October 2010 Vol. 12 issue 7 Outrigger mats · October 2010 cranes & access 3 On the cover: 17...

Transcript of October 2010 Vol. 12 issue 7 Outrigger mats · October 2010 cranes & access 3 On the cover: 17...

. . . . . L i t h i u m s p i d e r l i f t f o r C T E . . . . . K o b e l c o b u i l d s i n I n d i a . . . . . T e r e x b u y s R e c o m . . . . .

October 2010 Vol. 12 issue 7

ww

w.

ve

rt

ik

al

.n

et

ww

w.

ve

rt

ik

al

.n

et

RT Scissor lifts

Heavy liftissue

Outriggermats

SAIEpreview

October 2010 cranes & access 3

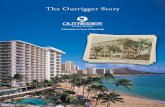

On the cover:

17 Heavy lifting

Outrigger mats

RT scissors

A new Terex CC8800-1 owned by ALElifts a 1,475 tonne reactor in Sines,Portugal - the heaviest lift applicationever for a single Terex crane.

25

In the next Issue of C&A: Loader cranes, truckmounted aerial lifts, Tower cranes and a review

of SAIE.

Books & Models 53ALLMI Focus 55

Training 57IPAF Focus 59

PASMA 61Innovations 63Your Letters 64

What’s on 68On-line directory 74

35

SUBSCRIPTIONS: Cranes & Access is published eight times a yearand is available on payment of an annual subscription of £40.00. If you wish to subscribe, please send a crossed cheque made payableto The Vertikal Press Ltd to: Subscriptions, The Vertikal Press, PO Box6998, Brackley, Northants NN13 5WY. Address changes should also besent to this address. Please include the address label from a recent issuewith all correspondence and allow 3 months for changes to be effective.

SUBSCRIBE ONLINE AT: www.vertikal.net/en/journal_subscription.phpBULK DISCOUNTS: These are available to companies wishing to takeout multiple subscriptions. Please contact the subscriptions managerfor more details. Tel: +44 (0)8448 155900 Fax:+44 (0)1295 768223E-mail: [email protected] & Bühne: The Vertikal Press also publishes a German magazinewhich deals with the same issues as Cranes & Access, but is writtenfor German users and buyers. Details available on request. While every effort is made to ensure the accuracy of informationpublished in Cranes & Access, the Editor and Publisher can acceptno responsibility for inaccuracies or omissions. Views expressed inarticles are those of the authors and do not necessarily reflect thoseof the Editor or Publisher. Material published in Cranes & Access isprotected under international copyright law and may not be reproducedwithout prior permission from the publishers.

c&acontents

Rough Terrain scissor lifts 35

We take a look at the market for large roughterrain lifts and some of the more unusual products that are now available, many of

which no longer use a scissor type mechanism to lift the platform.

Why SAIE? 43We ask why you should go to

this year’s SAIE exhibition inBologna, Italy and provide a

four page preview of the new product launches that you

might expect to see when youget there.

The Crane InterestGroup meeting 49

Mark Darwin reports form this year’s annualCPA mobile Crane Interest Group and covers

some of the more heated presentations.

SAIE Stop Press 67Some last minute, new product introductions

for the big Italian show.

In the next C&A

regulars

Comment 5News 6

Terex buys into tower crane maker, Spieringsback on track, Kobelco to build plant in China,

Caterpillar and Soilmec team up to produce foundation cranes, Grove launches two newRough Terrain cranes, Specialist Hire Group consolidates cranes, Leigh Farmer makes a

comeback, Boels goes with Skyjack, OlympicPark says no to Particulate Filters, Manitowoc

restructures its debt, JLGswitches to steel covers,

Isoli delivers demountablelift, CTE launches lithium

ion battery powered spiderlift, Verticaaldagen and

Elevarte reviews,Comoplast acquires

Solideal, Custers appointsin the UK, Terex and JLG

win large US militaryorders for telehandlers.

Heavy lifting 17The growth of the

alternative heavy liftcranes is giving usersincreased choice. But

how will this affect the big capacity crawler

cranes from the majorcrane manufacturers?

Cranes&Access investigates and looks at

several heavy lift applications from

around Europe.

Outrigger mats 25In our annual look at the subject of outrigger

mats we make a simplistic and possibly naïveproposal to cut accidents in half. Mike Allanson,

operations manager for BFL Alimats and craneAP warns that doubling up on safety factors

may backfire.

October 2010 cranes & access 5

Restoring commonsense As we enter the winter season we areonce again confronted by the popularmedia’s reporting of health and safety‘madness’ - access platforms used forremoving conkers from trees and

Christmas lights cancelled due to the risks and costs of putting them up.

The UK construction industry is continuing with its own health andsafety ‘madness’ at the moment with major contractors adding moreand more requirements, paperwork and costs on to suppliers. Thelatest issue gathering momentum with some contractors is therequirement that equipment operators provide proof that they aremedically fit to operate the machinery safely. This is currently in theearly stages of ‘discussion’ but the worst-case scenario may meanthat all operators will need a ‘current’ medical certificate beforebeing allowed on to site - and this after surveys and statistics showthat the risk is negligible to non-existent.

But where is all this health and safety leading and will it reducerisks to workers? Ultimately, it has to be a reasonable trade offbetween risk and common sense. The long-awaited report on healthand safety by Lord Young encourages this return to ‘common sense’in the management of risk in Britain. Young said that ‘health andsafety had for too long been allowed to become a joke in the mediaand among the public’.

This latest report is backed by HSE chairman, Judith Hackitt, whoagrees that the report ‘is an important milestone on the road torecovery for the reputation of real health and safety and the opportunity to refocus health and safety on what it is really about -managing workplace risks’.

Hackitt also said that the ‘HSE will continue to champion a sensibleand proportionate approach to dealing with serious risks in theworkplace – not eliminating every minor risk from everyday life’.

A common sense approach to the medical certificates would be tofollow the existing guidelines for HGV drivers - a medical test everyfive years from the age of 45. However this common senseapproach needs to be widely communicated in the hope that majorcontractors will also adopt a similar attitude - a sensible and proportionate approach to dealing with risks.

We are all in favour of reducing accidents and injuries, but whenthere is overzealous enforcement of legislation that results in stupidend results (take the over-sizing of crane outrigger pads for example) it loses all credibility and can have the opposite effect.

Hopefully Lord Young’s report will be a step towards restoring acommon sense approach to risk management

Mark Darwin

Please mail, email or fax any comments you may have, to the editor, stating if we may publish them or not.

The Vertikal PressPO box 6998 Brackley NN13 5WY. UK

Tel: +44(0)8448 155900 Fax: +44(0)1295 768223email: [email protected]: www.vertikal.net

In Germany:

Vertikal VerlagSundgaualle 15, D-79114,

Freiburg, GermanyTel: 0761 8978660 Fax: 0761 8866814

email: [email protected]: www.vertikal.net

Germany, Scandinavia, Austria and Switzerland

Karlheinz Kopp, Vertikal Verlag,Sundgaualle 15,D-79114, Freiburg, Germany

Tel: +49 (0)761 89786615 Fax:+49 (0)761 8866814

email: [email protected]

Italy Fabio Potestà, Mediapoint,

Corte Lambruschini,Corso Buenos Aires 8, V Piano-Interno 7,

I-16129 Genova, ItalyTel: 010 570 4948 Fax: 010 553 0088

email: mediapointsrl.it

The NetherlandsHans Aarse

39 Seringenstraat, 3295 RN, S-Gravendeel, The Netherlands

Tel:+31-78 673 4007 Mobile:+31(0) 630421042email: [email protected]

UK and all other areas Pam Penny

PO box 6998 Brackley NN13 5WY. UKTel: +44(0)8448 155900

email: [email protected]

Design & Artwork by:bp design Ltd.

Tel: 01707 642141 Fax: 01707 646806email: [email protected]

ISSN: 1467-0852

© Copyright The Vertikal Press Limited 2010

Editors:Leigh Sparrow

Mark Darwin

Associate Editors:Rüdiger Kopf (Freiburg)

Alexander Ochs (Freiburg)Andrew Klinaichev (Moscow)

Sales & customer support:Pam Penny

Karlheinz KoppClare Engelke

Production:Nicole Engesser

Publisher:Leigh Sparrow

The Vertikal Press Ltd.MEMBERS OF

Letters, emails, faxes and

phone calls are welcome and

should be sent to:

The Editor,

cranes & access,

PO Box 6998, Brackley

NN13 5WY, UK

Tel: +44(0)8448 155900

Fax: +44(0)1295 768223

email: [email protected]

cranes&access

The Vertikal Press also publishes:

For users & buyers of lifting equipment

c&acomment

October 2010 Vol. 12 issue 7

6 cranes & access October 2010

news c&a

Caterpillar and Soilmec have confirmed their plan to jointlydevelop a range of foundationcranes. The agreement follows thelaunch at Bauma of the 65 tonneSoilmec SC-65 lattice boomedcrawler crane which was designedand built in collaboration with CAT.

Since then the machine has goneon to complete the final phases ofits field validation programme in ademanding working environment ona Trevi Group managed job site. Thetwo partners in the project say thatthe cooperation leverages Soilmec’sexpertise in the foundation sector

CAT andSoilmecconfirmagreement

Spierings unveiled the City Boy at Bauma

with Caterpillar’s ability to bringtogether an extensive range of world class components, systemsand technologies supported on aglobal basis. It is planned that thenew crane range will be extended to include further models with capacities of between 60 and 200

tonnes. They will initially be distributedvia Soilmec dealers, but also madeavailable to those Caterpillar dealerswho have demand within their salesterritory.

The Soilmec SC-65 is a joint venture with CAT

Kobelco in China moveKobelco Cranes has announced a joint venture in China to manufacturecrawler cranes. Chengdu Kobelco Cranes Co will be established this monthwith a ¥2 billion (€17.6 million) of capital with Kobelco owning 51 percentof the equity and local partner Sichuan Chengdu Chenggong ConstructionMachinery Co. holding the balance.

The joint venture will build a new 6,900 square metre plant on a 133,000 squaremetre site in Sichuan Province. Production at the new facility is planned to startin August 2012 and is expected to build models up to 250 tonnes capacity withannual production ramping up to 80 units a year within five years.

The new venturefollows Kobelco’srecentlyannounced $12.7million crane production facilityin Sri City SpecialEconomic Zone inIndia which willbuild crawlercranes from 90 to 250 tonnes capacity. Kobelcoclaims a 17.4 percent share ofthe worldwidecrawler crane market.

Kobelco will produce cranes

up to 250 tonnesin both China

and India.

Recom builds theComedil luffing range

Terex buys into Italiancrane manufacturerTerex has acquired a 33 percent stake in Italian-based luffing jibtower crane builder Recom with the aim to make a full takeoverin the longer term. Privately held Recom is based in Belluno, Italyand designs and manufactures luffing jib tower cranes that aredistributed exclusively by Terex Cranes under the Comedil brand.

Recom was established in 2003 by Ferruccio Moritsch, the founder ofComedil tower cranes - now owned by Terex - to design and buildluffing jib tower cranes for the worldwide market and has been sellingthrough Terex Cranes’ distribution network since 2008. Terms of thetransaction were not disclosed.

....And takes a run at Demag CranesIn a separate move Terex has retained Goldman Sachs to advise on apossible bid to acquire a substantial holding in Demag Cranes, theGerman-based overhead and Gottwald port crane manufacturer. Themove follows an earlier strong rebuff by Demag of an uninvitedapproach from Konecranes of Finland. Terex and Demag declined tocomment.

October 2010 cranes & access 7

newsc&a

Tutt Bryant delistsTat Hong has completed its full takeover of the Tutt Bryant Group,acquiring all of the shares in the business that it did not alreadyown. As a result Tutt Bryant was delisted from the Australianstock market on 14th October.

Tutt Bryant is one of Australia’s largest crane rental companies andowns Muswellbrook Crane Services, Bradshaw Ultra Heavy Haulageand Tutt Bryant Crane Hire. It is also big in general rental includingaccess equipment and crane sales and distribution through EQ Hire, BT Equipment, Kingston Industries and Paramount Hire Services.

The Specialist Hire Group has consolidated its crane hire operations into a singlecompany under the Specialist Hire Group Crane Division. The business is a combination of Jardine Crane Hire (acquired 2003) Marsden Crane Hire (2004),cranes from Steelforce Bowmech and more recently Telford and Heartlands CraneHire. More on this along with a face to face interview in our November issue.

Spierings issued a update statement in early October followingthe bankruptcy in June of some of the companies within theSpierings Group. The main operational companies SpieringsKranen BV and Spierings Verkoop BV were not part of the bankruptcy process, allowing the service and parts departmentsto remain fully operational throughout. New crane productionrestarted in a small way in early July and is now gathering pace.The restructuring has shrunk the business to 40 employees,although it has the same plant, tools and equipment and is basedat the same location.

In July, Marcel de Jong joined the management team as generalmanager of Spierings Cranes, while Leo Spierings retains ownershipof the company.

Speaking of de Jong’s appointment, Spierings said: “For many years,Marcel de Jong managed several production companies and willfocus on improving efficiency inside Spierings and increase thereturn on investment of the company.”

The company says that it has retained all orders that were on thebooks as of June 15th and in August delivered the first newSpierings SK498-AT4 to Hardeman Isolatie of Kootwijkerbroek,Holland along with three fully refurbished cranes, two SK488-AT4sand an SK365-AT3.

As to when production of the new City Boy crane, shown as a prototype at Bauma, will start, Spierings said: “It is not totally clear, but the planning is well organised for an open day and a demonstration of the radical new crane at the beginning of nextyear.” In the meantime he is looking to expand the company’s distributioncoverageacross thewhole ofEurope.

First JCB 515-40’s go to workUK-based rental company Rocket Rentals of Dursley, Gloucestershire, hastaken delivery of two of the first JCB 515-40 ultra compact telehandlers, thesmallest model ever produced by the manufacturer. The two units, part of anorder for six, were specified with air-conditioning, solid tyres and licensedfor road use.

The first unit went straight out on a three month rental to Devizes–based contractor Gaiger Bros on a school renovation project in Warminster. The 515-40’s 1.56 metre overall width allowed it to gain access through the very narrow site entrance.

Gaiger says that the alternative would have been to have used a high-masted forklift for handling the materials in its compound on a nearby sports field and acompact dumper to take them through the narrow entrance to the point of construction. As a result it is delighted to have saved on the rental of a secondmachine and also highlighted health and safety benefits of keeping the loads palletised and avoiding the manual handling of bricks that would have been necessary with the dumper option. The 515-40 has an overall height of 1.8 metres is just 2.97 metres long and weighs less than 3.5 tonnes.

The first JCB 515-40 telehandlers have been delivered.

Spierings backin production

Arend Hardeman (L) of Hardeman Isolatie takes delivery of two newSpierings cranes from Leo Spierings.

The Spierings City Boy

at Bauma earlier

this year.

Thihatmer hands over at TeupenAlfons Thihatmer, chief executive of spider and truck mounted lift manufacturer Teupen, has announced that he will assign his current management responsibilities to Michael Wotschke and will resign from theTeupen group management board on his own initiative by the end of this year.

Thihatmer has been a managing director of Teupen since 1986 and has played asignificant role in the company’s development, including launching tracked aeriallift production leading to the company’s current leadership in the mid to large spider lift market. He will retain an involvement with the company as a consultantand shareholder, with particular focus on the development of new products.

Alfons Thihatmer (L) and Michael Wotschke at Bauma 2010

Specialist consolidates into single unit

Specialist CraneHire merged itsoperating unitsinto a single business earlierthis month and hastaken delivery of anew 110 tonneGrove GMK5110-1

8 cranes & access October 2010

news c&aSteel covers forJLG boom lifts

JLG is switching from composite moulded covers on itsdiesel boom lifts sold in the Americas to steel. The move isdriven by customer requests for covers that are more ruggedand easier to repair, as well as being less costly. The firstunits to feature the new covers are the 600S, 800S and800A models.

European units will continue to be supplied with the more rounded composite covers unless there is a clear demand toswitch. Steel cover kits can be purchased for retrofitting, shouldan owner wish to covert an existing machine.

US-based Lift-A-Loft has introduced a new pick-up mounted scissor lift that can be removed in around 10 minutes. The TL22has been developed for shorter jobs where speed across site orto the job is of real benefit. The 6.65 metre platform height liftfeatures a 1.34 metre wide platform with 227kg capacity andincludes a standard 900mm deck extension which provides outreach to the rear. The TL22 can be mounted in any pickuptruck that has 1,250kg of payload and a 2.4 metre bed. It features a self-contained power pack that automatically re-charges from the vehicle’s electrical system. The unit meetsthe requirements of ANSI A92.2, does not require outriggers but is not yet CE approved.

Pick-up scissor lift

The new Lift-A-Loft TL22

210 Skyjack scissors for BoelsDutch-based international rental company Boels has ordered 210, 19ftSkyjack SJ111 3219 micro scissor lifts.The first 126 are in the process of beingdelivered with the remainder scheduledfor next year. The new order follows anorder for 50 units last year.

UK access entrepreneur LeighFarmer is set to return to the accessbusiness with a newcompany, PremierPlatforms Ltd, whichis registered in Cannock in the Midlands.The new company will offer a range of services including new and used equipment sales, service and inspections, operator training and contract hire with possibly some shortterm rental. Farmer founded HigherPlatforms in 1990 which was also located in Cannock, building the business into one of the Top 20 UKaccess rental companies with a fleet of435 units. He sold it to Lavendon inAugust 2007 for £8.9 million.

Olympic Park DPFs - final decisionThe on-going saga over the retro-fitting of diesel particulate filters (DPFs) to cranes, telehandlers and platforms on London’s Olympic Park site has finally reached a conclusion. The Olympic Delivery Authority (ODA) has taken the decision not to implement the requirement to retrofit DPFs to Non-Road Mobile Machinery. The decision follows a cost analysis study which concluded “that the costs and benefits of DPFs do not represent good value for money when compared with other measures".

See www.vertikal .net for more details of the study

Select Plant Hire, part of the LaingO’Rourke group of companies and oneof the UK’s largest crane owners, haspurchased a Sennebogen 683R HD telescopic crawler crane from distributor E H Hassell & Sons.

The 80 tonne Sennebogen 683R HeavyDuty has a five section 42 metre telescopic main boom plus 10 metreswingaway extension. Other featuresinclude hydraulically extendable undercarriage and second winch.

CTE introduceslithium spider Italian truck and spider lift manufacturer CTE will show a lithiumion battery powered version of its 17metre Traccess 170E spider lift atSAIE. The CTE T170E will offer aroundfive hours of continuous operation andwill require eight hours to completelyrecharge.

The bulk of the machine will be the sameas the standard model, with a 17 metreworking height, 7.5 metres outreach,200kg platform capacity and overallwidth over the outriggers of 2.8 metres.See Why SAIE - a preview to the showon page 43 and 67.

The new CTE T170E has lithium battery power.

The new steel covers on a JLG 860SJThe new steel covers on a JLG 860SJ

Select buys firstSennebogen

Select has purchased its first Sennebogencrane, a 683R Heavy Duty telescopic crawler.

Leigh Farmerreturns

LeighFarmer

October 2010 cranes & access 9

Manitouraises funds for Alzheimer’sManitou UK has raised £4,000 for the Alzheimer’s society following a fund raising activity at a number oftrade shows earlier this month. The initiative involved collecting donations in return for either a Manitoufeed bucket or a ‘Bag for Life’ at the Royal Highland Show, Cereals and South West Grass event 2009.

newsc&a

Terex seeks credit amendmentTerex is seeking an amendment to its bank credit facility to liftsome of the more restrictive covenants and provide greater flexibility for the use of the proceeds from the sale of its miningbusiness earlier this year.

Manitowoc restructures debtManitowoc has reached an agreement from its senior lenders for an amendment to itscredit agreement that becomes effective with the pay down of term debt from theissuance of at least $500 million of senior unsecured notes. The change will providemore flexibility and a longer maturity.

(L-R) Caryn Davis of the Alzheimers Society withSarah Hunter, Paul Bidwell and Owen Buttle ofManitou UK

Tanfield completesrights issueTanfield, owner of Snorkel has completed a rights issue, selling 20 millionnew shares to raise £1.8 million net of costs. Shareholders took up 50.4percent of the offering, leaving the underwriters – three of the company’sdirectors – to pick up the balance. The directors - Roy Stanley, DarrenKell and Jon Pither - have also agreed to provide a standby loan of up to£750,000 in order to cover any short term cash shortfalls.

Manitowoc unveiled two newGrove Rough Terrain cranes at itsCrane Expo 2010 event in ShadyGrove Pennsylvania earlier thismonth, one of which – the 135tonne RT9150 – we announced inour last issue. The second newmodel is the 59 tonne GroveRT765E-2, which will replace thehighly popular RT760 of which morethan 2,000 units have been soldsince its launch in 2001. The RT765maintains the overall dimensions ofthe RT760, including the 33.5 metre

main boom length and 62.8 metremaximum boom/extension combination, along with much of its componentry and controls.However it has a new, strongerbase boom section, structuralupgrades to the chassis and superstructure frame, a new telescopic cylinder, new lift cylinder,larger counterweight and mostnoticeable the company’s brandnew cab.

The RT9150 - the largest two axleGrove ever - combines the chassis

of the 130 ton RT9130Ewith the basic superstructure of theGrove GMK5130-2 All-Terrain crane. It is said to offer substantial lift capacity improvementsover the 9130, while the60 metre Twin Lock pinnedboom (a Grove RT first) isalmost 12 metres longer.Maximum tip height ismore than 95 metres whenfitted with inserts and thehydraulically luffed bi-foldswingaway extension. Thenew model will come into

its own on large sites or plants where highreach is required and a long and complexAT chassis a disadvantage.

The cranes outriggers and counterweightcan both be self-removed/ installed fortransport. Both cranes are also equippedwith new, quieter, cleaner Tier 4 engines forNorth America and Europe. Tier 3 powerunits are available for markets where lowsulphur diesel is not yet available.

New RTs from Grove

The new Grove RT765is said to have a loadchart at least five percent better thananything else in theclass

GroveRT9150extensions

The RT9150 is the largest Grove two axle crane ever built

The new Grove cab

10 cranes & access October 2010

Spanish DaysSpain was the centre of attention for the powered access industry lastmonth with both the Elevarte and Europlatform events held in Madrid.

Europlatform attracted more than 100 delegates to hear a wide range ofspeakers including ex-JLG president Craig Paylor, Carlos Fernandez Araoz ofSpanish rental company Gam and Malcolm Bowers of Lifterz and the AccessLink. Craig Paylor of JLG issued a number of warnings including a predictionof steep price increases for new lifts as the recession eases, the threat ofAsian manufacturers buying up large access rental companies and the risingover-specification of aerial lifts. He recommended that rental companies agetheir equipment rather than replace it.

Exclusively TeupenUK-based Aerial Platforms has agreedan exclusive supply deal with Teupendistributor Ranger for the purchase ofTeupen spider lifts. The first threeunits - a Leo 15GT, a Leo 18GT and aLeo 23 GT - have already been delivered. Jason Seddon of AerialPlatforms said: “We will offer the liftson a national basis and see majorgrowth in this sector over the nextfive to 10 years.” Seddon also says aLeo 30T and 40GTX have beenordered for delivery in April 2011.

JLG has won a $40 million contractto supply 280 telehandlers to the USMarines. The units will be built atthe company’s McConnellsburg,Pennsylvania facility over the nexttwo years.

The telehandlers - known as EBFL(extendable boom forklifts) by themarines and MMVs (Millennia Military

Vehicles) in military circles - have a maximum capacity of 11,000 pounds,(5,000kg) and a lift height of 42ft/12.9 metres.

Elevarte

the all new

rangeof electric powered platforms from Versalift

It’s here!

• Low emissions

• Virtually silent operation

www.versalift.co.ukemail us at: [email protected]

Access to a greenerworld

Friday 17th September saw thefirst Elevarte crane and accessexhibition open its doors at a siteon the outskirts of Madrid. Theevent was supported by 31exhibitors - with all of major manufacturers represented - andfollows the informal formula ofPlatformers Days in Germany,Vertikal Days in the UK andVerticaaldagen in Holland. morephotographs from Elevarte can befound on www.vertikal.net

Jason Seddon (R) takes delivery ofa new Teupen Leo 23GT from AndyFirth of Ranger

The JLG MMV telehandler

$40 million US Marine deal

October 2010 cranes & access 11

A lift to the church?When Richard Allsop of UK-based ChrisAllsop Crane Hire of Colwick, Nottingham,married Georgina Lane recently, his weddingcar was far from the usual limousine. Insteadhe used an 80 tonne Tadano Faun ATF80-4All Terrain crane to travel to the churchalthough the couple used a more traditionalhorse and carriage once married.

Dutch-based access equipmentmanufacturer Custers Hydraulica ofVenray, has appointed Mansfield,Nottinghamshire-based Hi-Lift Accessas its UK dealer.

Hi-Lift - which currently offers a full rangeof access services including new andused equipment sales and rental focusingon Teupen spider lifts and Ruthmann truck

mounts - will start with Custers non-powered products, including foldingscaffold bases, painters scaffolds up to31 metres in length, platforms and footbridges, roof/window scaffold, roofedge protection systems, alloy spanscaffold towers up 12 metres andstairway towers.

The company also has plans to offer

Custers powered access range, includingtrailer and truck mounted lifts and itstracked boom for forestry work.Custers also recently announced an allelectric truck/van mounted lift, theTaurus 265-12.5E.

Founded in 1901, Custers was part ofSGB between 1977 and an MBO in1995. It built its first truck mounted liftin 1962 adding scaffold products inthe early 1980’s.

Richard Allsop andGeorgina Lanewith the Tadano

Italian-based aerial lift manufacturer Isoli, hasrecently designed and built a demountable truckmounted version of its 21 metre PNT 210J aeriallift for a customer needing the versatility of bothan access platform and a flat-bed truck, completewith loader crane.

The solution uses the popular 3.5 tonne Nissan 35.11and interchangeable platform/flat bed system allowingthe customer to choose between the 21 metre workingheight, 10 metre outreach articulated boom lift with in-line stabilisers or the flatbed truck and loader crane.

The Italian customer says that this system has theadvantage of reduced insurance and tax by usinga single chassis for two purposes.

A Custers span tower

Demountabletruck mount

Custers appoints Hy-Lift

The platform de-mountswhen not in use

Installed and readyto go in half an hour

newsc&a

12 cranes & access October 2010

news c&aPositive news fromVerticaaldagenThe second Verticaaldagen access, crane and telehandler event near Tilburg, Holland,attracted almost 40 exhibitors and almost 800 visitors from the Dutch crane and access rentalindustry, with several companies chalking up some unexpected orders for new equipment.

The new MEC 40S Titan Boom

The 20ft Dingli JCPT0808 and JCPT1012narrow scissor lifts on the Alp Lift stand.

Patrick Biasin, previously generalmanager of ATN, the French mast boommanufacturer, recently joined wasSkyjack. Biasin covers the whole ofFrance as district manager from hishome base in Tonneins.

The Gerenuk 500 telehandler mountedglass handler on the Heli stand.

Collé had an impressive stand thatincluded several Palfinger platformsincluding this P260 on a 3.5tonne chassis.

A 20 metre CMC TB200, one of 18new truck mounts ordered by Boels

There were several tracked mini cranesincluding this 17.4 metre reach, 4 tonnemaximum Hoeflon C610.

Ruthmann took the opportunity tolaunch its new TB270 and TBR200models in Holland.

A 14 metre Dingli dual mast selfpropelled vertical lift on the FaraoneNetherlands stand.

The impressive new 16 metre MecaplúsME16SL demonstrated its capabilities.

The Komatsu LC08M-1 mini crane’stracks extend from 850 to 1,580mm whilethe counterweight extends hydraulically.

New products included MEC’s40ft/12.2 metre Titan 40S in Riwalcolours fresh from Elevarte inSpain; scissor and vertical mastlifts from Chinese manufacturerDingli; the Guerenuk 500 glassmanipulator telehandler attachmentand two platforms specificallydesigned for tree work - a 26 metretruck mounted platform built byCusters for the City of Maastrichtand the new 16 metre MecaplúsME16SL self-propelled boom.

Electric RT scissor lifts were alsosomething of a theme, with theworld’s largest battery electricpowered lift - the 34 metre HollandLift leading the pack along with theIteco 12180DE.

An unusual exhibit was a 1,590kgKomatsu LC08M-1 mini crane.While no longer in production the800kg crane sported a range ofimpressive features for its size,including a 5.1 metre all hydraulicboom and hoist with 43metres of cable storage.

Chinese manufacturer Dingli hadseveral aluminium self-propelledmachines at the show on differentstands and in different liveries.

Kraan en Truck Service showed oneof 18 CMC new truck mounts thatit has sold to rental company Boels.The order, which follows six unitsthat it acquired last year, includesfour TB200 articulated booms, 10PL 210/212 straight telescopicsand four PL190 straight booms.

Other companies reporting salesincluded AllLift Michielsen whichtook an unexpected order for threeGSR truck mounts and Eurosupply.

Alp Lift which imports Airo scissorsand booms has taken on the Dingliscissor lift distribution for Hollandand Belgium. The two units onshow - a classic 20ft narrow and26ft/46inch model - lookedimpressive in terms of qualityand finish and as good as anyChinese-built scissor lift wehave seen to date.

Heli demonstrated the Guerenuk500 telehandler mounted glassmanipulator. The battery poweredunit is operated by remote controland features a short side shiftmounted telescopic boom that luffsthrough almost 180 degrees, ashort articulated linkage ads further

control, while tworotators add a wristaction to thevacuum frame.

Tuxford, Nottinghamshire-based transport company Walker & Son has takendelivery of a new 100 tonne Grove GMK4100L. Founded in 1954, thecompany is best known for its distinctive red and cream trucks, howeverit also has a fleet of eight mobile cranes ranging from a 12 tonne Iron Fairyto its new 100 tonne ‘flagship’.

The GMK4100L’s 60 metre main boom tops the company’s previous largest -Liebherr LTM1080/1 - by a full 12 metres while offering some significantincreases in capacity.

“Our new crane will enable us to carry out heavier lifts and longer reaches, forwork such as in power stations, collieries and petrochemical sites that we wouldhave previously had to cross-hire,” said Walker’s crane hire manager, Bob Wilson.

Canadian-based rubber track manufacturer Camoplast has acquiredLuxembourg-based material handling tyre, wheel and rubber trackproducer Solideal. The deal should be finalised later this month.

The merged company, Camoplast Solideal Inc, will become one of the world’sleading producers of industrial tyres, rubber tracks and undercarriages witha particularly strong presence in solid wheels and tyres for materialhandling equipment.

Solideal and Camoplast brands will continue to be managed independently. Camoplast Solideal will operate R&D and manufacturing facilities in NorthAmerica, Europe and Asia, with a workforce of about 7,400 employees.

Terex has won an $18.9 million contract tobuild 200 Terex TX51-19MD, 5,000 lb capacity,Light Rough Terrain Forklifts (LRTF) telehandlersfor the United States Marine Corps.

The initial delivery of more than 100 units is valued at around $9 million.The Marines first acquired the TX51-19MD LRTF, a militarised version of acommercial model in 2001 following extensive trials. The unit is designed tomeet the rigorous demands of the USMC which includes fording, beachoperations and helicopter transportation.

Thomas Manley, vice president, Terex government programs said:“We have been fulfilling military contracts for nearly a decade and the Corpshas been one of our most loyal customers. They are demanding because oftheir mission and they deserve the best we can provide.”

Terex winsUS Marinetelehandler deal

100 tonne Grove for Walker

October 2010 cranes & access 13

Walkers new flagship,the Grove GMK4100L

TerexTX51-19MD

newsc&a

All tyred out

October 2010 cranes & access 15

newsc&aAbdullah Ali Kanoo, 83, chief

executive of the Yusuf Bin AhmedKanoo Group passed away onOctober 10th.

German-based Power-Lift is offering to make PDF files available for all old UpRight and Snorkel lifts back to 1970.

The US crane operator certification businessNCCCO has won its litigation against the CaliforniaCrane School.

French-based lifting and transport companyDufour has purchased a new Kobelco CKE2500-2crawler crane.

Tower crane electronics company SMIE has confirmedJean-Charles Delplace as its new managing director.

Caterpillar has informed its dealers that it plans to implement a two percent price increase inJanuary as business improves.

WesternOne of Canada, is rebranding its VolvoRents/Deerfoot Rentals and On Site Equipmentacquisitions and dropping the Volvo Rents franchise.

Bigge Crane and Rigging is relocating its eastcoast Head Quarters to a larger facility inRichmond, Virginia.

Cargotec has won two contracts to refurbish andupgrade ship-to-shore cranes at Port Klang.

The UK’s Access Link held its autumn meeting atthe Terex/Genie assembly plant in Coventry inSeptember.

GGR held an open day at its Blantyre depot inScotland in late September to introduce its latestlifting equipment.

This year’s IPAF Professional DevelopmentSeminars in the UK attracted a record number ofdelegates.

Manitowoc has appointed UN Maskinservice asthe dealer for Grove mobile cranes in Denmark.

Demag/Gottwald and REFU Elektronik havereceived German government funding to exploremore efficient drivetrains.

Dovebid is selling 64 Fraco and Scanclimber mastclimbing work platforms by auction, with finalbids due by November 30th.

Manitowoc has appointed DaveHull as senior vice president ofsales and marketing in NorthAmerica.

Oil States Industries has agreed aJV with G&T Oilfield and Offshoreto manufacture Nautilus cranes in India.

West Coast USA-based Coast Crane Company -the crane and access sales and rental company -has filed for Chapter 11 and is looking to restructure under a new owner Clearlake Capital Group. Mark Yarnold, UK key account manager forSnorkel, completed a 2,000 mile road trip in afully loaded articulated truck in late September. Terex Cranes has appointed Frank Bardonaro as managingdirector of Terex Cranes in theAmericas. Harsco has appointed David C.Everitt of Deere and James M.Loree of Stanley Black & Decker as non-executive directors.Socage will launch a new 28 metre truck mounted lift, the DA328 at SAIE in Bologna thisOctober. Ashtead’s US rental operation Sunbelt Rentals,has opened its first branch in Oklahoma, Yukonon the outskirts of Oklahoma City.Lavendon UK is requiring all managers to take an Institution of Occupational Safety and Health (IOSH) course.Torgny Eriksson, a non-executivedirector at Finnish rental companyRamirent, has died aged 63.Vp, owner of UK Forks hasannounced the departure in November of group financial director Mike Holt. Harsco, the owner of SGB, Hünnebeck and PatentScaffold – now Harsco Infrastructure - has completed its bond offering. UK-based Generation Training Services has addeda mobile training unit to its range of accessrelated training services. Rental and asset management company ResultGroup has appointed Steve Eldred as its newEuropean projects director. Robert G. Bohn, chairman andchief executive of Oshkosh, ownerof JLG, will retire at the end of theyear. President Charlie Szews willtake over his role.The National Commission for theCertification of Crane Operators (NCCCO) haslaunched its Rigger Level II certification. UK-based One Stop Hire has opened a new location in Widnes, Cheshire, its largest locationto date. Suspended platform specialist Spider, hasappointed Frank Roberts as district sales representative in St Louis. Scott Powerline Equipment of Monroe, Louisianahas delivered an Elliott 30105R boom truck withwork platform, crane and rock drill to theAmerican Salt Mine Company 470 metres underground. E.S. Access Platforms has been placed in administration and it is likely that its assets will be sold off.JCB has agreed a financial settlement from oneof the ‘Asian’ companies that it accused of copying its products at Bauma in April.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

See www.vertikal.net news archive for full versions of all these stories

•

•

•

•

Skyjack has sold off the spare parts rights forits straight mast RT fork truck line - previouslybuilt by Ingersoll Rand.

Dutch rental company Riwal had its premisessearched by police following a war crimesaccusation.

Lavendon chairman David Hollywood, hasresigned and is succeeded by John Standen,the company's senior non-executive director.

Snorkel Deutschland the new master distributor for Germany has sold its first units- two articulated A46 JRT boom lifts - toRoggermaier Arbeitsbühnen.

Heavy lifting and transport company ALEhas formed a new marine engineering and operational services division ALE MarineEngineering.

UK crane specialistAinscough has appointedJulian Dyer as heavy cranesales manager for the UKSouth region while JohnLewis previously of VentureLifting joins its Bristol depot.

Aerial Platforms has recently moved from theAccess Link to the Access Alliance.

Konecranes was strongly rebuffed by Demag Cranes in September after making atakeover/merger approach.

The Crane Industry Council of Australia (CICA) has appointed three new directors toits board - Cheryl Woodhart of RMBEngineering, Dean Short of Freo Group and Ray Brenton of Thiess.

Kranlyft has appointed MiniCrane Co, a newcompany within the Sevzapkanat Group as the new Maeda distributor for Russia.

Australian-based Stephensons Cranes has been fined A$65,000 and ordered to publicisethe facts of the case following a lifting accident.

Tat Hong has completed its full acquisition of Tutt Bryant the Australian crane rental and sales company and delisted it from the ASX.

UK crane hire companyAinscough has appointed anew marketing manager,Victoria Tonge, responsible for advertising, internal communications and PR.

A new crane operator training company IS Training has been established in the UK this summer, based in Preston.

Gerhard Flesch of German access specialistFlesch Arbeitsbühnen celebrated his 70th birthday with customers and friends earlierthis month.

JLG has decided to pull out of ARA/Rentalshow 2011 in Las Vegas citing its proximity to Conexpo as the reason.

Harsco Infrastructure, (SGB, Hünnebeck andPatent) has opened a prototype ‘super centre’location in Las Vegas.

Abdullah Kanoo

Lavendon IOSH

Robert Bohn

Victoria Tonge

Julian Dyer

Frank Bardonaro

David Hull

Jean-CharlesDelplace

The Access Link

News HIGHLIGHTS

October 2010 cranes & access 17

h e a v y l i f t i n gc&a

With Manitowoc’s new 2,300tonne 31000 in final stages oftesting and Liebherr’s LR13000 inthe process of having its mainboom mounted, it wont be manymonths before all three of themajor crane manufacturers(Terex, Liebherr and Manitowoc)have a ‘conventional’, largecapacity (2,300 tonnes to 3,200tonnes) crawler crane availablefor delivery.

Out of date crawlersBut in the time it has taken todevelop these latest mega crawlers,have they been eclipsed by the‘heavy lift’ alternatives offeringcapacities up to 5,000 tonnes?

One fact that is certainly true is thatbuyers are not exactly hammering

at the doors of the majors to gettheir hands on these big beasts.Quite the opposite in fact withorders for the big crawlers(although never going to be high)lower than expected. This weakdemand is more surprising giventhat most manufacturers developingand building limited edition largecranes tend to develop the machinein conjunction with ‘guaranteed’end-user partners i.e. a lead customer that is willing to take atleast the first machine. Al Jaberwas the design partner and ownerof the first Terex Demag CC8800-1Twin, Bulldog Erectors for theManitowoc 31000. Liebherr on theother hand appears to have chosena different course and does not yethave a firm order.

But should Liebherr be worried?

Well there has been a global downturn in crane demand,although the sector for large crawlercranes has performed better thanmost. But is there also a shift awayfrom the main line crane manufacturers to the ‘heavy lift’alternatives from companies suchas ALE, Sarens, Mammoet andLampson, mostly building for theirown rental/contract operations.

One reason might be that mostmega lift cranes tend to carry outlifts from a single prepared position.In such cases this makes thecrawler undercarriage an expensiveand un-necessary addition.

than the range topping models.

Travelling or tracking large crawlercranes (more than 2,000 tonnes)can be precarious - as witnessed byLampson’s accident with its 1,100tonne Transilift at the Black Thundermine in Wyoming in 2008 - even ifthe ground has been carefullychecked and prepared beforehand.Perhaps the crawler crane hasfound its true upper limit at around1,800 tonnes, above which the latest generation modularlifters/cranes have the advantage?

Cost and delivery always play animportant role in the choice of largelifting equipment. ALE initially decided to design and build its ownheavy lifter after a total lack of

Chickenor egg?In a typical ‘chicken and egg’ situation there willalways be a discussion as to which came first - the larger capacity crane or the longer, heavier component that needs lifting? In last month’s featureon big crawler cranes we asked whether the newbreed of 3,000 tonne plus capacity cranes from themajor manufacturers had a useful role to play orwhether the mega lifts were better suited to thegrowing number of ‘big lift’ alternatives and indeedwhether this was the way forward? We take a look atsome of the latest big lift machines and assess theirpros and cons compared to crawler crane as well aslooking at some interesting European heavy lifts.

The new Manitowoc 31000 undergoing final testing

On the other hand we can see fromthe Hartinger contract in Germany(page20) space limitation meansthat the ‘smaller’ 1,200 tonnecrawler may have to be fully riggedprior to the lift and then track intoposition. Or occasionally track withthe load on the hook for a short distance as in ALE’s GreaterGabbard offshore wind farm projectwhich required the Terex CC8800-1to track 35 metres across the fabri-cation yard with the 823 tonne jacket. However both these craneshad capacities considerably less

interest from the major manufacturers to come up with asolution to lift a 100 metre long,3,000 tonne column which wasrequired on a petro chemical contract in Saudi Arabia.

By doing its own design and build,it claims to have reduced its costssignificantly, the design was specific for the required contractand the company had total control(as well as responsibility) of thebuild-time and delivery date. It alsoended up with a unique crane thatwould give the company an edge

ALE purchased thisTerex CC8800-1 earlier

this year

Liebherr’s 600 tonnecapacity LR1600

18 cranes & access October 2010

h e a v y l i f t i n g c&awhen pricing for heavy lift jobs. ALEalso designed the crane in such away that with minor modifications –widening the base for instance – amuch larger 5,000 tonne capacitycrane could easily be produced.

In-house advantagesFor these larger, global lifting andtransportation companies keeping it‘in-house’ has its advantages. ALE’smoves appear to have spurred itscompetitors into action and nowmost of the major players in thismarket – ALE, Mammoet, Sarensand Lampson – have designed anew range of cranes. Because ofthis it is difficult to see why theymight be tempted to buy smallercapacity and possibly more expensive 2,300, 3,000 or 3,200tonne crawler crane from the major manufacturers.

At this point we should clarify thatwhile all four of the above heavy lift

companies have produced plansand designs for land based cranesabove 3,000 tonnes, only ALE hasin fact built one - the 4,300 tonnecapacity AL.SK190 – and it is in theprocess of adding a second to itsfleet during the second half of nextyear. The ALE SK is a more radicaldesign than the Mammoet andSarens ‘ringer’ designs, with the latest Lampson bridging the designgap between the conventionalcrawler and modular lifter by usingtwo tracked undercarriages.

Basically the ALE SK uses its counterweight as its centre of rotation which the company claimsprovides a much better workingenvelope, as well as helping reducethe need to track to a different position. Because of the crane’s different configuration the modelnumbering has been changed toreflect the way the industry

measures performance – so theSK190 and SK350 now mean190,000 tonne/metre and 354,000tonne/metre load moments measured from the centreline ofrotation. Measured this way, eventhe smaller SK190 has a loadmoment about 19 percent and theSK350 more than 120 percent morethan its nearest rival - the 160,000tonne/metre Mammoet PTC-160DS.

“Big cranes from major manufacturers such as the Terex8800 Twin are very wide machinesand very difficult to move unlessoperating on a very open site,” saysALE’s executive director MichaelBirch. “As well as having almostfour times the load moment of the8800, the AL.SK190 is much easierto erect, operate and transport andcan be relocated on site by skiddingor by self propelled modular transporters (SPMTs) when fullyassembled and rigged.”

Both SK cranes are equipped with astandard quick winch system (150metres/hour) for loads up to 600

tonnes and a strand jack lifting system (10 metres/hour) for loadsup to 5,000 tonnes.

Traditional ringersMammoet announced the plans ofthe larger PTC-160DS (Platformringer Twin boom Containerisedcrane) even before it had built itssmaller brother - the 100,000tonne/metre PTC120DS. Bothcranes use a traditional ringer withrollers for slewing and use the sameboom and jib configurations as wellas the same counterweight andwinches. The difference is the footprint with the PTC160DS havinga 54.5 metre diameter ring about 10metre larger than the PCT120DS.

Sarens new 3,250 tonne, 120,000tonne/metre heavy lift crane – theSGC120 – is also a classic ringerslewing on a double ring trackwhich sits on a load bearing matsystem. The concept has apparentlybeen in development with RiggingInternational for some but timedevelopment has been spurred onfollowing Sarens acquisition of the

The Mammoet PTC Maxima

Sarens 1,200 tonneGottwald AK680

ALE’s 190,000tonne/metre

AL.SK190 at itslaunch

October 2010 cranes & access 19

h e a v y l i f t i n gc&a

company last June. Work is scheduled to start early next yearand performance examples includethe ability to handle 600 tonnes at100 metre radius.

The SGC120 uses up to six highpower winches rather than strandjacks, with 61 tonnes of line pulland line speeds of up to 20metres/minute making it more akinto a regular heavy lift crane.

And for applications requiring frequent movement, it can bemounted on a dual track rail systemlaid out to suit the job site.

The SGC120’s load moment puts itfirmly between Mammoets pair ofPTC lifters but one major feature isits 90 metre luffing jib compared tothe 43 metres available on the PTCmachines.

The ALE, Sarens and Mammoetcranes can all be broken down totransport in standard 40ft containers and when set up on site,use similar sized reinforced containers filled with locallysourced materials for the 3,600tonnes of counterweight.

The growth of these Europeanheavy lifters and the collapse of

two of the largest 'bespoke' cranesin North America in 2008 – theVersaCrane TC36000 owned byDeep South Crane and Rigging ofBaton Rouge, Louisiana and theLampson Transilift working at theBlack Thunder Mine in Wyoming –means the initiative in the largecapacity alternative crane sector isfirmly on this side of the Atlantic.

New LampsonHowever earlier this yearKennewick, Washington-basedmanufacturer Lampson signed acontract with Hitachi Transport for anewly designed crane the LTL-3000– which has a lifting capacity about20 percent more than the 2,600 USton LTL-2600. The unit is beingdesigned and built over the next 22months specifically for the construction of a new advancedboiling water reactor at HigashidoriNN-1 nuclear power plant for Tokyo Electric Power Company.

Although Lampson claims that theLTL-3000 will be the largest mobile

crawler crane in the world its projected lift capacity of a littlemore than 2,800 tonnes is a longway short of the 3,200 tonne Terex8800-1Twin.

The Lampson LTL is unlike any ofthe European heavy lift cranes inthat in true Lampson style it aims tocombine the heavy lift capacity of abig ringer crane with the mobility ofa crawler by using two, individuallypowered twin track crawler transporters - one at the front supporting the main boom and backmast, and the one at the rear supporting the counterweight.

The front crawler transporter unitincreases to a 15 metre square withthree metre wide track pads andRolli-Flex rollers. The stinger, strutand counterweight frame will besimilar to the LTL-2600, but willincorporate the ability to telescopebetween 24, 30 and 36 metre positions to significantly reduce thetime to perform ‘mode’ changes.

The crane will be equipped newwinches and stronger cable to provide a 50 percent increase in line speed. The LTL-3000 121 metreboom will have 6.1 x 4.8 metrecross section, but will maintain theLampson pin together design concept. The crane will also have a36 metre jib.

At least Lampson has a partner andfirst sale for its LTL-3000. Whetheror not other planned heavy lifterssee the light of day remains to beseen, particularly bearing in mindthere will be three more conventional crawlers on the marketin the coming months.

Liebherr’s 3,000 tonneLR13000 shortly before

having its main boom mounted

Sarens SGC 120

Has the crawler cranefound its upper limit of

about 1,800 tonnes?

MammoetPTC120DS

The Lampson LTL-3000 is saidto have a lift capacity 20% more than the LTL-2600.

20 cranes & access October 2010

heavy l i f t ing c&a

Global heavy transport and lifting company ALEhas been making further investments in its largecapacity crane fleet. The most recent additionbeing its second 4,300 tonne AL.SK190 that itclaims is the world’s largest land-based cranewith a load moment of 190,000 tonne/metres.Earlier in the year, the company also added a1,600 tonne Terex CC8800-1 crawler crane at acost of €11 million which successfully completeda record breaking inaugural lift at the Galprefinery near Sines, Portugal.

ALE investsat the top end

Record breaking lift The Sines job involved thetransport, lifting and installationof a 1,457 tonne, 42 metre long 5.5metre diameter reactor. The movefrom Sines docks to the refinery –a distance of nine kilometres, wascompleted with 68 lines of SPMTs(Self Propelled Modular Transporter)and is said to be the heaviest loadever moved on Portuguese roads.Overhead restrictions forced theload to take a deviation througha mine area with inclines of upto 10 percent.

Once the vessel was on site thenew CC8800-1 worked at a radiusof 13.1 metres with a 60 metremain boom. The counterweightincluded its full 295 tonnes of

superstructure counterweight, 60tonnes carbody counterweight and640 tonnes of superlift ballast -suspended at a 30 metre radius.A specially designed rail mountedALE gantry was used for tailing-inpurposes. The lift was close tothe cranes 1,500 tonne maximumcapacity for the configuration andis said to be the heaviest lift evercarried out by a single TerexDemag crane.

And on to the next jobThe Terex CC8800-1s second outing involved up-ending andloading-out 35 jackets as part ofthe Greater Gabbard offshore windfarm project. The wind farm -located 23km off the Suffolk coast

in the UK - is set to be the largestin the world when completed.

The jackets – each weighingbetween 450 tonnes to 823 tonnes- had to be loaded onto bargesbefore being transported anderected at the wind farm site.The 1,600 tonne capacity TerexCC8800-1 was brought in to

up end the heaviest jacket, whilstit was tailed using Terex DemagTC2800-1 and CC2500-1 cranes.

Once vertical, the CC8800-1 -with full Superlift - transportedthe 823 tonne jacket 35 metresacross the fabrication yard beforeplacing the load onto a barge foronward transport.

The record breaking lift was at or closeto the CC8800-1s maximum capacity forthe configuration.

68 lines of SPMTs were used totransport the 1,457 tonne, 42m long reactor

Finding the right equipmentfor the job is often the key tosuccess. When KarlHartinger, the crane andheavy transport company fromWarburg, Germany, was askedto lift 30 metre long cylindersonto a 108 metre high chimney in Kessel, Germany itselected a Liebherr LTR 11200equipped with 84 metres ofluffing jib. Because of thelack of space, the luffing jibhad to be erected outside thesite and the crane the trackedinto position fully rigged. Thenarrow-track crawler provedto be the ideal crane to negotiate the narrow accesspassage and tight workingarea and carry out the lift.

The Terex CC8800-1 hadto load-out 35 jacketsweighing between 450to 823 tonnes

October 2010 cranes & access 21

heavy l i f t ingc&a

Built in 1890, the London-built SSRobin is the world’s last remainingsteam coaster and needed to belifted on to a pontoon for its returntrip to London following a £1.9million restoration. The SS Robin isa unique piece of maritime history,listed on the National Historic Fleetregister and regarded as one of themost important British-built ships.

The LGD1550 was riggedat 33 metre radius whilethe TC 2800-1 worked at34 metres. The twocranes carefully raised the300 tonne, 44 metre long,seven metre wide shipfrom the dock’s slipwayand placed it onto afloating dock/pontoon.

Gary Bowler, Ainscough HeavyCranes contracts manager said:“This was a complex lift, whichneeded to be planned to precisionto protect this unique piece ofmaritime history. We needed to liftthe vessel from a four degree inclineon the slipway and used a speciallydesigned rigging system to level theload before positioning it on the

Ainscough Crane Hire has used two of its new heavy lift lattice boomtruck cranes – an 800 tonne capacity Liebherr LGD1550 and 600 tonneTerex Demag TC 2800-1 - to lift the historic ship SS Robin fromLowestoft’s dry dock for the SS Robin Trust, ready for its journey to theRiver Thames in London, where it is set to become a floating museum.

Historic SSRobin lift

pontoon – ensuring no unnecessarystresses were put on the structure.The SS Robin is an important partof our national heritage and it wasan honour to be involved inthe project.”

Project management consultantsKampfner bought the historicvessel for £1 from the owners ofthe Cutty Sark 10 years agoand founded the SS RobinTrust leading a technicalteam of East Anglian andLondon-based marineconsultants, engineers,naval architects andshipwrights in a uniquehistoric ship conservationproject.

David Kampfner, project

director, said: “This irreplaceableGrade 1 listed vessel is the only one left of her type and will nowbe saved for the nation. We aredelighted that this technicallychallenging lift was a hugesuccess and an important milestonein the conservation of this listedhistoric ship.”

Sarens UK - working for design and constructmanagement contractor BAM Nuttall - recentlycompleted the replacement of two, three span,six deck Network Rail bridges between Arundeland Amberley stations in West Sussex, England.

heavy l i f t ing c&a

scaffolding. All were completedin readiness for the double bridgereconstruction which had to becarried out during a 74 hour, bankholiday weekend railwaypossession slot. Work that had tobe completed included the removalof the old track, the two existingbridge decks, the cutting of theexisting abutments and piersfollowed by the installation of fournew cill beams, eight ballast walls,new bearings and 12 new decks,slewing existing cables into newtrough routes and the laying of newballasted track over both bridges….No time for napping then!

The project was successfullycompleted without any incidentsor accidents ahead of programmeoffering Network Rail a large costsaving. The value of the work withinthe weekend possession alone wasmore than £3 million.

Difficult accessAccess to site was particularlychallenging because of the narrow,rural roads and travelling across theflood plain ground. Two, 800 metrelong temporary roads wereconstructed to cope with more than2,000 vehicle movements, includingthe large cranes and steel deck

Double bridgereplacement

The sites located on two adjacentfarms, were on the same line andless than a mile apart in low-lyingflood plain farmland borderingtwo Sites of Special ScientificInterest and within a Site ofNature Conservation Importance.

Sarens used two truck mountedlattice boom cranes - a 1200 tonnecapacity Gottwald AK 680-3 fittedwith 101 metres boom, and 250tonnes of Superlift ballast and an800 tonne capacity Demag TC3200H fitted with 78 metres ofmain boom and 250 tonneSuperlift ballast.

The six month preparation includedconstructing two temporary roads,ditch crossings, crane foundationsand building the new bridgecomponents, cable slewing and

22 cranes & access October 2010

transporters. More than 13,000tonnes of locally sourced recycledaggregates were used to constructthe raised roads across the floodplain (which included streams andditches) so that no oils or fuelscould contaminate the surroundingarea. At the end of the project, thetemporary road was removed andthe aggregate sold back to thesupplier for re-screening and re-use.

The poor ground also necessitatedthe design and construction oftemporary foundations for thecranes to work from, whichincluded steel grillage systems tominimise the amount of excavation.All the concrete casting of thedecks, cill beams and ballast wallswas completed on site due to therestricted road access.

Automatic guided concrete cuttingwire techniques reduced the levelof the existing piers to receive thenew bearings allowing for preciseand efficient cutting to a depththat traditional saws could notreach. Furthermore noise anddust emissions wereconsiderably reduced.

The new bridges are easier tomaintain with the new ballastedtrack giving greater flexibility thanthe original which was fixed tothe decks, while the new bearingscan be replaced separately.

This crane was well set up in termsof mats, but the engineeredaggregate platform- located neara stream was compromisedby heavy overnight rains andcollapsed when the weight wentover the outriggers closestto the edge.

Sustainability andenvironmental The new construction provides twonew bridge decks with a lifespan

of 120 years. Extensive ecologyreports and surveys costing£50,000 were undertaken beforeand during construction works.Construction methodologies werealtered and pro-active ecologymeasures such as bat boxes wereinstalled along the access roads,greatly benefiting the localbat population.

Substantial river protectionmeasures were also used acrossthe site, such as spill equipment,safety boats and containmentbooms. Scaffold was erectedunder the existing decks withinthe river’s tidal zone and thedemolition was programmed tobe carried out at low tide withthe scaffold temporarilyencapsulated to contain all debris.The site also adopted a dualgenerator system, which switchedto a smaller generator when lesscapacity was required, considerablyreducing the diesel required.

Health and SafetyThe tight schedule and with morethan 300 personnel (including 36from Sarens) from 32 differentcontractors on site and over 10,000man hours worked, meant that therisk of accidents was high,however none were recorded.

£500,000 savingsThe scheme was completed aheadof schedule within the critical, highrisk 74 hour main possession withno delays to passenger services.

Value engineering throughout thecontract ensured client costsavings of £500,000, thanks tothe road material recycling,generators, steel procurement,pre-casting concrete on site andusing multi-skilled resources toundertake the work directlyrather than using subcontractors.

One of the two bridgereplacement sites

October 2010 cranes & access 25

Halving accidentsovernight

outr iggersc&a

If only all crane and aerial lift userswould ensure that they fullyunderstood the need to a) extendoutriggers properly and b) to spreadthe outrigger load over as wide anarea as possible, we would cutaccidents in half overnight.

The puzzling fact is that in spite ofthe clear evidence that some simpleset up rules will prevent mostoutrigger related accidents, theirfrequency shows no sign of lettingup. To get the average person onthe street to understand a couple ofbasic rules would take about 10minutes and would stop at least 75percent of all outrigger accidents.These are:

When it comes to general craneand lift work rather than overheadutility work, poor outrigger set-upis by far and away the biggestkiller.

While that is not the end of thestory, this highly simplisticapproach alone would prevent themajority of accidents. Over the pastfour years we have been senthundreds of accident photographs,a large number of them clearlycaused by ground failure andoutrigger set up. In the vastmajority of cases either no outriggermats of any size were used, or theoutriggers were not fully extendedor not even deployed.

Moving on from thebasic rulesIt is said that you can’t make anymachine ‘idiot proof’ and that is anirrefutable fact of life. However itought to be possible to teach an idiotthe two rules above in no time at all.

The next simple message thatwould pick up a further few percentor so of accidents is: “Avoid settingup near to a bank, just as youwould not park your car on the veryedge of a cliff.” Putting a load ontosomething that regularly crumblesinto the sea or a river makes nosense at all.

Finally for the more complexset-ups such as where limitedspace requires a machine to usepartial outrigger set up, if theoperator is not totally familiar withthe machine’s load charts and ratedload indicator programmes, heshould not be in the cab in thefirst place. But for the sake of oursimplistic exercise – you couldforbid such an operator from partialoutrigger set-ups and send a moreskilled individual to such jobs.

The point of the above exercise isnot to provide a real life set ofoperators’ instructions, but simplyto illustrate how it should bepossible to slash the risk ofoverturning accidents caused bypoor outrigger set-up.

So why do we still haveso many outrigger/ground related tip overs?So if it is simple to train operatorsin the very basics of properoutrigger set-up, why do we stillhave so many accidents?

Automatic safetyWhile it should be relativelystraightforward to set the machinesoutriggers correctly and to

remember to use decent mats, oneaspect of the process looks likebecoming entirely automated. An

increasing number of aerial liftsand cranes are now being fittedwith automatic progressivesensors on the outrigger beamsand pressure sensors onthe outrigger jacks.

This ties in well with theincreasingly versatile butmore complicated load chartsfor cranes and lifts that allowmultiple outrigger positions,including asymmetric settings.The provision of full outriggersensing and automatic load chartselection seems like a good ideaand could be a definitive aid tosafety. For aerial lifts anincreasing number of machineswill limit or extend the outreachdepending on the size of theoutrigger base and the weight inthe platform, something that isunquestionably advantageousand simple to use.

Load sensing specialist Mobais planning to introduce a newultrasonic outrigger beamposition sensor that will makeit easier for manufacturers tobuild reliable position sensinginto their products. The devicesends a sound beam from thebox endto the beam end of theoutrigger assembly. The benefitis that nothing but a total sealedblockage of the inside of thebox and beam will disrupt thesignal, allowing the device to befitted to existing machineswithout fear of disruptionfrom internal hoses etc.

It is a plain and simple fact that the majority of crane andaerial lift accidents are caused by a few common errors.The two greatest causes are contact with overhead powerlines and incorrect outrigger set-up/ground failure.

• Always put the mats suppliedunder the outrigger pads

• Always extend the machine’soutriggers to their full widthand ensure all of them areloaded (the mats will notmove if they are loaded!)

• Laziness/bone idleness - call itwhat you will, all too often theoperator figures that the groundis firm enough so thinks ‘I can’tbe bothered to lug those matsdown from the deck or fromtheir storage brackets.’ Whenhis crane has overturnedcausing hundreds of thousandsof pounds of damage or worsestill people are seriously injuredor dead – he will wish that hehad bothered to use them!

• Total ignorance of the need forthem, usually coupled with anabsence of any on the machine.In such cases it generallyreflects back on the owner oremployer a) in not training theoperator properly and b) in notbothering to ensure that matswere provided.

Accidents relating to poor outriggerset up show no sign of slowing up

In this accident a two shift scenario caught the operator unaware that hisrear outriggers had been left in the retracted position

If operators would only use the mats provided, regardless of groundconditions tipping accidents would be significantly reduced

Two main reasons:

26 cranes & access October 2010

Taking control awayThere will be those who argue thatsuch devices take yet more controlaway from the operator. This is thesame debate that we saw in NorthAmerica over the implementationof Load Moment Indicators in the1980’s and 1990’s. The fact is thatoperators need to be aware of andfully understand the need forcorrect outrigger set up. Andanyway these automatic deviceswill only solve half of the problem -they will not detect the presenceof a decent outrigger mat undereach jack pad. However oncewidely fitted they should put a stopto the idiots who don’t extend theoutriggers at all or forget that theyhave not extended the beamsbehind them when they do anunplanned slew in that direction.Perversely the greatest dangermight come when the majorityof cranes and lifts are so equipped,causing accidents with thosethat are not?

So the need to hammer homethe importance of outriggers willremain as important as ever.

Good mats well placedOne of the best things a crane ortruck mounted lift owner can dois to purchase a decent set ofoutrigger mats suited to the size ofthe crane or lift. For cranes of 80tonnes and less and all but the very

Here is an excellent set up with the mats stored close to the outriggers,with a ramp to help load and unload them. Behind is a neat storagelocker for cribbing timbers

o u t r i g g e r s c&a

largest truck mounted lifts a set ofhigh quality polythene/nylon orproper wood mats with a diameterof around 600mm/2ft will covermost eventualities with 300mm forthe smaller truck mounts and trailerlifts and 800 to 900mm mats forlarger units or for mid-sizedmachines on very soft ground.

Once the mats have been sourcedthey need to be stored on themachine and if they are to be usedregularly the storage points need tobe well placed and designed toallow the pads to be removed andreplaced easily. This is particularlytrue of the larger ones. With manuallifting regulations restricting theweights that a single person shouldlift, the larger mats will benefit froma design that makes it easier to rollthem out of their storage pockets.

CribbingOn all but the smallest cranes andlifts, a few decent timbers used forcribbing can compensate for slopesor depressions or further spread theload by placing them under theregular mats. Once again goodstorage for these will ensure theyare ready to hand and looked after.In the UK the Health & SafetyExecutive will stop a crane or lift ifthey see old split scraps of woodbeing used in place of mats or propercribbing so not dealing with thisissue can be costly on many levels.

Cribbing like this is highly dangerous

This crane was well set-upin terms of mats, but theengineered aggregateplatform - located near astream - was compromisedby heavy overnight rains andcollapsed when the weightwent over the outriggersclosest to the edge.

Working on built-up platforms

This mat actually clips on to the machines outrigger pad

This neat little mat is used withvan mount stabilisers ratherthan outriggers

While the use of wood squaresis frowned up in some circles,it is far better than nothing andis a practical solution for liftsthat simply require stabilising,or for firm ground.

www.timbermat.co.uk

LIMITEDTIMBERMAT

Even in extreme tidal conditions our heavy dutymats provide a strong stable base.

emtek mats providing a stable baseallowing a 160t lift to be completed safely

Our Heavy duty platformprotection mats.

Heavy duty crane access mats

T: +44 (0) 161 476 6252 F: +44 (0)161 476 6253 UK Local low call: 0844 800 9560

emtek mat designed specifically for Nasa toenable the installation of the new WebbSpace Telescope, which is replacing theHubble Telescope.

emtek mats manufactured to fit into aspecifically designed steel frame

Portable Access & Temporary Protection Solutions

Emtek Engineered Access Mats

• Extensive stock comprising of various sizes to tackle any job.

• Nationwide design, delivery and Installation service.

• In house manufacturing to customer specifications.

• Marine Hardwood, Oak and Softwood avaliable.

• Excellent rates for hire or purchase.

• Network Rail & National Grid approved product.

• Timbermat are proud to announce the launch of the emtek mat.

• The worlds first engineered matting system.

• Designed specifically for the Crane industry.

• The only mat on the market with tested and certified load calculations.

• Can be designed and built to specific site requirements.

• New laminating technology enables higher load carrying capacities.

• Superior in strength to standard mats twice its depth and weight.

• Reduces mat transportation by up to 50%.

• On site expert advice and design.

October 2010 cranes & access 29

Assessingmobile cranehardstands

outr iggersc&a

Having previously worked for a company which suffered mobilecrane overturns caused by groundfailure – I witnessed the aftermathand was also involved in one of theinvestigations, which left quite animpression on me. Fortunately,none of them resulted in injuries,due to good luck rather than goodplanning. Whilst I did not plan any of the failed lifts these experiencesplanted the serious seeds of concern which led to me to team up with Chris Massey of BFL todevelop the Alimats system fiveyears ago.

I find the topic of ground consideration fascinating, thanks tothe variety of differing opinions onthe subject. When asked about thesuitability of our three square metremat area for a particular lift, it canbe difficult to respond whenprospective clients use such variedmethods of calculating the proposedmat area.

We have noted a marked increase in demand for our mats in recentmonths, some of which is undoubtedly down to increasedengineering input into ground load

After fifteen years of workingwith mobile cranes, It still surprises me how fragmented we are as an industry regardingground assessment and outriggerloadings.

bearing assessments. Safety factorsare increasingly being applied by thespecialist engineers as an integralpart of their ground bearing capacityconsiderations. Some AP’s notfamiliar with obtaining such detailedinformation are also unwittinglyapplying their own additional safetyfactors. This has resulted in someeyebrow-raising, huge mat requirements for relatively smallmobile cranes, which threatens toundermine the current trend ofimproving standards regarding hardstand assessments and information provision from clients.

Contractors and AP’s alike - reflecting on the clearly excessiveconclusions of some of these ‘calculations’ – are questioning themerit of ‘doing it properly’. We needto question the methodology ratherthan the need to obtain solid engineering input for a crane’s hardstanding, which we should allencourage.

Inconsistent outriggerload calculation –an old concernTemporary works engineers areoften frustrated at the apparentinconsistency of outrigger load

information provided by AP’s. For anear identical lift using the samecrane, it is not unusual for the engineer to be given an outriggerloading of say 20 tonnes by one APand 50 tonnes by another. The problem stems from the differentmethods of calculation used.Guidance regarding the various calculation methods remainssparse, leaving many AP’s to followwhat they were taught during theirtraining.

drastically different – in somecases more than double. This isbecause actual predicted outriggerloads do not automatically includean additional safety margin (recommended for all lifts), whereas the other methods do,albeit not a defined factor.

Whilst many AP training coursesadvocate the 75 or 100 percentmethods, it is clear that the actualloadings will be considerably less.The perceived wisdom behind thisapproach is that planning for theabsolute worst case scenario willguarantee a satisfactory conclusion. However when a specific load bearing capacity isprovided by an engineer, it normallyalready includes a significant factorof safety. When this is combinedwith worst case outrigger loadings,the resulting mat requirement canbe unnecessarily large, impracticaland uneconomic. So where a specialist engineer has calculatedthe loadings with a safety factor,the AP would do well to work withactual predicted outrigger loadings. This will result in a sensible,economic and safe specification ofoutrigger mat sizes.

Hardstand consideration and outrigger load spreadcontinues to be a subject of protracted debate.Mike Allanson, operations manager for BFLAlimats and an Appointed Person (AP) for morethan 15 years offers an interesting perspective.

Mike Allanson

The three most commonmethods are:

•Actual predicted outriggerloadings from cranemanufacturer’s charts andsoftware (e.g. Liebherr’s LICCON system, Cranimax /Cranimation, etc).

•75% of the gross weight of thecrane plus the weight of the load, applied through a single outrigger

•100% of the gross weight of the crane plus the weight of the load, applied through a single outrigger

In this example it is clear that the AP hasworked closely with the contractors engineers

All three have their own rationale andmerit, but the end results are

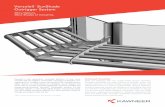

The standard 3m² Alimats outrigger mat system