NI 43-101 Technical Report for the Costerfield Mine ... · PDF file17.3.3 Uphole Airleg...

Transcript of NI 43-101 Technical Report for the Costerfield Mine ... · PDF file17.3.3 Uphole Airleg...

NI 43-101 Technical Report for the Costerfield Mine, specifically the

Augusta Lodes and Brunswick Mill, of Mandalay Resources Corporation at

Costerfield, Victoria, Australia

Prepared for: Mandalay Resources Corporation

76 Richmond Street, Suite 330 Toronto, Ontario

M5C 1P1 CANADA

Prepared by: SRK Consulting (Australasia) Pty Ltd

Level 6, 141 Queen Street Brisbane

4000 AUSTRALIA

Effective Date: 1 March 2010

Report Date: 14 May 2010

Project Code: PLI003

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │i

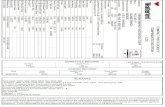

NI 43-101 Technical Report for the Costerfield Mine, specifically the Augusta Lodes and Brunswick Mill, of Mandalay Resources Corporation at Costerfield, Victoria, Australia

PLI003

Document Reference: PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3.docx

Mandalay Resources Corporation 76 Richmond Street, Suite 330 VANCOUVER V6E 2E9 Toronto, Ontario M5C 1P1 Canada

SRK Consulting (Australasia) Pty Ltd Level 6, 141 Queen Street, Brisbane QUEENSLAND 4000 Australia

Compiled by: Peer Reviewed by:

Chris Raleigh Principal Consultant (Mining)

John Blackburn Principal Consultant (Mining)

Contributors:

Kobus du Plooy BSc (Geology and Geochemistry)

Brett Muller BE (Minerals Engineering and Extractive Metallurgy)

Adriaan du Toit BSc (Geology and Hydrology)

Bruce Sommerville BSc (Mining Geology)

Endorsed by QP: Chris Raleigh

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │ii

SRK Report Distribution Record

Project Number: PLI003

Date Issued: 14 May 2010

Name/Title Company

Mark Sander Mandalay Resources

This document is protected by copyright vested in SRK. It may not be reproduced or transmitted in any form or by any means whatsoever to any person without the written permission of the copyright holder, SRK.

Rev No. Date Revised By Revision Details

0 28 April 2010 Chris Raleigh Draft report issued to client

1 12 May 2010 Chris Raleigh Report issued to client

2 13 May 2010 Chris Raleigh Report issued to client

3 14 May 2010 Chris Raleigh Final report issued to client

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │i

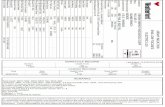

Table of Contents (Section 1.3.1)

Summary (Item 3) ............................................................................................................ viii

1. Introduction (Item 4) ............................................................................................... 1-1

1.1 Terms of Reference and Purpose of the Report ........................................................ 1-1 1.1.1 Terms of Reference .................................................................................................. 1-1 1.1.2 Purpose of the Report ............................................................................................... 1-1

1.2 Reliance on Other Experts and Sources of Information (Item 5) ............................... 1-1 1.2.1 Reliance on other Experts ........................................................................................ 1-1 1.2.2 Sources of Information.............................................................................................. 1-1

1.3 Qualifications of Consultants ..................................................................................... 1-2 1.3.1 Qualification and Experience .................................................................................... 1-2 1.3.2 Site Visit .................................................................................................................... 1-2

1.4 Effective Date ............................................................................................................ 1-2 1.5 Units of Measure ....................................................................................................... 1-3

2. Property Description and Location (Item 6) ......................................................... 2-1

2.1 Property Location ...................................................................................................... 2-1 2.2 Tenements ................................................................................................................. 2-1 2.3 Survey Grid Location ................................................................................................. 2-4 2.4 Royalties and Taxes .................................................................................................. 2-5

2.4.1 Royalties ................................................................................................................... 2-5 2.4.2 Taxes ........................................................................................................................ 2-5

2.5 Environmental Liabilities and Permitting .................................................................... 2-5 2.5.1 Required Permits and Status .................................................................................... 2-5 2.5.2 Compliance Evaluation – Groundwater License ...................................................... 2-6

3. Accessibility, Climate, Local Resources, Infrastructure and Physiography (Item 7) .................................................................................................................... 3-1

3.1 Topography, Elevation and Vegetation ..................................................................... 3-1 3.1.1 Topography ............................................................................................................... 3-1 3.1.2 Elevation ................................................................................................................... 3-1 3.1.3 Vegetation ................................................................................................................. 3-1

3.2 Climate and Length of Operating Season ................................................................. 3-1 3.2.1 Climate ...................................................................................................................... 3-1 3.2.2 Operating Season ..................................................................................................... 3-1

3.3 Physiography ............................................................................................................. 3-2 3.4 Access to Property .................................................................................................... 3-2 3.5 Local Resources and Infrastructure ........................................................................... 3-2

3.5.1 Access Road and Transportation ............................................................................. 3-2 3.5.2 Power Supply ............................................................................................................ 3-2 3.5.3 Water Supply ............................................................................................................ 3-3 3.5.4 Buildings and Ancillary Facilities .............................................................................. 3-3 3.5.5 Camp Site ................................................................................................................. 3-3 3.5.6 Tailings Storage Area ............................................................................................... 3-3 3.5.7 Waste Rock Storage Area ........................................................................................ 3-3 3.5.8 Manpower ................................................................................................................. 3-3

4. History (Item 8) ....................................................................................................... 4-1

4.1 Ownership ................................................................................................................. 4-1 4.2 Past Exploration and Development ........................................................................... 4-1 4.3 Historic Mineral Resource and Reserve Estimates ................................................... 4-1 4.4 Historic Production .................................................................................................... 4-2

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │ii

5. Geological Setting (Item 9) .................................................................................... 5-1

5.1 Regional Geology ...................................................................................................... 5-1 5.2 Local Geology ............................................................................................................ 5-3 5.3 Project Geology ......................................................................................................... 5-5

6. Deposit Type (Item 10) ........................................................................................... 6-1

7. Mineralisation (Item 11) ......................................................................................... 7-1

7.1 Mineralised Zones ..................................................................................................... 7-1 7.2 Relevant Geological Controls .................................................................................... 7-1

8. Exploration (Item 12) .............................................................................................. 8-1

8.1 Surveys and Investigations ........................................................................................ 8-1

9. Drilling (Item 13) ..................................................................................................... 9-1

9.1 Type and Extent of Drilling ........................................................................................ 9-1 9.1.1 Procedures ............................................................................................................... 9-2

9.2 Drill Hole Collar and Survey Control .......................................................................... 9-4

10. Sampling Method and Approach (Item 14) ......................................................... 10-1

10.1 Sampling Methods ................................................................................................... 10-1 10.1.1 Diamond Core Sampling ........................................................................................ 10-1 10.1.2 Underground Face Sampling .................................................................................. 10-2

11. Sample Preparation, Analyses and Security (Item 15) ...................................... 11-1

11.1 Sample Preparation and Assaying Methods ........................................................... 11-1 11.1.1 Testing Laboratories ............................................................................................... 11-1 11.1.2 Sample Preparation ................................................................................................ 11-1 11.1.3 Sample Analysis ..................................................................................................... 11-1

12. Data Verification (Item 16) ................................................................................... 12-1

12.1 Blanks ...................................................................................................................... 12-1 12.2 Standards ................................................................................................................ 12-2 12.3 Laboratory Repeats ................................................................................................. 12-3 12.4 Assay Repeats ........................................................................................................ 12-4 12.5 Conclusion ............................................................................................................... 12-4

13. Adjacent Properties (Item 17) .............................................................................. 13-1

13.1 Statement ................................................................................................................ 13-1

14. Mineral Processing and Metallurgical Testing (Item 18) ................................... 14-1

14.1 Mineral Processing Facility ...................................................................................... 14-1 14.1.1 Introduction ............................................................................................................. 14-1 14.1.2 Process Plant Background ..................................................................................... 14-1 14.1.3 Facility Description .................................................................................................. 14-1 14.1.4 Operating Background ............................................................................................ 14-1 14.1.5 Recoveries .............................................................................................................. 14-1 14.1.6 Risk to Throughput and Recovery .......................................................................... 14-1 14.1.7 Crushing and Screening Circuit .............................................................................. 14-2 14.1.8 Milling Circuit .......................................................................................................... 14-2 14.1.9 Flotation Circuit ....................................................................................................... 14-2 14.1.10 Leaching Circuit ...................................................................................................... 14-2

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │iii

14.1.11 Metal Accounting .................................................................................................... 14-2 14.2 Status of Processing Facility ................................................................................... 14-2 14.3 Historical Plant Performance ................................................................................... 14-3 14.4 Forecast Plant Performance .................................................................................... 14-5

14.4.1 Metallurgical Performance ...................................................................................... 14-5 14.4.2 Processing Costs .................................................................................................... 14-8

14.5 Metallurgical Testing .............................................................................................. 14-10 14.6 Processing Risks ................................................................................................... 14-11 14.7 Mechanical and Civil Review ................................................................................. 14-11

14.7.1 Mechanical ............................................................................................................ 14-11 14.7.2 Structural and Civil ................................................................................................ 14-12

14.8 Tailings Storage ..................................................................................................... 14-12 14.9 Data Sources ......................................................................................................... 14-12

15. Mineral Resources and Mineral Reserve Estimates (Item 19) .......................... 15-1

15.1 Resource Estimation ............................................................................................... 15-1 15.1.1 Summary ................................................................................................................ 15-1 15.1.2 Database ................................................................................................................ 15-4 15.1.3 Compositing ............................................................................................................ 15-5 15.1.4 Specific Gravity ....................................................................................................... 15-6 15.1.5 Variogram Analysis and Modelling ......................................................................... 15-7 15.1.6 Grade Estimation .................................................................................................... 15-9 15.1.7 Resource Classification ........................................................................................ 15-10

15.2 Reserve Estimation ............................................................................................... 15-10 15.2.1 Conversion of Mineral Resources to Mineral Reserves ....................................... 15-10 15.2.2 Mineral Resources ................................................................................................ 15-12 15.2.3 Planned Dilution .................................................................................................... 15-12 15.2.4 Unplanned Dilution ............................................................................................... 15-13 15.2.5 Ore Loss ............................................................................................................... 15-13 15.2.6 Mineral Reserve Estimate .................................................................................... 15-14

16. Other Relevant Data and Information (Item 20) ................................................. 16-1

17. Additional Requirements for Development Properties and Production (Item 25)................................................................................................................. 17-1

17.1 Mining Operations ................................................................................................... 17-1 17.1.1 Geotechnical Considerations .................................................................................. 17-1 17.1.2 Geotechnical Characterisation ............................................................................... 17-1 17.1.3 Structural Geology .................................................................................................. 17-2 17.1.4 Stope Design Parameters ...................................................................................... 17-2 17.1.5 Ground Conditions and Ground Support ................................................................ 17-3 17.1.6 Mine Development .................................................................................................. 17-3 17.1.7 Decline Development .............................................................................................. 17-4 17.1.8 Level Development ................................................................................................. 17-4 17.1.9 Production ............................................................................................................... 17-4

17.2 Services ................................................................................................................... 17-6 17.2.1 Ventilation ............................................................................................................... 17-6 17.2.2 Ventilation Requirements ....................................................................................... 17-7 17.2.3 Ventsim Modelling .................................................................................................. 17-7 17.2.4 Pumping ................................................................................................................ 17-10 17.2.5 Power .................................................................................................................... 17-12 17.2.6 Ancillary Equipment .............................................................................................. 17-14

17.3 Mining Method ....................................................................................................... 17-14 17.3.1 Cut & Fill ............................................................................................................... 17-14 17.3.2 Cut & Fill Parameters ............................................................................................ 17-15 17.3.3 Uphole Airleg Stoping ........................................................................................... 17-15 17.3.4 Mining Method Description and Design Criteria ................................................... 17-15 17.3.5 Blasthole Stoping .................................................................................................. 17-17

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │iv

17.3.6 Mining Recovery ................................................................................................... 17-18 17.4 Processing ............................................................................................................. 17-19

17.4.1 Metallurgical Performance and Recoverability ..................................................... 17-19 17.5 Markets .................................................................................................................. 17-21 17.6 Contracts ............................................................................................................... 17-21 17.7 Environmental Considerations ............................................................................... 17-21

17.7.1 Remediation .......................................................................................................... 17-21 17.7.2 Closure Plan ......................................................................................................... 17-25 17.7.3 Conceptual Hydrogeological Model ...................................................................... 17-25

17.8 Impact on the Receiving Environment ................................................................... 17-25 17.8.1 Dewatering ............................................................................................................ 17-25 17.8.2 Water Disposal ..................................................................................................... 17-25 17.8.3 Groundwater ......................................................................................................... 17-25 17.8.4 Water Quality ........................................................................................................ 17-26 17.8.5 Dust – Air Quality .................................................................................................. 17-26 17.8.6 Noise ..................................................................................................................... 17-26

17.9 Royalties and Taxes .............................................................................................. 17-26 17.9.1 Royalties ............................................................................................................... 17-26 17.9.2 Taxes .................................................................................................................... 17-27

17.10 Capital Costs ......................................................................................................... 17-27 17.10.1 Capital Development ............................................................................................ 17-27 17.10.2 On Going Capital .................................................................................................. 17-27

17.11 Operating Costs ..................................................................................................... 17-27 17.11.1 Manning ................................................................................................................ 17-28 17.11.2 Equipment ............................................................................................................. 17-28

17.12 Economic Analysis ................................................................................................ 17-28 17.12.1 LOM Plan and Economics .................................................................................... 17-28 17.12.2 Sensitivity .............................................................................................................. 17-28 17.12.3 Mine Life ............................................................................................................... 17-31

18. Interpretation and Conclusions (Item 21) ........................................................... 18-1

18.1 Geological ................................................................................................................ 18-1 18.1.1 Field Surveys .......................................................................................................... 18-1 18.1.2 Analytical and Testing Data .................................................................................... 18-1 18.1.3 Mineral Resources .................................................................................................. 18-1

18.2 Geotechnical ............................................................................................................ 18-1 18.3 Environmental .......................................................................................................... 18-1 18.4 Mining ...................................................................................................................... 18-2 18.5 Process .................................................................................................................... 18-2 18.6 Other Relevant Information ..................................................................................... 18-2

19. Recommendations (Item 22) ................................................................................ 19-1

19.1 Geological ................................................................................................................ 19-1 19.2 Geotechnical ............................................................................................................ 19-1 19.3 Environmental .......................................................................................................... 19-1 19.4 Mining ...................................................................................................................... 19-2 19.5 Processing ............................................................................................................... 19-2

20. References (Item 23) ............................................................................................ 20-1

21. Glossary ................................................................................................................ 21-1

21.1 Mineral Resources and Reserves ........................................................................... 21-1 21.1.1 Mineral Resources .................................................................................................. 21-1 21.1.2 Mineral Reserves .................................................................................................... 21-1

21.2 Glossary .................................................................................................................. 21-2

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │v

List of Tables

Table 2-1: Tenement details .................................................................................................... 2-1 Table 2-2: Costerfield mine grid (from Fredericksen, 2009) .................................................... 2-4 Table 2-3: Summary of relevant Work Plans and Work Plan Variations .................................. 2-5 Table 2-4: Summary of planning permits from the City of Greater Bendigo ............................ 2-6 Table 4-1: Mineral Resource Estimate (W, E, C & N lodes) as at 31 March 2009 ................... 4-1 Table 4-2: Quarterly Historical Production from Augusta Mine ................................................ 4-2 Table 4-3: Augusta Mine production with Mandalay Involvement ............................................ 4-2 Table 9-1: Drilling history at Costerfield ................................................................................... 9-1 Table 14-1: Historical plant performance data ......................................................................... 14-3 Table 14-2: Planned versus actual feed tonnes ....................................................................... 14-6 Table 14-3: Planned versus actual antimony grade and recovery ........................................... 14-7 Table 14-4: Planned versus actual gold grade and recovery ................................................... 14-7 Table 14-5: March 2010 processing budget ............................................................................ 14-9 Table 14-6: Key reagent consumption rates .......................................................................... 14-10 Table 15-1: Diluted Mineral Resources for Augusta (W, E, C & N lodes) as at 31 March

2009 ...................................................................................................................... 15-2 Table 15-2: Estimated Costerfield Resources as at 1-Mar 2010 including Brunswick Vein

as estimated by AMC Consultants ........................................................................ 15-3 Table 15-3: Reconciled mine production vs mill production for ore derived from Augusta

Mine ...................................................................................................................... 15-4 Table 15-4: Composite statistics for E Lode – Face Composites (domain 10) ........................ 15-5 Table 15-5: Composite statistics for E Lode – Face Composites (domain 11 and 12) ............ 15-5 Table 15-6 Composite statistics for W Lode – Face Composites ........................................... 15-5 Table 15-7: Composite statistics for E Lode – Drill Hole Composites ...................................... 15-6 Table 15-8: Composite statistics for W Lode – Drill Hole Composites ..................................... 15-6 Table 15-9: Variogram models drill hole composites ............................................................... 15-8 Table 15-10: Variogram models face sample composites ......................................................... 15-8 Table 15-11: Dip and strike correction factors ........................................................................ 15-10 Table 15-12: Breakdown of NRPT 1 ....................................................................................... 15-11 Table 15-13: Summary of Transition including Dilution and Ore Loss ..................................... 15-14 Table 15-14: Summary of Mineral Reserve as at 1 March 2010 ............................................. 15-15 Table 17-1: Current equipment and ventilation requirements at 0.05m3/s/kW ......................... 17-7 Table 17-2: Ventilation modelling - Ventsim criteria ................................................................. 17-8 Table 17-3: Surface 415V substation loading ........................................................................ 17-14 Table 17-4: Underground 1000V substation loading ............................................................. 17-14 Table 17-5: Recent history of Unplanned Dilution ................................................................. 17-15 Table 17-6: Planned versus actual plant feed tonnes ............................................................ 17-19 Table 17-7: Planned versus actual antimony grade and recovery ......................................... 17-20 Table 17-8: Planned versus actual gold grade and recovery ................................................. 17-20 Table 17-9: Mining operating cost breakdown ....................................................................... 17-27 Table 17-10: LOM economic results ........................................................................................ 17-28 Table 21-1: Glossary ................................................................................................................ 21-2 Table 21-2: Abbreviations ........................................................................................................ 21-3

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │vi

List of Figures

Figure 2-1: Mine site location .................................................................................................... 2-1 Figure 2-2: Plan of area of ML 4644 from DPI, Victorian State Government ............................ 2-2 Figure 2-3: Plan detailing reduction in EL3310 ......................................................................... 2-3 Figure 2-4: Relationship between mine grids (from Fredericksen, 2009).................................. 2-4 Figure 3-1: Monthly average temperature and rainfall .............................................................. 3-2 Figure 4-1: Historical production from Augusta Mine ................................................................ 4-2 Figure 5-1: Regional geology .................................................................................................... 5-2 Figure 5-2: Local geology .......................................................................................................... 5-3 Figure 5-3: Costerfield lode systems ......................................................................................... 5-4 Figure 5-4: Schematic cross section through the Augusta deposit ........................................... 5-5 Figure 6-1: E Lode 1070 Level South ....................................................................................... 6-1 Figure 6-2: Mineralisation in E Lode 1070 Level South ............................................................ 6-2 Figure 7-1: Stibnite mineralisation as stibnite matrix supported quartz breccia ........................ 7-1 Figure 8-1: Exploration target area for W Lode. ........................................................................ 8-2 Figure 9-1: Drill hole locations in the Costerfield area .............................................................. 9-2 Figure 9-2: Drilling procedures used by AGD ........................................................................... 9-3 Figure 10-1: Location of drill samples and underground development ..................................... 10-1 Figure 10-2: Face sampling guide for Augusta Mine ................................................................ 10-3 Figure 12-1: Analysis of blanks ................................................................................................. 12-1 Figure 12-2: Analysis of Standard ADG07-01 ........................................................................... 12-2 Figure 12-3: Analysis of Standard G902-2 ................................................................................ 12-2 Figure 12-4: Analysis of Standard G902-8 ................................................................................ 12-3 Figure 12-5: Laboratory preparation duplicate .......................................................................... 12-3 Figure 12-6: Laboratory assay repeats ..................................................................................... 12-4 Figure 12-7: Inter-laboratory repeats ........................................................................................ 12-4 Figure 14-2: Recent antimony in tailings trend .......................................................................... 14-6 Figure 14-3: Recent gold tails trend .......................................................................................... 14-8 Figure 15-1: Density data compared to calculated value .......................................................... 15-7 Figure 15-2: CIM relationship between Mineral Resources and Mineral Reserves ................ 15-11 Figure 15-3: Planned and Unplanned Dilution ........................................................................ 15-13 Figure 17-1: Augusta rockmass classification ........................................................................... 17-2 Figure 17-2: Typical ground conditions and ground support in ore drives ................................ 17-3 Figure 17-3: Long section showing all stopes and development .............................................. 17-4 Figure 17-4: Isometric view of stoping and development on the East and West lodes ............. 17-5 Figure 17-5: Long section of W lode stopes .............................................................................. 17-5 Figure 17-6: Long section of E lode stopes ............................................................................... 17-6 Figure 17-7: Isometric view of Cut & Fill in the virgin area of Augusta ...................................... 17-6 Figure 17-8: Plan view of current ventilation system ................................................................. 17-8 Figure 17-9: Long section of current ventilation system ............................................................ 17-9 Figure 17-10: Long section view of future ventilation system ..................................................... 17-9 Figure 17-11: Site water schematic ........................................................................................... 17-10 Figure 17-12: Schematic of current dewatering system ............................................................ 17-11 Figure 17-13: Schematic of the LOM dewatering system ......................................................... 17-12 Figure 17-14: LOM plan for the power reticulation system ....................................................... 17-13 Figure 17-15: Long section of the uphole airleg stoping layout ................................................. 17-16 Figure 17-16: Cross section of orebody intersecting development ........................................... 17-18 Figure 17-17: Surface plan of plant site showing tailings dam facilities .................................... 17-23 Figure 17-18: Surface plan of the mine site, waste dump and evaporation dam ...................... 17-24 Figure 17-19: Project sensitivity to gold price variation from USD1000/oz ............................... 17-28 Figure 17-20: Project sensitivity to antimony price variation from USD6000/t .......................... 17-29 Figure 17-21: Project sensitivity to exchange rate variation from the 1.0 AUD: 0.9USD Base

Case ................................................................................................................... 17-29

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │vii

Figure 17-22: Project sensitivity to mine production rate variation ............................................ 17-30 Figure 17-23: Project sensitivity to mining cost variation .......................................................... 17-30 Figure 17-24: Sensitivity to increase in Au tail grade ................................................................ 17-31

List of Appendices

Appendix A: Certificates of Authors

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │viii

Summary (Item 3)

Report Purpose

The purpose of the report is to ensure that the resultant ore resources and reserves of the Costerfield Augusta Mine (Augusta) have been verified and are reported to the standard required by the National Instrument (NI) 43-101 of the Canadian Securities Administrators.

Property Location and Ownership

The Augusta mine site is located at Costerfield, approximately 10 km northeast of Heathcote, 50 km east of Bendigo and 100 km north of Melbourne, the state capital of Victoria, Australia. The mine is located at a latitude of 36

0 52‟ 27” S and a longitude of 144

0 47‟ 38” E.

Primary approval for mine operation is held with the Mining License MIN 4644 issued by the Victorian State Government which was renewed in June 2008 for a further two years and so is due for renewal by 30 June 2010. The tenement details are presented in Table 2-1.

AGD Operations Pty Ltd, a wholly owned subsidiary of Mandalay Resources Corporation (Mandalay), holds the mining and exploration licences.

History of Costerfield and Discovery of Augusta

The Costerfield area has had a large number of different mining operators since 1860, mining for both gold and antimony. The most extensive operations existed in the periods 1860 to 1883 and 1904 to 1925. Between 1934 and 1980, there was ongoing exploration and intermittent small-scale production by several companies, including a period managed by the Victorian Mines Department.

With more extensive exploration of the Costerfield deposits, a processing plant was constructed in 1995 to re-treat the old tailings plus the oxide material which was mined from the Brunswick open pit.

Following continued exploration and resource definition drilling, the Augusta deposit was discovered and, following a successful feasibility study, the development of an underground mine was commenced in 2006.

Geology and Mineralisation

The Augusta gold and antimony deposit is located on the western edge of the Melbourne Trough in the Lachlan Geosyncline. Gold and antimony mineralisation occurs in thin lode veins. The veins are hosted within a broader, strongly foliated shear system and are composed of laminated to brecciated quartz and massive sulphide mineralisation containing stibnite and gold.

Exploration

The Costerfield Au/Sb field was discovered during the 1860s and has a long exploration history. Recent exploration by AGD has been by surface drilling and has been focused on the Augusta mine area.

Resources and Reserves

Mineral Resources for the E and W lodes in the Measured and Indicated category (the lodes currently in production) were developed in 2009. Mineral Resources estimates were also prepared in 2009 for the C and N lodes. The Measured and Indicated Resources for the E and W lodes as at 31 March 2009 are 224,200 tonnes (t) ore @ 11.8 g/t Au and 6.4% Sb. Accounting for the extraction of ore between 1 April 2009 and 28 February 2010 it is estimated that the Measured and Indicated Resource as at 1 March 2010 is 218,500 t @ 11.8 g/t Au and 6.4% Sb.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │ix

Mineral Resources have been estimated using the two-dimensional approach which is considered appropriate, given the very thin nature of the deposit and that there is little possibility of mining selectivity in the across-dip direction. Grades have been estimated using ordinary kriging. Diamond drill holes and mine face data have been used in the grade estimations.

Mineral Resources have been reported using a 4.6 g/t Au Equivalence at a minimum mining thickness of 1.2 m. Measured Resources are restricted to those parts of the mine in which underground development has occurred due to the variable nature of the grade and thickness.

The development of the Mineral Reserves initially required the creation of mining shapes in the Mine 2-4D computer program. Following the application of dilution and mining recovery factors, and with some risk associated with the Environmental Modifying Factor, the Mineral Reserve for this short life operation which has significant potential, is considered to be 65,576 t of ore at 13.1 g/t gold and 7.0% antimony.

SRK understands that there are ongoing discussions with the relevant authorities, particularly the environmental related authorities, to resolve the outstanding issues.

Production

Production was commenced at the Augusta Mine in 2006.

With the previous Mineral Resource statement as at 31 March 2009 production from the mine, as reported by AGD Operations, has been 21.3 kt @ 7.1 g/t Au and 4.3% Sb from 1 April 2009 to 28 February 2010. All production was from the Measured and Indicated Resources for E and W lodes.

The underground mine has decline access via 4 m wide and 4 m high development mined at a gradient of 1 in 8 (12.5%). This decline development has been mined to approximately 1070 m RL or 100 m below surface. There is horizontal access to the E and W lodes of the orebody, at approximately 8 m level intervals. The orebody width is variable – up to 1.2 m and the dip of the orebody of 690.

Access to the lower levels of the orebody is being achieved by extending the decline to the lower horizons to enable orebody confirmation with diamond drilling and orebody development.

The ore in the upper levels of the mine has been extracted by long hole stoping. The stope height, and orebody inconsistency on the hanging wall, has resulted in increased dilution from hanging wall fall off. In addition, there was a safety hazard with entry to these stoping areas.

With deteriorating ground conditions, the extraction method has been changed to cut and fill mining to improve the mining recovery and reduce dilution. This method, apart from improving the recovery by reducing ore loss and increasing the head grade by lowering dilution, also improves the consistency of production by decreasing the unpredictability of the hanging wall conditions with lower cut heights. It also allows the level interval to be increased to 20 m.

With the application of this improved production plan, the required 4,000 t of ore per month at the necessary gold and antimony grade is likely to be achieved.

The processing facility comprises a two-stage crushing process, two milling stages in series, with classification and gravity concentration in closed circuit, rougher, scavenger and cleaner flotation for the production of gravity gold and an antimony and gold concentrate.

Because the processing facilities are located near residences noise restrictions currently confine plant operation to 5.5 days per week.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │x

Capital and Operating Costs

The capital costs applied to this assessment are those required to maintain the operation during the period of extraction of the current mineral reserves – from March 2010 and November 2011. This totals AUD1.984M or AUD30.27/t which covers the mine capital development and the minor capital expenditure for the necessary replacement of some items during this period.

The operating costs covered in this evaluation are made up of those incurred by the mine, the mill and the administration areas. This totals AUD15.527M or AUD236.79/t.

Economic Analysis and Sensitivity

With the short life of the Mineral Reserves, the economic analysis was limited to the assessment of revenue, costs, EBITDA, Pre Tax Profit and Cash Surplus.

Mining Plus consultants determined that the total revenue that would be realised over the production period of these ore reserves would be AUD38.2M. The total costs of the operation over this short mine life would be AUD25.3M, resulting in an EBITDA of AUD12.9M. The Pre Tax Profit was AUD8.8M and the Cash Surplus was AUD8.5M. This cash surplus will in part be used to cover the AUD1.1M Exploration program that Mandalay has approved, in a concerted attempt to lengthen the mine life.

Sensitivities of these results to metal prices, exchange rate, production and cost variations of +20% to -20% are presented.

There is the greatest sensitivity in Pre Tax Profit and Cash Flow to variations in gold price, exchange rate and production rate.

Conclusions and Recommendations

Conclusions

The major conclusions include those from the geological area that appropriate methods of data gathering and analysis are being applied and that resource estimates are made using both diamond drill and face sample data.

In the geotechnical area, it was concluded that increased confidence would result from a well-managed geotechnical database.

From the environmental point of view, it was concluded that there is risk associated with compliance in the areas of waste dump management, the management and containment of the mine and process water plus water sampling and noise level readings.

The major conclusions in the mining operation area include the fact that the change to cut and fill mining is progressively improving the operating results, the critical mining risk assessments are carried out with diligence and there is no spare capacity in the technical services area.

On the understanding that there is risk associated with the Environmental Modifying Factor, a Mineral Reserve has been established on the Measured and Indicated Resource. This totals 65,576 t at 13.1 g/t gold and 7.0% antimony.

It was concluded that the process plant conditions are improving, the projected plant throughput and costs are in line with historical results and the projected plant recoveries are achievable. However, there is sensitivity to a possible increase in the gold tail grade.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │xi

Recommendations

The major recommendations in the geological area include the recommendation that, following the planned exploration drilling program, a new Mineral Resource be developed.

In the geotechnical area, the recommendations include the development of a geotechnical database, additional geotechnical drilling is required and a formal risk assessment on the likelihood of ground failures resulting from water accumulation.

Environmental recommendations include the rectification of non-compliance issues, the updating of the groundwater abstraction license, the assessment of the use of mine water for dust suppression, development of a hydrogeological model, compilation of an approved Environmental Management Program, a review of current monitoring methods and the collation of all environmental information.

Recommendations in the mining area include that the current risk assessment process should be continued; that the mine should expedite the conversion to cut and fill mining with the appropriate equipment to achieve optimal results, and that the establishment and maintenance of the appropriate technical staff so as to continually achieve the required operating results and the maintenance of an appropriate operator training program, should be ensured. Recommendations in the process area include the maintenance of the antimony tail grade and management of any increase of the gold tail grade, until the proposed online analysis system is installed and commissioned. Additional recommendations include the increase to the maintenance budget until steady state operation is realised and better actual operating data is available and the establishment of a metallurgical test program for ore from each new mining area.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │1-1

1. Introduction (Item 4)

1.1 Terms of Reference and Purpose of the Report

1.1.1 Terms of Reference

The Augusta Underground Mine at Costerfield, Victoria, Australia is 100% owned by AGD Operations Pty Ltd, which itself became a 100% owned subsidiary of Mandalay Resources Corporation (Mandalay), beginning 1 December 2009. A review of the mine was carried out in September 2009 by SRK Consulting (Australasia) Ltd (SRK) at the request of Plinian Capital (Plinian), which at the time, was considering investing in Mandalay. Based in part on that review, Plinian completed its investment and provided key managers for Mandalay. Following on from this review, SRK were requested by Plinian to carry out an audit of the Mineral Resources and Mineral Reserves of the Augusta Mine and produce a National Instrument (NI) 43-101-compliant report.

1.1.2 Purpose of the Report

The purpose of the report is to ensure that the resultant resources and reserves of the Costerfield Mine, specifically of the Augusta lodes, have been verified and are reported to the standard required by the NI 43-101.

1.2 Reliance on Other Experts and Sources of Information (Item 5)

1.2.1 Reliance on other Experts

The preparation of this report has required the technical input from other experts.

In preparing the geological section of this report SRK has relied on other experts as listed below:

Mr Dean Fredericksen (MSc Hons) undertook the Mineral Resource estimate for E and W lodes at Augusta and assessment of data quality for the Augusta deposit.

Mr Rodney Webster (BAppSc) undertook the Mineral Resource estimate for C and N lodes at the Augusta deposit and the assessment of data quality and Mineral Resource estimate for Brunswick Deposit.

AGD personnel have been relied on for information pertaining to mining and exploration tenements.

Mr Dean Fredericksen, Mr Rodney Webster and AGD personnel have been relied on for the geological sections of this report – namely Sections 5, 6, 7, 8, 9, 10, 12 and 15.

In preparing the mining section of this report, SRK has relied on other experts, namely:

Mr Brad Evans (BEng, MAusIMM) of Mining Plus Consultants compiled the Augusta Life-of-Mine Plan (LOM).

In preparing the processing section of this report, SRK has relied on other experts as listed below:

Mr Brett Muller of Simulus Pty Consulting Metallurgical Engineers, has been relied on for Section 14 and Section 17-4.

1.2.2 Sources of Information

The report is compiled from information supplied by AGD, together with that obtained from site visits by each of the authors, which included trips to the underground operations and the surface facilities including the process plant, the tailings dams, the waste dump and the ancillary services.

In addition, this report has relied on information appearing in the Augusta LOM Plan of April 2010 that has been developed by Mining Plus Mining Consultants.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │1-2

1.3 Qualifications of Consultants

1.3.1 Qualification and Experience

Each of the authors of this report is a qualified person in their preferred field.

In the geological area, Bruce Sommerville [BSc Hons (Mining Geology), BAppSc (Geology), MAusIMM, MAusIG, MGSAus] is a Principal Consultant with more than 15 years‟ experience in geoscience and mine planning roles which includes 10 years in the areas of Mineral Resources and Ore Reserves in operating mines and projects. Bruce specialises in resource estimation and 3D modelling.

Covering the field of geotechnical engineering is Kobus du Plooy [BSc (Geology and Geochemistry), PrSciNat, MIEAus] who is a Senior Consultant and rock mechanics engineer with 15 years of operating and consulting experience. One area of Kobus‟ expertise, apart from operational review and assistance, is numerical modelling to assess geotechnical conditions, ground support and pillar design plus the design and interpretation of rock engineering strategies.

Adriaan du Toit [BSc (Geology and Hydrology), PrSciNat who is a Senior Consultant with 18 years of experience in environmental hydrogeology covered the important hydrogeological area of the report. He brings his wide knowledge and international experience together to evaluate the impact of new or existing projects on the environment and to find practical, cost effective solutions.

The process plant review has been carried out by Brett Muller [BEng (Minerals Engineering and Extractive Metallurgy), BCom (Finance)], of Simulus Engineers who has a broad range of experience covering plant operations and commissioning, troubleshooting, detailed design, project management and metallurgical testwork management.

The mining engineering and project management aspects of this report has been carried out by Chris Raleigh [BSc (Mining Engineering), FAusIMM (CP), RPEQ], a Principal Consultant with more than 35 years of mining experience in many different areas of the industry, including gold, base metals and industrial minerals, in the operating, projects and planning areas, in large and small underground and open pit operations, in Australia and overseas.

The peer review of this report has been carried out by John Blackburn [BE (Mining), MBA, MAusIMM] a Principal Consultant who has more than 35 years of experience working in underground and open pit mines with mining companies, consultants and suppliers, and who has underground operating experience including open stoping, cut and fill stoping and slot stoping. John‟s specialist areas include production planning and scheduling, mine planning and scheduling, mine costing and due diligence.

1.3.2 Site Visit

To ensure that this report is based on a complete set of data and information, the relevant consultant visited the operation during the months of January, February and March 2010 to review each area of activity at the operation.

1.4 Effective Date

The effective date of this report is 1 March 2010.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │1-3

1.5 Units of Measure

Symbol Meaning

Φ diameter

g/t grams per metric tonne

k thousand

kg kilogram

kl kilolitre

m metre

M million

m3 cubic metre

ML megalitre – 1000 litres

Mt million tonnes

Mtpa million tonnes per annum

Oz Troy ounce or 31.1035 grams

t tonne

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-1

2. Property Description and Location (Item 6)

2.1 Property Location

The Augusta mine site is located at Costerfield, approximately 10 km northeast of Heathcote, 50 km east of Bendigo and 100 km north of Melbourne, the state capital of Victoria, Australia.

The mine is located at a latitude of 360 52‟ 27” S and a longitude of 144

0 47‟ 38” E. The location and

access roads are detailed in Figure 2-1.

Figure 2-1: Mine site location

The Brunswick Processing Plant, which comprises a 75,000 tpa antimony and gold gravity-flotation-CIP circuit is also adjacent to the main access road. Two tailings dams are positioned in close proximity to the processing plant with the construction of a third tailings dam having just been completed.

2.2 Tenements

AGD Operations holds the Mining License MIN4644 issued by the Victorian State Government under the Mineral Resources (Sustainable Development) Act 1990. This license is renewable and currently valid until 30 June 2010. This license covers the current and future planned mining activity.

The tenement details, including the Exploration Licenses EL 3310 & EL 4848, are shown in Table 2-1.

Table 2-1: Tenement details

Number and type (Name) Licensee Location Area Expiry date

MIN 4644 (Costerfield) AGD Operations P/L Costerfield 1219.3 ha 30/06/2010

EL 3310 (Costerfield) AGD Operations P/L Costerfield 59.0 GRATS 17/09/2011

EL 4848 (Antimony Creek) AGD Operations P/L SW Costerfield 18.0 GRATS 27/01/2012

The Plans of Area of the Mining License No. 4644, and the recent reduction in Exploration License EL 3310, issued by the Department of Primary Industries (DPI) of the State Government of Victoria, are shown in Figure 2-2 and Figure 2-3.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-2

Figure 2-2: Plan of area of ML 4644 from DPI, Victorian State Government

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-3

Figure 2-3:Plan detailing reduction in EL3310

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-4

2.3 Survey Grid Location

The survey grid for the Costerfield Project has been established with the Costerfield Grid North set at 19°west of MGA 94 (Map Grid Australia) North (29° west of Magnetic North).

All mining survey information, including that for diamond drill hole data, is stored in Costerfield Mine Grid co-ordinates.

The details of the grid conversion, between the MGA 94 and the Costerfield Mine Grid (CMG) are detailed in Table 2-2 and Figure 2-4.

Table 2-2: Costerfield mine grid (from Fredericksen, 2009)

Figure 2-4: Relationship between mine grids (from Fredericksen, 2009)

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-5

2.4 Royalties and Taxes

2.4.1 Royalties

Royalties apply to the production of antimony. This royalty is applied at 2.75% of the revenue realized from the sale of antimony produced, less the selling costs.

For the life of the current proven and probable reserves, the total antimony revenue is AUD15,169,671; the total selling costs are AUD863,438 and the royalty payable is AUD393,421. No royalty on gold production exits.

There is no Royalty payable on gold production.

2.4.2 Taxes

Mandalay reports that there are approximately AUD40M in tax loss carry forwards for AGD that will effectively eliminate any income tax being paid in the short life of the current Mineral Reserves.

Income Tax on Australian company profits is set at 30%. The Australian Federal Government has now announced changes to the taxation rates for companies, which will decrease the tax rate to 28% in future years, as well as impose an additional resources-based tax on profits that exceed 6%. These tax changes are yet to be imposed.

2.5 Environmental Liabilities and Permitting

2.5.1 Required Permits and Status

A summary of Work plans and Variations, plus Planning Permissions associated with mining and processing activities are given in Table 2-3 and Table 2-4.

Work Plans issued under the mining licenses:

There are an extensive number of Work Plans issued between 1994 under MIN4073 up to the latest mining license MIN4644 (Work Plan Variations dated February 2005, October 2005, November 2005, February 2006 & October 2006).

Table 2-3: Summary of relevant Work Plans and Work Plan Variations

DPI Work Plans & Variations

Date Registered Description

Work Plan 16/02/1994 Treatment of Tailings

Work Plan Variation 20/01/1995 Treatment of Tailings

Work Plan Variation 1/06/1995 Construction of Brunswick Tailings Dam

Work Plan Variation 22/08/1995 Tailings Treatment and Brunswick Tailings Dam Construction

Work Plan Variation 20/06/1996 Tailings Treatment and Brunswick Tailings Dam Construction

Work Plan Variation 11/11/1997 Bombay Minerva Open Cut Mine

Work Plan Variation 26/10/2004 Underground Mining Augusta

Work Plan Variation 26/10/2004 Underground Mining Augusta

Work Plan Variation 8/11/2005 Open Cut Mining of Oxide Ore from the Augusta Deposit at Costerfield South

Work Plan Variation 8/02/2006 Upgrade / modification of processing plant

Work Plan Variation 30/10/2006 Change in environmental monitoring program

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │2-6

Table 2-4: Summary of planning permits from the City of Greater Bendigo

Council Planning Permits

Date Issued Description

PP1777 5/12/1995 Gold and Antimony Recovery from Tails

PP1834 5/08/1996 Mining

PP1861 20/6/1996 Lot 2 Subdivision

PP1887 11/12/1996 Shed to house pilot plant for continued research on antimony / gold

PP2248 17/6/1997 Open Cut Mining and Gold Antimony Recovery

2248 (Amended) 7/11/1997 Open Cut Mining and Gold Antimony Recovery

DM/753/03 14/1/2004 Underground Mine

DM/253/2005 8/11/2005 Establishment and Operation of Open Pit Gold / Antimony Mine

A review of the Work Plans and the abovementioned Planning Permits indicates that numerous generic conditions are associated with these plans and permits

No significant liabilities relating to the above Works plans and Planning Permits were found.

Groundwater license:

The mine has in place a Section 51, 67 & 145 (Water Act, 1989) Groundwater License for the abstraction of 69 million litres per annum up to 30 June 2019 (License No. 8005313).

This abstraction entitlement is subject to numerous conditions, as per the Second Schedule of this license.

2.5.2 Compliance Evaluation – Groundwater License

Some inconsistencies between the groundwater license conditions and the current situation at the mine were found. The potential liability cost of this is unknown but non-compliance does increase the risk of the Department of Water temporarily or permanently revoking or cancelling this right, which will have a direct impact on mining operations.

The following identifies some issues requiring immediate attention:

1 The extraction volume entitlement is 69 ML/annum. According to mine records abstraction over the past 11 months has been 72.8 ML. This is reportedly due to exploration / dewatering drill holes not being tapped off at the completion of the drilling program. AGD report that these holes were tapped off during December and as a result, extraction volumes have dropped significantly. The legal authorised abstraction entitlement is measured from 1 July to 30 June each year. To comply with the remaining allocation of 13.4 ML for the 2009/10 year the extraction must be up to 3.35 ML/month. AGD believe that dewatering will be within the extraction license entitlement.

2 First Schedule Conditions: The authorisation of this right is for the extraction of groundwater from specific bores that have been numbered and identified. Each bore has an allowable extraction rate and volume. These conditions are not being complied with, as dewatering is taking place from the underground workings and not from the designated bores. AGD have advised that this issue is being addressed.

3 Second Schedule Conditions: There is non-compliance with the following conditions:

Condition 1.1 (a) – Take water except by the method approved by the Authority

Condition 4.3 (a) – Metering

Although meters are installed on the site, they are not measuring at the authorised abstraction points as listed under the First Schedule conditions. The recommendations (Section 19) of this report address the above three issues.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │3-1

3. Accessibility, Climate, Local Resources, Infrastructure and Physiography (Item 7)

3.1 Topography, Elevation and Vegetation

3.1.1 Topography

The topography of the Costerfield area includes some rugged hill country, undulating rises, gentle slopes and drainage depressions.

3.1.2 Elevation

The area has an average elevation of approximately 245 m ASL, with the range being from about 216 m ASL to about 268 m ASL.

3.1.3 Vegetation

The vegetation landscape varies from mixed species of open forest in the valleys and gentle slopes, with shrubby box gum on the stony gravelly hills and heath and grasses on the dry slopes and ridges. Much of the undulating land and alluvial flats have been cleared of vegetation for farming purposes.

3.2 Climate and Length of Operating Season

3.2.1 Climate

The local climate of the Costerfield district is „semi-arid‟ or „Mediterranean‟ in character so that, generally speaking, the winters are cool and wet whilst the summers are hot and dry. There is a high probability of violent electrical storms occurring in summer and these can often yield high intensity downpours.

Annual rainfall in the area is approximately 575 mm with most occurring between April and October. The temperature ranges from -2°C in winter (May to August) to +40°C in summer (November to February). Monthly average data from Redesdale (the nearest weather recording station to Costerfield, which is some 19 km south west of Heathcote) is shown in Figure 3-1.

3.2.2 Operating Season

With occasional heavy rainfall occurring between April and October the operating season for the operation is not unduly affected by climatic conditions. This results in the ability for the year round operation of the facilities with only short duration interruptions caused by the weather.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │3-2

Figure 3-1: Monthly average temperature and rainfall

3.3 Physiography

The project area is in the western catchment of the Lower Goulburn River. It is flat to undulating terrain ranging in elevation from 160 m ASL in the east, along the Wappentake Creek, to 288 m ASL in the northwest.

The area is a mixture of cleared grazing / cropping land and blocks of lightly timbered Box-Ironbark forest. The forested land is largely the rocky, rugged hill country administered by the Department of Sustainability and Environment as State Forest, while most of the undulating land and alluvial flats is privately held freehold land, which has been cleared for farming.

The Project Area adjoins the north west boundary of the Puckapunyal Military Area.

3.4 Access to Property

The Costerfield Project is accessed off the Heathcote-Nagambie Road at a distance of 11 km from the junction with the main McIvor / Northern Highway, at a distance of approximately 100 km north of Melbourne.

3.5 Local Resources and Infrastructure

3.5.1 Access Road and Transportation

The access road to the project, off the Heathcote-Nagamie Road is a narrow width bitumen strip with gravel shoulders, which are maintained in good condition. Private transport is utilised to move the mine personnel to and from the operation.

3.5.2 Power Supply

The Costerfield Project purchases electricity directly from the main national electricity grid and has connections at both the Brunswick plant site and the Augusta underground mine site.

AGD Operations purchases this power under contract from Tru Energy Australia. This three-year contract expires at the end of May 2011.

0

10

20

30

40

50

60

70

0

5

10

15

20

25

30

35

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Rai

nfa

ll (m

m)

Tem

pe

ratu

re (d

egr

ee

s C

)

Monthly Average Temperature and RainfallRedesdale weather station

Mean Rainfall Mean Maximum Temperature Mean Minimum Temperature

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │3-3

Supply from the National Grid to AGD high voltage installations is in two locations:

1 Augusta mine, a 800 kW feed at a power factor of 0.8

2 Brunswick plant, a 758 kW feed at a power factor of 0.8

The power to the underground mine from the Augusta mine substation is supplied through a 42 m cased borehole for 415V feed, and via a step–up transformer and a 42 m cased borehole for the 1000V feed.

The power to the Brunswick plant supplies the gold and antimony processing plant, the administration building and the workshop.

3.5.3 Water Supply

The dewatering of the mine totals 206 kL/d. The underground and surface operations of the operation require 45 kL/d. The mine water is pumped from the underground mine to a 40 ML evaporation pond adjacent to the Augusta Mine facilities.

The water required by the process plant is sourced from a bore located adjacent to the plant, from standing water within the old Brunswick pit, recycled from the tailings dam, and also from the Augusta Mine dewatering system.

The project does not have a permit to discharge water from the site.

The site has a 69 ML water right for extraction from underground and from two surface bores. An application to increase this to 200 ML per annum has been submitted to the relevant authority.

The site water storage capacity is approximately 40 ML excluding the tailings storage facilities.

3.5.4 Buildings and Ancillary Facilities

Appropriate office and ablution facilities are located on the mine site as per the detail in Figure 17-18. The additional ancillary facilities include the workshop and store.

3.5.5 Camp Site

There is no camp site in the mining license area. All employees live in the surrounding towns with some travelling from Bendigo each day, a distance of some 100 km.

3.5.6 Tailings Storage Area

Tailings are now being deposited in the new Cell 2 of the Bombay Tailings Dam. The Bombay Cell #1, in which tailings from the current operation were deposited until Cell #2 was completed, is nearly full. Old tailings from the Brunswick Tailings Dam are currently being treated at the adjacent Processing Plant facility. The plan of the Tailings Dam area is shown in Figure 17-17.

3.5.7 Waste Rock Storage Area

It is understood that AGD has commenced negotiations with the authorities to increase the size of the waste (barren or low grade) rock storage area. Due to the status of the current facility, this is considered of utmost importance. The plan of the Waste Rock Storage Area is shown in Figure 17-18.

3.5.8 Manpower

The workforce for the mine operation is sourced from the surrounding area plus from as far afield as the large mining town of Bendigo.

There is adequate manpower available in the area for the foreseeable expansion plans.

The working roster is made up of three 8-hour shifts per day for five standard working days per week.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010

SRK Consulting (Australasia) Pty Ltd RALE/SOMM/DUPL/DUTO/MULL/wulf PLI003_Costerfield_Augusta_RR_Audit_NI 43-101_Technical_Report_Rev3 │3-4

The mining crew consists of shift boss supervision, maintenance fitters in the surface workshop, decline development miners and production operators. The capital development and production operators include jumbo operators, loader drivers, hand-held miners, microscoop operators and truck drivers. In addition, there are offsiders to assist the decline crew and nippers to assist and transport equipment for the production crews.

The planned management, administration, technical staff and supervisors total 10 in March 2010, while the mining and maintenance crews total 37. The mining crews reduce with the completion of the decline development in June 2010 and the other capital development being completed by January 2011. The mine operating workforce commences at 25, reducing progressively to 10 by November 2011.

SRK Consulting │ PLI003 Costerfield - Mandalay Resources NI 43-101 Technical Report 14 May 2010