Off-circuit tap-changer DEETAP® DU · 2009-12-02 · Unauthorized copying and di stribution of...

Transcript of Off-circuit tap-changer DEETAP® DU · 2009-12-02 · Unauthorized copying and di stribution of...

NOTE!

The product may have been modified after this document went to press.We expressly reserve the right to make changes to the technical data, the design or the scope of delivery.In general, the information provided and the arrangements agreed during processing of the rele-vant offers and orders are binding.

Table of Contents

Table of Contents

1 Safety ............................................................................................................................................................ 71.1 Safety Instructions ....................................................................................................................................... 71.2 Safety regulations ........................................................................................................................................ 71.3 General notes ................................................................................................................................................ 8

1.3.1 Appropriate use ...................................................................................................................................................... 81.3.2 Responsibility of the user .................................................................................................................................... 8

2 Design/Types ................................................................................................................................................. 92.1 Off-circuit tap-changer DEETAP® DU, survey (special designs possible, see TD 266/04).................. 10

3 Transportation and storage........................................................................................................................ 113.1 Scope of delivery .......................................................................................................................................... 113.2 Packaging ...................................................................................................................................................... 12

3.2.1 Use .............................................................................................................................................................................. 123.2.2 Suitability, installation and manufacturing .................................................................................................. 123.2.3 Markings.................................................................................................................................................................... 12

3.3 Transportation, receipt and handling of shipments ................................................................................ 123.4 Storage of shipments ................................................................................................................................... 133.5 Unpacking shipments and checking for transportation damages ......................................................... 13

3.5.1 Unpacking................................................................................................................................................................. 143.5.2 Lifting out................................................................................................................................................................. 15

3.6 Transport........................................................................................................................................................ 18

4 Installation of the DEETAP® DU for cover mounting ............................................................................. 194.1 MR mounting flange.................................................................................................................................... 194.2 Mounting flanges made by the customer................................................................................................. 204.3 Template ........................................................................................................................................................ 204.4 Installing the DEETAP® DU with contact circle diameter 400 mm and 600 mm up to

Um 300 kV ................................................................................................................................................. 214.5 Installation of the DEETAP® DU for cover mounting - separation of head and cage

(for contact circle diameter 400 mm and 600 mm starting with voltage range 362 kVand contact circle diameter 850 mm)....................................................................................................... 224.5.1 Required tools ......................................................................................................................................................... 224.5.2 Summary of mounting steps .............................................................................................................................. 234.5.3 Removing the DEETAP® DU head:..................................................................................................................... 234.5.4 Mounting the head onto the transformer ..................................................................................................... 244.5.5 Mounting the DEETAP® DU to the head......................................................................................................... 25

4.6 Installation for cover mounting - separation of head and cage withoptional supporting flange (for contact circle diameter 400 mm and 600 mmstarting with voltage range 362 kV and contact circle diameter 850 mm)........................................ 274.6.1 Summary of mounting steps .............................................................................................................................. 274.6.2 Removing the head from the off-circuit tap-changer .............................................................................. 284.6.3 Mounting the off-circuit tap-changer to the temporary installation structure............................... 284.6.4 Mounting the off-circuit tap-changer to the head.................................................................................... 29

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009278/06 EN 3

Table of Contents

5 Installation of the off-circuit tap-changer for bell-type tank mounting........................................... 325.1 Preparation of the transformer for installation of the DEETAP® DU in the bell-type tank ............. 32

5.1.1 Required tools ......................................................................................................................................................... 325.1.2 Positioning the fork (supporter)........................................................................................................................ 32

5.2 Installation of the off-circuit tap-changer for bell-type tank mounting ........................................... 325.2.1 MR mounting flange............................................................................................................................................. 325.2.2 MR design suggestion for mounting flanges made by yourself ............................................................. 335.2.3 Template.................................................................................................................................................................... 335.2.4 Installation ............................................................................................................................................................... 34

5.3 Summary ........................................................................................................................................................ 41

6 Connection of the transformer winding................................................................................................... 42

7 Transformer ratio test................................................................................................................................. 43

8 Drying procedure of the transformer and filling with oil...................................................................... 448.1 Drying process............................................................................................................................................... 44

8.1.1 Vacuum-drying ....................................................................................................................................................... 448.1.2 Vapor-phase drying ............................................................................................................................................... 44

8.2 Filling with oil ............................................................................................................................................... 44

9 Final assembly .............................................................................................................................................. 459.1 Driving............................................................................................................................................................ 459.2 Bevel gear/gear unit of the off-circuit tap-changer head .................................................................... 459.3 Drive shaft (square tube) ............................................................................................................................ 459.4 Coupling the off-circuit tap-changer with manual drive or motor-drive unit................................... 46

9.4.1 Operate the off-circuit tap-changer into the adjustment position ...................................................... 469.4.2 Symmetrical coupling ........................................................................................................................................... 46

9.5 Connection of the tap-change supervisory control................................................................................. 479.6 Function test ................................................................................................................................................. 489.7 Complete oil filling....................................................................................................................................... 489.8 Grounding...................................................................................................................................................... 489.9 Dangers associated with the transformer test ......................................................................................... 49

10 Safety devices............................................................................................................................................... 5010.1 Off-circuit tap-changer with hand wheel/operating wrench on the off-circuit tap-changer head 5010.2 Manual drive TAPMOTION® DD.................................................................................................................. 5110.3 TAPMOTION® ED motor-drive unit ............................................................................................................ 52

11 Maintenance................................................................................................................................................. 54

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 278/06 EN4

Table of Contents

12 Appendix ....................................................................................................................................................... 5512.1 DEETAP® DU, installation drawing for cover mounting, contact circle diameter 400 mm

(7258721E) ................................................................................................................................................... 5512.2 DEETAP® DU, installation drawing for cover mounting, contact circle diameter 600 mm

(7258732E) ................................................................................................................................................... 5612.3 DEETAP® DU, installation drawing for cover mounting, contact circle diameter 850 mm

(7366011E) ................................................................................................................................................... 5712.4 DEETAP® DU, off-circuit tap-changer head for bell-type tank, contact circle diameter 400 mm

(7259752E) ................................................................................................................................................... 5812.5 DEETAP® DU, off-circuit tap-changer head for bell-type tank, contact circle diameter 600 mm

(7259762E) ................................................................................................................................................... 5912.6 DEETAP® DU, off-circuit tap-changer head for bell-type tank, contact circle diameter 850 mm

(7330231E) ................................................................................................................................................... 6012.7 DEETAP® DU, lifting device (72673703)................................................................................................... 6112.8 DEETAP® DU, position of the supporter (7372720E).............................................................................. 6212.9 DEETAP® DU, tap-change supervisory control (7269770E) ................................................................... 6312.10 DEETAP® DU, mounting flange for off-circuit tap-changer head TK 400 (7420060E) .................... 6412.11 DEETAP® DU, mounting flange made by the customer for off-circuit tap-changer head TK 400

(7420080E) ................................................................................................................................................... 6512.12 DEETAP® DU, mounting flange for off-circuit tap-changer head TK 600/850 (7420060E) ............ 6612.13 DEETAP® DU, mounting flange made by the customer for off-circuit tap-changer head

TK 600/850 (7420130E) ............................................................................................................................. 6712.14 DEETAP® DU, template for off-circuit tap-changer head TK 400 (7420180E).................................. 6812.15 DEETAP® DU, template for off-circuit tap-changer head TK 600/850 (7420190E) ......................... 6912.16 DEETAP® DU, additional drawings bottom cage ring (7259355E)........................................................ 7012.17 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 400, Um 170 kV (7354960E) ............................................................................................................ 7112.18 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 400, Um 245 kV (7354941E) ............................................................................................................ 7212.19 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 600, Um 170 kV (7354970E) ............................................................................................................ 7412.20 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 600, Um 245 kV (7354861E) ............................................................................................................ 7512.21 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 850, Um = 72.5 kV (7364420E)........................................................................................................... 7712.22 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 850, Um = 170 kV (7366021E)............................................................................................................ 7812.23 DEETAP® DU, fixing the off-circuit tap-changer on the lower cage ring (application-specific),

TK 850, Um 245 kV (7366031E) ............................................................................................................ 8012.24 DEETAP® DU, off-circuit tap-changer head, contact circle diameter 400 mm (7257351E) ............ 8212.25 DEETAP® DU, off-circuit tap-changer head, contact circle diameter 600/850 mm (7257372E).... 8312.26 DEETAP® DU, off-circuit tap-changer head with hand wheel, contact circle diameter 400 mm

(7257381E) ................................................................................................................................................... 8412.27 DEETAP® DU, off-circuit tap-changer head with hand wheel, contact circle diameter

600/850 mm (7257392E) ........................................................................................................................... 8512.28 DEETAP® DU, off-circuit tap-changer head with hexagon, contact circle diameter 400 mm

(7257401E) ................................................................................................................................................... 8612.29 DEETAP® DU, off-circuit tap-changer head with hexagon, contact circle diameter 600/850 mm

(7257412E) ................................................................................................................................................... 8712.30 DEETAP® DU, connection terminal contact circle 400/600 mm, connection terminal 850 mm

(Y, D, BB, 7257301E) ................................................................................................................................... 88

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009278/06 EN 5

Table of Contents

12.31 DEETAP® DU, connection terminal contact circle 850 mm (ME, MD, SP, YD, 7340950E)................ 8912.32 DEETAP® DU, output terminal contact circle 400/600/850 mm (7257282E)..................................... 9012.33 DEETAP® DU, connecting rails (7262151E) .............................................................................................. 9112.34 Manual drive TAPMOTION® DD, standard design (7365301E).............................................................. 9212.35 DEETAP® DU, snap-on ring wrench with plug-on tube for off-circuit tap-changer-head

with hexagon (8978511E) .......................................................................................................................... 9312.36 DEETAP® DU, motor-drive unit ED-S, protective housing, dimension drawing (8988013E) ............ 9412.37 DEETAP® DU, motor-drive unit ED-L, protective housing, dimension drawing (8988023E)............. 9512.38 DEETAP® DU, bevel gear CD 6400, dimension drawing (7366440E).................................................... 9612.39 DEETAP® DU, horizontal drive shaft (limit dimensions, 7258893E) ..................................................... 9712.40 DEETAP® DU, manual drive TAPMOTION® DD, vertical drive shaft (limit dimensions, 7376951E).. 9912.41 Manual wheel drive/hexagonal drive, tripping/locking circuit, connection diagram (1531579)..... 10012.42 DEETAP® DU, manual drive TAPMOTION® DD, connection diagram (2150823)................................. 10112.43 DEETAP® DU, motor-drive unit ED-S, connection diagram (1579393) ............................................... 10412.44 DEETAP® DU, additional drawings (7257233E) ....................................................................................... 106

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 278/06 EN6

1 Safety

1 Safety

1.1 Safety InstructionsThe following safety instructions relating to the operation of the DEETAP® DU are used in these Operating Instructions.

These instructions must always be followed!

Special safety labels are used for certain hazards, such as elec-tric shock:

The following specific safety warnings are used in these oper-ating instructions:

1.2 Safety regulations• Always comply with all warning and hazard notices.

Failure to follow the safety instructions may lead to acci-dents and severe injury to you or your colleagues.

• Please read these operating instructions before com-missioning the equipment!Please read these operating instructions before switching on the DEETAP® DU. As the user, you are responsible for ensuring that users of the device have fully understood the operating and safety instructions.

• Train your staff!Before asking staff to work with the DEETAP® DU, provide training regarding general and special safety instructions and accident prevention regulations.

• Only suitably qualified personnel should work with the DEETAP® DU!The DEETAP® DU is designed solely for application in elec-trical or energy systems and facilities operated by appro-priately trained staff. This staff comprises people who are familiar with the installation, assembly, commissioning and operation of such products.

DANGER!

Refers to an imminent danger that will result in death or severe injury if not avoided.

ATTENTION!

Refers to a potentially harmful situa-tion. If this situation is not prevented, the product or something in the vicinity may be damaged.

NOTE!

Contains important information and special notes.

DANGER!

Danger of electric shock!Refers to an imminent danger due to electricity that will result in death or severe injury if not avoided.

Risk of electric shock!

Danger of tip-ping!

Fire hazard!

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 7278/06 EN

1 Safety

1.3 General notesThe product and associated equipment and special tools sup-plied with it comply with the relevant legislation, regulations and standards, particularly health and safety requirements, ap-plicable at the time of delivery.

If used as intended in compliance with the specified require-ments and conditions in these operating instructions as well as the warning notices in these operating instructions and at-tached to the product, then the product does not present any hazards for persons, property or the environment. This applies during the entire lifespan, from delivery through installation and operation to disassembly and disposal.

The operational quality assurance system ensures a consistent-ly high quality standard, particularly when it comes to obser-vance of the health and safety requirements.

1.3.1 Appropriate useUse is considered to be appropriate if

• the product is operated according to the agreed delivery conditions and technical data, and

• associated equipment and special tools supplied with it are used solely for the intended purpose and in accordance with the specifications of these operating instructions.

1.3.2 Responsibility of the userIn order to avoid accidents, malfunctions and collisions as well as undesired effects on the environment, the respective re-sponsible party for transportation and installation, operation and maintenance as well as for the disposal of the product or parts of the product must ensure that:

• only qualified and trained personnel are used,

• before performance of the job and later at regular intervals as well as after special occurrences, personnel are instruct-ed as to possible dangers and the required safety measures to prevent such dangers,

• regulations and operating instructions for safe working as well as the relevant instructions for staff procedures in the case of accidents and fires can be read at all times and dis-played in the workplace where applicable.

• the devices and precautions required for safe work as well as the personal protective equipment required for certain jobs must be available and also put to use,

• the required maintenance cycles must be adhered to and only the spare parts, lubricating and auxiliary agents ac-cepted by the manufacturer may be used.

ATTENTION!

Any other use is not permitted unless express approval was obtained from MR.

DANGER!

Danger of death and severe injury!Substantial property damage and environmental damage!When prerequisites and conditions are not adhered to or the warnings are not obeyed, dangerous situations are possible due to:

• electrical voltage

• falling and/or tipping parts as well as dangerously cramped condi-tions due to moving parts

• leaking oil.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 20098 278/06 EN

2 Design/Types

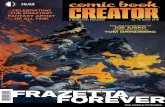

2 Design/TypesThe off-circuit tap-changers DEETAP® DU are available in the following designs (see basic connections in Figure 1):

• Linear off-circuit tap-changer

• Off-circuit tap-changer for single bridging connection

• Off-circuit tap-changer for double bridging connection

• Series-parallel off-circuit tap-changer

• Star-delta off-circuit tap-changer

• Back-and-boost off-circuit tap-changer

• Off-circuit tap-changer for special applications

Off-circuit tap-changers are designed on the principle of a modular system allowing maximum rated through-currents of 200 A, 400 A 600 A, 800 A and 1000 A per current path.

Off-circuit tap-changers DEETAP® DU are available with up to 17 operating positions (see survey, Figure 2 and Figure 3).

All models correspond to IEC 60214-1: 2003.

Switching concept: The off-circuit tap-changer is changed over from one operating position to the next by rotating an in-sulating drive shaft. The DEETAP® DU off-circuit tap-changer is activated via a step-by-step gear with a hand wheel or op-erating wrench or with manual drive TAPMOTION® DD or mo-tor-drive unit TAPMOTION® ED.

Figure 1 DEETAP® DU types

DANGER!

Danger of electric shock!Danger of death!Danger of destruction of DEETAP® DU and transformer!Perform installation, electrical instal-lation work and commissioning cor-rectly!

• The DEETAP® DU with the relevant drive unit is to be used only with the transformer specified in the order. Any alterations or modifica-tions to the DEETAP® DU are for-bidden without first consulting MR.

• Installation, electrical connection and commissioning of the DEETAP® DU must be carried out exclusively by suitably qualified personnel and under strict obser-vation of these operating instruc-tions.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 9278/06 EN

2 Design/Types

2.1 Off-circuit tap-changer DEETAP® DU, survey (special designs possible, see TD 266/04)

Figure 2 Max. rated through current up to 1000 A

Figure 3 Max. rated through current up to 2000 A

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200910 278/06 EN

3 Transportation and storage

3 Transportation and storage

3.1 Scope of deliveryOff-circuit tap-changer, manual drive and motor-drive unit are shipped in the adjustment position.

The off-circuit tap-changer equipment is shipped as follows:

• Off-circuit tap-changer DEETAP® DU (Figure 4), choice of with

- Hand wheel

- Snap-on ring wrench

- Manual drive TAPMOTION® DD (Figure 5)

- TAPMOTION® ED (Figure 6)

• Unpacking info sheet

• Quick assembly instructions

• Drive shaft with coupling parts and bevel gear (omitted for model with hand wheel/snap-on ring wrench)

Figure 4 Off-circuit tap-changer DEETAP® DU

Figure 5 TAPMOTION® DD

Figure 6 TAPMOTION® ED

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 11278/06 EN

3 Transportation and storage

3.2 Packaging

3.2.1 UseThe purpose of the packaging is to protect the packaged goods both during transportation and loading/unloading as well as during storage so that it cannot be changed to its disadvan-tage. The packaging must protect the packaged goods from permissible transportation stresses such as jarring, jolting, moisture (rain, snow, condensed water). The packaging also prevents undesired changes during storage of the packaged goods within the packaging. The packaged goods must be pre-pared for shipment before actually packaging so that the goods can be transported safely, economically and in accor-dance with regulations.

3.2.2 Suitability, installation and manufacturingThe packaging is suitable for:

• all common types of transportation

• storage outdoors

• stackability - 1000 kg/m2 top surface

The packaged goods are packed in a stable wooden box. This box ensures that the shipment is secure in the intended trans-portation position and none of its parts touch the loading sur-face of the transportation means or touch the ground after unloading.

The packaged goods are stabilized inside the box with half shells and transverse braces against undesired changes in po-sition. The half shells and transverse braces are nailed to the side walls of the box.

The sealing packaging surrounds the packaged goods on all sides with a PE foil. The amount of drying agent inside this blocking layer limits the relative humidity. The PE foil was bonded after the drying agent was added and the air was suc-tioned off. This is indicated in that the foil lies flat on the ship-ping goods.

3.2.3 MarkingsThe packaging has a signature with information on safe trans-portation and correct storage.

The following picture symbols apply to the shipment (of non-hazardous goods, Figure 7). Adherence to these symbols is mandatory.

Figure 7 Shipping pictograms

3.3 Transportation, receipt and handling ofshipments

In addition to oscillation and shock stress, jolts must also be expected during transportation. To exclude possible damage, falling, tipping, tipping over and bouncing must be prevented.

If a box falls from a certain height (e.g. when slings tear) or ex-periences unbroken fall, damage must be expected regardless of the weight.

Every delivered shipment must be checked for the following by the recipient before acceptance (acknowledgment of receipt).

• Completeness based on the delivery slip

• All kinds of exterior damage.

Checking must take place after unloading when the box can be accessed from all sides.

Protect against moisture Top Fragile goods

DANGER!

Danger of tipping!Severe, even lethal bodily injuries!Danger due to tipping or falling load!Danger of damage to the off-circuit tap-changer due to falling and tip-ping over!

• Selection of the slings and secur-ing the load may only be per-formed by trained and appointed persons.

• Do not walk under the hanging load.

• Use transportation means and hoists with a carrying capacity of > 500 kg.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200912 278/06 EN

3 Transportation and storage

Proceed as follows if you determine visible exterior transpor-tation damage when the shipment is received.

• Immediately enter the determined transportation damages in the shipping documents and have the deliverer counter-sign this.

• In case of severe damage, total loss and high damage costs, immediately contact the sales department of Maschinen-fabrik Reinhausen and the applicable insurance company.

• Do not change anything after damages have been deter-mined and also save the packaging materials until a deci-sion has been made as to surveying by the transportation company or the transportation insurance company.

• Together with the involved transportation company, make a protocol of the damage on site! This is indispensable when submitting damage claims!

• If possible, photograph damages on packaging and pack-aged goods. This also applies to corrosion on the packaged goods due to penetration of moisture (rain, snow, con-densed water).

• Be absolutely sure to also check the sealing packaging.

• Name the damaged parts.

When damages are hidden, i.e. damages which are not deter-mined until unpacking after the receipt of the shipment, pro-ceed as follows:

• Immediately make liable the party which possibly caused the damage by telephoning and in writing and prepare a damage protocol.

• Comply with the deadlines in the particular country and make inquiries in this regard in time.

With hidden damage, making the transportation company lia-ble (or other party which caused the damage) is extremely dif-ficult. Such damage claims only have hope of success when this is expressly specified in the insurance conditions.

3.4 Storage of shipmentsStorage of packaged goods for a limited timePackaged goods with a functioning sealing packaging can be stored outdoors when the following conditions are complied with.

The following requirements should be met when selecting and setting up the storage location.

• Stored goods protected against moisture (flooding, water from melting snow and ice), dirt, pests such as rats, mice, termites and so on, and against unauthorized access.

• Boxes placed on wooden blocks and boards as a protection against ground moisture and for better ventilation.

• Carrying capacity of the foundation is sufficient.

• Entrance and exit paths kept free.

Check stored goods at regular intervals. Also provide suitable measures after storms, heavy rain or snow and so on.

Protect the packaging foil from direct sunlight so that it does not disintegrate under the UV rays and the packaging is no longer sealed.

If installation is delayed beyond the expected lifespan of the package sealing, suitable measures must be taken before the sealing is lost. The following measures can be used:

• Correctly regenerate the drying agent and restore the packaging sealing.

• Unpack the packed goods and store in suitable storage space (well ventilated, as dust-free as possible, humidity < 50 %).

3.5 Unpacking shipments and checking for transpor-tation damages

• Transport the packaged box to the place where installation will take place.

• When unpacking, check the packaged goods for their con-dition. Check the mounting materials kit against the deliv-ery slip for completeness.

ATTENTION!

Impairment of the functional safety!Damage to off-circuit tap-changer! The off-circuit tap-changer will be damaged when it is stored with inef-fective packaging sealing at climati-cally unsuitable sites.Leave the off-circuit tap-changer in its sealed packaging until installation. Do not open the sealed packaging until immediately before installation.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 13278/06 EN

3 Transportation and storage

3.5.1 Unpacking

1) Check the box for exterior damages. Before opening the box, make sure that it is positioned vertically in accor-dance with the applicable markings (Figure 8).

Figure 8

2) Open the cover with a suitable tool (Figure 9).

Figure 9

3) Remove the nails with which the upper, styrofoam half shells are secured. Remove the half shells (Figure 10).

Figure 10

4) Also remove the nails with which the traverse braces are secured and remove the braces (Figure 11).

Figure 11

5) Now carefully cut open the foil (Figure 12).

Figure 12

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200914 278/06 EN

3 Transportation and storage

3.5.2 Lifting out

Figure 13 WRONG! Lifting sling at the off-circuit tap-changer head

Figure 14 WRONG! Lifting sling at the off-circuit tap-changer column

Figure 15 WRONG! Lifting sling at screening rings

ATTENTION!

Impairment of the functional safety!Damage to off-circuit tap-changer!• Do not use lifting slings at the off-

circuit tap-changer head, the off-circuit tap-changer column or the screening rings!

• The use of lifting slings at the off-circuit tap-changer head, the off-circuit tap-changer column or the screening rings may damage the off-circuit tap changer.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 15278/06 EN

3 Transportation and storage

1) You will need one (or preferably two) cranes to lift out the off-circuit tap-changer and set it up.

Use sling ropes for fastening at the eyelets of the off-circuit tap-changer head (Figure 17) and a lifting sling for fastening at the off-circuit tap-changer base (see Figure 18 for suitable attachments points).

Figure 16

Figure 17 Attachment points at the off-circuit tap-changer head

Figure 18 Attachment points at the off-circuit tap-changer base

DANGER!

Danger of tipping!Severe, even lethal injuries!Danger due to tipping or falling load.Danger of damage to the off-circuit tap-changer due to falling and tip-ping over!

• Selection of the slings and secur-ing the load may only be per-formed by trained and appointed persons.

• Do not walk under the hanging load.

• When only one crane is used, pre-vent damage to the contact pieces by not exceeding an angle of incli-nation of 45° (Figure 16).

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200916 278/06 EN

3 Transportation and storage

Version with one crane Version with two cranes

a) Lift the DEETAP® DU out of the shipping box (see Figure 19).

b) Have two half shells ready.

c) Place the DEETAP® DU on the half shells.

d) Now disconnect the lifting slings from the base of the DEETAP® DU.

Figure 19 e) Now stand the DEETAP® DU up by again lifting the ropes

attached to the DEETAP® DU head (see Figure 20).

Figure 20 f) Secure the DEETAP® DU in its standing position, e.g. by

leaving the DEETAP® DU attached to the tightened sling ropes until installation (see Figure 23).

a) Lift the DEETAP® DU out of the shipping box (see Figure 21).

Figure 21 b) Stand the DEETAP® DU up by lowering the one crane and

raising the other (see Figure 22).

Figure 22 c) Secure the DEETAP® DU in its standing position, e.g. by

leaving the DEETAP® DU attached to the tightened sling ropes until installation (see Figure 23).

Figure 23

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 17278/06 EN

3 Transportation and storage

3.6 Transport

Figure 24 Figure 25

ATTENTION!

Damage to off-circuit tap-changer!The set-down cylinder should only be used for transport.Remove the set-down cylinder after installing the off-circuit tap-changer in the transformer.

or

DANGER!

Danger of tipping!Severe, even lethal bodily injuries!Damage to off-circuit tap-changer!The off-circuit tap-changer may only be set down if it is supported by a crane.

Set-down cylinder

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200918 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4 Installation of the DEETAP® DU for cover mounting

4.1 MR mounting flangeA mounting flange is needed to mount the off-circuit tap-changer head (see Figure 26, Figure 27 and section 12, drawing 7420060E for contact circle 400 mm, drawing 7420160E for contact circle 600 mm and 850 mm).This can be supplied as an option.

Figure 26 MR mounting flange for 400 mm contact circle diameter

Figure 27 MR mounting flange for 600/850 mm con-tact circle diameter

No separation of head and cage Separation of head and cage Separation of head and cage - Installation with supporting flange

Contact circle diameter: 400/600 mmUm 300 kV

Contact circle diameter: 400/600 mmUm 362 kVContact circle diameter: 850 mm

Contact circle diameter: 400/600 mmUm 362 kVContact circle diameter: 850 mm

Standard Standard Supporting flange on request

Supporting flang

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 19278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4.2 Mounting flanges made by the customerWhen you make the mounting flange yourself, this must cor-respond to the sealing surface of the off-circuit tap-changer head (see Figure 28, Figure 29 and section 12).

Figure 28 Mounting flange made by the customer with 400 mm contact circle diameter

Figure 29 Mounting flange made by the customer with 600/850 mm contact circle diameter

4.3 TemplateWe recommend using a template ( see Figure 30, Figure 31and section 12, drawing 7420180E for contact circle 400 mm, drawing 7420190E for contact circle 600/800 mm) to position the stud bolts (M12, length 45 mm), or to mark the tapped holes. If requested, the template will be supplied with the first installation of a off-circuit tap-changer free of charge.

Figure 30 Template for 400 mm contact circle diame-ter

Figure 31 Template for 600/850 mm contact circle di-ameter

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200920 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4.4 Installing the DEETAP® DU with contact circle diameter 400 mm and 600 mm up to Um 300 kV

Before mounting, the off-circuit tap-changer is lowered through the cover aperture into the transformer (see Figure 32 and section 12, installation drawing 7258721E und 7258732E).

1) Place the off-circuit tap-changer on a level surface. Before setting up the off-circuit tap-changer head on the mounting flange, clean the sealing surfaces (bottom of the off-circuit tap-changer head including the sealing groove and top of the mounting flange, Figure 32).

Figure 32

2) Place the included oil-proof seal in the sealing groove of the off-circuit tap-changer head without twisting the oil-proof seal (Figure 32). In delivery state the Geneva wheel crank (Figure 33) is in the following position (Figure 34):

Figure 33 Position of the Geneva wheel crank

Figure 34 Geneva wheel crank in delivery state3) Before lifting or positioning the off-circuit tap-changer

head, turn the Geneva wheel crank of the step-by-step gear inwards by 90° starting from the adjustment position (see Figure 35, Figure 36 and appendix, installation draw-ing 7258721E und 7258732E).

Figure 35

Figure 36 Geneva wheel crank turned inwards by 90°4) Lift the off-circuit tap-changer over the mounting flange

and lower it carefully into the opening of the mounting flange. Take care not to damage the connection terminals and screening rings.

5) Check the mounting position of the off-circuit tap-chang-er head when it is installed. Adhere to the marking on the off-circuit tap-changer head regarding the drive side (see installation drawings 7258721E und 7258732E).

6) Screw the off-circuit tap-changer head onto the mounting flange.

7) Turn the Geneva wheel crank of the step-by-step gear back into the adjustment position by 90° (see Figure 37 and in-stallation drawing 7258721E und 7258732E).

Figure 37 Geneva wheel crank turned back to the adjust-ment position by 90°

ATTENTION!

Damage to off-circuit tap-changer!• Before installation please pay at-

tention to mounting position.

• After installation move to adjust-ment position.

Off-circuit tap-changer head

Mounting flange

Clean the sealing surfaces

Geneva wheel crank

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 21278/06 EN

4 Installation of the DEETAP® DU for cover mounting

8) Remove the set-down cylinder together with the mounting material (Figure 38).

Figure 38 Removing the set-down cylinder

4.5 Installation of the DEETAP® DU for cover mount-ing - separation of head and cage (for contact circle diameter 400 mm and 600 mm starting with voltage range 362 kV and contact circle diameter 850 mm)

For installing the DEETAP® DU, the head must be removed since the off-circuit tap-changer contact circle diameter is greater than the inner diameter of the mounting flange (Fig-ure 39).

Figure 39 The head is then positioned to the mounting flange of the transformer cover and the COMTAP® ARS mounted to the head from below (Figure 40).

Figure 40

4.5.1 Required toolsEnsure that the tools shown below are available before start-ing to install the DEETAP® DU (Figure 41).

Figure 41

NOTE!

For particularly long off-circuit tap-changers, the lower cage ring must be mounted with insulation as per the order-specific dimensional drawing.This mounting must be done by the transformer manufacturer (see sec-tion 12, installation drawing 7259355).

NOTE!

The following figures show contact circle diameter 850 mm.

Set-down cylinder

Lifting traverse

For oiling the shaft of the Geneva gear

Transformer oil

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200922 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4.5.2 Summary of mounting steps

1) Remove the off-circuit tap-changer head.2) Clean the sealing surfaces.

Place the included oil-proof seal in the sealing groove of the off-circuit tap-changer head.

3) Lubricate the switching tube coupling and the Geneva wheel.

4) Lift the off-circuit tap changer cage from below up to the transformer cover (65-80 mm).

5) Turn the Geneva wheel crank by 90 ° at the off-circuit tap-changer head.

6) Position the off-circuit tap-changer head in its mounting position on the mounting flange.

7) Position the off-circuit tap-changer cage at the off-circuit tap-changer head.

8) Mount the lifting traverse.9) Lift the off-circuit tap-changer cage using the lifting tra-

verse (gap of approx. 5 mm between mounting flange and off-circuit tap-changer head).

10) Screw the off-circuit tap-changer head to the off-circuit tap-changer cage (3 x M16 with washers).

11) Position the off-circuit tap-changer head onto the mount-ing flange using the lifting traverse.

12) Remove the lifting traverse.13) Mount the remaining screws (2 x M16 with washers).14) Mount the locking screws.15) Turn the Geneva wheel crank back into the original posi-

tion by 90°.16) Screw the off-circuit tap-changer head to the transformer

cover.

The single mounting steps are described in detail in the follow-ing.

4.5.3 Removing the DEETAP® DU head:1) Unscrew all 5 locking screws (wrench 30 mm, Figure 42).

Figure 42

2) Unscrew the 5 screws below with hexagon socket (wrench 14 mm, Figure 43).

Figure 43 Take the DEETAP® DU head off the cage (Figure 44).

Figure 44

3) In delivery state the Geneva wheel crank (Figure 45) is in the adjustment position (Figure 46).

Figure 45

Figure 46

ATTENTION!

Damages to the DEETAP® DU!Before installation please pay atten-tion to mounting position. After in-stallation move to adjustment position.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 23278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4.5.4 Mounting the head onto the transformer1) Before setting up the DEETAP® DU head on the mounting

flange, clean the sealing surfaces (bottom of the DEETAP® DU head including the sealing groove and top of the mounting flange).

2) Place the included oil-proof seal in the sealing groove of the DEETAP® DU head without twisting the oil-proof seal (Figure 47).

Figure 47

3) Lubricate the coupling (Figure 48) and the Geneva wheel (Figure 49) with oil.

Figure 48

Figure 49 4) Check the mounting position of the cage. This mounting

position determines the mounting position of the DEETAP® DU when installed.

5) Lift the cage from below up to the transformer cover (Fig-ure 50).Leave a clearance of 65 to 80 mm between the cage ring and the upper edge of the mounting flange (Figure 51).

Figure 50

Figure 51

NOTE!

In order to avoid coupling faults, the DEETAP® DU head and the cage must remain in the adjustment position during reassembly (for adjustment position please refer to the order-related adjustment plan).

DANGER!

Danger of tipping!Severe, even lethal injuries!Danger of damage to the DEETAP® DU! Secure the DEETAP® DU against tipping and falling.

Transformer cover

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200924 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

6) Turn the Geneva wheel crank of the step-by-step gear in-wards by 90° (Figure 52 and section 12, installation draw-ing 7327712E).

Figure 52 7) Position the off-circuit tap-changer cage at the the off-

circuit tap-changer head, since the head can only be screwed to the cage in one position (Figure 53).

Figure 53

4.5.5 Mounting the DEETAP® DU to the headAfter checking the correct mounting position, the lifting tra-verse can be mounted.Make sure the five fixing points match each other (Figure 54)!

Figure 54

1) Mount the lifting traverse (Figure 55).

Figure 55

ATTENTION!

Damages to the DEETAP® DU!Only use the set-down cylinder for lifting and never the circumferential screening ring.

DANGER!

Danger of tipping!Severe, even lethal injuries!Danger of damage to the DEETAP® DU! Secure the DEETAP® DU against tipping and falling.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 25278/06 EN

4 Installation of the DEETAP® DU for cover mounting

2) Lift the cage with the lifting traverse until an air gap of ap-prox. 5 mm is visible between head and mounting flange (Figure 56).

Figure 56 3) First screw the head to the cage ring with the 3 screws

(M16x60 including safety elements, Md=80+10 Nm, Fig-ure 57).

Figure 57

4) Lower the DEETAP® DU to the mounting flange. Remove the lifting traverse (Figure 58).

Figure 58 5) Screw the head to the cage ring with the remaining 2

screws (M16x60 including safety elements, Md=80+10 Nm, Figure 59).

Figure 59 6) Clean the sealing surfaces of the locking screws. Mount all

5 locking screws, wrench 30 mm, Md=20 Nm (Figure 60).

Figure 60

max. 10 Nm

Air gapapprox. 5 mm

Screw together 3x

Screw together 2x

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200926 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

7) Turn the Geneva wheel crank of the step-by-step gear back into the adjustment position by 90° (Figure 61 and section 12, installation drawing 7327712E).

Figure 61 8) Screw (Md = 35+5 Nm) the DEETAP® DU head and the

mounting flange together with washers and 24 nuts M12/wrench 19 (Figure 62).

Figure 62 9) Remove the set-down cylinder after the installation (Fig-

ure 63).

Figure 63

4.6 Installation for cover mounting - separation of head and cage with optional supporting flange (for contact circle diameter 400 mm and 600 mm starting with voltage range 362 kV and contact circle diameter 850 mm)

For installing the DEETAP® DU, the head must be removed since the off-circuit tap-changer contact circle diameter is greater than the inner diameter of the mounting flange. De-pending on the installation situation, it may be useful to use the supporting flange, which is available on request (Figure 64).

Figure 64

4.6.1 Summary of mounting steps1) Remove the off-circuit tap-changer head.2) Clean the sealing surfaces.

Place the included oil-proof seal in the sealing groove of the off-circuit tap-changer head without twisting the oil-proof seal.

3) Lubricate the switching tube coupling and the Geneva wheel.

4) Position the off-circuit tap-changer cage with supporting flange in the temporary installation structure.

5) Turn the Geneva wheel crank by 90 ° at the off-circuit tap-changer head.

6) Position the off-circuit tap-changer head in its mounting position on the mounting flange.

7) Position the off-circuit tap-changer cage at the off-circuit tap-changer head.

8) Mount the lifting traverse.9) Lift the off-circuit tap-changer cage using the lifting tra-

verse (gap of approx. 5 mm between mounting flange and off-circuit tap-changer head).

10) Screw the off-circuit tap-changer head to the off-circuit tap-changer cage (3 x M16 with washers).

11) Position the off-circuit tap-changer head onto the mount-ing flange using the lifting traverse.

12) Remove the lifting traverse.13) Mount the remaining screws (2 x M16 with washers).14) Mounting the locking screws.15) Turn the Geneva wheel crank back into the original posi-

tion by 90°.16) Screw the off-circuit tap-changer head to the transformer

cover.

The single mounting steps are described in detail in the follow-ing.

NOTE!

For particularly long off-circuit tap-changers, the lower cage ring must be mounted with insulation as per the order-specific dimensional drawing.This mounting must be done by the transformer manufacturer (see sec-tion 12, installation drawing 7259355).

Set-down cylinder

Supporting flange

Temporary installation structure

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 27278/06 EN

4 Installation of the DEETAP® DU for cover mounting

4.6.2 Removing the head from the off-circuit tap-changer

1) Unscrew all 5 locking screws (wrench 30 mm, Figure 65).

Figure 65 Unscrewing the locking screws

2) Unscrew the 5 screws below with hexagon socket (wrench 14 mm, Figure 66).

Figure 66 Unscrewing the screws below

3) Take the off-circuit tap-changer head off the cage (Figure 67).

Figure 67 Taking off the off-circuit tap-changer head

4.6.3 Mounting the off-circuit tap-changer to the temporary installation structure

1) Before setting up the off-circuit tap-changer head on the mounting flange, clean the sealing surfaces (bottom of the off-circuit tap-changer head including the sealing groove and top of the mounting flange).Place the included oil-proof seal in the sealing groove of the off-circuit tap-changer head without twisting the oil-proof seal (Figure 68).

Figure 68

2) Lubricate the coupling (Figure 69) and the Geneva wheel (Figure 70) with oil.

Figure 69 Lubricating the coupling

NOTE!

In order to avoid coupling faults, the off-circuit tap-changer head and the cage must remain in the adjustment position during reassembly (for adjustment position please refer to the order-related adjustment plan).

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200928 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

Figure 70 Lubricating the Geneva wheel3) Check the mounting position of the cage. This mounting

position determines the mounting position of the off-cir-cuit tap-changer when installed. Lift the cage towards the transformer tank (Figure 71).

Figure 71 4) Set a distance of approx. 75 mm between the supporting

flange bottom and mounting flange top using spacer blocks (Figure 72).

Figure 72 5) Before lifting the off-circuit tap-changer head, turn the

Geneva wheel crank of the step-by-step gear inwards by 90° starting from the adjustment position (Figure 73).

Figure 73

6) Position the off-circuit tap-changer head in its correct mounting position on the mounting flange (Figure 74).

Figure 74

4.6.4 Mounting the off-circuit tap-changer to the head

After checking the correct mounting position, the lifting tra-verse can be mounted.Make sure the five fixing points match each other (Figure 75)!

Figure 75

62 a

fter

inst

alla

tion

Transformer cover

ATTENTION!

Damage to off-circuit tap-changer!Only use the supporting flange or the set-down cylinder for lifting and never the circumferential screening ring.

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 29278/06 EN

4 Installation of the DEETAP® DU for cover mounting

1) Mount the lifting traverse (Md=10 Nm, Figure 76).

Figure 76 Mounting the lifting traverse2) Lift the cage with the lifting traverse until an air gap of ap-

prox. 5 mm is visible between head and mounting flange (Figure 77).

Figure 77 Lifting the cage

3) First screw the head to the cage ring with the 3 screws (M16x60 including safety elements, Md=80+10 Nm, Fig-ure 78).

Figure 78 Screwing the head to the cage ring4) Remove the spacer blocks.

Lower the off-circuit tap-changer to the mounting flange.Remove the lifting traverse (Figure 79).

Figure 79

5) Screw the head to the cage ring with the remaining 2 screws (M16x60 including safety elements, Md=80+10 Nm, Figure 80).

Figure 80

max. 10 Nm

Air gap of approx. 5 mm

Screw together 3x

Screw together 2x

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200930 278/06 EN

4 Installation of the DEETAP® DU for cover mounting

6) Clean the sealing surfaces of the locking screws. Mount all 5 locking screws, wrench 30 mm, Md=20 Nm (Figure 81).

Figure 81 7) Turn the Geneva wheel crank back into the adjustment po-

sition by 90° (Figure 82).

Figure 82 8) Screw (Md=35+5 Nm, Figure 83) the off-circuit tap-

changer head to the mounting flange with washers and nuts.

Figure 83

9) Remove the set-down cylinder together with the mounting material (Figure 84).

Figure 84

NOTE!

For particularly long off-circuit tap-changers, the lower cage ring must be mounted with insulation as per the order-specific dimensional drawing.This mounting must be done by the transformer manufacturer (see sec-tion 12, installation drawing 7259355).

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 31278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

5 Installation of the off-circuit tap-changer for bell-type tank mounting

5.1 Preparation of the transformer for installation of the DEETAP® DU in the bell-type tank

5.1.1 Required toolsEnsure that the tools shown below are available before start-ing to install the off-circuit tap-changer (Figure 85).

Figure 85 Required tools

5.1.2 Positioning the fork (supporter)When positioning the fork ensure correct vertical (Figure 86) and horizontal position (Figure 87) of the fork in the fitted transformer. We strongly recommend measuring the actual di-mensions of the transformer and positioning the fork accord-ing to Figure 86.

Figure 86 Vertical position of the fork

Figure 87 Horizontal position of the fork

5.2 Installation of the off-circuit tap-changer for bell-type tank mounting

5.2.1 MR mounting flangeA mounting flange is needed to mount the off-circuit tap-changer head (see Figure 88, Figure 89, Figure 90 and sec-tion 12, drawing 7420060E for contact circle 400 mm, drawing 7420160E for contact circle 600 mm and 850 mm). This can be supplied as an option.

Figure 88 MR mounting flange with 400 mm contact circle diameter

Figure 89 MR mounting flange with 600/850 mm con-tact circle diameter

Bell-type tank installation

Separation of head and cage - Installation with supporting flange

Contact circle diameter: 400/600/850 mm

Bell-type tank version on request

Supporting flange

Lifting traverse Spacer blocks Transformer oil

For oiling the shaft of the Geneva gear

Spacer blockSpacer block

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200932 278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

Figure 90

5.2.2 MR design suggestion for mounting flanges made by yourself

When you make the mounting flange yourself, this must cor-respond to the sealing surface of the off-circuit tap-changer head (see Figure 91, Figure 92, Figure 93 and section 12).

Figure 91 Mounting flange made by the customer with400 mm contact circle diameter

Figure 92 Mounting flange made by the customer with600/850 mm contact circle diameter

Figure 93

With the mounting flange manufactured by the customer a rectangular section is also possible. Please note that the overall height "mounting flange+transformer wall thickness" must be < 50 mm (Figure 94).

Figure 94

5.2.3 TemplateWe recommend using a template ( see Figure 95, Figure 96and section 12, drawing 7420180E for contact circle 400 mm, drawing 7420190E for contact circle 600/850 mm) to position the stud bolts (M12, length 45 mm), or to mark the tapped holes. If requested, the template will be supplied with the first installation of a off-circuit tap-changer free of charge.

Figure 95 Template for 400 mm contact circle diame-ter

Figure 96 Template for 600/850 mm contact circle di-ameter

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 33278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

5.2.4 InstallationThe installation of the off-circuit tap-changer requires the use of a supporting structure (supporter) that allows the off-cir-cuit tap-changer to be provisionally attached to the support-ing flange. The off-circuit tap-changer is lifted onto the supporting structure, fixed in this provisional mounting posi-tion and connected to the leads.

The off-circuit tap-changer head is then removed from the off-circuit tap-changer. After the bell-type tank has been placed on top, the off-circuit tap-changer beneath is lifted to its final mounting position by means of a lifting traverse and mechanically screwed to the head.

Proceed in detail as follows:

1) Lift the off-circuit tap-changer into the supporting struc-ture (Figure 97).

Figure 97

Supporting structure

Supporting flange

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200934 278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

2) Check the mounting position (Figure 98) and secure the cage (supporting flange) to the supporting structure temporarily by using spacer blocks (Figure 99).

Figure 98 Vertical position of the fork

Figure 99

Spacer blocks Spacer blocks

Fixing with spacer blocks

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 35278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

3) The connection of the off-circuit tap-changer to the trans-former winding is described in section 6.Make sure that the connection of the leads is free of me-chanical tension (Figure 100, Figure 101, Figure 102)!

4) After installation of the off-circuit tap-changer, a trans-former ratio test is to be performed (see section 7).

5) Slightly lift the off-circuit tap-changer to remove the spacer blocks, and lower the off-circuit tap-changer to the supporting structure.

Figure 100

Figure 101

Figure 102

NOTE!

The mounting position of the off-cir-cuit tap-changer must be aligned to the off-circuit tap-changer head that will be mounted with the bell-type tank set up later on.To ensure the correct function of the off-circuit tap-changer, the leads must be connected so that they nei-ther pull nor put pressure on the off-circuit tap-changer connection ter-minals when the off-circuit tap-changer is in its final mounting posi-tion. This is done by using spacer blocks while the off-circuit tap-changer is being mounted.

X

Connect leads

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200936 278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

6) Unscrew all 5 locking screws (wrench 30 mm, Figure 103).

Figure 103 Unscrewing the locking screws7) Unscrew the 5 screws below with hexagon socket (wrench

14 mm, Figure 104).

Figure 104 Unscrewing the screws below

8) Take the off-circuit tap-changer head off the cage (Figure 105).

Figure 105 Taking off the off-circuit tap-changer head

Figure 106 Cage without off-circuit tap-changer head

NOTE!

In order to avoid coupling faults, the off-circuit tap-changer head and the cage must remain in the adjustment position during reassembly (for adjustment position please refer to the order-related adjustment plan).

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 2009 37278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

9) Remove the set-down cylinder together with the mounting material.

10) Lift the bell-type tank over the active part of the trans-former (and thus over the off-circuit tap-changer insulat-ing bar cage, Figure 107).

Figure 107 11) Depending on the specified height, a distance of 65-80 mm

must be left between the cage floor and the mounting flange top.

See drawing:Contact circle 400 mm: 7259752EContact circle 600/850 mm: 7259762E

12) Before setting up the off-circuit tap-changer head on the mounting flange, clean the sealing surfaces (bottom of the off-circuit tap-changer head including the sealing groove and top of the mounting flange).

13) Place the included oil-proof seal in the sealing groove of the off-circuit tap-changer head without twisting the oil-proof seal (Figure 108).

Figure 108 14) Lubricate the coupling sleeve (Figure 109) and the Geneva

wheel (Figure 110) with oil.

Figure 109 Lubricating the coupling sleeve

Figure 110 Lubricating the Geneva wheel

Set-down cylinder

Operating Instructions BA 278/06 DEETAP® DUUnauthorized copying and distribution of this document and the utilization and communication of its contents are strictly prohibited unless expressly authorized.Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model and ornamental design registration.

©Maschinenfabrik Reinhausen GmbH 200938 278/06 EN

5 Installation of the off-circuit tap-changer for bell-type tank mounting

15) Before lifting the off-circuit tap-changer head, turn the Geneva wheel crank of the step-by-step gear inwards by 90° starting from the adjustment position (Figure 111).

Figure 111 16) Position the off-circuit tap-changer head on the cage. The

off-circuit tap-changer head can only be screwed to the cage in one position (Figure 108, Figure 112, Figure 115).

Figure 112

17) Mount the lifting traverse (Md=10 Nm, Figure 113).

Figure 113 Mounting the lifting traverse18) Lift the cage with the lifting traverse until an air gap of ap-