OPTICAL SYSTEM FOR HIGH- POWER LASER …...The Selective Laser Sintering (SLS) of plastics has...

Transcript of OPTICAL SYSTEM FOR HIGH- POWER LASER …...The Selective Laser Sintering (SLS) of plastics has...

66 66 Annual Report 2015 Annual Report 2015 67

Sub

ject

to

alt

erat

ion

s in

sp

ecifi

cati

on

s an

d o

ther

tec

hn

ical

info

rmat

ion

. 06/

2016

.

Fraunhofer Institute for Laser Technology ILT, www.ilt.fraunhofer.de

DQS certified by DIN EN ISO 9001, Reg.-No.: DE-69572-01

Fraunhofer Institute for Laser Technology ILT, www.ilt.fraunhofer.de

DQS certified by DIN EN ISO 9001, Reg.-No.: DE-69572-01

Sub

ject

to

alt

erat

ion

s in

sp

ecifi

cati

on

s an

d o

ther

tec

hn

ical

info

rmat

ion

. 06/

2016

.

1

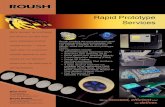

1 Schematics of the optical system beam path.

Task

The Selective Laser Sintering (SLS) of plastics has become

established as an additive manufacturing process, in particular,

for the production of complex prototypes and in small series.

More and more, however, users are demanding both higher

productivity through higher construction rates and a greater

reproducibility of component properties. Therefore, a novel

optical system for CO2 laser radiation should be designed to

improve both the productivity and consistency of SLS.

Method

By increasing the laser power as well as the laser beam

diameter, Fraunhofer ILT aims to increase productivity. Thanks

to the large laser beam diameter, large-volume core areas of

the component can be exposed, thereby saving time (e.g. by

increasing the layer thickness), which is analogous to the high-

power Selective Laser Melting of metals. However, to maintain

a high detail resolution and surface quality in the area of the

component contour, the component contour should be exposed

with a small beam diameter. To implement these different

beam diameters, Fraunhofer ILT uses a 3D focusing system

that allows for a dynamic and almost continuous variation of

the beam diameter.

The reproducibility of the component properties shall be

increased by homogenizing the temperature distribution in

the exposure plane. This will be achieved both through the

use of a homogenized intensity distribution and by the use of

an acousto-optical modulator (AOM) so as to prevent power

peaks when the laser is switched on.

Result

Fraunhofer ILT has completed the conceptual design of the

optical system to adapt, both dynamically and variably, the

beam diameter and the intensity distribution. Based on

simulation results, the Gaussian beam diameter can be varied

from 0.5 - 4 mm at laser powers of up to 600 W (instead of

the usual 30 - 70 W). In addition, beam shaping optics can

be integrated into the overall system to create homogenized

intensity distributions (top hat or line distribution). In the next

step, the system will be constructed and characterized in an

experimental setup.

Applications

The optical system can be used in next generation high-power

laser sintering systems.

The R&D project underlying this report has been carried out

on behalf of the Federal Ministry of Education and Research

under grant number 02PN2091.

Contact

Christoph Gayer M.Sc.

Telephone +49 241 8906-8019

OPTICAL SYSTEM FOR HIGH-POWER LASER SINTERING

![A Review of Heat Treatments on Improving the Quality and ......Laser Sintering (SLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) (Figure1) [5]. However, if one](https://static.fdocuments.us/doc/165x107/611db5aff1fafb782f3cd5e0/a-review-of-heat-treatments-on-improving-the-quality-and-laser-sintering.jpg)

![Optimizing selective laser sintering process by grey ...doras.dcu.ie/22813/1/main2.pdf · The selective laser sintering (SLS) was invented in 1989 [1]. In this process, laser employed](https://static.fdocuments.us/doc/165x107/601e4d4954f29749226768bf/optimizing-selective-laser-sintering-process-by-grey-dorasdcuie228131main2pdf.jpg)