ORMB11-1 - Session 14

-

Upload

sandeep-kumar -

Category

Documents

-

view

218 -

download

0

Transcript of ORMB11-1 - Session 14

-

8/11/2019 ORMB11-1 - Session 14

1/28

Operations Management ORMB11-1

Session 14 Capacity continued)

-

8/11/2019 ORMB11-1 - Session 14

2/28

Dipankar Bose - XLRI

Case Alden Products, Inc.

European Manufacturing

Company

Products and Pricing

Consolidating API Europe

Production process Employees

Current Problems at Uniplant

API Competitive Guidelines and Uniplant

Justifying Uniplant Expansion Justifying New Plant

Contract Fillers

3-Shift Operation

Other non capacity related issues

-

8/11/2019 ORMB11-1 - Session 14

3/28

Dipankar Bose - XLRI

Company

Plants

Peoria, IllinoisHeadquarter

Nijmegen, HollandKnown as Uniplant

Buxbridge, UK

Main Subsidiaries

France, Italy, Spain, Germany

Competitors

Proctor & Gamble, Unilever, Gillette

-

8/11/2019 ORMB11-1 - Session 14

4/28

Dipankar Bose - XLRI

History API Europe

Before 1962Production at subsidiaries including UK

Consolidation of European subsidiaries except UK

Uniplant became operationalMid-1964

From 1964 to 1982

Uniplant expanded 6 times

1989Capacity expansion decision for Alden-Europe

The UK plant has capacity about 100 million units

Want to increase capacity based on export growth

African and Middle East export markets

-

8/11/2019 ORMB11-1 - Session 14

5/28

Dipankar Bose - XLRI

Products and Pricing

Premium priced personal care products

Approx. 1500 products at 50 different countries

Skin creams/ Lotions/ Soaps/ Shampoos/ Toiletries/

Deodorants Higher quality, innovative and unique

Products designed for specific season

Priced 15% above normal products

Gross margin around 60% Part of this is needed to finance R&D, advertising and

channel support

Net profit around 5%

-

8/11/2019 ORMB11-1 - Session 14

6/28

Dipankar Bose - XLRI

Products and Pricing Continued

Products vary in countries due to

Market size/ Relative popularity of product/ Trade

structures/ Pricing policies

Country managers has freedom to

Add/drop/reposition/emphasize products

According to perception of local market conditions

Major decisionExecutive Vice President, Alden Europe

-

8/11/2019 ORMB11-1 - Session 14

7/28Dipankar Bose - XLRI

Consolidating API Europe Operations

at Uniplant Advantages

Most of the production facilities were running near at

100% capacities

Many of these are inefficient

Difficult to locate and train adequate managerial andstaff personnel

Europe was planning to move to free trade among group of

common market countries

Tariffs and other discriminatory practices were about tobe abolished

Consolidating helps to reduce uncertainty

Cost of building central unit will give economies of scale

Existing plants can be used as regional warehouses

-

8/11/2019 ORMB11-1 - Session 14

8/28Dipankar Bose - XLRI

Consolidating API Europe operations

at Uniplant More Advantages

Easy for vertical integration with

On-site polymer plant

Sales processing and storage facilities

Reduced purchasing cost Packaging cost is 150% of raw material cost

Standardizing quality

Speeding up the development and introduction to new

products Why Holland?

Access to raw material/ Proximity to market via rail

and highways/ Labor cost/ Tax rate/ Political and

social stability

-

8/11/2019 ORMB11-1 - Session 14

9/28Dipankar Bose - XLRI

Production Process Uniplant

Storage tanksMixing and processingFilling lines

Finished product storagePackagingShipping

Currently the plant utilizes 17 of 30 hectares

12 high speed filling lines Two 8 hour shifts/ 5 days a week

During peak season also weekends

Cleaning and equipment maintenance after each shift

Capacity depends on Product mix and Size mix

Slightly below 90% capacity

Almost 300 million units a year

Possible to produce 340 million units a year

-

8/11/2019 ORMB11-1 - Session 14

10/28

Dipankar Bose - XLRI

Employees at Various API Plants

Uniplant420 employees

260 permanent production personnel

Temporary workersStudents from nearby University

Less than 10% of total forceDuring peak season the number doubles

Buxbridge plant at UK

200 employees in manufacturing Also have the flexibility of temporary workforce like

Uniplant

Peoria

1200 employees in three 8-hour shift

-

8/11/2019 ORMB11-1 - Session 14

11/28

Dipankar Bose - XLRI

Capacity Issues for Alden Europe

Total expected sales is going to be double from 1988 to

2000

Unit sales growth 5-6% on an average

With 2-shift operation and 100% capacity utilization

Current capacity 440 million units

Called Peak Capacity

Plan was with 15% capacity cushion

Currently they are operating with 90% utilization

Another 8-10 high speed filling is required

-

8/11/2019 ORMB11-1 - Session 14

12/28

Dipankar Bose - XLRI

Current Problems at Uniplant

Strategy

Between these two plants no standardization of

Cost system/ Inventory control techniques/ Quality

control procedures

One of the problems is short production runs It takes about one hour to changeover from one high

speed filling line to another

Substantial discount were given to low volume products

If they accept a years sales in a single shipment Uniplant resisted increase in SKU as

Both indirect and direct manufacturing cost depends

more on no of SKUs

Than on plants total production volume

-

8/11/2019 ORMB11-1 - Session 14

13/28

Dipankar Bose - XLRI

Current Problems at Uniplant Other

Issues

Between 1970 -1988Uniplant has gone through crises

Explosion in petrochemical price following oil shocks

Basic hourly wage at Holland increased from one of the

lowest to one of the highest Series of European recessions

Less than 35% of raw material at Uniplant came from

Holland

Cost+10% was their pricing policy (mark-up 10%) Plan to keep increase in product price within

80% of inflation rate in Holland

-

8/11/2019 ORMB11-1 - Session 14

14/28

Dipankar Bose - XLRI

Current Problems at Uniplant Other

Issues Continued

Country marketing organizationsComplaints about

Uniplant from

Late deliveries/ Poor responsiveness to

Marketing inquiries and requests

Problems related to exchange rate and transportation cost

Option Utilizing local Contract Fillers

Renegotiating pricing arrangement with Uniplant (will

reduce Uniplantsmark-up from 10% to 5%)

Equalizing unit transportation costs for all subsidiaries

-

8/11/2019 ORMB11-1 - Session 14

15/28

Dipankar Bose - XLRI

API Competitive Guidelines and

Uniplant

Competitive guideline argues in favor of

Flexibility in product and volume

Better responsiveness

Quality and service are also important Cost is having lowest importance

Uniplant manager was not in favor of increasing SKU

This is against Competitive guideline

-

8/11/2019 ORMB11-1 - Session 14

16/28

Dipankar Bose - XLRI

Justifying Uniplant Expansion

Equipments are imported from United states or EEC

countries

A modern high speed filling line costs Dfl. 6 million Adds 40 million units capacity per year

Uniplant requires additional 10 million investment

New facility requires 30 million

Expanded Uniplant can justify a blow molding facility for

producing its own plastic bottles

-

8/11/2019 ORMB11-1 - Session 14

17/28

Dipankar Bose - XLRI

Justifying Uniplant Expansion

Continued

Direct manufacturing cost at France or Italy is estimated

slightly higher than Uniplant

They may not have access to temporary university

student workers

New plant will also require higher employees as they

require 20% as administrative worker

For 40 million unit additional 50-100 employees arerequired

The problem is unpredictability of distribution cost at

various countries

-

8/11/2019 ORMB11-1 - Session 14

18/28

Dipankar Bose - XLRI

Justifying New Plant

Diversify APIs risk

Better against exchange rate fluctuations

Danger of protectionism and other non-tariff barriers are

reduced

-

8/11/2019 ORMB11-1 - Session 14

19/28

Dipankar Bose - XLRI

Contract Fillers

Allowed Italy to use contract fillers

By early 1989

15% of API Europe sales are filled by them

UK used 30% of them France fillers charge 5-10% less

Italy charges 20-30% less

Why they charge less than Uniplant?

Estimate

50 million units will be potential candidates for filling

by 1990 (80% in France and Italy)

100 million units will be by 2000

-

8/11/2019 ORMB11-1 - Session 14

20/28

Dipankar Bose - XLRI

Problem with Contract Filler

Loss of control over quality

Increased cost of inspection with increase in volume and it

increases indirect cost

Once a product line is stopped

It is difficult to build the capability again

It can reduce economies of scale The secrecy of the formulas can be risked

-

8/11/2019 ORMB11-1 - Session 14

21/28

Dipankar Bose - XLRI

3-Shift Operation Problems

Uniplant is reluctant to move to 3-shift operation

May decrease desired quality of work

Will increase congestion and confusion

Increasing no of shifts will increase only 50%

They are actually 9 hours in a plant

Cleaning and equipment maintenance is done off shift

3-shift will complicate worker schedule

-

8/11/2019 ORMB11-1 - Session 14

22/28

Dipankar Bose - XLRI

Other Non Capacity Related Issues

What is your view on Uniplantsperformance from 1981

to 1988?

How is the option of transshipment between Uniplant andUK operations?

What organizational issues can be important when

considering new facilities? Should it be allowed to compete with Uniplant?

-

8/11/2019 ORMB11-1 - Session 14

23/28

Dipankar Bose - XLRI

END OF CASE

-

8/11/2019 ORMB11-1 - Session 14

24/28

Dipankar Bose - XLRI

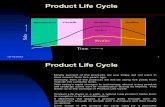

Ways to Develop Capacity Alternatives

Design flexibility into system

Take stage of life cycle into account

Take System Approach to capacity planning

Prepare to deal with capacity chunks Attempt to smooth out capacity requirements

Identify the optimal operating level

Choose a strategy if expansion is involved

-

8/11/2019 ORMB11-1 - Session 14

25/28

Dipankar Bose - XLRI

Develop Alternatives Breakeven

Analysis

Assumptions of Cost-Volume Analysis

One product is involved

Everything produced can be sold

Variable cost per unit is the same regardless of volume Fixed costs do not change with volume

Revenue per unit constant with volume

Revenue per unit exceeds variable cost per unit

Cost-Volume Relationships

Break-Even Problem with Step Fixed Costs

Multiple Product break-even point

-

8/11/2019 ORMB11-1 - Session 14

26/28

Dipankar Bose - XLRI

Breakeven Analysis Step Fixed Cost

A manager has options to purchase 1-3 machines. The

details are as follows:

Variable cost = 10/unit, Revenue = 40/unit

Determine BEP at each stage.

If annual demand is between 580-660 units, how many

machines should be purchased?

No of Machines Annual fixed cost total) Range of Output

1 9,600 0 to 300

2 15,000 301 to 600

3 20,000 601 to 900

-

8/11/2019 ORMB11-1 - Session 14

27/28

Dipankar Bose - XLRI

Breakeven Analysis Example

Homework

ABC Manufacturing intends to increase capacity by

overcoming a bottleneck operation through the addition of

new equipment. Two vendors have presented proposals as

follows:

The price for each product is 20.

What is the breakeven quantity for each proposal?

At what capacity would both plans incur the same cost?

Proposal Fixed cost Variable cost

A 50,000 12

B 70,000 10

-

8/11/2019 ORMB11-1 - Session 14

28/28

Dipankar Bose - XLRI

Some Short-Term Capacity Options

Lease extra space temporarily

Authorize overtime

Staff second or third shift with temporary workers

Add weekend shifts Alternate routings, using different work stations that may

have excess capacity

Schedule longer runs to minimize capacity losses

Level output by building up inventory in slack season

Postpone preventive maintenance (risky)

Use multi-skilled workers to alleviate bottlenecks

Allow backorders to increase, extend due date promises, or

have stock-outs

Subcontract work