabrication operations.

We can now perform masterful tube bending up to 2” in diameter — right at your worksite! Realize drastic reductions in scrap and rework — and on-hand tubing inventory — no matter how challenging or complex your bending application.

Let Us Help You Realize a Healthier Bottom Line!

Testing Inspection Relief Valve Setting

Wrapping Wrapping

Tube Bending KittingWelding CoilingSwaging

OUR FABRICATION WORK PROCESSWe work collaboratively with you – every phase of your project: