Numerical study of mass transfer coefficient in a 3D flat-plate rectangular microchannel bioreactor

Transcript of Numerical study of mass transfer coefficient in a 3D flat-plate rectangular microchannel bioreactor

International Communications in Heat and Mass Transfer 34 (2007) 217–224www.elsevier.com/locate/ichmt

Numerical study of mass transfer coefficient in a 3D flat-platerectangular microchannel bioreactor☆

Yan Zeng a,⁎, Thong-See Lee a, Peng Yu a, Hong-Tong Low b

a Department of Mechanical Engineering, National University of Singapore, Singapore 117576, Singaporeb Division of Bioengineering, National University of Singapore, Singapore 117576, Singapore

Available online 18 December 2006

Abstract

Microchannel bioreactors have been used in many studies to investigate the fluid microenvironment around cells. In the presentstudy, a three-dimensional numerical model was developed to simulate the fluid flow and mass transfer in a 3D flat-platerectangular microchannel bioreactor with a monolayer of cells adherent to the bottom. The numerical results of mass transfer werewell correlated in terms of two dimensionless parameters: Sherwood number at base (Sh) and effective distance (κ). Thegeneralized results show the mass transfer characteristic in the flat-plate microchannel bioreactors, which may find applications inculturing cells in these bioreactors.© 2006 Elsevier Ltd. All rights reserved.

Keywords: Microchannel bioreactor; Cell culture; Mass transport

1. Introduction

Microfluidic systems could provide better control of cell–cell, cell–substrate and cell–medium interactions [1].Flat-plate microchannel bioreactors have been used in cell culture to investigate the flow microenvironment aroundcells in vitro [2–4].

Ledezma et al. [2] analyzed the oxygen transport in a radial-flow microchannel bioreactor containing hepatocytes onthe bottom numerically. The oxygen concentration was found to be affected significantly by the plasma flow rate andthe initial oxygen tension. 2D flat-plate microchannel bioreactors have been used to study the effects of flow andoxygenation on hepatocytes [3,4]. Although these studies [2–4] show that the design of such microscale cell culturesystems would involve the consideration of perfusion requirements for cell viability, their results were presented toserve their specific applications. There is little information on dimensionless parameters for general applications toconsider mass transport of oxygen, glucose, lactate and other species in cell culture.

Traditional 2D model has been used to investigate the flow and mass transport in a flat-plate microchannelbioreactor [2–4] since the channel width is much larger than the channel height and the side wall effect isnegligible. However, 3D configuration is more realistic in practical applications and a 2D model for mass transport

☆ Communicated by K. Suzuki and Nishio.⁎ Corresponding author. Division of Fluid Mechanics, Department of Mechanical Engineering, National University of Singapore, 9 Engineering

Drive 1, Singapore 117576, Singapore.E-mail address: [email protected] (Y. Zeng).

0735-1933/$ - see front matter © 2006 Elsevier Ltd. All rights reserved.doi:10.1016/j.icheatmasstransfer.2006.11.007

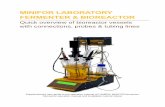

Fig. 1. Scheme of the 3D flat-plate rectangular microchannel bioreactor (not to scale).

218 Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

simulation may have limitation which lies in the difference of the velocity profiles through 2D and 3D channels: forthe true 3D channels, the velocity profile is parabolic in both the flow direction (x direction) and the width direction(z directions), but the velocity profile through 2D channels is only parabolic in flow direction (x direction).Therefore, in order to study a true 3D configuration and make the results more useful for practical applications, a3D model is used to simulate the flow and mass transport in the present study.

The main objective of the present study is to analyze the concentration distribution in a 3D flat-plate rectangularmicrochannel bioreactor. It examines the important dimensionless parameters to be considered for general application. Theeffects of various mass transfer parameters on the species transport at the base are correlated by two dimensionlessparameters: dimensionless mass transfer coefficient Sherwood number at base (Sh) and effective distance (κ). To ourknowledge, this is the first theoretical study on the dimensionless mass transfer coefficient Sherwood number (Sh) in a 3Dflat-plate rectangular microchannel bioreactor with Michaelis–Menten kinetics reaction at base.

2. Methods and theory

The bioreactor modeled in this paper consists of a flat-plate rectangular microchannel with dimensions typically of width 500 μm,height 200 μm and length 3 cm (Fig. 1), as described in detail elsewhere [5], although the dimensions do not affect the results which arepresented in dimensionless form. The aspect ratio of channel is defined as: α=H /W, whereH is the channel height andW is the channelwidth (Fig. 1). The culture medium flows through the channel along x direction. A monolayer of cells is assumed to be adherent to thebottom of the channel and consumes species from the culture medium, forming the reaction at base.

Adherent cell height was reported in an order from 2–20 μm [6] and it may have effect on the flow and mass transport [7,8].However, the ratio of cell height to channel height in the present study is only in an order of 0.01–0.1. The preliminary study [9]indicated that cell height has some effect on the mass transfer in microchannels when the ratio of cell height to the channel heightis larger than 0.2, which means that in the present study, cell height effect could be neglected for mass transfer calculation.

The conservation equations for continuity, momentum and species transport are expressed by the form of Cartesian tensornotation as follows:

Continuity equation: jd UY ¼ 0 ð1Þ

Momentum equation: qðUYdjÞ UY ¼ −jpþ lj2 UY ð2Þ

Species transport equation: UYdjC ¼ Dj2C ð3Þ

where UY

is the velocity; p is pressure; ρ is density; μ is the viscosity; C is the species concentration and D is the diffusivity of thespecies in culture medium.

219Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

Flow boundary conditions are: the axial velocity is uniform and known at inlet; the axial velocity is fully developed at outlet; andthe no-slip condition is applied at the walls.

The species concentration boundary conditions are: given inlet concentration Cin is a constant; ∇C=0 at outlet and upper wallsurface; Michaelis–Menten behavior [4,10] is used at base, expressed as:

at y ¼ 0; DACAy jy¼0

¼ VmdgdCjy¼0

Km þ Cjy¼0ð4Þ

where Vm is the maximal species uptake rate per cell; Km is Michaelis–Menten constant and γ is the cell density.Generally, flows in microdevices differ from their macroscopic counterparts because the small scale may make molecular effects

such as wall slip more important. However, in liquids, these effects will not occur unless the channels are smaller than approximately3 nm [11], which is too much smaller than the dimensions for the cell culture microchannels of 10–100 μm [2]. Thus, conventionalcontinuum hydrodynamics, which also has been used to describe the flow in microchannel bioreactors by other researchers [2–5],can provide adequate description in the present study.

Important dimensionless parameters are defined as follows to present the non-dimensional results: (i) the dimensionless speciesconcentration, C=C/Cin. (ii) Themass transfer Peclet number,Pe=UmH /D, whereUm is themean perfusion velocity of the channel whichis the uniform inlet flow velocity. The Peclet number is defined in terms of the channel height as the diffusion is assumed to bemainly in thevertical direction. (iii) The Damkohler number,Da=VmHγ / (DCin). (iv) The dimensionlessMichaelis–Menten constant, Km=Km/Cin. (v)The dimensionless mass transfer coefficient Sherwood number, Sh=kLH /D, where kL is the fluid-phase mass transfer coefficient. (vi)Another useful dimensionless parameter, effective distance, κ=x / (H ·Pe), which has been used previously by Nollert et al. [12,13].

Commercial software-FLUENT is used to solve the governing Eqs. (1)–(3). The second-order upwind discretization form is used todiscretize the convection term. The SIMPLEC algorithm is used to solve the velocity-pressure coupled equations. The species transportmodel is used to solve species concentration distribution. The computed results confirmed that the solutions are grid-independent.

The present numerical model is verified by comparing against an analytical solution [3] of oxygen concentration on the bottom ina 2D flat-bed microchannel bioreactor with constant flow velocity in flow direction and constant reaction rate at base. The numericalsolution and the analytical solution agree well (Fig. 2), which indicates that the present numerical model is satisfactory.

3. Results and discussion

Fig. 3 shows the dimensionless species concentration profiles at the axial plane (z=W /2), base plane (y=0) and transverse plane (at x=L /2). The species concentration decreases along the axial direction (Fig. 3a,b) as expected since the species is being consumed continuously.The species concentration decreases towards the base (Fig. 3a,c) as expected in view of the reaction at the base. Because of the effect of three-dimensional flow due to the side wall, the species concentration there is lower (Fig. 3b,c). However, this lateral effect is not large.

Fig. 4 shows the effect of dimensionless parameters on the concentration distribution at base. Fig. 4(a) shows the effect of Pecletnumber (Pe). Pe represents the ratio of convection to diffusion. At constant Da and Km, the species concentration will be higher at

Fig. 2. Validation of the numerical model in present study: comparison of species concentration at the base wall between analytical solution from Ref.[3] and numerical solution from present study in a 2D flat-plate microchannel.

Fig. 3. Species Concentration Profile in the 3D Flat-Plate rectangular Microchannel Bioreactor: (a) At Center Axial Plane (z=W / 2); (b) At BottomPlane (y=0); (c) At Transverse Plane (x=L / 2). Other parameters are: Pe=100, Da=0.5, Km=0.068 and α=0.4.

220 Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

higher Pe because of the increased convection of species by the flow. Fig. 4(b) shows the effect of Damkohler number (Da). Darepresents the ratio of reaction at the base to diffusion of species from the culture medium. For constant Pe and Km, higherDa resultsin lower concentration at the base because of higher reaction there. Fig. 4(c) shows the effect of Km. Compared with Km=0, whichmeans the maximum absorption at base, for constant Pe and Da, larger Km results in smaller absorption at base [Eq. (4)], and thushigher concentration there.

In general, the concentration distribution of species is affected by reaction, diffusion and convection, as characterized bydimensionless parameters Pe, Da and Km. The concentration distribution is correlated by these parameters, which have also beenused previously for the case of oxygen transport by Roy [4].

According to the flow characteristics and the definitions of dimensionless parameters, Sherwood number at base (Sh) is given by(see the Appendix for details):

Sh ¼ Da

ðCm− C0Þd

C0

ðKm þC0Þð5Þ

where Cm is the dimensionless average concentration and defined by Cm/Cin; C0 is the dimensionless concentration at base anddefined by C0/Cin. Cin is the given inlet concentration.

For the case of Km=0, Eq. (5) changes into:

Sh0 ¼ Da

ðCm− C0Þð6Þ

The analytical solution of Sh0 is given by (see the Appendix for details):

Sh0 ¼ 1

13−

2p2Pln¼1

1n2 cosðnpÞ � expðjdn2p2Þ

ð7Þ

Fig. 5 shows the data plotted as Sherwood number (Sh) against effective distance (κ), using two figures to cover the wide range ofeffective distance. It is of interest that except at larger effective distance, using the two parameters could approximately make all thedata collapsed onto a single curve.

Fig. 4. Effect of different mass transfer parameters on species concentration at base in axial direction (x direction ) along the center line of the baseplane (y=0): (a) Pe effect at Da=0.5 and Km=0.068; (b) Da effect at Pe=10 and Km=0.068; (c) Km effect at Pe=10 and Da=0.3.

221Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

For the case of Km=0, in which the reaction rate is constant at the maximal value, the results are seen to collapse onto a single curvefor all Pe andDa. For such a case with a constant reaction rate at base, Sh0 is uniquely defined by the effective distance. Sh0 drops withincreasing effective distance (κ) as the concentration boundary layer grows. When the concentration boundary layer becomes fullydeveloped, Sh0 approaches the minimum value of about 2.82 (numerical solution) and 3.0 (analytical solution) in the present study, asdescribed in the classical Graetz solution [14,15] in which the minimum Sh0 value is different and equals to 4.36 for constant wall flux.The difference lies in that the cell assumption only happens at the base of the rectangular microchannel in the present study, but there isconstant mass flux around the entire wall of the whole vessel in the classical Graetz solution. In the present study, the minimum values ofSh0 at base in analytical and numerical solutions are different, which demonstrates that the velocity profile has some effect, since slugflow was used in analytical solution; but the effect is not large because the difference is only within 6%.

For each Da at Km≠0, which is more realistic in applications, there is a range of effective distance (κ) beyond which the collapseof data is not possible. Sh first begins to drop with increasing κ as the concentration boundary layer grows and then it will keepnearly constant within a range of κ. After that Sh continues to drop slowly and this causes the collapse of data impossible. This maybe because of the non-linear Michalies–Menten kinetics boundary condition. Along the axial direction, the base concentrationbecomes smaller and smaller until C0≪Km, Michaelis–Menten boundary condition [Eq. (4)] changes into the first order boundarycondition, which leads to the slow decrease of Sh. The present Sh results are more close to the results with zero-order but not first-

Fig. 5. Sherwood number at the centerline of the base as a function of effective distance: (a) at different Km with Da=0.3, 0.5 and α=0.4; (b) atdifferent Km with Da=0.1 and α=0.4; compared with analytical and numerical solutions at Km=0.

222 Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

order boundary condition at base (data not shown). This may be because Km is usually very small compared with C0 at the formerpart of the effective distance.

In cell culture, theminimum species concentration at the base needs to be noticed because of the nutrients limitation, especially oxygenlimitation which can be defined as cell hypoxia when C0b Km [4], in Michaelis–Menten kinetics species uptake process. Thus it is ofsignificance to ensure enough species transport for cells, which means C0≥Km (Km≠0) [4]. By defining C0=Km, the critical Sherwoodnumber at base (Shc) for cell culture is found to be nearly the same (Shc=2.78) at differentDa and Km, although the corresponding criticaleffective distance (κc) is different, shown in Fig. 6. This may be because when C0≥Km, Sh and κ could collapse all the data onto onesingle curve; and all the Shc are in the flat part (constant value part) of this curve. The results in Fig. 6 may find general application in cellculture in the flat-plate rectangular bioreactor to ensure enough species for cell viability if Sh at base is chosen to be higher than 2.78.

The critical Sherwood number (Shc=2.78) could be a significant index for judging general mass-transfer-dominantconditions. The reason may be because the Sherwood number (Sh) actually decreases gradually and slowly, although it seemsnearly constant after a quick decrease near the inlet as shown in Fig. 5. Based on the requirement of the minimum speciesconcentration, which is C0≥ Km as given above, there is a critical Sherwood number (Shc) corresponding to the minimumconcentration Km Thus the general criterion by Sherwood number, which can be expressed as Sh≥Shc, may be useful to

Fig. 6. Relationship between critical Sherwood number at base (Shc) and critical effective distance (κc) at different Da and Km.

223Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

evaluate whether the mass transport is sufficient for a specific channel, although the mass transfer coefficient should becalculated from numerical analysis.

4. Conclusions

The present study has considered the mass transfer in a 3D flat-plate rectangular microchannel with a monolayer ofcells attached at base. It was found that for the present range of parameters 0bDa≤0.5 and 0bPe≤1000, the masstransport in a 3D model is close to that in a 2D model with the channel aspect ratio α≤0.4, which suggests that for thepresent range of the parameters, a 2D model is sufficient and effective to study the mass transfer in a flat-platemicrochannel bioreactor so as to save time and CPU consumption compared with the calculation process of 3Dmodels.

The numerical data approximately collapsed onto a single curve when plotted using two parameters: Sherwoodnumber (Sh) and Effective distance (κ). The correlated results reveal the mass transfer characteristic in flat-platemicrochannel bioreactors. The minimum Sh to avoid insufficient species for culturing cells in flat-plate microchannelbioreactors has been found to be about 2.78. These results may be useful for general applications in culturing cells inmicrochannel bioreactors, for example in the calculation of the critical Shc to avoid species insufficiency.

Appendix

In the present model (Fig. 1), the species of interest is assumed to transfer from the inlet to the cell surface at thebottom of the channel by a convective–diffusive mechanism which is dependent of the local fluid mechanics and canbe characterized by a fluid-phase mass transfer coefficient kL. The species flux is given by [13]: js=kL(Cb−C0); whereCb is the bulk concentration and C0 is the concentration at base. In our case, we choose Cb=Cm, where Cm is theaverage concentration. And thus:

js ¼ kLðCm−C0Þ ðA1Þ

On the channel bottom, cells are assumed to consume species, which follows theMichaelis–Menten kinetics [13], witha rate given by:

jc ¼ VmgC0

Km þ C0ðA2Þ

At steady state, the transport to the base is balanced by the consumption at base, which is given by js= jc so that:

kLðCm−C0Þ ¼ VmgC0

Km þ C0ðA3Þ

Rearranging Eq. (A3) leads to Eq. (5).Analytical solution can be obtained from the simple case of uniform flow in x direction and the diffusion in y

direction. The mass transport equation can be simplified to:

AC

Ax¼ L

H1Pe

A2C

Ag2 ðA4Þ

where x =x /L and y =y /H.With the boundary conditions:

Cðx; yÞ ¼ 1 at x ¼ 0; 0V y V1 ðA5Þ

AC

Ay¼ Da at y ¼ 0; 0V x V1 ðA6Þ

224 Y. Zeng et al. / International Communications in Heat and Mass Transfer 34 (2007) 217–224

AC

Ay¼ 0 at y ¼ 1; 0V x V1 ðA7Þ

The species concentration in the whole bioreactor is given by:

Cðx; yÞ ¼ 1þ 16Da−

LHdDaPe

x−12Dað1− y Þ2 þ 2Da

p2Xln¼1

ð−1Þnn2

cos½npð1−yÞ�exp −n2p2LH

xPe

� �ðA8Þ

Thus the species concentration at base ( y =0) is given by:

C0 ¼ 1−LHDaPe

x−Da3

þ 2Dap2

Xln¼1

ð−1Þnn2

cosðnpÞexp −n2p2LH

xPe

� �ðA9Þ

And the average species concentration along x direction is given by:

Cm ¼Z 1

0Cðx; yÞdy ¼ 1−

LHdDaPe

x ðA10Þ

Substituting Eqs. (A9) and (A10) into Eq. (6) leads to Eq. (7).

References

[1] A. Folch, M. Toner, Microengineering of cellular interactions, Annu. Rev. Biomed. Eng. 2 (2000) 227–256.[2] G.A. Ledezma, A. Folch, S.N. Bhatia, U.J. Balis, M.L. Yarmush, M. Toner, Numerical model of fluid flow and oxygen transport in a radial-flow

microchannel containing hepatocytes, J. Biomech. Eng. 121 (1999) 58–64.[3] A.W. Tilles, H. Baskaran, P. Roy, M.L. Yarmush, M. Toner, Effects of oxygenation and flow on the viability and function of rat hepatocytes co-

cultured in a microchannel flat-plate bioreactor, Biotechnol. Bioeng. 73 (2001) 379–389.[4] P. Roy, H. Baskaran, A.W. Tilles, M.L. Yarmush, M. Toner, Analysis of oxygen transport to hepatocytes in a flat-bed microchannel bioreactor,

Ann. Biomed. Eng. 29 (2001) 947–955.[5] Y. Zeng, T.S. Lee, P. Yu, H.T. Low, Fluid flow and mass transfer in a rectangular microchannel bioreactor, 4th International Conference on

Computational Heat and Mass Transfer, Paris, France, 2005.[6] V.R. Patil, C.J. Campbell, Y.H. Yun, S.M. Slack, D.J. Goetz, Particle diameter influences adhesion under flow, Biophys. J. 80 (2001) 733–1743.[7] R.L. Satcher Jr., S.R. Bussolari, M.A. Gimbrone Jr., C.F. Dewey Jr., The distribution of fluid forces on model arterial endothelium using

computational fluid dynamics, J. Biomech. Eng. 114 (1992) 309–316.[8] T. Yamaguchi, K. Hoshial, H. Okino, A. Sakurai, S. Hanai, M. Masuda, K. Fujiwara, Shear stress distribution over confluently cultured

endothelial cells studied by computational fluid mechanics, ASME, BED 24 (1993) 167–170.[9] Y. Zeng, T.S. Lee, P. Yu, H.T. Low, Effect of surface roughness on mass transfer in a flat-plate microchannel bioreactor, International

Symposiumon Physics of Fluids, Huangshan, China, 2005.[10] U.J. Balis, K. Behnia, B. Dwarakanath, S.N. Bhatia, S.J. Sullivan, M.L. Yarmush, M. Toner, Oxygen consumption characteristics of porcine

hepatocytes, Metab. Eng. 1 (1999) 49–62.[11] K.V. Sharp, R.J. Adrian, J.G. Santiago, J.I. Molho, Liquid Flows in Microchannels, The MEMS Handbook, vol. 6.1, CRC Press, Boca Raton,

2001.[12] M.U. Nollert, S.L. Diamond, L.V. Mclntire, Hydrodynamic shear stress and mass transport modulation of endothelial cell metabolism,

Biotechnol. Bioeng. 38 (1991) 588–602.[13] M.U. Nollert, L.V. Mclntire, Convective mass transfer effects on the intracellular calcium response of endothelial cells, J. Biomech. Eng. 114

(1992) 321–326.[14] J.M. Tarbell, Mass transport in arteries and the localization of atherosclerosis, Annu. Rev. Biomed. Eng. 5 (2003) 79–118.[15] C.O. Bennett, J.E. Myers, Momentum, Heat and Mass Transfer, Mc-Graw Hill, New York, 1962.