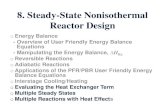

Nonisothermal case: adiabatic approach

description

Transcript of Nonisothermal case: adiabatic approach

Nonisothermal case: adiabatic approach

Prof. Dr. Marco Mazzotti - Institut für Verfahrenstechnik

1. Approach

Therefore two new concepts become important:

1. Energy balances

2. Changes of L and G within the column

In the adiabatic approach energy balances are calculated under following assumptions:

• There is no heat exchange through the walls of the column

• The gas and liquid stream leaving a stage are at the same temperature

Calculating changes of L and G within the column are important when dealing with large solute fractions. This is often the case when calculating non-isothermal columns.

Once, pressure and initial composition and temperature of the solvent are set we can consider them as data. This is a list of known variables:

Specifications

y1Gas final composition, y1

Gn+1

TGn+1

Data and set values

yn+1

x0Pressure, p

Gas flow rate, Gin

Gas initial composition, yn+1

Solvent initial composition, x0

Equilibrium data, y=f(x,T)

p

y = f(x,T)

TL0

Gas Temp. at inlet TG1

Liquid Temp. at inlet, TL2

Ln

TLn

Unknowns

xn

Solvent flow rate at inlet, L2

Number of stages, n

Solvent final composition, xn

G1 L0

n

Solvent flow rate outlet, L1

TG1

Gas Temp. at outlet TG2

Gas Temp. at outlet TL1

2. Balances

Material Balance of column:

T)f(x,y

yGxLyGxL

GLGL

11nn1n1n00

1n1n0

The amount of liquid increases from the bottom to the top of the column. It is calculated by adding up the amount of solvent and the amount of absorbed solute. The same way the amount of gas is calculated. It deacreases from the top to the bottom of the column as the solute absorbs to the liquid.

Energy Balance of column

)T(TcpHH

ΔH)T(TcpHH

HGHLHGHL

0G

0GG

S0

L0LL

G11Lnn1Gn1nL00

HS represents the molar enthalpy of mixing or the integral heat of solution, at the prevailing concentration and at the base temperature T0

J/(mol K)Heat capacitycp

J/molChange of solute enthalpy between liquid and gas phase

Hs

J/molEnthalpy at reference stateH0

J/molEnthalpyH

To solve the problem the gas outlet temperature and the amount of liquid solvent have to be estimated or calculated by a nother method, e.g. the isothermal approach

3. Solution of the system

Now all necessary values of the bottom of the column can be calculated by the energy and mass balances.

From the bottom of the column a new set of mass and material balances can be made including the first stage. (green canvas) From these balances all unknowns of the first stage can be calculated. This is repeated including one more stage every time until the required specification is reached.