NS blade / Advanced Air Knife for Hot Dip …... “NS blade” / Advanced Air Knife for Hot Dip...

Transcript of NS blade / Advanced Air Knife for Hot Dip …... “NS blade” / Advanced Air Knife for Hot Dip...

www.metec-estad2015.com

“NS blade” / Advanced Air Knife for

Hot Dip Continuous Galvanizing Line

NS means Nippon steel & Sumikin engineering.

Hatsuki KAKUNO

Makoto KATSUBE

Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

2

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

1. Difficulty of High Speed CGL Operation

As Line Speed increases, zinc-takeout pulled by strip increases.

②Difficulty in thin coating

③Edge over coat

■Generation of edge splash leads to the loss of zinc consumption.

■ Generation of edge splash and top dross loss in High Speed Operation

Zinc pot

Air knife

↑Strip

Strip

Coating target

Over Coat

① Top dross loss

3

1. Difficulty of High Speed CGL Operation

■ Generation of edge splash in High Speed Operation

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Jet collision

4

Wiping gas flow

Wiping width(> Strip width)

Nozzle

Impinging jet

Strip

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

・Splash ・edge over coating

■ Ordinary nozzle Jet collision issue

1. Difficulty of High Speed CGL Operation

5

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

■ Baffle plate issue

1. Difficulty of High Speed CGL Operation

Less than 5mm

Ineffective condition

Strip

Edge baffle plate

Wiping gas flow

Wiping width(> Strip width)

Nozzle

6

Wiping nozzle

Cross section of nozzle

NS blade

Strip

Tracking

Wiping gas flow

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

NS blade

2. Features of NS blade

■ Configuration of NS blade Air knife

7

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

8

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

1. Non contact baffle setting Safety for high speed operation

2. According to the jet effect,

EOC and splash shall be avoided even at high speed operation *EOC: Edge over coating

BLADE

Nozzle

Wiping width ( Strip width)

Wiping gas flow

Position variable

2. Features of NS blade

■ NS blade advantage

9

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Air pressure

Zinc temperature :460℃

Nozzle

≒43

0

Nozzle gap

1.5m

Sound meter

Camera

Strip width :280mm Strip thickness :0.71mm

3. High speed coating test using NS blade

■ Schematic of experiment apparatus

10

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Wiping nozzle

Front view Side view

Edge splash

Front view Side view

Reduce Edge

Splash

(a) Ordinary nozzle

(b) NS blade

3. High speed coating test using NS blade

■ Test results 1 / Edge splash (Front view and side view)

11

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Without NS blade With NS blade

3. High speed coating test using NS blade

■ Test results 1 / Edge splash (Front view and side view)

12

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Flow velocity vector

X

Z

Y Y

Z

X

3. High speed coating test using NS blade

13

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

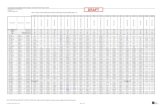

■ Test results 2/ Coating thickness distribution

5 10 15 20

Coat

ing

weig

ht

Distance from strip edge (mm)

Coating weight distribution (near the strip edge)

F w/o EB

B w/o EB

F With EB

B with EB

without BLADE (F)

without BLADE (B)

with BLADE (F)

with BLADE (B)

-20%

+60%

+40%

+20%

Target

Edge over coat

Very little variation

in the coating weight

⇒ NS blade is effective in prevent of Edge over coat and allow thin coating

Strip

3. High speed coating test using NS blade

14

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Improve Noise level ■ Test results 3/ Noise level

3. High speed coating test using NS blade

15

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Galvanizing Line 55%Aluminum+Zinc coating lineCoil spec. 0.23mm thick X 914mm width 0.35mm thick X 1200mm width

Line 160mpm 150mpm speed

Coating Z08(40g/m2 per side) AZ40(20g/m2 per side)thicknessSplash None None

Overcoat None None

Noise 105dB 100dB

■ Operation condition

4. Commercial line test

16

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

■ Coating weight distribution

4. Commercial line test

60

80

100

120

140

160

180

0 5 10 15 20 25

Re

late

ive

Co

atin

g th

ickn

ess

[%]

60

80

100

120

140

160

180

0 5 10 15 20 25

NS blade

Ordinary nozzle

Distance from strip edge [mm] Left side Right side

17

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

5. Conclusion

17

Hatsuki KAKUNO, Makoto KATSUBE, Muneshige OGAWA

NIPPON STEEL & SUMIKIN ENGINEERING CO., LTD., JAPAN

18 JUNE.2015

Without NS blade With NS blade

■ Coating test at test line ⇒ Reduce EOC, noise level and zinc splash

■ Commercial line operation (GI and 55% Al+Zinc bath)

⇒ Achieve maximum line speed and minimum coating weight operation