Novel Virus Clearance and Virus Detection Technologies and ... · HTS platforms • Subgroup C:...

Transcript of Novel Virus Clearance and Virus Detection Technologies and ... · HTS platforms • Subgroup C:...

-

Novel Virus Clearance and Virus Detection Technologies and Applications

Qi Chen, PhD Process Virology, Purification DevelopmentGenentech Inc., A Member of the Roche Group

CMC Forum JapanDecember 3, 2018

-

Outline

Virus Safety

Cell Substrate Testing

Raw Material

Selection &Treatment

Virus Clearance

In-process Testing

• Virus clearance– Eco friendly detergent– Small virus retentive filtration – CHO RVLP removal

• Virus risk of CHO cell lines– CHO Retrovirus-like Particles (RVLP)

non-infectivity

• Recent industry trend– NGS for virus detection– Virus clearance validation for

continuous processing

• Proposal of ICH Q5A revision

2

Three Pillars of Product Virus Safety –ICH Q5A

CHO cell derived therapeutic protein products have not been implicated in virus

transmission

-

• Alkyl polyglucoside• non-ionic detergent• Natural ingredient from corn and

coconut• Used in baby shampoo and other

consumer products• Readily biodegradable

• LDAO – Biogen Eco Friendly Zwitterionic (Amphoteric) Detergent Conley, L. et al., Biotechnol and Bioeng 2017 114(4):813-820

TRITON X-100

TRITON CG-110

Triton CG-110 – Genentech/Roche Non-ionic Eco-friendly Detergent 3

X-MuLV inactivation in HCCF at 12°C 1 hour

Inactivation of other enveloped viruses HCCF, 0.3%, 1 hour, 20oC

• Effective inactivation of enveloped viruses• Comparable inactivation by Triton X-100 and Triton

CG-110

-

Parvovirus Retention by Small VRF

• Parvovirus passage has been reported in select virus filters post de-pressurization or reduced flow conditions

‒ Virus diffusion out of pore in absence of flow‒ Low pressure (low flow) has been correlated with reduced LRV‒ Virus passage may be filter dependent

• Dishari et al., 2015; LaCasse et al., 2016; and Yamamoto et al., 2014

4

LaCasse and Brorson lab, Biotechnol. Prog., 2016

-

MMV Worst Case Run for Filter 1

• Worst case conditions (high and low flux, pause, high mass throughput)

• Constant flux mode• Stepwise reduction of flux:

300 L/m2h (LMH) 140 LMH 20 LMH pause Buffer chase at 140 LMH

• 2x volume and mass throughput• MMV LRVs ≥ 6.40, ≥ 6.28 by plaque

assay

0

100

200

300

400

0 500 1000 1500 2000 2500

Flux

(LM

H)

Volume Throughput (L/m2)

1 hour pause

5

Molecule Volume Through

put (L/m2)

Mode of Operation

MMV LRV

1 2,300 Constant Flux

≥ 6.40 ≥ 6.28

2 2,100 Constant Flux

≥ 7.46≥ 7.79

3 2,100 Constant Pressure

≥ 5.62

4 1,450 Constant Pressure

≥ 6.74

• All studies performed with 1% MMV spike

• High flux/high pressure followed by low flux/pressure and 1 hr process pause

• Fractionate load pre and post process pause

• No impact of low flux and pause on MMV removal

-

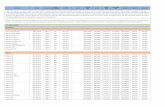

Filter 1 DoE: Volume Throughput, Filter Fouling and MMV Removal

Protein concentr. L L L M M H H H L L L M M H H H L L L M M H H H

Filter lot 1 2 3 1 3 1 2 3 1 2 3 2 3 1 2 3 1 2 3 1 2 1 2 3Pressure H M L M H L H M L H M M L M L H M L H L H H M L

IgG1 Mab 1 Mab 2 Mab 5Orange squares represent MMV log reduction factors (LRFs). Coloured bars represent volume throughput. Runs terminated due to > 90% flow decay are marked with an asterisk. L: low, M: medium, H: high.

Results: filter fouling does not impact MMV removal

0200400600800

100012001400160018002000

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Vol

ume

Thro

ughp

ut [L

/m2 ]

0

1

2

3

4

5

6

7

MM

V R

educ

tion

Fact

or [l

og10

]

* * * * * * * * * * * * * * * * * * * * *

Mass_throughput_LRF

1.97213165.92

1.34919246.06

2.69291765.92

2.0630966.06

1.5202746.06

2.11930956.12

1.6252866.13

2.14232356.24

3.995885.99

2.3287866.07

3.80838726.1

3.7923216.67

3.8243796.54

5.648595.67

3.9724895.88

3.5125266.15

13.54180525.82

13.34424565.71

13.27855485.82

17.2379675.64

15.0902285.7

15.2678565.88

13.045275.71

10.8928365.7

Mab 1

Mab 2

Mab 5

Mass throughput

log10 reduction factor

Mass Throughput [kg/m2]

MMV Reduction Factor [log10] (≥)

Volume_throughput_LRF

245.295.92

167.816.06

334.945.92

210.526.06

155.136.06

136.296.12

104.526.13

137.776.24

4975.99

289.656.07

473.686.1

324.136.67

326.876.54

379.15.67

266.615.88

235.746.15

1667.715.82

1643.385.71

1635.295.82

1552.975.64

1359.485.7

966.325.88

825.655.71

689.425.7

Volume Throughput

log10 reduction factor

Volume Throughput [L/m2]

MMV Reduction Factor [log10]

Throughput_mass_volume

low protein; lot 1; HP1.9721316

low protein; lot 2; MP1.3491924

low protein; lot 3; LP2.6929176

mid protein; lot 1; MP2.063096

mid protein; lot 3; HP1.520274

high protein; lot 1; LP2.1193095

high protein; lot 2; HP1.625286

high protein; lot 3; MP2.1423235

low protein; lot 1; LP3.99588

low protein; lot 2; HP2.328786

low protein; lot 3; MP3.8083872

mid protein; lot 2; MP3.792321

mid protein; lot 3; MP3.824379

high protein; lot 1; MP5.64859

high protein; lot 2; LP3.972489

high protein; lot 3; HP3.512526

low protein; lot 1; MP13.5418052

low protein; lot 2; LP13.3442456

low protein; lot 3; HP13.2785548

mid protein; lot 1; LP17.237967

mid protein; lot 2; HP15.090228

high protein; lot 1; HP15.267856

high protein; lot 2; MP13.04527

high protein; lot 3; LP10.892836

Mab 1

Mab 2

Mab 5

Volume throughput [L/m2]

Mass throughput [kg/m2]

Volume throughput [L/m2]

Mass throughput [kg/m2]

Viresolve Pro total volume and mass throughput

245.29

167.81

334.94

210.52

155.13

136.29

104.52

137.77

497

289.65

473.68

324.13

326.87

379.1

266.61

235.74

1667.71

1643.38

1635.29

1552.97

1359.48

966.32

825.65

689.42

Vmax Viresolve Diagramm

low protein; lot 1; HP2.55672

low protein; lot 2; MP1.72056

low protein; lot 3; LP3.7788

mid protein; lot 1; MP2.7146

mid protein; lot 3; HP1.9404

high protein; lot 1; LP2.799

high protein; lot 2; HP2.3636

high protein; lot 3; MP2.799

low protein; lot 1; LP5.97372

low protein; lot 2; HP3.28032

low protein; lot 3; MP5.49132

mid protein; lot 2; MP5.3703

mid protein; lot 3; MP5.5107

high protein; lot 1; MP8.2099

high protein; lot 2; LP5.8557

high protein; lot 3; HP4.5147

low protein; lot 1; MP0

low protein; lot 2; LP0

low protein; lot 3; HP0

mid protein; lot 1; LP0

mid protein; lot 2; HP25.5522

high protein; lot 1; HP24.49

high protein; lot 2; MP27.571

high protein; lot 3; LP18.7546

Mab 1

Mab 2

Mab 5

Vmax [L/m2]

Mmax [kg/m2]

Vmax [L/m2]

Maximum mass capacity based on Vmax [kg/m2]

Maximum mass capacity based on Vmax Variation of protein concentration, membrane lot and (over-) pressure based on DoE

318

214

470

277

198

180

152

180

743

408

683

459

471

551

393

303

0

0

0

0

2302

1550

1745

1187

Viresolve

MABRunProteinFilterlotpressure [bar]log10 reduction factor (≥)Vmax [L/m2]Beladung nach Vmax [kg/m2]tatsächliche Bel [L/m2]tatsächliche Bel [kg/m2]Filtrationszeit [h]Beladung (70% von Vmax) [kg/m2]Filterfläche für 10kg [m2] (Beladung 70% von Vmax)Flux (v throughput/t) [L/m2/h]

Mab 11low protein1HP5.923183245.31.972.001.745.8122.6low protein; lot 1; HP

22MP6.062142167.811.351.831.178.591.5low protein; lot 2; MP

33LP5.924704334.92.693.622.573.992.6low protein; lot 3; LP

4mitd protein1MP6.062773210.52.062.001.855.4105.3mid protein; lot 1; MP

53HP6.061982155.11.521.501.327.6103.4mid protein; lot 3; HP

6high protein1LP6.121803136.32.121.531.905.388.9high protein; lot 1; LP

72HP6.131522104.51.631.231.616.284.7high protein; lot 2; HP

83MP6.241803137.82.141.671.905.382.7high protein; lot 3; MP

Mab 29low protein1LP5.997436497.04.005.584.062.589.0low protein; lot 1; LP

102HP6.074083289.72.333.002.234.596.6low protein; lot 2; HP

113MP6.16835473.73.815.183.732.791.4low protein; lot 3; MP

12mid protein2MP6.674595324.13.794.083.652.779.4mid protein; lot 2; MP

133LP6.544716326.93.823.703.752.788.3mid protein; lot 3; MP

14high protein1MP5.675518379.15.653.835.581.898.9high protein; lot 1; MP

152LP5.883936266.63.973.503.982.576.2high protein; lot 2; LP

163HP6.153035235.73.512.173.073.3108.8high protein; lot 3; HP

Mab 517low protein1MP5.823890321667.713.547.5821.480.5219.9low protein; lot 1; MP0

182LP5.718792711643.413.348.0048.550.2205.4low protein; lot 2; LP0

193HP5.8210027811635.313.285.4355.370.2301.0low protein; lot 3; HP0

20mid protein1LP5.646269701553.017.248.0047.320.2194.1mid protein; lot 1; LP0

212HP5.72302261359.515.098.0017.380.6169.9mid protein; lot 2; HP

22high protein1HP5.88155024966.315.277.2516.650.6133.3high protein; lot 1; HP

232MP5.71174528825.713.057.7018.750.5107.2high protein; lot 2; MP

243LP5.7118719689.410.898.0012.750.886.2high protein; lot 3; LP

Vmax nicht auswertbar

verblockt

VorstudieTitrationsstudie

tatsächliche Bel [L/m2]tatsächliche Bel [kg/m2]Vmax [L/m2]tatsächliche Bel [L/m2]Beladung nach Vmax [kg/m2]Vmax [L/m2]

Mab1blank run low prot. Lot 11291.010.34601

low protein; lot 1; HP974.07.71257245.33318

low protein; lot 2; MP918.07.31164167.812214

low protein; lot 3; LP216.01.7266334.94470

blank run high prot. Lot 1807.012.01767

high protein; lot 1; LP187.02.8232136.33180

high protein; lot 2; HP397.05.9512104.52152

high protein; lot 3; MP337.05.0438137.83180

Mab2blank run low prot. Lot 28946.81658

low protein; lot 1; LP335.02.7488497.06743

low protein; lot 2; HP326.02.6495289.73408

low protein; lot 3; MP541.04.3822473.75683

blank run high prot Lot 2327.04.6431

high protein; lot 1; MP406.05.7568379.18551

high protein; lot 2; LP349.04.9485266.66393

high protein; lot 3; HP243.03.6340235.75303

Mab3blank run low prot. Lot 31520.012.39496

low protein; lot 1; MP168313.644701667.7323890

low protein; lot 2; LP1658.013.449891643.4718792

low protein; lot 3; HP1669.013.559181635.38110027

blank run high protein Lot 3935.014.02420

high protein; lot 1; HP96814.54905966.3241550

high protein; lot 2; MP914.013.71269825.7281745

high protein; lot 3; LP968.014.54020689.4191187

Viresolve

1257

1164

266

232

512

438

Titrationstudy

Prestudy (mid pressure)

Vmax [L/m2]

Mab 1

BioEx

974

918

216

187

397

337

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 1

7.743

7.294

1.72

2.78

5.916

5.03

Titrationstudy

Prestudy (mid pressure)

Mass throughput [kg/m2]

Mab 1

488

495

822

568

485

340

Titrationstudy

Prestudy (mid pressure)

Vmax [L/m2]

Mab 2

335

326

541

406

349

243

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 2

2.693

2.618

4.347

5.725

4.924

3.62

Titrationstudy

Prestudy (mid pressure)

Mass throughput [kg/m2]

Mab 2

1683

1658

1669

968

914

968

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 5

13.635

13.431

13.515

14.517

13.707

14.52

Titrationstudy

Prestudy (mid pressure)

Mass throughput [kg/m2]

Mab 5

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 1

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 2

Titrationstudy

Prestudy (mid pressure)

Volume throughput [L/m2]

Mab 5

MABProteinRunFilterlotVmax [L/m2]Beladung nach Vmax [kg/m2]tatsächliche Bel [kg/m2]tatsächliche Bel [L/m2]Filtrationszeit [h]Filterfläche für 10kg [m2] (70% von Vmax)

spiked10.0

spiked20.0

spiked30.0

spiked10.0

spiked20.0

spiked30.0

spiked10.0

spiked20.0

spiked30.0

spiked10.0

spiked20.0

spiked30.0

spiked10

spiked20

spiked0

HPunspiked30

spiked10

spiked20

spiked30

-

Parvovirus LRV for larger viruses for BLA

MMV LRV SV40 LRV X-MuLV LRV

Vpro LRV ≥ 6.40 ≥ 6.28

≥ 2.91 ≥ 2.94

≥ 3.24 2.94

Pre-filter Loss 0.35 1.68 3.21

X-MuLV(80 – 110 nm)

MMV(18 – 22 nm)

SV40(45 nm)

• In this study, X-MuLV and SV40 LRVs were under-estimated for virus filter capacity due to significant pre-filtration loss

• Evaluation of parvovirus removal at worst case conditions for process understanding• Applying MMV LRV to larger viruses

• Meeting Report: Joint BWP/QWP workshop with stakeholders in relation to prior knowledge and its use in regulatory applications 23 November 2017, European Medicines Agency, London

-

X-MuLV Clearance by Used Resin 8

• Both Genentech and industry experience showed that virus clearance LRVs are maintained after extended resin reuse with proper cleaning

• Virus clearance by used protein A resin can be supported by platform data

‒ Meeting Report: Joint BWP/QWP workshop with stakeholders in relation to prior knowledge and its use in regulatory applications 23 November 2017, European Medicines Agency, London

Protein A

AEX

CEX

-

High Titer RVLP Stock for Spike Studies

Sample Lot 1 Lot 3

Protein A FlowthroughLog10(particles/mL)

9.1 8.3

RVLP stockLog10(particles/mL)

11.6 10.7

Recovery 62% 93%

LRV by 0.22um filter 0.5 0.2

LRV by NFR 6.2 5.4

CHO RVLP Stock TEM

High RVLP stock titer• QPCR: 10.7 log10 particles/mL• TEM: 10.7 log10 particles/mL• Q-PERT: 10.7 nU/mL (1 nU ≈ 1pc, Collaboration with

Scott Lute and Kurt Brorson )

Low RVLP aggregation & Particles integrity demonstrated• TEM morphology• NFR removal near QPCR assay LOQ

Comparable chromatography removal of RVLP and X-MuLV

RVLP X-MuLV

QSFF F/T

Load (total copies) 11.0 10.6

Pool (total copies) ≤4.6 4.8

LRV ≥6.4 5.8

QSFF B/E

Load (total copies) 11.0 10.7

Pool (total copies) ≤4.5 ≤4.6

LRV ≥6.5 ≥6.1

9

-

• Use real particles of concern instead of model retrovirus• Experiments can be performed in regular process development labs• Overall comparable RVLP and X-MuLV removal

10

Antibody Resin Type RVLP LRV (QPCR) Experiment TypeXMuLV LRV

(TCID50)

A Multimodal AEX 1.99*4.48 Process optimization1.02*5.06

BMultimodal AEX 1.24*≥3.31

Process optimization

-≥5.78

AEX 1.08*≥5.540.56*≥6.42

C CEX 4.13 Pre-validation/confirmation ≥5.72

D Multimodal AEX 4.55 Pre-validation/confirmation ≥6.13

CEX: cation exchange; AEX: anion exchange*LRVs before and after process optimization

RVLP and X-MuLV Removal by Chromatography

CHO RVLP spike is an alternative to X-MuLV spike studies

Data by Roche Penzberg Downstream Purification

-

Virus Clearance Platform for mAbs and non-mAbs

• 3 dedicated, robust virus clearance steps

- Operate within robust parameter ranges

- Modular validation

- Decreased reliance on chromatography steps

• Clinical purification process

Affinity Chromatography

with Low pH ≤ 3.60

Chromatography 2

Small-Virus Retentive Filtration

HCCF with Detergent

(Triton CG110)

Chromatography 1Dedicated

Step

ModularX-MuLV

LRV

Modular MMV LRV

Detergent 6.6 --

Low pH 7.1 --

Virus Filtration 5.7 5.7

XMuLV LRV 19.4

11

-

Molecular Characterization of CHO RVLPs

• A full length CHO RVLP provirus sequence‒ Multiple nucleotide substitutions, insertions, and deletions disrupt both the gag-pol and

env open reading frames‒ Can not produce type C particles from this locus‒ YS Lie et al, 1994

• cDNA clones from CHO RVLP‒ No functional endonuclease due to multiple interruptions of ORF‒ K Anderson et al, 1991

• Chinese hamster genome sequencing‒ Protein BLAST identified 403 hamster proteins with homology to retrovirus protein

domains. ‒ RNA-seq detected minimal env transcripts ‒ NE Lewis et al, 2013

12

Lewis et al., Nature Biotechnology. 2013. 31: 759-765.

-

Industry Experience: RVLP Infectivity Never Observed

CHO RVLP infectivity has never been observed

13

• Industry experience‒ No single case of CHO RVLP infectivity observed‒ 185 manufacturer cell banks of mouse, rat or hamster origin were tested, infectious

retrovirus was not detected in cell lines of hamster or rat origin‒ AJ Shepherd et al, 2003

• Genentech experience with CHO cell lines‒ Testing the presence of infectious retroviruses

• Cocultivation with indicator cell lines (of multiple species) with S+L- Focus assay and Reverse Transcriptase assay as endpoints

• Extended S+L- Focus Assay‒ ~30 years of virus testing history‒ >90 cell lines tested‒ >50 molecules tested

-

Virus Clearance Target

CHO RVLP NS0 Retrovirus Plasma-Derived

Virus in starting material 104-9 vp/mL Up to 1010 vp/mL

(~101-2 ffu/mL) ≤ LOQ

Infectious virus No yes HIV, HCV, HBV, HAV, B19, …

Virus pathogenesis No Unknown Yes

Virus transmission history No No Yes

Virus clearance target ≤ 1 vp/106 doses

(ICH Q5A Appendix 5)≤ 1 vp/106 doses(ICH Q5A Appendix 5)

≤ 1 vp/106 doses(EMA/CHMP/BWP/706271/2010)

• ICH Q5A states that each of the three overlapping approaches for product virus safety (cell bank testing, in process testing and virus clearance) is to reduce risks of INFECTIOUS viruses.

• Q5A also acknowledges that CHO RVLPs are well characterized and non-infectious

• Yet, same virus clearance target applies for products with distinctly different virus risk profiles.

• CHO retrovirus clearance target could be reduced due to its non-infectivity

14

-

Why Next Generation Sequencing? 15

• Current assays (in vivo, in vitro, virus specific PCR assays) have been generally effective for demonstrating the absence of adventitious viruses in biological products.

• Emergence of advanced nucleic acid based technologies such as NGS for broad virus detection

• Contamination of rotavirus vaccine by Porcine Circovirus 1 (PCV1) detected by NGS (2010)• Detection of a novel rhabdovirus in the Sf9 insect cell line (2014)• Higher sensitivity and speed than in vivo tests• Broad virus detection• Poor detection of viruses in vivo assays are expected to detect – Gombold et al., Vaccine, 32:2916-

2926, 2014

• EU directive on the protection of animals used for scientific purposes (2010)• Replacement, Reduction and Refinement of animal testing (3Rs)

-

Progress So Far 16

• NGS application in adventitious virus testing• 1 assay for all tests, eg. cell banks, virus seed lots, bulk harvests

• Advanced Virus Detection Technologies Interest Group (AVDTIG), an FDA/industry group

• Subgroup A: sample selection/preparation/processing• Subgroup B: Virus standards and reference materials – 5 reference virus stocks to evaluation of

HTS platforms• Subgroup C: Development of a complete and correctly annotated, publicly available virus reference

database -- RVDB• Subgroup D: Bioinformatics pipelines analysis• Subgroup E: follow up strategies to confirm the identity of a “hit”

• Multiple studies to demonstrate NGS capability to detect viruses• Detection of spiked virus panels

• Challenges• Assay standardization and validation, as the methods are complex and evolving• Bioinformatics expertise• False positives• Consistent global regulatory guidance

-

Regulatory Guidance on NGS in EU for Vaccines – Ph. Eur.

Detection of viral extraneous agents by novel molecular methods

Novel, sensitive molecular techniques with broad detection capabilities are available, including deep sequencing or high throughput sequencing methods.

The use of these new broad molecular methods has highlighted the gaps with the existing testing strategy by identifying previously undetected viral contaminants in final product, the cell banks from which it was produced and intermediate manufacturing stages.

High throughput sequencing detects genomes while the existing in vivo methods are based on observations of the effects viruses have on experimental animals.

The implementation of such new broad molecular methods as substitutes for in vivo methods requires a comparison of the specificity (breadth of detection) and the sensitivity of the new and existing methods. For this purpose, an appropriate panel of representative well-characterised model viruses should be used to assess the ability of the new method to detect viruses that are (or are not) detected by the in vivo methods and, to determine if the sensitivity is at least equivalent to the sensitivity of the in vivo methods.

5.2.14. Substitution of in vivomethod(s) by in vitro method(s) for

the quality control of vaccines

• Introduction of molecular biology methods for specific extraneous agents

• Introduction of broad molecular methods (such as high throughput sequencing) for broad detection of all viruses

2.6.16. Tests for extraneous agents in viral vaccines for human use

• Novel, sensitive molecular techniques with broad detection capabilities are available, including Massive Parallel Sequencing (MPS) methods, degenerate PCR for whole virus families or random-priming methods (associated or not with sequencing), hybridisation to oligonucleotide arrays and mass spectrometry.

• These methods may be used either as an alternative to in vivo or specific NAT tests or as a supplement/alternative to in vitro culture tests, in agreement with the competent authority.

5.2.3. Cell substrates for the production of vaccines for human

use

17

The rapid progress made in adventitious virus detection by NGS may also enable its application for virus testing for cell line derived products and other novel biologics modalities

-

Continuous Processing

• Process Intensification has shown the potential for significant improvement in manufacturing

• Implementation for biopharmaceuticals production will lead to reduced equipment size and higher productivity

• Various technology options exists or are in-development to enable continuous processing or connected processing

• How to ensure virus clearance?

Konstantinov 2015

-

Virus Inactivation

• Continuous virus inactivation by low pH‒ In-line adjustment of pH‒ System designed to ensure incubation time and mixing

• Batch virus inactivation has been shown to have comparable results to continuous

Johnson, 2017Gillespie 2018

-

Virus Filtration

• Virus filtration can be operated as continuous or batch mode‒Continuous virus filtration with multiple in-line filters‒Batch post connected chromatography steps

• Mechanism of action will not change for virus retention by filtration, upstream variation could be minimized by surge tanks

• Integrity of filter must be ensured

Johnson, 2017

-

Summary and Looking into the Future

• ICH Q5A was published in 1998. CHO cell derived therapeutic protein products have not been implicated in virus transmission

• Tremendous progress has been made in developing effective and robust virus clearance unit operations, platform purification processes, as well as virus assays and virus clearance study approaches

• New technologies such as NGS provide better virus detection tools and may replace in vivo and in vitro virus testing, while continuous processing require novel approaches to ensure virus clearance capacity and validation

• Advances in technology and industry experience may warrant revision of ICH Q5A‒ CHO retrovirus clearance target could be reduced due to its non-infectivity‒ Parvovirus removal validation applied to larger viruses ‒ No protein A used resin virus clearance validation based on prior knowledge‒ NGS to replace in vivo virus testing

21

-

Acknowledgement

Genentech Process Virology and Purification DevelopmentRoche Penzberg Downstream PurificationChugai Downstream Purification

22

Novel Virus Clearance and Virus Detection �Technologies and ApplicationsOutlineSlide Number 3Parvovirus Retention by Small VRFMMV Worst Case Run for Filter 1 Filter 1 DoE: Volume Throughput, Filter Fouling and MMV RemovalParvovirus LRV for larger viruses for BLAX-MuLV Clearance by Used Resin High Titer RVLP Stock for Spike StudiesSlide Number 10Virus Clearance Platform for mAbs and non-mAbsMolecular Characterization of CHO RVLPsIndustry Experience: RVLP Infectivity Never ObservedVirus Clearance TargetWhy Next Generation Sequencing?Progress So FarRegulatory Guidance on NGS in EU for Vaccines – Ph. Eur.Continuous ProcessingVirus InactivationVirus FiltrationSummary and Looking into the FutureAcknowledgement