Operator’s manual K1 Kombikutter...TKS Operator’s manual 9 Tekniset tiedot Extra equipment 230...

Transcript of Operator’s manual K1 Kombikutter...TKS Operator’s manual 9 Tekniset tiedot Extra equipment 230...

TKS Operator’s manual

1

988713

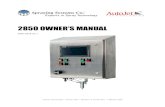

Operator’s manualK1

Kombikutter

Operator’s manual K1 Kombikutter EN, issue 2007-12

TKS Operator’s manual

2

TKS Operator’s manual

3

CE – Declaration of conformityWe,T. Kverneland & Sønner AS,Kvernelandsvegen 100N-4355 KvernelandNorge

declare that the product:

Tks - Kombikutter K1

has been built in conformity with the Machine Directive (Order no. 522) and meets the relevant fundamental health and safety requirements.

Kverneland, 13 December

Tønnes Helge KvernelandGeneral Manager

Enter the serial number of the machine here:

T. Kverneland & Sønner AS, manufacturer of agricultural products, reserves the right to change the design and/ or specifi cation of its products without prior warning.This does not imply any obligation to modify previously supplied machines.

TKS Operator’s manual

4

GuaranteeThis TKS product is guaranteed against manufacturing and material defects for one year.

If the owner wishes a defect to be covered by the product guarantee, he or his representative must inform the dealer of this when ordering parts and/ or repairs. Claims must be reported within the guarantee period.The dealer must complete a claims form for each case covered by a guarantee and send it to TKS or TKS’s distributor/ importer within the 10th of the month following the one in which the defect was reported.The defective parts shall be marked with the claim number and be kept for up to 6 months so that TKS or TKS’s distributor/ importer can inspect them.Since TKS products are used outside the manufacturer’s control, we can only guarantee the prod-uct quality, and not that it will perform its function, nor are we liable for any consequential damage.

The guarantee is not valid if: a) third party spare parts are used, or the product is repaired or altered without the ap proval of TKS. b) the operating and servicing instructions have not been followed. c) the machine has been used for other purposes than those for which it is designed. d) the damage occurs as a result of external forces such as high voltage fl uctuations due to a low supply voltage, lightning or other electrical phenomena.

The guarantee does not cover damage due to normal wear and tear.Offi cial safety regulations specify requirements that apply to the users/ owners and manufacturers of this machine, relating to the careful review of safety hazards that may arise when this type of machine is used correctly. Therefore, TKS and our importer/ distributor are not responsible for the functioning of components that are not shown in the spare parts catalogue for this product. TKS reserves the right to change the design of the product without this implying any obligations in relation to previously supplied machines.

NB! It must be possible to identify all enquiries relating to this product by the product’s serial number; see page 7 on Machine identifi cation.

T. Kverneland & Sønner AS,Kvernelandsvegen 100N-4355 KvernelandNorway

e-post : [email protected] : + 47 51 77 05 00Fax : + 47 51 48 72 28

TKS Operator’s manual

5

Content

CE-Declaration of conformity. . 3

Guarantee. . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . 6

Machine identifi cation . . . . . . . . . . 7

Technical data. . . . . . . . . . . . . 9Main dimensions . . . . . . . . . . . . . . 10

Model description. . . . . . . . . . . . . . 12

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1 Installing a ceiling-mounted . . . . . . . .

Kombikutter. . . . . . . . . . . . . . . . . . . 20

1.1 Ceiling-mounted unit on 2 rails . . . 20

1.2 Ceiling-mounted unit on 1 rail . . . . 20

1.3 Turning corners on a rail . . . . . . . . 21

1.4 Installing a stationary machine. . . . 22

1.5 Installing the power supply. . . . . . . 23

1.6 Installing a power cable on a wire . 24

1.7 Cable drum . . . . . . . . . . . . . . . . . . 24

1.8 Cable carriages . . . . . . . . . . . . . . . 25

1.9 Powered rail . . . . . . . . . . . . . . . . . . 25

2 Use of the machine . . . . . . . . . . . . 26

3 The Kombikutter’s . . . . . . . . . . . . . . .

control panel . . . . . . . . . . . . . . . . . 27

4 Multi-function time relay . . . . . . . . . 28

5 Maintenance and care . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . 31

5.1 Tightening the conveyor belt . . . . . 32

5.2 Thigtening the chain of . . . . . . . . . . .

the drum and conveyor belt . . . . . 33

6 Programming and operating . . . . . . .

the inverter . . . . . . . . . . . . . . . . . . 34

6.1 Fine adjusment of functions . . . . . . 35

7 Wiring diagram. . . . . . . . . . . . . . . . 38

8 Feilsøking Kombikutter K1 . . . . . . . 44

Notes . . . . . . . . . . . . . . . . . . . . . . . . . 46

TKS Operator’s manual

6

IntroductionCongratulations on buying your new TKS product. You have chosen a functional, high quality product. A network of helpful dealers will be able to advise you on its use, as well as provide servicing and spare parts.All TKS products are designed, tested and built in close cooperation with farmers and machine workshops to ensure optimal effi ciency and reliability.

Please read this instruction manual carefully and familiarise yourself with the machine‘s manner of operation before starting to use it. There are many conditions and variables that can affect the machine’s functionality and manner of operation. It is therefore vital that you consider all known conditions and adapt usage according to these.

By being thorough and making the necessary adaptations to local conditions, you will ensure the best possible results.

Good luck!

Yours faithfullyT. Kverneland & Sønner AS

IK1_04

TKS Operator’s manual

7

Machine identifi cationThe machine’s serial number and the address of the manufacturer are written on the machine. See the illustration on this page.Please use the information on the name plate when making any enquiries about spare parts or servicing.This product is CE marked. This mark, along with the associated written EU confi rmation, means that the product fulfi ls current health and safety requirements, and complies with the following directives: Machine Directive (order no. 522)

2680

300

300

300

3300

6800

2950

3620

2200

1250

55025

0

TKS Operator’s manual

8

IK1_05

Important dimensions when installing a Kombikutter

TKS Operator’s manual

9

Tekniset tiedot

Extra equipment

230 VAC / 400 VACShredder 5,5 kW 19,9 Amp / 11,5 AmpConveyor belt 0,55kW 2,68 AmpPower for ceiling rails X 2 0,4kW 1,82 Amp

Powered ceiling rails

Floor cart

Side dispenser

Reservoir

Automation system (Mullerup)

1745

1730

498

1770

2780 (LANG: 3280)1550

tks 3200kp tks 3200kp

157

0

UND

ER S

KINN

E1600 MELLOM 2800 (LANG: 3300) 364

160

0 -

2010

2140

TKS Operator’s manual

10

IK1_01

IK1_01

Stationary machine

Suspended from 2 rails

Main dimensions of the Kombikutter K1

1550

UND

ER S

KINN

E

2855 (LANG 3355)

1600

- 2

010

1630

1500 C-C

1660

947

732

195

0

715

3049 (LANG 3549)2439

145

5 190

0

TKS Operator’s manual

11

IK1_01

IK1_01

Suspended from 1 rail

Floor cart

To be moved 4 cm off centre laterally towards the drum’s engine (A)

TKS Operator’s manual

12

Model description and area of useThe TKS Kombikutter has been designed to shred/ cut silage, round bales, square bales and most types of forage. The machine can be delivered as a stationary machine (placed over a feed hatch or on its own stand).It can also be supplied as a cart that runs along the fl oor or for mounting on ceiling rails. These versions have two speeds.

The Kombikutter has a 750 mm diameter drum. It also has a rotating conveyor belt. The machine is supplied with a standard set of 32 knives. The choice of knives should be based on the type of feed to be shredded. If aggressive cutting is required, all of the knives should be fi tted.The Kombikutter shreds/ cuts most types of round bales and silage, with the size it cuts to being dependent on the consistency and nature of the feed.

The machine runs very silently, and due to its large drum the main engine only requires 5.5 kW of power. The conveyor belt has its own geared engine. The speed of the conveyor belt can be adjusted using an inverter. This gives you a lot of fl exibility. The conveyor belt can be adjusted to the correct pressure against the drum for whatever type of feed. The machine can be opened on both sides and at the back when you want to load it with feed. The machine’s control panel is at the front, but during operation it can be pulled out so that you can run the machine at the same time as seeing what is happening to the feed.

NOTE! The recommendations contained in this instruction manual are based on normal use. Individual users may encounter situations that require a different approach from the guidelines given here. Changes to the machine and equipment as a result of such situations do not give grounds for claims against the manufacturer or supplier.

The climate, temperature, type of grass, time at which it was cut, baling equipment and conservation method used are some of the issues that may affect the functioning and performance of the machine. It is important to make any necessary adjustments, and to set up the machine for the relevant conditions.This will produce the best possible results.

TKS Operator’s manual

13

TKS Operator’s manual

14

Safety Please pay particular attention to this symbol. It means that there is a safety risk, and describes precautions that should be taken in order to avoid accidents.

Before operating, adjusting or repairing the machine, the user, technician or owner should familiarise himself with the safety instructions contained in this installation manual.Pay attention and be careful when handling agricultural machinery. Read and take note of the safety instructions in this manual.

Safety at work is your responsibility!

General safety instructions

Please read and understand these general safety instructions.

There is a risk of stones being thrown up-wards and backwards when the machine is in operation.

Use of the machineThe machine must only be used for the purpose for which it is designed.

OperationThe operator of the machine must stay at the end of the machine where the control panel is located.

ObservationThe operator must keep the machine in view prior to starting it and during operation. This is very important for safety reasons.

How the machine worksThe operator must familiarise himself with how the machine works and functions, so that it can be used safely and properly.

Keep a safe distanceHumans and animals must be kept away from the machine when it is in operation.Keep your distance from working, rotating and moving parts.

Be safety consciousNever enter the machine when it is in operation. When performing maintenance, disconnect the power supply.

A

TKS Operator’s manual

15

ShieldsCheck that all shields are sound and correctly installed. Do not start the machine before doing this.Damaged screens must be repaired or replaced immediately.

Spare partsFor safety reasons we recommend that you only use original spare parts. The use of third party spares invalidates the product guarantee.

MaintenanceEnsure that the machine is properly maintained and is kept in good condition. Never attempt to change the mechanical workings of the machine.

The area in which the machine is operating must be physically sealed off or locked to prevent danger to humans or animals

Control panelThe power supply must be cut off before opening the panel.

Rotational directionThe arrow (A) indicates which way the drum rotates. The sticker indicating the rotational direction of the drum should be put on the left-hand side.

NOTE! If the rotational direction is wrong, you must switch two phases in the main power supply.

IK1_02

TKS Operator’s manual

16

Additional safety instructions for the Kombikutter

The machine s marked with warning signs. If these signs are damaged, they must be replaced. The order number is shown on the illustrations in this section. See Fig. 10 for their location on the machine.

Warning sign UH220532 (Fig. 1)Caution! Read and understand the instruction manual before using the machine, and before making any adjustments or performing any maintenance.

Warning sign UH220544 (Fig. 2)Risk of crushing injury. Keep a safe distance from the area between the Kombikutter and reservoir.

Warning sign UH220526 (Fig. 3)You may damage your fi ngers if you trap them between the chain and the chain wheel.

Warning sign UH220527 (Fig. 4)Risk of cutting your hand. There is a risk of cutting your hand on the drum’s knives when the drum is in operation.

Warning sign UH220539 (Fig. 5)Risk of breaking your fi ngers. You risk break-ing your fi ngers if you trap them between the conveyor and the base.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

988010

TKS Operator’s manual

17

Warning sign 988010 (Fig. 6)NB! The conveyor belt must be kept tight, and the screws on the belt must be retightened.

Fig. 6

UH220544

UH220532

UH220526

UH220527

UH220539

UH220539

988010

UH220544

988010

UH220307

UH220307

UH220527

UH220307

TKS Operator’s manual

18

Overview of safety risks

IK1_03

Fig. 10

TKS Operator’s manual

19

Lifting the machine with a crane

Only use approved lifting equipment.The machine must be lifted from the points marked with a lifting symbol. See Fig. 10 no. UH220307

Caution! Ensure that no-one is under or close to the machine when it is being lifted.Lift the machine using a strap attached to the main frame of the machine, so that the lift is balanced. Check that the straps are properly fi xed before starting the lift.Use an extra strap to help keep the machine in position.

New machine – caution

Read the instruction manual. Be particularly careful when starting a new machine for the fi rst time. Installationfaults.Be particularly careful when starting a new machine for the fi rst time. Installation faults, incorrect operation, etc. may lead to expensive repairs and loss of earnings. The TKS product guarantee does not cover damage resulting from failure to follow the recommendations contained in the instruction manual.Please pay particular attention to this symbol. It is used to highlight important information, to help prevent incorrect installation and operation.

Pay particular attention to the following when commissioning a new machine:Check that the machine is correctly installed and that it is not damaged. Check that electric cables are long enough and positioned such that they can follow the movements of the machine without being damaged.Lubricate the machine where shown on Fig. 17 in Section 3 on Maintenance

Remember that the operator is responsible for the product being properly packed.

Fig. 15

Fig. 16

1600 MELLOM

2140

1550

TKS Operator’s manual

20

IK1_01

IK1_01

1.1 Ceiling-mounted unit on 2 rails IPE 120

The machine for two rails is mainly for use on straight rails, but is capable of deviating slightly from a straight line. This deviation can be up to 1:20. If possible, the rails can be hung directly from the ceiling, using the fi ttings that are most appropriate for your ceiling. If the ceiling cannot be used, you will need to install beams to hang the rails from; contact your dealer for details of systems and prices. The distance between fi xings can be 3.0 m for IPE 120 rails and 4.0 m for IPE 160 rails. Where the unit is lowered, it must be attached to the ceiling at all corners.The unit mounted on dual ceiling rails has 2 powered trolleys and 2 unpowered trolleys. The trolleys have two speeds. The standard speeds are 6/25 m/min. See Fig. 15

1.2 Ceiling-mounted unit on 1 rail

1 Installing a ceiling-mounted KombikutterIf the Kombikutter is delivered for ceiling mounting, it is fi tted with trolley attachments. The trolleys are supplied separately. When installing, the rails must be fi tted fi rst. See the brochure on “lifting equipment” for advice. Then the trolleys are threaded on to the rail. Fit stoppers to the ends of the rail. Then hang the machine from the trolleys. Ensure that the Kombikutter cannot drive so close to the end wall that it constitutes a risk of crushing injuries. Use a padded buffer. Finally install the power supply as appropriate.

If mounted on a single rail, the unit can turn corners and cope with TKS points. NB! If you don’t achieve suffi cient power, you will need to reduce the speed, increase the engine size or use 4-wheel drive. It is important for their to be pressure on the drive wheels.Filling can be done on corners, arcs or using a rail opener. The rail can either be the IPE 160 with up to 3.5 m between fi xings or IPE 120 with up to 2 m between fi xings. To install the rails, use the TKS ceiling fi ttings for the relevant type of ceiling.The unit mounted on 1 rail has two powered trolleys.The trolleys have 2 speeds.The standard speeds are 6/25 m/min.See Fig. 16

E

F

D

B

C

A

E

F

D

B

C

A

TKS Operator’s manual

21

1.3 Turning corners on a rail

Measure the clearances very carefully. Build a framework of boards with the correct external dimensions. See Fig. 17

Short Long

A 200 cm 220 cm

B 100 cm* 120 cm*

C 100 cm* 120 cm*

D 280 cm 320 cm

E 160 cm 160 cm

F 200 cm 220 cm• Minimum dimensions

Fig. 17

TKS Operator’s manual

22

1.4 Installing a stationary machine

If the Kombikutter is to be used in a stationary position, it is normal to position the machine over a feed hatch so that you can release the feed directly on to the feed tray. Alternatively you can build it up, so that it is possible to gain access under it with a wheelbarrow, wheeled grab or fork. You can also use a grass conveyor belt where appropriate.Install the machine somewhere that it will be easy to load it with feed. It is usual to use a rail system and a TKS electric hoist with a hook or hydraulic grab, a tractor with a spear for round bales or similar to fi ll it with round bales.To make it easier to clean spillage from under the machine, it is an advantage to raise the machine 10-15 cm up from the fl oor. The machine is supplied with standard feet that can be replaced. The machine must be fi rmly planted, without any risk of it moving during operation.

TKS Operator’s manual

23

1.5 Installing the power supply

Power consumption:

230V 400V

Floor cart 2 X 1,5kW 9,0A 5,0A

Ceiling-mounted unit 2 X 0,4kW 4,0A 2,5A

Cutter engine 5,5kW 20,7A 15,0A

Feeder 0,55kW 2,7A 1,5A

Size of fuse 32 A 25A

Power requirement of cable drumCable Drum

mm² Stretched out Max. 15 m Max. 34m Max. 60m

4 x 1,5 16 A

4 x 2,5 25 A 15m - 15A

4 x 4 32 A 15m - 20A 34m - 16A 60m - 16A

4 x 6 40 A 34m - 30A 60m - 25A

All electrical installation must be done by a qualifi ed electrician.Use power supply cables of a suitable diameter (at least 3.5 mm²).

Attention! Please remove the plug socket and assure that the fuse box is disconnected before opening it.The type of power supply you use should refl ect your power requirements, the type of installation and any structural issues.The installation procedure for stationary machines is simplest, requiring a socket for the machine’s power supply cable.

For carts that run along the fl oor, you can use a cable on a wire if the cart only runs in a straight line. A cable drum should be used if there are straight sections and corners. You can also use a powered rail on straight sections.

Ceiling-mounted units can be installed with all types of power supply.

TKS Operator’s manual

24

A cable drum should be used in rooms where it is diffi cult to hang the cable on a wire. For long lengths or L-shaped buildings, a combination of a wire and a drum may be appropriate. See Fig. 19.

1.6 Installing a power cable on a wire

Drill a hole in the wall at each end, or mount brackets, and attach wire tighteners. Then fi x the wire as tightly as possible using manual force, before tightening it further using the nuts.The wire must be right up against the milking pipe, or preferably above it, but no more than 50 cm above the shredder. The wire should hang approx. 30 cm out to the side. If it runs on two ceiling-mounted rails, the wire must be 30 cm to the side of the rail, or right up under one of the rails.The cable should be fi xed to cable clips at 1 m intervals. See Fig. 18.

1.7 Cable drum

Fig. 19

Fig. 18

A B C

TKS Operator’s manual

25

1.8 Cable carriages Cable carriages can be used for ceilingmounted units. Suitable for straight sections and corners. Max. distance 3 m. If you have any tight corners, the distance must be less than the radius of the corner. Use a stopper for the trolley at the end of the rail to prevent the trolley from hitting the cable carriages and damaging them.Please note that you must have space to park the cable carriages when driving towards them. Ensure that the cable cannot be reached by animals (gnawing, tearing).

Fig. 21

Fig. 20

1.9 Powered railThe rails can be used to power the unit for all types of rail systems, including round corners. Fix the rail to an angle bracket that is attached with clips to the top of the L-beam or directly to the ceiling. See Fig. 20.Max. distance between fi xings 2 m. Suitable for all types of rails. The power supply is guided through an arm fi xed to the trolley or the Kombikutter. Individual adjustments will often need to be made depending on your premises. 4-way is used for max. 35 A. 7-way is used for max. 70 A.(Wires are connected in parallel pairs). For use in damp/ cold environments, you must install a heating band in the rail. A transformer designed for the length of rail in question is connected to the heating band, which keeps the rail warm and dry.The right transformer for the length of rail will be calculated by TKS on request.

• End piece A• Connection clip (used for joints and at

connecting points) B• Sliding fi xings (allow expansion) CSee Fig. 21.

TKS Operator’s manual

26

2 Use of the machineThe drum can only turn one way. Round bales can be put in whatever way you like, but we recommend putting them in so that they can rotate in the direction of the dispenser. There must not be any round bales or silage up against the drum when you start it.

Customised adjustments are the key to good results.

Check list for commissioning the machine

HIGHLY IMPORTANT!• The power supply must have a high enough

voltage during all phases, and fuses and power cables must be big enough.

• The power supply must be connected to the Kombikutter’s control panel by an authorised electrician.Adjust the overload protection relay, based on your measurements and the power rating of the equipment.

• Start the engine of the drum from the control panel. Check that the cutting drum is rotating in the right direction. If you need to switch the phases, you must do this on the power supply cable coming from the fuse box.

• Never start the drum’s engine when there are bales lying against the drum. Reverse the conveyor belt so that the drum is free when it is started.

• The cutter is equipped with frequency control for the speed of the conveyor belt. The conveyor belt can also be operated manually both forwards and backwards.

• If using chopped silage, the machine must not be overloaded (not above the top of the drum).

Depending on how it is used/ the type of feed, adjustments may be needed in order to customise it to your conditions.

It is very important to adjust the feed speed to local conditions, so as to avoid choking the drum.This is very important if you want to achieve good results. You will need to use trial and error here.

The speed is infi nitely adjustable using the potentiometer on the control panel (see page 34 item 6).

TKS Operator’s manual

27

Operate side dispenser

Operate trolleys

Operate reservoir

Reverse conveyor belt

Potentiometer for adjusting speed of conveyor belt

Start/ stop conveyor belt

Fig. 25

3 The Kombikutter’s control panelStationary machine:

Emergency stop

Start/ stop drums

Functions:

Reverse conveyor belt

Start/ stop conveyor belt

Start/ stop drums

Potentiometer for adjusting speed of conveyor belt

Fig. 26

Emergency stop

TKS Operator’s manual

28

Inverter

Time relay

Type DMB51CM24=T1The relay’s function is to start the inverter if it detects overloading, i.e. excessive pressure against the drum. The relay has 3 settings. These are factory set, and under normal circumstances it shouldn’t be necessary to adjust any of them.The inverter produces a slight delay, which is determined by the relay. This factory setting for this delay is 2 seconds. If you want a longer delay, you can adjust this using the middle dial marked “TIME”. A longer delay may be appropriate if you want to reduce the feed rate. In such cases it is best to combine this with any adjustment of the “overload detection” (n60) on the inverter.

With the factory settings, the machine works as follows:If the pressure against the cutting drum becomes to high, the conveyor belt stops for 2 seconds before restarting. The speed of the conveyor belt can be adjusted (infi nitely) on the inverter.If you have diffi cult feed, such as frozen round bales, it may be a good idea to reduce the speed of the conveyor belt and adjust the time relay.

Can be adjusted as follows:Dial marked “RANGE” set to 1s.Time delay = 1s X 3 = 3 secondThe top dial marked “FUNCTION” must always be set to “OP”.

4 Multi-function time relay

If you lose your power supply, or if the overload protection relay trips, the emergency stop button must be pressed fully in for a moment until an orange light appears in the time relay.If this light does not come on, the conveyor belt will not work under the automatic mode.See Fig. 27

Fig. 27

TKS Operator’s manual

29

TKS Operator’s manual

30

5 Maintenance and careChecklist for maintenance and care

NB! Always pull out the plug before inspecting, maintaining or repairing the machine. • Always pull out the plug before inspecting,

maintaining or repairing the machine. You should clean the conveyor belt, cogwheels, axles and bearing casings as required and at least once a year.

• The conveyor belt must always be tight. This is particularly important when you fi rst start using it. It must not be tightened asymmetrically. Tighten it the same number of turns on both sides.

• Ensure that drive chains are also kept tight. Check them regularly for slack or damage.Bearing journals and chains should be lubricated every 24 operating hours or at least once a month.

• Ensure that drive chains are also kept tight. Check them regularly for slack or damage.

• Ensure that electrical equipment is not subjected to excessive temperature fl uctuations. This can lead to condensation and short circuits.

• The oil in the worm gears should not be exposed to temperatures below minus 30 degrees C. If the machine needs to run normally at below -30 degrees C, contact the manufacturer for advice and guidance.

• The knives on the drum are made of tempered steel with a precision engineered cutting edge. Check the edge regularly for damage or wear and tear. You can sharpen the blades while the knives are still attached to the drum. This is easy to do by dragging an angle grinder across the inside of each knife blade.

2

34

1

1

3

2

TKS Operator’s manual

31

Lubrication1 Lubrication of bearing on operating side of conveyor belt2 Lubrication of bearing on reverse side of conveyor belt3 Lubrication of drum bearing4 Drip lubrication of drum and conveyor belt chains

Fig. 30

IK1_06

988010

TKS Operator’s manual

32

5.1 Tightening the conveyor belt

To prevent the conveyor belt from pulling asymmetrically, derailing or rubbing against the drum, it is important to keep it tight. This should be checked at regular intervals. You can tighten it by turning the adjustment screw on the back of the machine. See Fig. 31

NB! It is important to retighten it after only 1-2 bales/ cut bales because of varnish etc. that gets rubbed off and makes the belt slack.

NB! Tighten it the same number of turns on both sides. Run the conveyor belt without any load after tightening it to check that everything is working properly.

Adjustment screw

Fig. 31

Back hatch

TKS Operator’s manual

33

Adjustment screw

Guide wheel for chain

Fig. 32

5.2 Tightening the chain of the drum and conveyor belt

Check the adjustment screws for the chains at regular intervals.See Fig. 32

The chains must be lubricated once a week.

Adjustment screw

Guide wheel for chain

TKS Operator’s manual

34

6 Programming and operating the inverter. The inverter determines how the conveyor belt presses the feed against the drum. The inverter is pre-programmed by TKS.

The parameters are set as follows:

Adjustable P.S Infi nitely adjustable conveyor belt speed, scale of 0-50 Hz.(The speed must be appropriate for the consistency of the feed, and with highly dried or frozen feed the speed should be reduced). Adjust this on the potentiometer on the control panel..

n02=1 RUN and STOP / RESET on the control panel of the inverter are locked, and the terminals S1 and S2 are active. (External start and stop)

n09=50 Max. output frequency is set to 50 Hz.

n10=230 Max. output voltage is set to 230VAC.

n16=0,5 Acceleration time is set to 0.5 seconds. (Can be adjusted).

n17=0,3 Deceleration time is set to 0.3 seconds. (Can be adjusted).

n21=50 Frequency reference is set to 50 Hz

n32=2,8 Nominal engine current is set to 2.8 Amp. (The value corresponds to the value on the engine’s data plate).

n40=6 6 = overload detection. (Relay MC to MA = normally open).

n46=4 Switch - frequency

n59=1 Overload detection only at constant frequency.

n60=84 Overload detection. (Level is based on the inverter’s nominal current as a %. The level should not exceed 100%).It may be necessary to adjust this level occasionally. This will depend on the type of feed being used.

n61=3,0 Overload detection time in seconds. (Determines how long it is before any overload is detected).It may occasionally be necessary to adjust this, but to avoid overloading the engine and inverter we recommend that you do NOT set this time to higher than 3 seconds.

TKS Operator’s manual

35

Inverter, Omron 3G3JV

Fig. 33

It may occasionally be necessary to adjust the parameters n16, n17, n60 and n61, which should be done in the following way:

1 Press the blue mode button. The indicator light will move from left to right. Repeat until the red indicator comes on for PRGM. The display will show e.g. n01.

2 Press the arrow buttons up or down until you reach the required parameter, e.g. n60.

3 Press the yellow Enter button. The display will show the current value. E.g. 70

4 Press the arrow buttons up or down until you reach the required value, e.g. 80

5 Press the yellow Enter button to save the new value. Wait a short while. The display will show n60

6 Press the blue mode button, and the green indicator light for FREF will come on.

6.1 Fine adjustment of functions

TKS Operator’s manual

36

The engine cannot be started if the PRGM or LO/RE indicator light is on.

When the green indicator light FREF is on, the display shows the selected speed of the conveyor belt’s engine as measured in Hz. This can be infi nitely adjusted using the potentiometer on the control panel.

By pressing the blue mode button once the green indicator light will come on for FOUT.The display will show the current speed to the conveyor belt’s engine measured in Hz.

Press the blue mode button until the green indicator light comes on for IOUT. The display will show the current for the conveyor belt’s engine measured in Amps.

If you want to connect or disconnect cables to the inverter, the power supply must have been disconnected for at least 60 seconds.

Under no circumstances must you use “meggers” or similar equipment, as these can damage the internal components of the inverter. If this should nevertheless be necessary, you must disconnect all of the terminals on the inverter. Engines with capacitors must not be connected to the inverter.

Never use any other voltage supply than 1X 230VAC for the inverter.

TKS Operator’s manual

37

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

L1L2 U

VW

230V

400V

230V 3~

-Q1

24

6

1 2

3 4

5 6

1 2

3 4

5 6

-LO

1

Sikring 0,25 Amp

24 V

AC

230

VA

C

X1.1

X1.

2X

1.3

X1.4

X1.

5X1

.6X

1.7

X1.

8

2X10

A-F

1-K

1-K

2

Lask

ved

230

VA

C

NV

/400

VAC

L1L2

L3

Fors

ynin

g

Ver

n

Kont

akto

r

Mot

or

Funk

sjon

230

/ 400

VA

C

B&J

K3

22A

01 2

4V

Hov

edko

ntak

tor

B&J

K3

22A0

1 24

V

230

/ 400

VA

C

Ove

rstø

msr

ele

17 -

23 v

/ 23

0 V

AC

1

0 -1

4 v

/ 400

VAC

Mot

or 5

,5 K

W20

,8 -

12 A

mp

Mot

or V

alse

230

VAC

Sikr

ings

elem

ent M

erlin

Ger

in 1

0 A

mp

B

Frek

vens

omfo

rmer

Om

ron

3G3

JV 0

,55

KW

Mot

or 0

,55

KW

2,77

-1,

6 Am

p

Mot

or B

unnb

elte

230

VAC

Sik

ring

Syl.

20 X

5

1 A

mp

Tran

sfor

mat

or 3

0VA

23

0 / 2

4 V

AC

Ski

lletra

fo s

tyre

strø

m 2

4 V

AC

Hov

edst

røm

K1

Kom

biku

tter

1 5

29.0

6.04

/ 2.C.8 (X2.1)

/ 2.H.8 (X2.2)

/2.D

.3

Utg

ange

r till

eggs

utst

yr23

0V/(N

/400

V/)

0124

VAC

sty

rest

røm

29.0

6.04

B&J

Låsb

ar h

oved

bryt

erLT

S32

PFH

4 A4

32

1

BLÅ

GR

ÅB

run

SO

RT

GR

ÅB

run

SO

RT

2.5m

m x

5

400V

4mm

x 4

230V

/3.E.7 (L3)

/3.E.7 (L2)

/3.E.7 (L1)

/3.E.8 (N)

TKS Operator’s manual

38

7 Wiring diagram, mains power K1

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

MC

MA

MB

22 21-K1

-K1T

Y1

A1

-K1

A1

-K2

A1

-K214 13

-d1

A1

-d124 21

SC

S1S

2

-K1T11 15 1814

-d1

FCFR

FS

X2.

3X2

.4X

2.5

X2.6

X2.

7X

2.8

X2.

9X2

.10

X2.1

1X

2.12

X2.

13

X2.

1495 96-Q1

A2A

2A

2A

2/1

.C.2

/1.C

.1

-LO

1 ( /

.D.3

)

-LO

1 /.G

.7

OM

RO

N 3

G3

JV

/.E.3

1518

/ 1.G

.7

/ 1.G

.7

/ 1.G

.7

/ .E.

721

22

1314

1 3 5

2 4 6/ 1

.G.6

/ 1.G

.6

/ 1.G

.6

/ .F.

6

/ .E.

5 / .

F.3

1314

1 3 5642

21 111424

Tids

rele

fors

inke

t sta

rt bu

nnbe

lte

Funk

sjon

Op

Hov

edko

ntak

tor

Kon

takt

or v

alse

Hje

lper

ele

star

t / s

topp

bu

nnbe

lte a

uto

Frek

vens

omfo

rmer

bun

nbel

te

X2.1

X2.

2

910

118

75

63

42

1 2

2 5

Sty

rest

røm

K1

Kom

biku

tter

29.0

6.04

/4.D.8

/4.D.8

/4.D.7

/4.D.7

/4.D.6

/4.D.6

/4.D.5

/4.D.5

/4.D.3

/4.D.3

/4.D.2

/4.G.8 (X3.2)Tilleggsfunksjon (er)

1516

1718

1920

2122

-X2

12

13

19

18

17

16

15

14

/5.D.3

/5.D.2

/5.D.2

/5.D.1

/5.D.4

/5.D.4

/5.D.3

/5.D.3 10

9

8

7

6

5

4

3/4.H.7 (X3.3)

/4.H.2 (X3.10)

/4.H.2 (X3.9)

/4.H.3 (X3.8)

/4.H.3 (X3.7)

/4.H.4 (X3.6)

/4.H.5 (X3.5)

/4.H.6 (X3.4)

Til e

kstra

boks

821

26 T

akdr

ift

TKS Operator’s manual

39

Wiring diagram of control current to the main

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

Blå

Nve

d 40

0VA

C

/1.D.2 (X1.8)

L1L2

L3

/1.D.3 (X1.7)

/1.D.3 (X1.6)

/1.D.3 (X1.5)

Lask

ved

230

VAC

-LO

2

UV

W

L1L2

-K3

-K4

-K5

-K6

13

51

35

24

62

46

24

6

13

51

35

24

62

46

24

6

230V 3~

230V

/400

V3~

230V

/400

V3~

-Q2

-Q3

-Q4

Fors

ynin

g

Vern

Kont

akto

r

Effe

kt

Funk

sjon

230

/ 400

VAC

Mot

orve

rnbr

yter

GV

2 M

2095

1766

Hov

edve

rnbr

yter

/ se

rvic

ebry

ter

230V

AC

Frek

vens

omfo

rmer

3G

3 JV

9575

26

Inte

rnt I

om

form

er

1,1K

W

0,4

KW X

(2)

Mot

or(e

r) dr

ift ta

kvog

n

230/

400V

AC

230/

400V

AC23

0/40

0VA

C23

0/40

0VA

C

B&J

K310

A01

24V

AC

B&

J K

310A

01 2

4VAC

B&J

K31

0A01

24V

AC

B&

J K

310A

01 2

4VA

C

B&J

Ove

rstrø

msr

ele

230

/ 400

–2,

68 /

1,55

Mot

or re

serv

oar

0,18

KW

0,4

KW

Mot

or S

ideu

tmat

er

B&

J O

vers

trøm

srel

e23

0 / 4

00 –

2,6

/ 1,6

Hov

edst

røm

sskj

ema

Tak

drift

-re

serv

oar o

g si

deut

mat

er fo

r K1

og K

33 5

8212

6 -2

30V

AC

8212

7 -4

00V

AC

03.0

5.05

TKS Operator’s manual

40

Wiring diagram, mains power to roof robot, side dispenser and reservoir

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

X3.

2 24

VAC

Ops

jon

/2.G.8 (X2.2)

-K3

-K4

-K5

-K6

X3.

3X

3.4

X3.

5X

3.6

/2.F.2 (X2.15)

/2.F.2 (X2.16)

/2.F.2 (X2.17)

/2.F.1 (X2.18)

A1

A1

A1A

1

-K4

-K3

-K6

-K5

22 212122

2122

2122

A2

-Q3 9596

A2

A2

A2

-Q496 95

/2.C

.8 (X

2.1)

X3.

7X3

.8X

3.9

X3.

10

/2.F.1 (X2.19)

/2.F.1 (X2.20)

/2.F.1 (X2.21)

/2.F.1 (X2.22)

SCS1

S2

S3

-LO

2/3

.G.6

/3.F

.5/3

.F.3

/3.G

.5

/3.G

.5

/3.G

.5

/3.G

.4

/3.G

.4

/3.G

.4

/3.G

.3

/3.G

.3

/3.G

.3

/3.G

.2

/3.G

.2

/3.G

.21

2

34

56

2122

12

34

56

2122

12

34

56

2122

12

34

56

2122

/.F.6

/.F.7

/.F.4

/.F.5

Styr

estrø

m 2

4 V

AC

Res

ervo

arFr

em

Res

ervo

arTi

lbak

e Si

deut

mat

erH

øyre

Side

utm

ater

Ven

stre

Takd

rift::

: SC

= F

elle

s. S

1 =

Frem

. S2

= Ti

lbak

e. S

3 =

2 ha

st.

4 5

8212

6 -2

30VA

C82

127

-400

VAC

Sty

rest

røm

sskj

ema

Takd

rift -

rese

rvoa

r og

side

utm

ater

for K

1 og

K3

03.0

5.05

X3.

1JZ

-Y.1

JZ-Y

.2JZ

-Y.3

JZ-Y

.4JZ

-Y.5

JZ-Y

.6JZ

-Y.7

JZ-Y

.8JZ

-Y.9

JZ-Y

.10

TKS Operator’s manual

41

Control diagram for roof robot, side dispenser and reservoir

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

/ 2.H.5 (X2.2)

/ 2.H.1 (X2.3)

/ 2.H.2 (X2.5)

/ 2.H.2 (X2.4)

/ 2.H.2 (X2.6)

/ 2.H.1 (X2.7)

/ 2.H.3 (X2.9)

/ 2.H.3 (X2.8)

Felle

s 24

VA

CH

oved

-ko

ntak

tor

Sta

rtva

lse

Sto

ppva

lse

Sta

rtbu

nnbe

lteS

topp

bunn

belte

Bunn

belte

retu

rFo

rsyn

ing

retu

r bu

nnbe

lte

Felle

s dr

iftFr

am2

Has

tTi

lbak

eR

eser

voar

fram

Res

ervo

artil

bake

Ele

vato

rhø

yre

Ele

vato

rve

nstre

12

34

65

78

1011

1819

1415

1617

13

4,7

OH

M

912

4

1333

23

4 13

13 14

12 11

12 11

13 14

11 12

4

2313

13 14

14 13

/ 2.H.4 (X2.10)

/ 2.H.4 (X2.11)

/ 2.H.4 (X2.12)

/ 2.H.1 (X2.19)

/ 2.H.1 (X2.20)

/ 2.H.1 (X2.21)

/ 2.H.1 (X2.22)

Has

tighe

tsre

gule

ring

bunn

belte

Hov

edko

ntak

tor

Val

seBu

nnbe

lte fr

emB

unnb

elte

retu

r

Pot

entio

met

er 4

,7 o

hm

Drif

t Løp

ekat

t / G

ulvv

ogn

Res

ervo

arS

ideu

tmat

er

/ 2.H.2 (X2.15)

/ 2.H.2 (X2.16)

/ 2.H.2 (X2.17)

/ 2.H.1 (X2.18)

X3.3

X3.4

X3.5

X3.6

X3.7

X3.8

X3.9

X3.10

Skap

for d

rift R

1 og

R2

Tabl

å fo

r sty

ring

av

K1, R

1 og

R2.

24V

E.T

.

22/0

4-20

05

9470

43

5 5

TKS Operator’s manual

42

Wiring diagram for 24 V control cables K1, R1, R2

H G F E D C B A

87

65

43

21

H G F E D C B A

87

65

43

21

RE

V.EN

DR

ING

DA

TOS

IGN

TKS

Dat

o:

Tegn

et a

v:

God

kjen

t:

Titte

l:

Teg

ning

s nr

:

Sid

e:

Av:

-F2

GU

LVD

RIF

T (8

2102

) /

TAK

DR

IFT

(821

01)

230V

44

M

4

1333

2312 11

X3.

5X

3.4

X3.

3X

3.2

SC

S1

S2

S3U

VW

N/L

1L2

Om

ron

Frek

v.om

f.2.

2Kw

/ 1,

1KW

3G3M

V / M

INI J

7~2

30V

X3.6

X3.

7X3

.8

/1.D.2 (X1.8)

/1.D.3 (X1.6

SC

= F

ELL

ES

OG

NØ

DST

OP

P

S1

= FR

AMO

VER

S2

= B

AK

OV

ER

S3

= H

ØY

HA

STI

GH

ET

TABL

Å

TER

CH

ARLI

E P

F390

3000

2TK

S-n

r.947

000

M/k

abel

SPE

NN

ING

SIK

RIN

G

230V

AC

MG

C60

N 2

P 2

0A

230V

AC

FRE

M2H

AS

TBA

K

22.0

9.20

05

12

43

-LO

212

34

TKS Operator’s manual

43

Wiring diagram for fl oor operations with fuse

TKS Operator’s manual

44

Description of fault: Reason and corrective measure:• Cutter/ shredder drum has a

tendency to get stuck when you run the conveyor belt.

• A possible reason is that the drum is rotating in the wrong direction, which may result in feed getting stuck between the drum and the conveyor belt.

• Change the direction of the engine (it should rotate upwards as seen from the back).

• You can change the direction of rotation by switching 2 wires in the engine.

• Cutter/ shredder drum is unable to start with feed in the machine.

• Check that no feed is pressed against the drum. • Reverse any feed clear of the drum.• Check that the drum’s engine is correctly

connected in relation to the voltage supply.• 230V = triangular connection, and

400V = star connection

• Cutter/ shredder runs slowly, and only a small amount of feed comes out.

• The knives on the drum are blunt.• Sharpen them with an angle grinder or other suit-

able tool. (Do not grind the knives when they are hot, as they are factory tempered).

• The machine is overloaded and is unable to rotate the feed properly.

• Remove some of the feed to allow the drum to rotate.

• The cutter/ shredder engine is running, but the drum is not rotating.

• Check the chain and transmission on the back cover.

• NB! Remember to turn off the power supply to the machine before removing the cover.

• The cutter/ shredder drum’s engine won’t start

• Check the power supply.• The overload protection relay has been tripped. • There is a fault with the control panel or cable

(contact an electrician).

• The conveyor belt does not move forwards, but does reverse.

• Time relay T1 has not been activated. Turn off all functions, and press and release the emergency stop button. (When time relay T1 has been activated, a green and an orange diode should come on in the relay).

• Fault with time relay T1, or holding relay d1. (Contact an electrician).

8 Troubleshooting the KombikutterThis troubleshooting guide deals with the most likely problems that may occur with the machine:

TKS Operator’s manual

45

Description of fault: Reason and corrective measure:• The conveyor belt will go neither

forwards nor backwards• Check the inverter for alarms.

(Cf. the separate troubleshooting guide for the inverter). Check that the speed can be adjusted(Dial on control panel, potentiometer). When the dial is turned, the value on the display of the inverter should increase or decrease. If the display does not react, check and if necessary replace the potentiometer.

• The conveyor belt’s engine runs, but the conveyor belt does not move forwards or backwards

• There is a problem with the transmission from the chain.

• Check the chain and the transmission.

TKS Operator’s manual

46

Notes