O !#$%&'()*+,-#. $/ $0&&*)')#. $1(,.#$)* $ OSHA1910 · OSHA 1910.179 Overhead and Gantry Cranes...

Transcript of O !#$%&'()*+,-#. $/ $0&&*)')#. $1(,.#$)* $ OSHA1910 · OSHA 1910.179 Overhead and Gantry Cranes...

TheUnauthorized&AnnotatedGuideto

OverheadandGantryCranes

By

OverheadCraneConsulting,LLCOverheadCraneConsulting.com

(574)210-8612

Comment [LD1]: IMPORTANTNOTICE:OSHAinterpretationsaretheresponsibilityofthecraneownerandnotthatofD.LarryDunville,OverheadCraneConsulting,LLC.orothercontributors.

ThisdocumentislicensedundertheCreativeCommonsAttribution4.0InternationalLicense.

OSHA 1910.179

Licensed Under Creative Commons Attribution 4.0

Figure1-MasterImage

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 2 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a):DefinitionsApplicabletoThisSection1910.179(a)(1)A"crane"isamachineforliftingandloweringaloadandmovingithorizontally,withthehoistingmechanismanintegralpartofthemachine.Craneswhetherfixedormobilearedrivenmanuallyorbypower.1910.179(a)(2)An"automaticcrane"isacranewhichwhenactivatedoperatesthroughapresetcycleorcycles.1910.179(a)(3)A"cab-operatedcrane"isacranecontrolledbyanoperatorinacablocatedonthebridgeortrolley.

Figure2:OverheadCrane

Figure3:CabOperatedOverheadCrane

Comment [LD3]: Thetermscraneandhoistareoftenusedinterchangeablyandthat’sincorrect.Acraneisthestructurethatholdsthehoist.Thecranemoveslaterally(north/southandeast/west)whilethehoistdoesthelifting(up/down)motions.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 3 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

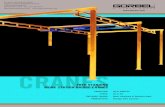

1910.179(a)(4)"Cantilevergantrycrane"meansagantryorsemigantrycraneinwhichthebridgegirdersortrussesextendtransverselybeyondthecranerunwayononeorbothsides.1910.179(a)(5)"Floor-operatedcrane"meansacranewhichispendantornonconductiveropecontrolledbyanoperatoronthefloororanindependentplatform.1910.179(a)(6)"Gantrycrane"meansacranesimilartoanoverheadcraneexceptthatthebridgeforcarryingthetrolleyortrolleysisrigidlysupportedontwoormorelegsrunningonfixedrailsorotherrunway.

Figure4:CantileverGantryCrane

Figure5:GantryCrane

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 4 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(7)"Hotmetalhandlingcrane"meansanoverheadcraneusedfortransportingorpouringmoltenmaterial.1910.179(a)(8)"Overheadcrane"meansacranewithamovablebridgecarryingamovableorfixedhoistingmechanismandtravelingonanoverheadfixedrunwaystructure.1910.179(a)(9)"Power-operatedcrane"meansacranewhosemechanismisdrivenbyelectric,air,hydraulic,orinternalcombustionmeans.1910.179(a)(10)A"pulpit-operatedcrane"isacraneoperatedfromafixedoperatorstationnotattachedtothecrane.1910.179(a)(11)A"remote-operatedcrane"isacranecontrolledbyanoperatornotinapulpitorinthecabattachedtothecrane,byanymethodotherthanpendantorropecontrol.1910.179(a)(12)A"semigantrycrane"isagantrycranewithoneendofthebridgerigidlysupportedononeormorelegsthatrunonafixedrailorrunway,theotherendofthebridgebeingsupportedbyatruckrunningonanelevatedrailorrunway.

Figure6:SemigantryCrane

Comment [LD4]: Thecriticalwordhereis“molten”whichreallymeansthehotmaterialhasreacheda“pouring”state.Simplyhandling“hotmaterial”doesNOTrequiremeetingallthespecificneedsofa“hot-metalhandlingcrane.”Heatshieldingofthehoistand/orlowerblockmaybeadequatefora“hot”butnot“Hotmetalhandling”craneTrue“hot-metalhandlingcranesarefarmoreexpensive,thereforebecarefulinusingthisterm.Yes,the“powersthatbe”havechosenaconfusinglyvaguetermhere,butit’sbeenthiswayfor30+years,sowe’reprobablygoingtohavetolivewithit.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 5 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(13)"Storagebridgecrane"meansagantrytypecraneoflongspanusuallyusedforbulkstorageofmaterial;thebridgegirdersortrussesarerigidlyornonrigidlysupportedononeormorelegs.Itmayhaveoneormorefixedorhingedcantileverends.1910.179(a)(14)"Wallcrane"meansacranehavingajibwithorwithouttrolleyandsupportedfromasidewallorlineofcolumnsofabuilding.Itisatravelingtypeandoperatesonarunwayattachedtothesidewallorcolumns.1910.179(a)(15)"Appointed"meansassignedspecificresponsibilitiesbytheemployerortheemployer'srepresentative.1910.179(a)(16)"ANSI"meanstheAmericanNationalStandardsInstitute.1910.179(a)(17)An"auxiliaryhoist"isasupplementalhoistingunitoflightercapacityandusuallyhigherspeedthanprovidedforthemainhoist.1910.179(a)(18)A"brake"isadeviceusedforretardingorstoppingmotionbyfrictionorpowermeans.1910.179(a)(19)A"dragbrake"isabrakewhichprovidesretardingforcewithoutexternalcontrol.1910.179(a)(20)A"holdingbrake"isabrakethatautomaticallypreventsmotionwhenpowerisoff.

Figure7:WallCrane

Comment [LD5]: Theisoneofthosewordswithspecial“OSHA”meaning.Wheneveryouseethisword,paycloseattention.Thisisamanagementdesignatedpositionandshouldberecordedsomewhereinyourcranesafetypapertrail.

Comment [LD6]: MuchofOSHAiscomprisedof“incorporationbyreference”oftheANSI(AmericanNationalStandardsInstitute)specifications.Beware,wheninterpretingOSHA.Forexample,thecranesection1910.179wastaken,toagreatextent,fromtheANSI/ASMEB30.2.OSHA1910.179isonly11pagesbutB30.2isabout50pages.Manywell-meaningcraneownersthinktheyare“freeandclear”havingmettherequirementsofthe11pagesofOSHA,butinfact,becauseof“incorporationbyreference”theyarealsosubjecttoB30.2!Note,B30.2issometimesreferencedasASNIB30.2andASMEB30.2andevenANSI/ASMEB30.2.Don’tworry,they’reallthesameandthecurrenteditionoftheprinteddocumentisactuallywrittenupasANSI/ASMEB30.2.

Comment [LD7]: Thisisanotheroneofthosespecial“OSHA”words.Thereareseveralspecifictypesofbrakes.TheproperinterpretationofOSHAandotherspecificationsrequiresthemorespecifictermsuchas“dragbrake”or“holdingbrake”etc(seefollowingdefinitions).Inotherwords,usingtheterm“brake”withoutoutamodifiersuchas“dragbrake”justmuddlestheconversationandmayleadtoanincorrectinterpretationoftheregulations.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 6 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(21)"Bridge"meansthatpartofacraneconsistingofgirders,trucks,endties,footwalks,anddrivemechanismwhichcarriesthetrolleyortrolleys.1910.179(a)(22)"Bridgetravel"meansthecranemovementinadirectionparalleltothecranerunway.1910.179(a)(23)A"bumper"[buffer]isanenergyabsorbingdeviceforreducingimpactwhenamovingcraneortrolleyreachestheendofitspermittedtravel;orwhentwomovingcranesortrolleyscomeincontact.

Figure9:RubberBumpers

Figure8:Bridge(yellowmemberslessendtrucks)

Comment [LD8]: The“bridge”isthestructuralsteelpartofthecrane.Oftenreferredtoasa“bridgecrane.”

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 7 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(24)The"cab"istheoperator'scompartmentonacrane.

Figure10:CabOperatedCrane

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 8 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(25)"Clearance"meansthedistancefromanypartofthecranetoapointofthenearestobstruction.

Figure11:CriticalDimensions

Comment [LD9]: Theterm“clearance”isagenerictermandthereforeoftencausesmoreconfusionthanclarification.Makesuretobespecificastothetype“clearance”you’rereferringtosuchas“clearanceabovethehoist”or“clearancetobottomofbridgegirder”,etc.Thisdrawingmayseemneedlesslyconfusingandonlyafewofthedimensionsarerelevanttoanyoneapplication.Theproblemisthatit’sadifferenttwoorthreecriticaldimensionsforeveryapplication.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 9 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(26)"Collectorscurrent"arecontactingdevicesforcollectingcurrentfromrunwayorbridgeconductors.1910.179(a)(27)"Conductors,bridge"aretheelectricalconductorslocatedalongthebridgestructureofacranetoprovidepowertothetrolley.1910.179(a)(28)"Conductors,runway"[main]aretheelectricalconductorslocatedalongacranerunwaytoprovidepowertothecrane.

Figure12:Collectors

Figure13:BridgeConductor

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 10 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(29)The"controlbrakingmeans"isamethodofcontrollingcranemotorspeedwheninanoverhaulingcondition.1910.179(a)(30)"Countertorque"meansamethodofcontrolbywhichthepowertothemotorisreversedtodeveloptorqueintheoppositedirection.1910.179(a)(31)"Dynamic"meansamethodofcontrollingcranemotorspeedswhenintheoverhaulingconditiontoprovidearetardingforce.1910.179(a)(32)"Regenerative"meansaformofdynamicbrakinginwhichtheelectricalenergygeneratedisfedbackintothepowersystem.1910.179(a)(33)1910.179(a)(33)"Mechanical"meansamethodofcontrolbyfriction.1910.179(a)(34)"Controller,springreturn"meansacontrollerwhichwhenreleasedwillreturnautomaticallytoaneutralposition.1910.179(a)(35)"Designated"meansselectedorassignedbytheemployerortheemployer'srepresentativeasbeingqualifiedtoperformspecificduties.1910.179(a)(36)A"driftpoint"meansapointonatravelmotioncontrollerwhichreleasesthebrakewhilethemotorisnotenergized.Thisallowsforcoastingbeforethebrakeisset.

Comment [LD10]: Thisisanotherofthe“OSHA”wordswithveryspecificmeaning.Wheneveryouseeeither“appointed”or“designated”makesuretounderstandthenuancedmeaningofthesentenceinwhichitisused.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 11 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(37)The"drum"isthecylindricalmemberaroundwhichtheropesarewoundforraisingorloweringtheload.1910.179(a)(38)An"equalizer"isadevicewhichcompensatesforunequallengthorstretchofarope.1910.179(a)(39)"Exposed"meanscapableofbeingcontactedinadvertently.Appliedtohazardousobjectsnotadequatelyguardedorisolated.1910.179(a)(40)"Fail-safe"meansaprovisiondesignedtoautomaticallystoporsafelycontrolanymotioninwhichamalfunctionoccurs.1910.179(a)(41)"Footwalk"meansthewalkwaywithhandrail,attachedtothebridgeortrolleyforaccesspurposes.1910.179(a)(42)A"hoist"isanapparatuswhichmaybeapartofacrane,exertingaforceforliftingorlowering.1910.179(a)(43)"Hoistchain"meanstheloadbearingchaininahoist.NOTE:ChainpropertiesdonotconformtothoseshowninANSIB30.9-1971,SafetyCodeforSlings.1910.179(a)(44)"Hoistmotion"meansthatmotionofacranewhichraisesandlowersaload.

Figure14:HoistDrum(unpaintedportion)

Figure15:IntegratedTrolleyonHoist

Comment [LD11]: Themechanicaldevicethatdoesthehoisting/liftingmotionsasopposedtothecranethatperformsthelateralmotions.Afrequentpointofconfusionisthatsomehoistshaveintegrated“trolleys.”TheTrolleysprovidehorizontaltravelalongthebridgebeam.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 12 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(45)"Load"meansthetotalsuperimposedweightontheloadblockorhook.1910.179(a)(46)The"loadblock"istheassemblyofhookorshackle,swivel,bearing,sheaves,pins,andframesuspendedbythehoistingrope.1910.179(a)(47)"Magnet"meansanelectromagneticdevicecarriedonacranehooktopickuploadsmagnetically.1910.179(a)(48)"Mainhoist"meansthehoistmechanismprovidedforliftingthemaximumratedload.1910.179(a)(49)A"mantrolley"isatrolleyhavinganoperator'scabattachedthereto.1910.179(a)(50)"Ratedload"meansthemaximumloadforwhichacraneorindividualhoistisdesignedandbuiltbythemanufacturerandshownontheequipmentnameplate(s).

Figure16:LoadBlock

Figure17:CraneMagnet

Comment [LD12]: The“RatedLoad”isacriticaltermwithaspecificengineeringconnotation.It’stheloadcapacitythecranewasdesignedtoliftandhasbeenloadtestedtoperform.Theterm“RatedCapacity”hasbeenusedintheOSHAerainplaceofsimplyusingtheterm“Capacity.”

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 13 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(51)"Rope"referstowirerope,unlessotherwisespecified.1910.179(a)(52)"Runningsheave"meansasheavewhichrotatesastheloadblockisraisedorlowered.1910.179(a)(53)"Runway"meansanassemblyofrails,beams,girders,brackets,andframeworkonwhichthecraneortrolleytravels.1910.179(a)(54)"Sidepull"meansthatportionofthehoistpullactinghorizontallywhenthehoistlinesarenotoperatedvertically.

Figure18:CraneRunway(excludingyellowbridge)

Figure19:SidePull

Comment [LD13]: Runwayisthetracksystemuponwhichthecranetravels.Therunwayisoftensuppliedbyadifferentvendorfromthecranesupplier.

Comment [LD14]: Sidepullisacriticalterminthecraneworld.It’stheactionofnotliftingwiththeropeperpendiculartothefloor.Sidepullingimposesaloadonthecraneitwasnotdesignedtohandle.AtworstSidepullingcanresultinstructuralfailureandatbestitresultsinrapidwireropewear.Instructionswarningagainstsidepullingaretobedisplayedoneveryhoistinplainsightoftheoperator.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 14 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(55)1910.179(a)(55)"Span"meansthehorizontaldistancecentertocenterofrunwayrails.1910.179(a)(56)1910.179(a)(56)"Standbycrane"meansacranewhichisnotinregularservicebutwhichisusedoccasionallyorintermittentlyasrequired.

Figure20:CraneSpan

Comment [LD15]: Cranespanisthewidthofthecrane.Thespantoend-truckwheelbaseratioistobe7:1fordoublegirdercranesperCMAASpec70and8:1forsinglegirdercranesperCMAASpec74.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 15 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(57)A"stop"isadevicetolimittravelofatrolleyorcranebridge.Thisdevicenormallyisattachedtoafixedstructureandnormallydoesnothaveenergyabsorbingability.1910.179(a)(58)A"switch"isadeviceformaking,breaking,orforchangingtheconnectionsinanelectriccircuit.1910.179(a)(59)An"emergencystopswitch"isamanuallyorautomaticallyoperatedelectricswitchtocutoffelectricpowerindependentlyoftheregularoperatingcontrols.1910.179(a)(60)A"limitswitch"isaswitchwhichisoperatedbysomepartormotionofapower-drivenmachineorequipmenttoaltertheelectriccircuitassociatedwiththemachineorequipment.1910.179(a)(61)A"mainswitch"isaswitchcontrollingtheentirepowersupplytothecrane.1910.179(a)(62)A"masterswitch"isaswitchwhichdominatestheoperationofcontactors,relays,orotherremotelyoperateddevices.

Figure21:RailStop

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 16 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(63)The"trolley"istheunitwhichtravelsonthebridgerailsandcarriesthehoistingmechanism.1910.179(a)(64)"Trolleytravel"meansthetrolleymovementatrightanglestothecranerunway.

Figure22:IntegratedTrolleywithHoist

Figure23:Trolley-travelmotion

Comment [LD16]: Thetrolleyisattachedtothehoistandprovideshorizontalmotion.Thetrolleyisoftenanintegralpartofthehoist,butinrealityaseparatecomponentwithpotentiallyradicallydifferentdutycycledemands.

Comment [LD17]: Conceptuallythetrolleymotionmayprovidesomeconfusioninthatit’samechanicalcomponentofthehoist,butprovideshorizontalmotion.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 17 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(a)(65)"Truck"meanstheunitconsistingofaframe,wheels,bearings,andaxleswhichsupportsthebridgegirdersortrolleys.

Figure24:TopRunningTrolleyFigure25:UnderRunningTrolley

Comment [LD18]: UsuallyreferredtoasanEnd-truck

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 18 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(b):GeneralRequirements1910.179(b)(1)Application.Thissectionappliestooverheadandgantrycranes,includingsemigantry,cantilevergantry,wallcranes,storagebridgecranes,andothershavingthesamefundamentalcharacteristics.Thesecranesaregroupedbecausetheyallhavetrolleysandsimilartravelcharacteristics.1910.179(b)(2)Newandexistingequipment.AllnewoverheadandgantrycranesconstructedandinstalledonorafterAugust31,1971,shallmeetthedesignspecificationsoftheAmericanNationalStandardSafetyCodeforOverheadandGantryCranes,ANSIB30.2.0-1967,whichisincorporatedbyreferenceasspecifiedinSec.1910.6.1910.179(b)(3)Modifications.Cranesmaybemodifiedandreratedprovidedsuchmodificationsandthesupportingstructurearecheckedthoroughlyforthenewratedloadbyaqualifiedengineerortheequipmentmanufacturer.Thecraneshallbetestedinaccordancewithparagraph(k)(2)ofthissection.Newratedloadshallbedisplayedinaccordancewithsubparagraph(5)ofthisparagraph.1910.179(b)(4)Windindicatorsandrailclamps.Outdoorstoragebridgesshallbeprovidedwithautomaticrailclamps.Awind-indicatingdeviceshallbeprovidedwhichwillgiveavisibleoraudiblealarmtothebridgeoperatoratapredeterminedwindvelocity.Iftheclampsactontherailheads,anybeadsorweldflashontherailheadsshallbegroundoff.

Comment [LD19]: Thisisanimportantparagraph.ThisiswhereOSHAextendsitscoveragetoothertypesofcraneswiththephrase,“…andothershavingthesamefundamentalcharacteristics.”It’smyinterpretationthisparagraphextendscoveragetojibcranes,travelingjibcranes,work-stationcranesetc.

Comment [LD20]: “Shall”meansitisrequired,asopposedtotheotherterm“Should”whichmeanssuggestedoradvisedbutnotlegallymandated.

Comment [LD21]: MuchofOSHA1910.179wastakendirectlyfromANSIB30.2andbecauseit’s“incorporatedbyreference”100%ofANSI/ASMEB30.2hasthelegalforceofOSHA1919.179.IOW,you’reflyingblindifyoudon’tpurchaseacopyofANSI/ASMEB30.2.It’savailablefromanumberofsources.Just“Google”B30.2andyou’llseeanumberofvendors.It’savailableinbothprintandPDFformatanditcosts$60.

Comment [LD22]: “IncorporatebyReference”Thesearecriticalwordsthatmeanthatthosespecificationsthatare“incorporatedbyreference”havethesameweightoflawastheOSHAspecitself!

Comment [LD23]: Onceacraneismodified,itmustbere-qualifiedasifitwereanewcrane.IOW,afullinspectionandloadtest.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 19 of 54

www.OverheadCraneConsulting.com [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(b)(5)Ratedloadmarking.Theratedloadofthecraneshallbeplainlymarkedoneachsideofthecrane,andifthecranehasmorethanonehoistingunit,eachhoistshallhaveitsratedloadmarkedonitoritsloadblockandthismarkingshallbeclearlylegiblefromthegroundorfloor.1910.179(b)(6)Clearancefromobstruction.

Comment [LD24]: The“RatedCapacity”mustbeplainlymarkedonthecrane.Thisisoneofthemostelementarychecks,evenbythe“newbie”OSHAinspector.

Comment [LD25]: Craneswithdualhoistcanprovideapointofconfusion.Ihavehadclientsthatneededa10toncranewith(2)10tonhoists.Someliftsrequiredasinglehookcapableofafull10tonswhileotherliftsrequiredtwohooks,eachcapableof5tons.Inthiscaseitismysuggestiontogetaloadlimitingsystemthatiscall“loadsumming”whichpreventstheaggregatetotalbeingliftednottoexceedthecapacityofthebridgecrane.ThisisnotanOSHArequirementbutadvisable.

Comment [LD26]: Theclearancesreferredtoherearethevertical/overheadcranetobuildingclearanceandthehorizontal/lateralclearanceofcranetostationarybuildingcomponent.CRITICALNOTE,buildingssettleandfootings,columnsandtrussesthereforemove.IwouldneverusetheminimumdimensionsunlessIhadaguntomyhead.Mysuggestionistouse6inchesverticaland4incheshorizontal.Atminimum,atleastgiveyourselfanadditionalinch.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 20 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(b)(6)(i)Minimumclearanceof3inchesoverheadand2incheslaterallyshallbeprovidedandmaintainedbetweencraneandobstructionsinconformitywithCraneManufacturersAssociationofAmerica,Inc,SpecificationNo.61,whichisincorporatedbyreferenceasspecifiedinSec.1910.6,(formerlytheElectricOverheadCraneInstitute,Inc).1910.179(b)(6)(ii)Wherepassagewaysorwalkwaysareprovidedobstructionsshallnotbeplacedsothatsafetyofpersonnelwillbejeopardizedbymovementsofthecrane.1910.179(b)(7)Clearancebetweenparallelcranes.Iftherunwaysoftwocranesareparallel,andtherearenointerveningwallsorstructure,thereshallbeadequateclearanceprovidedandmaintainedbetweenthetwobridges.1910.179(b)(8)Designatedpersonnel–Onlydesignatedpersonnelshallbepermittedtooperateacranecoveredbythissection.

Comment [LD27]: Minimumof3inches’verticalclearanceisamandatedrequirement.Seeabovewarning.

Comment [LD28]: Minimumof2incheslateralclearanceismandated.Seeabovewarning.

Comment [LD29]: Noteanother“incorporatedbyreference”.ThisspecificationwaswrittenbytheprecursortotheCMAA(EOCI,ElectricOverheadCraneInstitute)in1961.OSHA1910.6actuallyreferencesthemoremodernCMAASpec70.

Comment [LD30]: ImportantNote:Only“designatedpersonnelarepermittedtooperateacrane.Tomethisbegsthequestion,whoisdesignatedandhowisapersondesignated?Becausenothingisstated,myadviceistohavean“in-house”writtenpolicyandmakesureyouconformtoyourpolicyasevidencedbyapapertrail.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 21 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(c):Cabs1910.179(c)(1)Cablocation.1910.179(c)(1)(i)Thegeneralarrangementofthecabandthelocationofcontrolandprotectiveequipmentshallbesuchthatalloperatinghandlesarewithinconvenientreachoftheoperatorwhenfacingtheareatobeservedbytheloadhook,orwhilefacingthedirectionoftravelofthecab.Thearrangementshallallowtheoperatorafullviewoftheloadhookinallpositions.1910.179(c)(1)(ii)Thecabshallbelocatedtoaffordaminimumof3inchesclearancefromallfixedstructureswithinitsareaofpossiblemovement.1910.179(c)(2)Accesstocrane.Accesstothecaband/orbridgewalkwayshallbebyaconvenientlyplacedfixedladder,stairs,orplatformrequiringnostepoveranygapexceeding12inches.FixedladdersshallbeinconformancewiththeAmericanNationalStandardSafetyCodeforFixedLadders,ANSIA14.3-1956,whichisincorporatedbyreferenceasspecifiedinSec.1910.6.1910.179(c)(3)Fireextinguisher.Carbontetrachlorideextinguishersshallnotbeused.1910.179(c)(4)Lighting.Lightinthecabshallbesufficienttoenabletheoperatortoseeclearlyenoughtoperformhiswork.

Comment [LD31]: Another“incorporationbyreference.”It’savailablefromanumberofsources.Just“Google”A14.3andyou’llseeanumberofvendors.It’savailableinbothprintandPDFformat(notafreespec).

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 22 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(d):FootwalksandLadders1910.179(d)(1)Locationoffootwalks.1910.179(d)(1)(i)Ifsufficientheadroomisavailableoncab-operatedcranes,afootwalkshallbeprovidedonthedrivesidealongtheentirelengthofthebridgeofallcraneshavingthetrolleyrunningonthetopofthegirders.1910.179(d)(1)(ii)Wherefootwalksarelocatedinnocaseshalllessthan48inchesofheadroombeprovided.1910.179(d)(2)Constructionoffootwalks.1910.179(d)(2)(i)Footwalksshallbeofrigidconstructionanddesignedtosustainadistributedloadofatleast50poundspersquarefoot.1910.179(d)(2)(ii)1910.179(d)(2)(ii)Footwalksshallhaveawalkingsurfaceofantisliptype.NOTE:Woodwillmeetthisrequirement.

1910.179(d)(2)(iii)[Reserved]1910.179(d)(2)(iv)Theinneredgeshallextendatleasttothelineoftheoutsideedgeofthelowercoverplateorflangeofthegirder.

Comment [LD32]: Thisisaquestionthatcomesupmorefrequentlythanyoumightexpect.Notetheanswerinvokestheterm“shall.”

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 23 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(d)(3)Toeboardsandhandrailsforfootwalks.Toeboardsandhandrailsshallbeincompliancewithsection1910.23ofthispart.1910.179(d)(4)Laddersandstairways.1910.179(d)(4)(i)Gantrycranesshallbeprovidedwithladdersorstairwaysextendingfromthegroundtothefootwalkorcabplatform.1910.179(d)(4)(ii)Stairwaysshallbeequippedwithrigidandsubstantialmetalhandrails.Walkingsurfacesshallbeofanantisliptype.1910.179(d)(4)(iii)Laddersshallbepermanentlyandsecurelyfastenedinplaceandshallbeconstructedincompliancewith1910.27.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 24 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(e):Stops,Bumpers,RailSweeps,andGuards1910.179(e)(1)Trolleystops.1910.179(e)(1)(i)Stopsshallbeprovidedatthelimitsoftravelofthetrolley.1910.179(e)(1)(ii)Stopsshallbefastenedtoresistforcesappliedwhencontacted.1910.179(e)(1)(iii)Astopengagingthetreadofthewheelshallbeofaheightatleastequaltotheradiusofthewheel.1910.179(e)(2)Bridgebumpers-1910.179(e)(2)(i)Acraneshallbeprovidedwithbumpersorotherautomaticmeansprovidingequivalenteffect,unlessthecranetravelsataslowrateofspeedandhasafasterdecelerationrateduetotheuseofsleevebearings,orisnotoperatedneartheendsofbridgeandtrolleytravel,orisrestrictedtoalimiteddistancebythenatureofthecraneoperationandthereisnohazardofstrikinganyobjectinthislimiteddistance,orisusedinsimilaroperatingconditions.Thebumpersshallbecapableofstoppingthecrane(notincludingtheliftedload)atanaveragerateofdecelerationnottoexceed3ft/s/swhentravelingineitherdirectionat20percentoftheratedloadspeed.1910.179(e)(2)(i)(a)Thebumpersshallhavesufficientenergyabsorbingcapacitytostopthecranewhentravelingataspeedofatleast40percentofratedloadspeed.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 25 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(e)(2)(i)(b)1910.179(e)(2)(i)(b)Thebumpershallbesomountedthatthereisnodirectshearonbolts.1910.179(e)(2)(ii)1910.179(e)(2)(ii)Bumpersshallbesodesignedandinstalledastominimizepartsfallingfromthecraneincaseofbreakage.1910.179(e)(3)Trolleybumpers-1910.179(e)(3)(i)Atrolleyshallbeprovidedwithbumpersorotherautomaticmeansofequivalenteffect,unlessthetrolleytravelsataslowrateofspeed,orisnotoperatedneartheendsofbridgeandtrolleytravel,orisrestrictedtoalimiteddistanceoftherunwayandthereisnohazardofstrikinganyobjectinthislimiteddistance,orisusedinsimilaroperatingconditions.Thebumpersshallbecapableofstoppingthetrolley(notincludingtheliftedload)atanaveragerateofdecelerationnottoexceed4.7ft/s/swhentravelingineitherdirectionatone-thirdoftheratedloadspeed.1910.179(e)(3)(ii)Whenmorethanonetrolleyisoperatedonthesamebridge,eachshallbeequippedwithbumpersorequivalentontheiradjacentends.1910.179(e)(3)(iii)Bumpersorequivalentshallbedesignedandinstalledtominimizepartsfallingfromthetrolleyincaseofage.1910.179(e)(4)Railsweeps.Bridgetrucksshallbeequippedwithsweepswhichextendbelowthetopoftherailandprojectinfrontofthetruckwheels.1910.179(e)(5)Guardsforhoistingropes.1910.179(e)(5)(i)Ifhoistingropesrunnearenoughtootherpartstomakefoulingorchafingpossible,guardsshallbeinstalledtopreventthiscondition.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 26 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(e)(5)(ii)Aguardshallbeprovidedtopreventcontactbetweenbridgeconductorsandhoistingropesiftheycouldcomeintocontact.1910.179(e)(6)Guardsformovingparts.1910.179(e)(6)(i)Exposedmovingpartssuchasgears,setscrews,projectingkeys,chains,chainsprockets,andreciprocatingcomponentswhichmightconstituteahazardundernormaloperatingconditionsshallbeguarded.1910.179(e)(6)(ii)Guardsshallbesecurelyfastened.1910.179(e)(6)(iii)Eachguardshallbecapableofsupportingwithoutpermanentdistortiontheweightofa200-poundpersonunlesstheguardislocatedwhereitisimpossibleforapersontosteponit.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 27 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(f):Brakes1910.179(f)(1)Brakesforhoists.1910.179(f)(1)(i)Eachindependenthoistingunitofacraneshallbeequippedwithatleastoneself-settingbrake,hereafterreferredtoasaholdingbrake,applieddirectlytothemotorshaftorsomepartofthegeartrain.1910.179(f)(1)(ii)Eachindependenthoistingunitofacrane,exceptworm-gearedhoists,theangleofwhosewormissuchastopreventtheloadfromacceleratingintheloweringdirectionshall,inadditiontoaholdingbrake,beequippedwithcontrolbrakingmeanstopreventoverspeeding.1910.179(f)(2)Holdingbrakes.1910.179(f)(2)(i)Holdingbrakesforhoistmotorsshallhavenotlessthanthefollowingpercentageofthefullloadhoistingtorqueatthepointwherethebrakeisapplied.1910.179(f)(2)(i)(a)125percentwhenusedwithacontrolbrakingmeansotherthanmechanical.1910.179(f)(2)(i)(b)100percentwhenusedinconjunctionwithamechanicalcontrolbrakingmeans.1910.179(f)(2)(i)(c)100percenteachiftwoholdingbrakesareprovided.

Comment [LD33]: Thisisoftenreferredtoasasecondarybrake.Notethisbrakeisnota“stopping”brake,butratherabrakethatprevents“over-speeding.”Iotherwords,itprevents“freefall”andusuallyrestrictsthelowerspeedtoequaltoorlessthantheliftingspeed.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 28 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(f)(2)(ii)Holdingbrakesonhoistsshallhaveamplethermalcapacityforthefrequencyofoperationrequiredbytheservice.1910.179(f)(2)(iii)Holdingbrakesonhoistsshallbeappliedautomaticallywhenpowerisremoved.1910.179(f)(2)(iv)Wherenecessaryholdingbrakesshallbeprovidedwithadjustmentmeanstocompensateforwear.1910.179(f)(2)(v)Thewearingsurfaceofallholding-brakedrumsordiscsshallbesmooth.1910.179(f)(2)(vi)Eachindependenthoistingunitofacranehandlinghotmetalandhavingpowercontrolbrakingmeansshallbeequippedwithatleasttwoholdingbrakes.1910.179(f)(3)Controlbrakingmeans.1910.179(f)(3)(i)Apowercontrolbrakingmeanssuchasregenerative,dynamicorcountertorquebraking,oramechanicallycontrolledbrakingmeansshallbecapableofmaintainingsafeloweringspeedsofratedloads.1910.179(f)(3)(ii)Thecontrolbrakingmeansshallhaveamplethermalcapacityforthefrequencyofoperationrequiredbyservice.1910.179(f)(4)Brakesfortrolleysandbridges.1910.179(f)(4)(i)Foot-operatedbrakesshallnotrequireanappliedforceofmorethan70poundstodevelopmanufacturer'sratedbraketorque.

Comment [LD34]: Inotherwords,holdingbrakesare“normallyon”whennotpoweredandaredisengagedwhenpowered.

Comment [LD35]: Specialbrakingrequirementof“hotmetalhandling”applications.Remember,whenyouseetheterm“hot-metalhandling,”think“pourable”andnotsimplyhightemperature.

Comment [LD36]: Thetermbrakinghereneedstobeclarified.Brakingisusuallyinterpretedasstoppingbutinthiscaseonlymeansa“controlled”slowingofthespeed.

Comment [LD37]: Inthiscase,“powercontrolledbraking”meansthatitprevents“freefall”anda“safeloweringspeed”ismandated.A“safeloweringspeed”isusuallydefinedasaspeedequaltoorlessthantheliftingspeed

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 29 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(f)(4)(ii)Brakesmaybeappliedbymechanical,electrical,pneumatic,hydraulic,orgravitymeans.1910.179(f)(4)(iii)Wherenecessarybrakesshallbeprovidedwithadjustmentmeanstocompensateforwear.1910.179(f)(4)(iv)Thewearingsurfaceofallbrakedrumsordiscsshallbesmooth.1910.179(f)(4)(v)Allfoot-brakepedalsshallbeconstructedsothattheoperator'sfootwillnoteasilyslipoffthepedal.1910.179(f)(4)(vi)Foot-operatedbrakesshallbeequippedwithautomaticmeansforpositivereleasewhenpressureisreleasedfromthepedal.1910.179(f)(4)(vii)Brakesforstoppingthemotionofthetrolleyorbridgeshallbeofsufficientsizetostopthetrolleyorbridgewithinadistanceinfeetequalto10percentoffullloadspeedinfeetperminutewhentravelingatfullspeedwithfullload.1910.179(f)(4)(viii)Ifholdingbrakesareprovidedonthebridgeortrolleys,theyshallnotprohibittheuseofadriftpointinthecontrolcircuit.1910.179(f)(4)(ix)Brakesontrolleysandbridgesshallhaveamplethermalcapacityforthefrequencyofoperationrequiredbytheservicetopreventimpairmentoffunctionsfromoverheating.1910.179(f)(5)Applicationoftrolleybrakes.1910.179(f)(5)(i)Oncab-operatedcraneswithcabontrolley,atrolleybrakeshallberequiredasspecifiedunderparagraph(f)(4)ofthissection.

Comment [LD38]: Inotherwords,,stoppingdistanceforabridgeortrolleytravelingat30fpm“shall”benogreaterthan3feet(atfullload).

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 30 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(f)(5)(ii)Adragbrakemaybeappliedtoholdthetrolleyinadesiredpositiononthebridgeandtoeliminatecreepwiththepoweroff.1910.179(f)(6)Applicationofbridgebrakes.1910.179(f)(6)(i)Oncab-operatedcraneswithcabonbridge,abridgebrakeisrequiredasspecifiedunderparagraph(f)(4)ofthissection.1910.179(f)(6)(ii)Oncab-operatedcraneswithcabontrolley,abridgebrakeoftheholdingtypeshallberequired.1910.179(f)(6)(iii)Onallfloor,remoteandpulpit-operatedcranebridgedrives,abrakeofnoncoastingmechanicaldriveshallbeprovided.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 31 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(g):ElectricEquipment1910.179(g)(1)General.1910.179(g)(1)(i)WiringandequipmentshallcomplywithsubpartSofthispart.1910.179(g)(1)(ii)Thecontrolcircuitvoltageshallnotexceed600voltsfora.c.ord.c.current.1910.179(g)(1)(iii)Thevoltageatpendantpush-buttonsshallnotexceed150voltsfora.c.and300voltsford.c.1910.179(g)(1)(iv)Wheremultipleconductorcableisusedwithasuspendedpushbuttonstation,thestationmustbesupportedinsomesatisfactorymannerthatwillprotecttheelectricalconductorsagainststrain.1910.179(g)(1)(v)Pendantcontrolboxesshallbeconstructedtopreventelectricalshockandshallbeclearlymarkedforidentificationoffunctions.1910.179(g)(2)Equipment.1910.179(g)(2)(i)Electricalequipmentshallbesolocatedorenclosedthatlivepartswillnotbeexposedtoaccidentalcontactundernormaloperatingconditions.1910.179(g)(2)(ii)Electricequipmentshallbeprotectedfromdirt,grease,oil,andmoisture.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 32 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(g)(2)(iii)Guardsforlivepartsshallbesubstantialandsolocatedthattheycannotbeaccidentlydeformedsoastomakecontactwiththeliveparts.1910.179(g)(3)Controllers.1910.179(g)(3)(i)Cranesnotequippedwithspring-returncontrollersormomentarycontactpushbuttonsshallbeprovidedwithadevicewhichwilldisconnectallmotorsfromthelineonfailureofpowerandwillnotpermitanymotortoberestarteduntilthecontrollerhandleisbroughttothe"off"position,oraresetswitchorbuttonisoperated.1910.179(g)(3)(ii)Leveroperatedcontrollersshallbeprovidedwithanotchorlatchwhichinthe"off"positionpreventsthehandlefrombeinginadvertentlymovedtothe"on"position.An"off"detentorspringreturnarrangementisacceptable.1910.179(g)(3)(iii)Thecontrolleroperatinghandleshallbelocatedwithinconvenientreachoftheoperator.1910.179(g)(3)(iv)Asfaraspracticable,themovementofeachcontrollerhandleshallbeinthesamegeneraldirectionsastheresultantmovementsoftheload.1910.179(g)(3)(v)Thecontrolforthebridgeandtrolleytravelshallbesolocatedthattheoperatorcanreadilyfacethedirectionoftravel.1910.179(g)(3)(vi)Forfloor-operatedcranes,thecontrollerorcontrollersifropeoperated,shallautomaticallyreturntothe"off"positionwhenreleasedbytheoperator.1910.179(g)(3)(vii)Pushbuttonsinpendantstationsshallreturntothe"off"positionwhenpressureisreleasedbythecraneoperator.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 33 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(g)(3)(viii)Automaticcranesshallbesodesignedthatallmotionsshallfail-safeifanymalfunctionofoperationoccurs.1910.179(g)(3)(ix)Remote-operatedcranesshallfunctionsothatifthecontrolsignalforanycranemotionbecomesineffectivethecranemotionshallstop.1910.179(g)(4)Resistors1910.179(g)(4)(i)Enclosuresforresistorsshallhaveopeningstoprovideadequateventilation,andshallbeinstalledtopreventtheaccumulationofcombustiblemattertooneartohotparts.1910.179(g)(4)(ii)Resistorunitsshallbesupportedsoastobeasfreeaspossiblefromvibration.1910.179(g)(4)(iii)Provisionshallbemadetopreventbrokenpartsormoltenmetalfallingupontheoperatororfromthecrane.1910.179(g)(5)Switches1910.179(g)(5)(i)Thepowersupplytotherunwayconductorsshallbecontrolledbyaswitchorcircuitbreakerlocatedonafixedstructure,accessiblefromthefloor,andarrangedtobelockedintheopenposition.1910.179(g)(5)(ii)Oncab-operatedcranesaswitchorcircuitbreakeroftheenclosedtype,withprovisionforlockingintheopenposition,shallbeprovidedintheleadsfromtherunwayconductors.Ameansofopeningthisswitchorcircuitbreakershallbelocatedwithineasyreachoftheoperator.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 34 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(g)(5)(iii)Onfloor-operatedcranes,aswitchorcircuitbreakeroftheenclosedtype,withprovisionforlockingintheopenposition,shallbeprovidedintheleadsfromtherunwayconductors.Thisdisconnectshallbemountedonthebridgeorfootwalkneartherunwaycollectors.Oneofthefollowingtypesoffloor-operateddisconnectsshallbeprovided:1910.179(g)(5)(iii)(a)Nonconductiveropeattachedtothemaindisconnectswitch.1910.179(g)(5)(iii)(b)Anundervoltagetripforthemaincircuitbreakeroperatedbyanemergencystopbuttoninthependantpushbuttoninthependantpushbuttonstation.1910.179(g)(5)(iii)(c)Amainlinecontactoroperatedbyaswitchorpushbuttoninthependantpushbuttonstation.1910.179(g)(5)(iv)Thehoistingmotionofallelectrictravelingcranesshallbeprovidedwithanovertravellimitswitchinthehoistingdirection.1910.179(g)(5)(v)Allcranesusingaliftingmagnetshallhaveamagnetcircuitswitchoftheenclosedtypewithprovisionforlockingintheopenposition.Meansfordischargingtheinductiveloadofthemagnetshallbeprovided.1910.179(g)(6)RunwayconductorsConductorsoftheopentypemountedonthecranerunwaybeamsoroverheadshallbesolocatedorsoguardedthatpersonsenteringorleavingthecaborcranefootwalknormallycouldnotcomeintocontactwiththem.1910.179(g)(7)ExtensionlampsIfaservicereceptacleisprovidedinthecaboronthebridgeofcab-operatedcranes,itshallbeagroundedthree-prongtypepermanentreceptacle,notexceeding300volts.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 35 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(h):HoistingEquipment1910.179(h)(1)Sheaves.1910.179(h)(1)(i)Sheavegroovesshallbesmoothandfreefromsurfacedefectswhichcouldcauseropedamage.1910.179(h)(1)(ii)Sheavescarryingropeswhichcanbemomentarilyunloadedshallbeprovidedwithclose-fittingguardsorothersuitabledevicestoguidetheropebackintothegroovewhentheloadisappliedagain.1910.179(h)(1)(iii)Thesheavesinthebottomblockshallbeequippedwithclose-fittingguardsthatwillpreventropesfrombecomingfouledwhentheblockislyingonthegroundwithropesloose.1910.179(h)(1)(iv)Pocketsandflangesofsheavesusedwithhoistchainsshallbeofsuchdimensionsthatthechaindoesnotcatchorbindduringoperation.1910.179(h)(1)(v)Allrunningsheavesshallbeequippedwithmeansforlubrication.Permanentlylubricated,sealedand/orshieldedbearingsmeetthisrequirement.1910.179(h)(2)Ropes1910.179(h)(2)(i)Inusinghoistingropes,thecranemanufacturer'srecommendationshallbefollowed.Theratedloaddividedbythenumberofpartsofropeshallnotexceed20percentofthenominalbreakingstrengthoftherope.

Comment [LD39]: Thebottomblockmusthavea“closefitting”guard.ThisisoneofthemorecommonOSHAviolations.

Comment [LD40]: See1910.179(h)(2)(viii)

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 36 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(h)(2)(ii)Socketingshallbedoneinthemannerspecifiedbythemanufactureroftheassembly.1910.179(h)(2)(iii)Ropeshallbesecuredtothedrumasfollows:1910.179(h)(2)(iii)(a)Nolessthantwowrapsofropeshallremainonthedrumwhenthehookisinitsextremelowposition.1910.179(h)(2)(iii)(b)Ropeendshallbeanchoredbyaclampsecurelyattachedtothedrum,orbyasocketarrangementapprovedbythecraneorropemanufacturer.1910.179(h)(2)(iv)Eyesplices.[Reserved]1910.179(h)(2)(v)RopeclipsattachedwithU-boltsshallhavetheU-boltsonthedeadorshortendoftherope.Spacingandnumberofalltypesofclipsshallbeinaccordancewiththeclipmanufacturer'srecommendation.Clipsshallbedrop-forgedsteelinallsizesmanufacturedcommercially.Whenanewlyinstalledropehasbeeninoperationforanhour,allnutsontheclipboltsshallberetightened.

Comment [LD41]: Thisseeminglysimplestatementcanbeapointofrealcontention.Theproblemcomeswiththedefinitionof“itsextremelowposition.”Thiscaninrealitybethreedifferentpointsfromwhichtomeasure;1.Touchingthefloor2.Touchingthefloorofapitorloadingdock3.Thelowestpointasdictatedbyagearedlowerlimitswitch(whichcouldbemanyfeetabovethegroundlevel).

SeelinkedOSHAclarification.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 37 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(h)(2)(vi)Swagedorcompressedfittingsshallbeappliedasrecommendedbytheropeorcranemanufacturer.1910.179(h)(2)(vii)Whereverexposedtotemperatures,atwhichfibercoreswouldbedamaged,ropehavinganindependentwireropeorwire-strandcore,orothertemperature-damageresistantcoreshallbeused.1910.179(h)(2)(viii)Replacementropeshallbethesamesize,grade,andconstructionastheoriginalropefurnishedbythecranemanufacturer,unlessotherwiserecommendedbyawireropemanufacturerduetoactualworkingconditionrequirements.1910.179(h)(3)Equalizers.Ifaloadissupportedbymorethanonepartofrope,thetensioninthepartsshallbeequalized.1910.179(h)(4)Hooks.Hooksshallmeetthemanufacturer'srecommendationsandshallnotbeoverloaded.

Comment [LD42]: Thiscanbeapointofrealcontention.Thehoistmanufacturesreplacementropesareoftenveryexpensiveandownersseekalocal(cheaper)supplier.Becarefultousetheexactspecifiedropeasareplacement.Ifthereshouldbeansubsequentaccident,theownerisacceptingahugeliabilityifthewrongropewasfoundtobeused.Specialattentionshouldbepaidtointerchangingdomesticsized(inches)ropewithmetricrope.Theirdesignandmanufactureareoftensignificantlydifferent.Forexample,oneGermanhoistvendorI’maquatintedwithuseda“flatten”ropelaywithaTeflonliningbetweenlays.Ifahoistownerweretouseaconventionaldomesticreplacementropeandhadanaccident,theopposinglawyerwouldhaveafieldday.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 38 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(i):WarningDeviceExceptforfloor-operatedcranesagongorothereffectivewarningsignalshallbeprovidedforeachcraneequippedwithapowertravelingmechanism.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 39 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(j):Inspection1910.179(j)(1)Inspectionclassification.1910.179(j)(1)(i)Initialinspection.Priortoinitialuseallnewandalteredcranesshallbeinspectedtoinsurecompliancewiththeprovisionsofthissection.1910.179(j)(1)(ii)Inspectionprocedureforcranesinregularserviceisdividedintotwogeneralclassificationsbasedupontheintervalsatwhichinspectionshouldbeperformed.Theintervalsinturnaredependentuponthenatureofthecriticalcomponentsofthecraneandthedegreeoftheirexposuretowear,deterioration,ormalfunction.Thetwogeneralclassificationsarehereindesignatedas"frequent"and"periodic"withrespectiveintervalsbetweeninspectionsasdefinedbelow:1910.179(j)(1)(ii)(a)Frequentinspection-Dailytomonthlyintervals.

Comment [LD43]: Inspectionisrequiredofallnewandmodifiedcranes.TheinspectionprocessisfurtherdetailedinANSI/ASMEB30.2.Thisspecbyitselfisreallyvagueandincomplete.YouwillfinditmucheasiertousebothOSHA1910.179andANSI/ASMEB30.2togetherasasinglespec.

Comment [LD44]: Inspectionsaredividedintotwotypes,1)Frequentand2)Periodic.Thisisoneofthosetopicsinwhichusersjustwantaspecificrequirement,butOSHAdoesnotprovideone.Whenmakingadecisionastointervalhere,rememberthatyou’renotonlymeetingtherequirementsofOSHA,butpotentiallyaPlaintiffLawyerincourtafteraninjuryinvolvingacraneaccident.SinceOSHAissonebulousintheirinspectioncriteria,theownerisgivenawidelatitude.AsimpleruletaughttomebyourISO9001consultantwouldbeappropriatehere.

1.Saywhatyou’regoingtodo2.Thendowhatyousaid

TothisIwilladdathirdstep3.Leaveawelldocumentedpapertrail

Comment [LD45]: Inspectiontype#1)Frequentinspectionswhicharerequiredanywherefromdailytomonthlyintervals.Theintervalisdependentontheusageofthecrane.CMAADutyCycleClassificationcouldbeanexcellentyardstickbywhichtoassigninspectionintervals.Numberofshiftsperformedweeklyshouldalsobepartoftheequation.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 40 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(j)(1)(ii)(b)Periodicinspection-1to12-monthintervals.1910.179(j)(2)Frequentinspection.Thefollowingitemsshallbeinspectedfordefectsatintervalsasdefinedinparagraph(j)(1)(ii)ofthissectionorasspecificallyindicated,includingobservationduringoperationforanydefectswhichmightappearbetweenregularinspections.Alldeficienciessuchaslistedshallbecarefullyexaminedanddeterminationmadeastowhethertheyconstituteasafetyhazard:1910.179(j)(2)(i)Allfunctionaloperatingmechanismsformaladjustmentinterferingwithproperoperation.Daily.

Comment [LD46]: Inspectiontype#2)PeriodicInspections,whicharerequiredanywherefrom1to12monthintervals.Theintervalisagaindependentontheusageofthecrane.CMAADutyCycleClassificationcouldbeanexcellentyardstickbywhichtoassigninspectionintervals.Numberofshiftsperformedweeklyshouldalsobepartoftheequation.HardfactsliketheCMAAClassificationandnumberofshiftswouldmakeforanexcellentcriteriatoshowanOSHAinspectortojustifyaninspectionpolicy.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 41 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(j)(2)(ii)Deteriorationorleakageinlines,tanks,valves,drainpumps,andotherpartsofairorhydraulicsystems.Daily.1910.179(j)(2)(iii)Hookswithdeformationorcracks.Visualinspectiondaily;monthlyinspectionwithacertificationrecordwhichincludesthedateofinspection,thesignatureofthepersonwhoperformedtheinspectionandtheserialnumber,orotheridentifier,ofthehookinspected.Forhookswithcracksorhavingmorethan15percentinexcessofnormalthroatopeningormorethan10°twistfromtheplaneoftheunbenthookrefertoparagraph(l)(3)(iii)(a)ofthissection.1910.179(j)(2)(iv)Hoistchains,includingendconnections,forexcessivewear,twist,distortedlinksinterferingwithproperfunction,orstretchbeyondmanufacturer'srecommendations.Visualinspectiondaily;monthlyinspectionwithacertificationrecordwhichincludesthedateofinspection,thesignatureofthepersonwhoperformedtheinspectionandanidentifierofthechainwhichwasinspected.1910.179(j)(2)(v)[Reserved]1910.179(j)(2)(vi)Allfunctionaloperatingmechanismsforexcessivewearofcomponents.1910.179(j)(2)(vii)Ropereevingfornoncompliancewithmanufacturer'srecommendations.1910.179(j)(3)Periodicinspection.Completeinspectionsofthecraneshallbeperformedatintervalsasgenerallydefinedinparagraph(j)(1)(ii)(b)ofthissection,dependinguponitsactivity,severityofservice,andenvironment,orasspecificallyindicatedbelow.Theseinspectionsshallincludetherequirementsofparagraph(j)(2)ofthissectionandinaddition,thefollowingitems.Anydeficienciessuchaslistedshallbecarefullyexaminedanddeterminationmadeastowhethertheyconstituteasafetyhazard:

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 42 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(j)(3)(i)Deformed,cracked,orcorrodedmembers.1910.179(j)(3)(ii)Looseboltsorrivets.1910.179(j)(3)(iii)Crackedorwornsheavesanddrums.1910.179(j)(3)(iv)Worn,crackedordistortedpartssuchaspins,bearings,shafts,gears,rollers,lockingandclampingdevices.1910.179(j)(3)(v)Excessivewearonbrakesystemparts,linings,pawls,andratchets.1910.179(j)(3)(vi)Load,wind,andotherindicatorsovertheirfullrange,foranysignificantinaccuracies.1910.179(j)(3)(vii)Gasoline,diesel,electric,orotherpowerplantsforimproperperformanceornoncompliancewithapplicablesafetyrequirements.1910.179(j)(3)(viii)Excessivewearofchaindrivesprocketsandexcessivechainstretch.1910.179(j)(3)(ix)[Reserved]1910.179(j)(3)(x)Electricalapparatus,forsignsofpittingoranydeteriorationofcontrollercontactors,limitswitchesandpushbuttonstations.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 43 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(j)(4)Cranesnotinregularuse.1910.179(j)(4)(i)Acranewhichhasbeenidleforaperiodof1monthormore,butlessthan6months,shallbegivenaninspectionconformingwithrequirementsofparagraph(j)(2)ofthissectionandparagraph(m)(2)ofthissectionbeforeplacinginservice.1910.179(j)(4)(ii)Acranewhichhasbeenidleforaperiodofover6monthsshallbegivenacompleteinspectionconformingwithrequirementsofparagraphs(j)(2)and(3)ofthissectionandparagraph(m)(2)ofthissectionbeforeplacinginservice.1910.179(j)(4)(iii)Standbycranesshallbeinspectedatleastsemi-annuallyinaccordancewithrequirementsofparagraph(j)(2)ofthissectionandparagraph(m)(2)ofthissection.

Comment [LD47]: Partialinspectionrequiredofcraneoutofusefromover1monthbutlessthan6months.

Comment [LD48]: Cranesidleformorethan6monthsrequireafullinspectionpriortobeingputbackintoservice.ThisisafullinspectionincludingaloadtestperANSi/ASMEB30.2.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 44 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(k):Testing1910.179(k)(1)Operationaltests.1910.179(k)(1)(i)Priortoinitialuseallnewandalteredcranesshallbetestedtoinsurecompliancewiththissectionincludingthefollowingfunctions:1910.179(k)(1)(i)(a)Hoistingandlowering.1910.179(k)(1)(i)(b)Trolleytravel.1910.179(k)(1)(i)(c)Bridgetravel.1910.179(k)(1)(i)(d)Limitswitches,lockingandsafetydevices.1910.179(k)(1)(ii)Thetripsettingofhoistlimitswitchesshallbedeterminedbytestswithanemptyhooktravelinginincreasingspeedsuptothemaximumspeed.Theactuatingmechanismofthelimitswitchshallbelocatedsothatitwilltriptheswitch,underallconditions,insufficienttimetopreventcontactofthehookorhookblockwithanypartofthetrolley.1910.179(k)(2)Ratedloadtest.Testloadsshallnotbemorethan125percentoftheratedloadunlessotherwiserecommendedbythemanufacturer.Thetestreportsshallbeplacedonfilewherereadilyavailabletoappointedpersonnel.

Comment [LD49]: ThefullrequirementsofloadtestingareincludedinASMEB30.2

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 45 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(l):Maintenance1910.179(l)(1)Preventivemaintenance.Apreventivemaintenanceprogrambasedonthecranemanufacturer'srecommendationsshallbeestablished.1910.179(l)(2)Maintenanceprocedure.1910.179(l)(2)(i)Beforeadjustmentsandrepairsarestartedonacranethefollowingprecautionsshallbetaken:1910.179(l)(2)(i)(a)Thecranetoberepairedshallberuntoalocationwhereitwillcausetheleastinterferencewithothercranesandoperationsinthearea.1910.179(l)(2)(i)(b)Allcontrollersshallbeattheoffposition.1910.179(l)(2)(i)(c)Themainoremergencyswitchshallbeopenandlockedintheopenposition.1910.179(l)(2)(i)(d)Warningor"outoforder"signsshallbeplacedonthecrane,alsoonthefloorbeneathoronthehookwherevisiblefromthefloor.1910.179(l)(2)(i)(e)Whereothercranesareinoperationonthesamerunway,railstopsorothersuitablemeansshallbeprovidedtopreventinterferencewiththeidlecrane.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 46 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(l)(2)(ii)Afteradjustmentsandrepairshavebeenmadethecraneshallnotbeoperateduntilallguardshavebeenreinstalled,safetydevicesreactivatedandmaintenanceequipmentremoved.1910.179(l)(3)Adjustmentsandrepairs.1910.179(l)(3)(i)Anyunsafeconditionsdisclosedbytheinspectionrequirementsofparagraph(j)ofthissectionshallbecorrectedbeforeoperationofthecraneisresumed.Adjustmentsandrepairsshallbedoneonlybydesignatedpersonnel.1910.179(l)(3)(ii)Adjustmentsshallbemaintainedtoassurecorrectfunctioningofcomponents.Thefollowingareexamples:1910.179(l)(3)(ii)(a)Allfunctionaloperatingmechanisms.1910.179(l)(3)(ii)(b)Limitswitches.1910.179(l)(3)(ii)(c)Controlsystems.1910.179(l)(3)(ii)(d)Brakes.1910.179(l)(3)(ii)(e)Powerplants.1910.179(l)(3)(iii)Repairsorreplacementsshallbeprovidedpromptlyasneededforsafeoperation.Thefollowingareexamples:

Comment [LD50]: Note“designatedpersonnel.”

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 47 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(l)(3)(iii)(a)Cranehooksshowingdefectsdescribedinparagraph(j)(2)(iii)ofthissectionshallbediscarded.Repairsbyweldingorreshapingarenotgenerallyrecommended.Ifsuchrepairsareattemptedtheyshallonlybedoneundercompetentsupervisionandthehookshallbetestedtotheloadrequirementsofparagraph(k)(2)ofthissectionbeforefurtheruse.1910.179(l)(3)(iii)(bLoadattachmentchainsandropeslingsshowingdefectsdescribedinparagraph(j)(2)(iv)and(v)ofthissectionrespectively.1910.179(l)(3)(iii)(c)Allcriticalpartswhicharecracked,broken,bent,orexcessivelyworn.1910.179(l)(3)(iii)(d)Pendantcontrolstationsshallbekeptcleanandfunctionlabelskeptlegible.

Comment [LD51]: Notethisisancommonareaforaninspectortolevyaninfraction.Pendantsarebangedaroundandabused.Thisiscompoundedbythefacttheyareusuallybrightyellowandlocatedsuchthataninspectordoesn’tneedtoclimbaladder.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 48 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(m):RopeInspection1910.179(m)(1)Runningropes.Athoroughinspectionofallropesshallbemadeatleastonceamonthandacertificationrecordwhichincludesthedateofinspection,thesignatureofthepersonwhoperformedtheinspectionandanidentifierfortheropeswhichwereinspectedshallbekeptonfilewherereadilyavailabletoappointedpersonnel.Anydeterioration,resultinginappreciablelossoforiginalstrength,shallbecarefullyobservedanddeterminationmadeastowhetherfurtheruseoftheropewouldconstituteasafetyhazard.Someoftheconditionsthatcouldresultinanappreciablelossofstrengtharethefollowing:1910.179(m)(1)(i)Reductionofropediameterbelownominaldiameterduetolossofcoresupport,internalorexternalcorrosion,orwearofoutsidewires.1910.179(m)(1)(ii)Anumberofbrokenoutsidewiresandthedegreeofdistributionorconcentrationofsuchbrokenwires.1910.179(m)(1)(iii)Wornoutsidewires.1910.179(m)(1)(iv)Corrodedorbrokenwiresatendconnections.1910.179(m)(1)(v)Corroded,cracked,bent,worn,orimproperlyappliedendconnections.

Comment [LD52]: Analmostuniversallyoverlookedinspectionrequirement.Note“thorough”and“record”iscalledout.AOSHAinspectorhastobea“jackofalltrades.”Theywillinspecteverythingfromcranestothewaterfountains.Understandingallthesespecsisnearimpossible,butunderstandingthelackofrequireddocumentationiseasyforeventhenewestinspectorhire.FromthepointofviewofanOSHAinspection,thequalityofyourpaperworkismoreimportantthanthequalityoftheactualinspections.Ofcourse,thecorrectansweristogetthembothright,qualityinspectionsANDqualitypaperwork!

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 49 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(m)(1)(vi)Severekinking,crushing,cutting,orunstranding.1910.179(m)(2)Otherropes.Allropewhichhasbeenidleforaperiodofamonthormoreduetoshutdownorstorageofacraneonwhichitisinstalledshallbegivenathoroughinspectionbeforeitisused.Thisinspectionshallbeforalltypesofdeteriorationandshallbeperformedbyanappointedpersonwhoseapprovalshallberequiredforfurtheruseoftherope.Acertificationrecordshallbeavailableforinspectionwhichincludesthedateofinspection,thesignatureofthepersonwhoperformedtheinspectionandanidentifierfortheropewhichwasinspected.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 50 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(n):HandlingtheLoad1910.179(n)(1)Sizeofload.Thecraneshallnotbeloadedbeyonditsratedloadexceptfortestpurposesasprovidedinparagraph(k)ofthissection.1910.179(n)(2)1910.179(n)(2)Attachingtheload.1910.179(n)(2)(i)Thehoistchainorhoistropeshallbefreefromkinksortwistsandshallnotbewrappedaroundtheload.1910.179(n)(2)(ii)Theloadshallbeattachedtotheloadblockhookbymeansofslingsorotherapproveddevices.1910.179(n)(2)(iii)Careshallbetakentomakecertainthattheslingclearsallobstacles.1910.179(n)(3)Movingtheload.1910.179(n)(3)(i)Theloadshallbewellsecuredandproperlybalancedintheslingorliftingdevicebeforeitisliftedmorethanafewinches.1910.179(n)(3)(ii)Beforestartingtohoistthefollowingconditionsshallbenoted:1910.179(n)(3)(ii)(a)Hoistropeshallnotbekinked.

Comment [LD53]: “RatedLoad”isthecriticaltermhere.Theexceptionsarereallytwo,1)loadtestingand2)andthe“engineeredlift.”Moreon“engineeredliftsinASMEB30.2.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 51 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(n)(3)(ii)(b)Multiplepartlinesshallnotbetwistedaroundeachother.1910.179(n)(3)(ii)(c)Thehookshallbebroughtovertheloadinsuchamannerastopreventswinging.1910.179(n)(3)(iii)Duringhoistingcareshallbetakenthat:1910.179(n)(3)(iii)(a)Thereisnosuddenaccelerationordecelerationofthemovingload.1910.179(n)(3)(iii)(b)Theloaddoesnotcontactanyobstructions.1910.179(n)(3)(iv)Cranesshallnotbeusedforsidepullsexceptwhenspecificallyauthorizedbyaresponsiblepersonwhohasdeterminedthatthestabilityofthecraneisnottherebyendangeredandthatvariouspartsofthecranewillnotbeoverstressed.1910.179(n)(3)(v)Whileanyemployeeisontheloadorhook,thereshallbenohoisting,lowering,ortraveling.1910.179(n)(3)(vi)Theemployershallrequirethattheoperatoravoidcarryingloadsoverpeople.1910.179(n)(3)(vii)Theoperatorshalltestthebrakeseachtimealoadapproachingtheratedloadishandled.Thebrakesshallbetestedbyraisingtheloadafewinchesandapplyingthebrakes.1910.179(n)(3)(viii)Theloadshallnotbeloweredbelowthepointwherelessthantwofullwrapsofroperemainonthehoistingdrum.

Comment [LD54]: Itisnotunusualtoseetwistedcables,especiallyonlongerlifts.Technically,thiscouldresultinanOSHAviolation.Onhoistwithliftsinexcessof30feet,buyersshouldlookintousing“non-rotating”or“twist-resistant”wirerope.

Comment [LD55]: Sidepullwarning.

Comment [LD56]: Unlikethe“olddays,”therecanbenoridingofthehook.

Comment [LD57]: CarryingloadsoverpeoplecanresultinanOSHAviolation.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 52 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(n)(3)(ix)Whentwoormorecranesareusedtoliftaloadonequalifiedresponsiblepersonshallbeinchargeoftheoperation.Heshallanalyzetheoperationandinstructallpersonnelinvolvedintheproperpositioning,riggingoftheload,andthemovementstobemade.1910.179(n)(3)(x)Theemployershallinsurethattheoperatordoesnotleavehispositionatthecontrolswhiletheloadissuspended.1910.179(n)(3)(xi)Whenstartingthebridgeandwhentheloadorhookapproachesnearoroverpersonnel,thewarningsignalshallbesounded.1910.179(n)(4)Hoistlimitswitch.1910.179(n)(4)(i)Atthebeginningofeachoperator'sshift,theupperlimitswitchofeachhoistshallbetriedoutundernoload.Extremecareshallbeexercised;theblockshallbe"inched"intothelimitorruninatslowspeed.Iftheswitchdoesnotoperateproperly,theappointedpersonshallbeimmediatelynotified.1910.179(n)(4)(ii)Thehoistlimitswitchwhichcontrolstheupperlimitoftraveloftheloadblockshallneverbeusedasanoperatingcontrol.

Comment [LD58]: Note“qualifiedperson.”

Comment [LD59]: ThisisacommonsourceofOSHAviolation.Aloadcannotbeleftina“suspended”position.

Comment [LD60]: Pre-shiftoperatorinspectionisrequiredeveryday.Nodocumentationisrequired.Remember,theownersresponsibilityisnotonlytothepotentialOSHAinspector,butalsothePlaintiff’sAttorneyinthecaseofanaccident.Ownersneedtohavethispolicyinplaceandproofofitbeingrequiredoftheoperators.SeeANSI/ASMEB30.2formoredetailedinformation.

Comment [LD61]: Theupperlimitswitchcannotbeusedasanoperatingcontrol.Ioncehadanapplicationinwhichtheobjectbeingliftedhadtobecarriedoveratallmachine.Tomakesurehehadclearance,theoperatorwouldlifttheloaduntilitthelowerblockhittheupperlimitswitch.Hedidthisoneverylift.Thisresultedintheprematurefailureoftheupperlimitswitchanduponit’sfailure,adroppedload.Theuppertravellimitisnotdesignedtotakethatkindofadutycycle.Ifyourprocessrequiresthefrequentengagementoftheupperlimitswitch,atwolimitswitchlayoutisrequired.Thelowerofthetwolimitswitchesiscalledan“Operational”limitswitchandthehigherswitchisaconventionalupperlimitswitch.TheOperationallimitswitchisdesignedforafrequentengagementwhiletheUpperlimitswitchisdesignedasabackupprotection.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 53 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0

1910.179(o):OtherRequirements,General1910.179(o)(1)Ladders.1910.179(o)(1)(i)Theemployershallinsurethathandsarefreefromencumbranceswhilepersonnelareusingladders.1910.179(o)(1)(ii)Articleswhicharetoolargetobecarriedinpocketsorbeltsshallbeliftedandloweredbyhandline.1910.179(o)(2)Cabs.1910.179(o)(2)(i)Necessaryclothingandpersonalbelongingsshallbestoredinsuchamannerasnottointerferewithaccessoroperation.1910.179(o)(2)(ii)Tools,oilcans,waste,extrafuses,andothernecessaryarticlesshallbestoredinthetoolbox,andshallnotbepermittedtolielooseinoraboutthecab.1910.179(o)(3)Fireextinguishers.Theemployershallinsurethatoperatorsarefamiliarwiththeoperationandcareoffireextinguishersprovided.[39FR23502,June27,1974,asamendedat40FR27400,June27,1975;49FR5322,Feb.10,1984;51FR34560,Sept.29,1986;55FR32015,Aug.6,1990;61FR9227,March7,1996]

Comment [LD62]: IMPORTANTNOTICE:OSHAinterpretationsaretheresponsibilityofthecraneownerandnotthatofD.LarryDunville,OverheadCraneConsulting,LLC.orothercontributors.

08/05/16The Unauthorized & Annotated Guild to

OSHA 1910.179 Overhead and Gantry Cranes Page 54 of 54

www.OverheadCraneConsulting.com This document is licensed und the Creative Commons Attributions 4.0 International License [email protected] Licensed Under Creative Commons Attribution 4.0